Table of Contents

Market Insight: Flat Copper Wire

Market Analysis: Winding Wire – Industrial Demand for Flat Copper Wire in Transformers

The global demand for flat copper winding wire in transformer applications continues to grow, driven by increasing requirements for energy efficiency, compact design, and thermal performance in power and distribution systems. As a core component in both dry-type and oil-immersed transformers, flat copper wire offers superior current-carrying capacity and fill factor compared to round wire, enabling manufacturers to achieve higher power density and reduced losses. This efficiency is particularly critical in medium and high-voltage transformers used in utility infrastructure, renewable energy integration, and industrial power distribution.

Industrial demand is further amplified by regulatory standards such as IEC 60076 and IEEE C57, which mandate strict performance criteria for transformer efficiency, short-circuit strength, and thermal stability. Flat copper wire, due to its rectangular cross-section, allows for tighter winding configurations and improved heat dissipation, directly contributing to compliance with these standards. Additionally, the rise of smart grids and distributed energy resources has increased the need for reliable, high-performance transformers capable of handling variable loads—further reinforcing the technical advantages of precision-manufactured flat copper windings.

Quality in flat copper wire is not a secondary consideration—it is a fundamental determinant of transformer reliability and operational lifespan. Variations in dimensional tolerances, surface finish, or metallurgical properties can lead to localized hotspots, insulation breakdown, or mechanical deformation under electromagnetic forces. For instance, inconsistent edge rounding or surface oxidation can compromise insulation integrity during winding and long-term operation. Similarly, inadequate tensile strength or elongation characteristics may result in wire breakage during high-speed winding processes, increasing production waste and downtime.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in non-ferrous metal processing and winding wire solutions, we emphasize metallurgical consistency and precision engineering in every coil produced. Our flat copper wire undergoes rigorous quality control, including continuous annealing for optimal softness, laser-based dimensional monitoring, and surface defect detection systems. This ensures compliance with international standards and customer-specific requirements for conductivity (minimum 100% IACS), mechanical properties, and geometric accuracy.

The table below summarizes key quality parameters critical for flat copper wire in transformer applications:

| Parameter | Typical Requirement | Importance |

|---|---|---|

| Conductivity | ≥100% IACS | Minimizes resistive losses, improves efficiency |

| Tensile Strength | 200–250 MPa | Ensures winding integrity under stress |

| Elongation | ≥40% | Prevents cracking during coiling |

| Dimensional Tolerance | ±0.02 mm (thickness/width) | Ensures uniform winding and insulation fit |

| Surface Roughness | ≤2.0 µm Ra | Reduces risk of insulation damage |

In conclusion, the industrial demand for flat copper wire in transformers is shaped by evolving performance expectations and regulatory pressures. High-quality wire is not merely a material input—it is a critical enabler of transformer efficiency, reliability, and compliance. As power systems grow more complex, the role of precision-engineered winding solutions becomes increasingly pivotal.

Technical Specs: Flat Copper Wire

Technical Specifications: Flat Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and precision wire manufacturing expertise to deliver flat copper winding wire meeting stringent global industrial standards. Our technical specifications ensure optimal performance in motor, transformer, and inductor applications where dimensional accuracy, electrical integrity, and thermal stability are non-negotiable. Critical parameters are rigorously controlled through in-line monitoring and final batch validation per IEC 60317 and ASTM B357 standards.

Insulation breakdown voltage is a primary reliability indicator, defined as the minimum voltage at which insulation fails under controlled test conditions. Our flat copper wire undergoes 100% testing per ASTM D149 using a 0.5 kV/s ramp rate in ambient air. Minimum breakdown voltage is 3.5 kV for single-build insulation and 6.0 kV for heavy-build variants at nominal conductor thicknesses. This ensures robust dielectric strength even under voltage surges or partial discharge conditions in high-efficiency windings.

Elongation, measured via tensile testing per ASTM E8, directly impacts formability during coil winding. Our oxygen-free copper (OFC) conductors achieve 3–8% elongation at break, optimized for tight-radius bending without cracking. This range balances ductility for complex winding geometries with sufficient tensile strength (250–320 MPa) to prevent deformation under mechanical stress. Consistency is maintained through proprietary annealing profiles in continuous oxygen-free furnaces.

Thermal class defines the maximum continuous operating temperature of the insulated wire system. We supply classes 130°C (B), 155°C (F), 180°C (H), and 220°C (C), certified per IEC 60085. Class rating depends on the insulation system’s thermal endurance, not the copper conductor. Our polyamide-imide (PAI), polyester-imide (PEI), and ceramic-modified coatings undergo 10,000+ hour thermal aging tests to validate temperature indices. For instance, Class 220°C wire retains >50% of initial elongation after 2,000 hours at 220°C, critical for traction motors and aerospace applications.

The following table summarizes key technical parameters for our standard flat copper winding wire offerings

| Parameter | Standard Test Method | Typical Value Range | Critical Tolerance |

|---|---|---|---|

| Conductor Dimensions | IEC 60317-0-3 | Width: 1.0–10.0 mm | ±0.02 mm |

| Thickness: 0.2–2.0 mm | ±0.01 mm | ||

| Insulation Breakdown | ASTM D149 | 3.5–6.0 kV (rms) | Min. 90% of target |

| Voltage | |||

| Elongation | ASTM E8 | 3–8% | ±1.0% |

| Thermal Class | IEC 60216 | 130°C to 220°C | Class-certified |

| DC Resistivity (20°C) | ASTM B193 | ≤1.724 µΩ·cm | Max. +0.5% |

All values are validated under controlled laboratory conditions per referenced standards. Dimensional tolerances are held to ±0.01 mm on thickness and ±0.02 mm on width to ensure consistent fill factors in stator slots. Resistivity compliance guarantees minimal I²R losses, directly supporting energy efficiency targets in end-use equipment. Luoyang Xinzhaohe implements real-time statistical process control (SPC) for all critical parameters, with full traceability from cathode to coil. This precision engineering framework ensures our flat copper wire meets the exacting demands of high-performance electromagnetic systems worldwide.

Factory Tour: Manufacturing

Manufacturing Process of Flat Copper Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

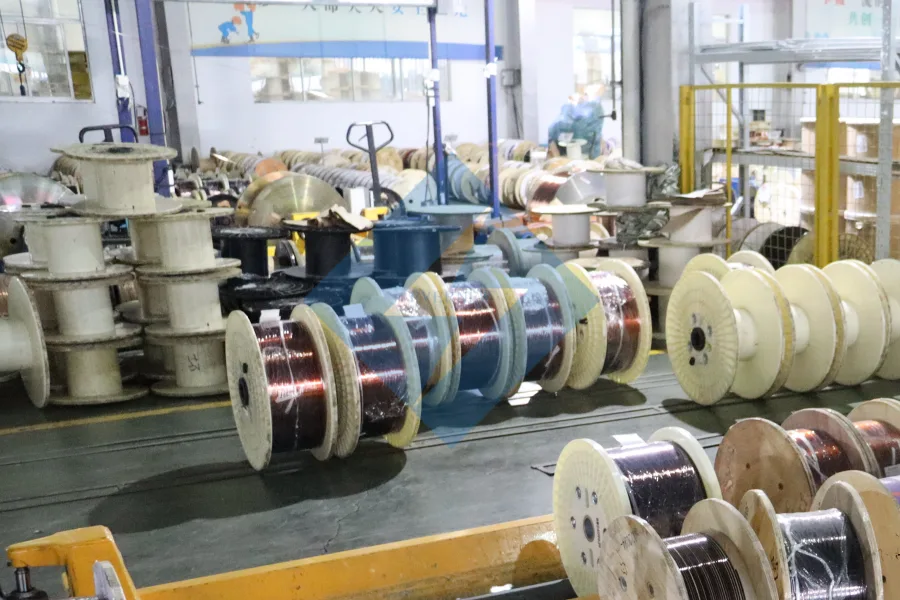

The production of flat copper winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical performance, and mechanical reliability. With over two decades of specialization in winding wire technologies, our process integrates precision engineering with rigorous quality control to meet the demands of high-performance applications in motors, transformers, and electric vehicle systems.

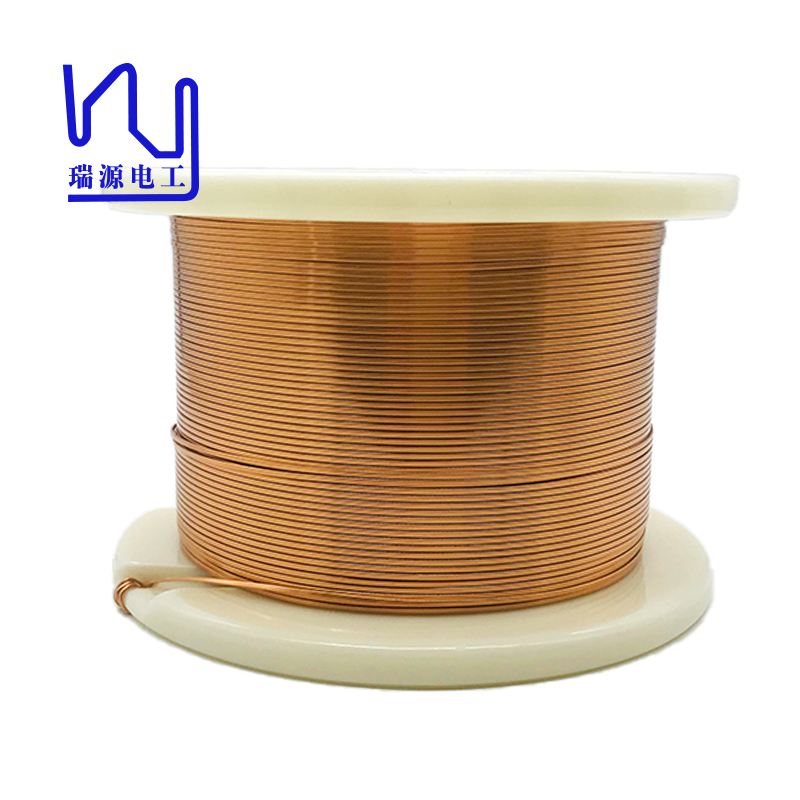

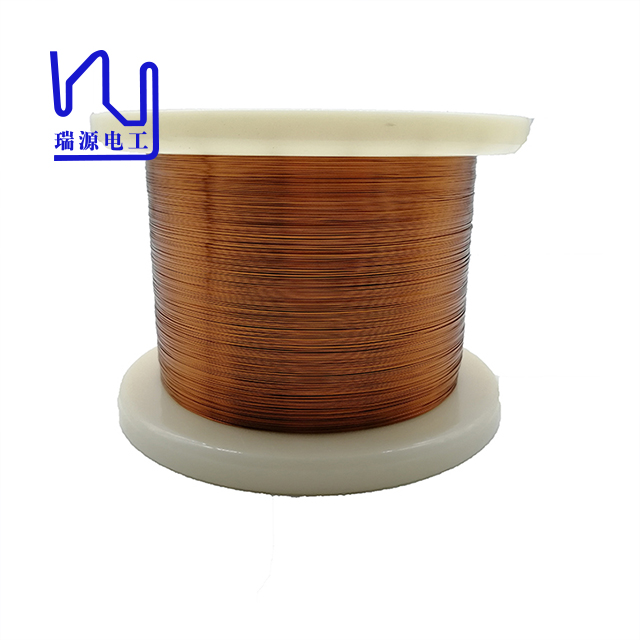

The process begins with rod drawing, where high-purity electrolytic copper rod (minimum 99.99% Cu) is fed into a multi-die drawing machine. The rod is progressively reduced in cross-section under controlled tension and lubrication to achieve the specified flat wire dimensions. This cold drawing stage is critical for establishing the final geometry, including width, thickness, and edge profile. Advanced tension control systems ensure uniform deformation and surface integrity, minimizing microcracking and dimensional variance. Throughout this stage, real-time diameter monitoring via laser gauges enables immediate correction of deviations.

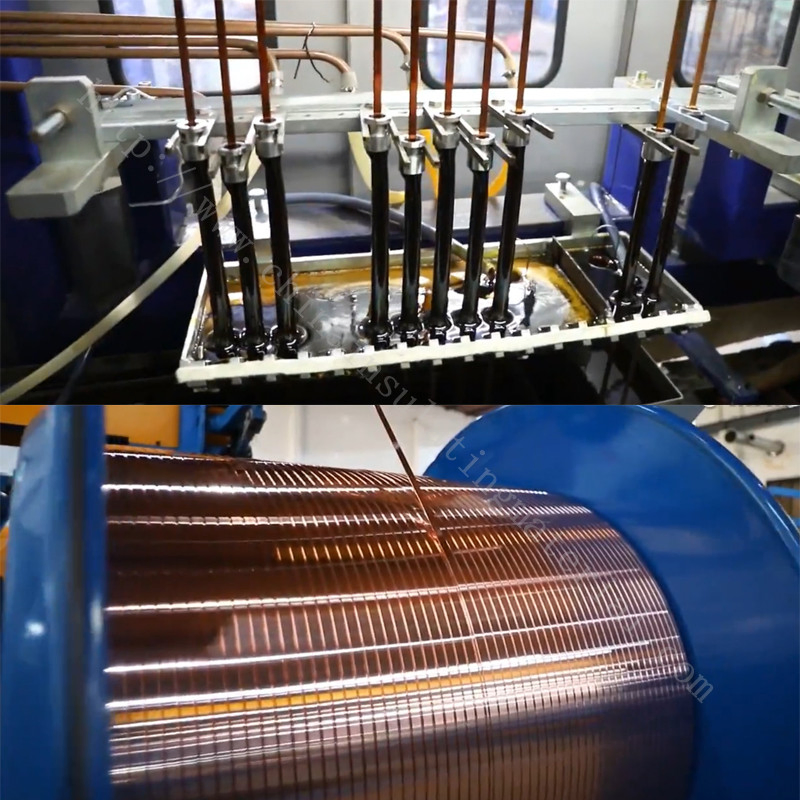

Following drawing, the wire undergoes a continuous annealing process in a controlled atmosphere furnace. The annealing cycle is precisely programmed to restore ductility lost during cold working, achieving the target temper—typically soft (annealed) or semi-hard—depending on customer specifications. The furnace atmosphere, composed of nitrogen and hydrogen, prevents oxidation and ensures a clean, oxide-free surface essential for subsequent enameling. Temperature profiles are continuously logged and adjusted to maintain metallurgical consistency across batches.

The annealed wire then enters the enameling line, where one or multiple layers of polymer insulation are applied. Common insulation systems include polyurethane (PU), polyester (PE), and polyesterimide (PEI), selected based on thermal class (up to 220°C) and solderability requirements. The wire passes through a series of coating dies and precision metering systems to ensure uniform film thickness. Each layer is cured in high-temperature ovens with optimized dwell times to achieve full cross-linking and dielectric strength. Multi-layer constructions may include bonding coatings for self-supporting coil fabrication.

Inline testing is integrated at every critical stage to ensure compliance with international standards, including IEC 60317 and GB/T 7095. Key tests include dielectric strength (hipot testing up to 6 kV), conductor continuity, dimensional accuracy, thermal shock resistance, and winding performance. Adhesion, abrasion resistance, and thermal aging tests are conducted on sample reels per defined AQL levels. All test data is digitally recorded and traceable to batch numbers.

Final inspection includes visual surface examination, package integrity checks, and certification of material test reports. Each shipment is accompanied by full conformance documentation, ensuring reliability and traceability for our global B2B partners.

Packaging & Logistics

Export Packaging Protocol for Flat Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging solutions specifically designed to mitigate risks inherent in global maritime logistics for flat copper winding wire. With over two decades of metallurgical and supply chain expertise, our system prioritizes dimensional stability, moisture exclusion, and mechanical integrity throughout extended sea voyages. All shipments utilize ISPM 15-compliant wooden pallets constructed from kiln-dried, non-resinous hardwoods. These pallets feature a minimum load-bearing capacity of 2,500 kg, reinforced stringers, and chamfered edges to prevent wire reel abrasion during handling. Pallet dimensions adhere strictly to ISO container standards (1,200 x 1,000 mm or 1,140 x 1,140 mm), ensuring optimal space utilization and secure stowage within 20-foot or 40-foot dry freight containers. Each pallet undergoes pre-shipment inspection for structural soundness and freedom from splinters or protrusions that could compromise protective barriers.

Moisture protection constitutes the critical defense layer against copper oxidation and chloride-induced corrosion during transit. We deploy a dual-film barrier system: a primary inner wrap of 0.15 mm thick vapor corrosion inhibitor (VCI)-impregnated low-density polyethylene (LDPE) film, conforming to ASTM D6098 standards. This film actively neutralizes corrosive agents at the molecular level. The secondary outer layer utilizes 0.20 mm moisture-proof co-extruded polyethylene film with a water vapor transmission rate (WVTR) ≤ 0.5 g/m²/24hr at 38°C and 90% RH, as certified per ISO 15106-3. All film seams are hermetically sealed using impulse heat welders, achieving seal strength ≥ 80 N/15mm width (ASTM F88). Relative humidity sensors are embedded within the sealed environment of sample reels per shipment batch to validate <60% RH throughout transit, the threshold for copper corrosion initiation.

Sea freight safety protocols integrate packaging with containerized transport dynamics. Wire reels are secured to pallets via steel strapping (minimum 16 mm width, 15 kN tensile strength) tensioned to 30% of breaking load, preventing axial shift during vessel motion. Pallets are block-stacked within containers with maximum 8 layers, utilizing dunnage to distribute point loads and avoid container wall contact. Critical documentation accompanies each shipment: ISPM 15 phytosanitary certificate, VCI film material safety data sheet (MSDS), and a humidity validation report. Our packaging design has achieved a 99.8% damage-free delivery rate across 12,000+ TEUs shipped since 2018, directly reducing total cost of ownership for clients through eliminated claims and accelerated just-in-time inventory processing. This systematic approach reflects our metallurgical understanding of copper’s susceptibility to environmental stressors and our commitment to supply chain resilience.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Flat Copper Wire Solutions

With over two decades of specialized experience in the production of high-performance winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the electromagnetic materials industry. Our expertise extends to the advanced manufacturing of flat copper wire, engineered to meet the rigorous demands of modern electrical and electronic applications, including transformers, reactors, electric motors, and high-efficiency generators. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, processing, quality assurance, and logistics, ensuring consistent product integrity and supply chain reliability.

Our production facility spans over 50,000 square meters and is equipped with state-of-the-art rolling, drawing, annealing, and insulation coating lines. This infrastructure enables us to produce flat copper wire with precise dimensional tolerances, ranging from 1.0 mm to 10.0 mm in width and 0.5 mm to 3.0 mm in thickness, with custom profiles available upon request. We utilize high-conductivity electrolytic copper (Cu ≥ 99.99%) sourced from certified refineries, ensuring minimal impurities and optimal electrical performance. All products comply with international standards, including IEC 60317, GB/T 7673, and ASTM B357, and are subject to rigorous in-process and final inspections.

Quality assurance is embedded at every stage of production. Our on-site laboratory conducts routine testing for electrical resistivity, tensile strength, elongation, bend performance, and dielectric strength. We also perform surface roughness analysis and dimensional metrology using laser-based measurement systems to guarantee consistency across batches. Our ISO 9001:2015 and ISO 14001:2015 certifications reflect our commitment to quality management and environmental responsibility.

In addition to technical excellence, Luoyang Xinzhaohe offers competitive lead times and flexible order scaling, supporting both large-volume OEM contracts and specialized low-volume runs. Our engineering team collaborates closely with clients to optimize wire specifications for specific winding configurations, thermal performance, and space utilization. Whether you require bare flat copper wire or products with enamel insulation (polyester, polyurethane, or high-temperature polyamide), we deliver tailored solutions that enhance efficiency and reliability in your end applications.

As a strategic partner, we prioritize long-term collaboration, technical transparency, and responsive service. Our export network spans Southeast Asia, Europe, and North America, backed by reliable containerized shipping and documentation compliance.

For technical consultations, sample requests, or pricing inquiries, contact us directly at cathy@transformerstrip.com. Let Luoyang Xinzhaohe Aluminum Co., Ltd be your trusted source for high-precision flat copper winding wire.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flat copper wire directly from China.