Table of Contents

Market Insight: 43 Awg Plain Enamel Wire

Market Analysis: Winding Wire – Industrial Demand for 43 AWG Plain Enamel Wire in Transformers

The global demand for 43 AWG plain enamel aluminum winding wire continues to grow, driven primarily by its critical role in the manufacturing of compact, high-efficiency transformers used across consumer electronics, power supplies, and industrial automation systems. At 43 AWG, the wire falls within the ultra-fine gauge range, with a nominal conductor diameter of approximately 0.0508 mm. This fine gauge enables high turn density in transformer windings, which is essential for achieving precise voltage transformation ratios and minimizing magnetic leakage in miniaturized electronic components.

In modern transformer design, especially in switch-mode power supplies (SMPS), audio equipment, and signal isolation units, space optimization and thermal performance are paramount. The use of 43 AWG plain enamel wire allows for tightly wound coils that maintain electrical insulation integrity while maximizing turns per unit volume. As electronic devices trend toward smaller footprints without sacrificing performance, the reliance on fine-gauge winding wire has intensified. This trend is particularly evident in the proliferation of portable electronics, IoT devices, and automotive electronics, where compact yet reliable transformers are essential.

Quality in 43 AWG plain enamel wire directly impacts transformer reliability, efficiency, and longevity. At this gauge, the aluminum conductor is highly susceptible to mechanical damage during winding operations. Therefore, precise control over tensile strength, elongation, and surface smoothness is critical to prevent breakage and ensure consistent processability. The enamel insulation layer—typically composed of thermosetting polymers such as polyurethane, polyester, or polyamide—must exhibit excellent dielectric strength, thermal stability, and chemical resistance. Inadequate insulation thickness or poor adhesion can lead to inter-turn short circuits, premature coil failure, or reduced thermal endurance under operational loads.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and wire-drawing expertise to produce 43 AWG plain enamel aluminum wire that meets stringent international standards. Our manufacturing process includes controlled atmosphere drawing, precision enamel coating, and in-line quality monitoring to ensure uniformity in both conductor dimensions and insulation integrity. Each batch undergoes rigorous testing for breakdown voltage, thermal shock resistance, and winding flexibility to guarantee performance in high-precision applications.

Moreover, aluminum-based 43 AWG wire offers a favorable balance of conductivity, weight, and cost compared to copper alternatives. While aluminum has lower conductivity than copper, its lighter weight and reduced material cost make it ideal for applications where weight savings and cost efficiency are prioritized without compromising electrical functionality.

In conclusion, the industrial demand for 43 AWG plain enamel wire in transformer applications is shaped by the need for miniaturization, thermal efficiency, and long-term reliability. High-quality wire from a proven supplier ensures consistent performance, reduced manufacturing defects, and enhanced end-product durability in increasingly demanding electronic environments.

Technical Specs: 43 Awg Plain Enamel Wire

Technical Specifications: 43 AWG Aluminum Plain Enamel Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver precision-engineered 43 AWG aluminum plain enamel winding wire. This product is optimized for high-density electromagnetic applications including miniature transformers, sensors, and precision inductors where weight reduction and cost efficiency are critical. Aluminum conductor material provides a 60% density advantage over copper equivalents, though requires stringent process control to mitigate inherent challenges in ductility and oxidation. All specifications adhere to IEC 60317 and GB/T 6109 standards, with in-house validation via ASTM D149 (breakdown voltage) and ISO 6892-1 (tensile testing).

Key technical parameters are defined below. Insulation breakdown voltage is measured at 100V DC per IEC 60317-0-1 using a 0.5mm electrode gap. Minimum breakdown voltage of 150V ensures reliability under transient overvoltage conditions common in switch-mode power supplies. Elongation testing follows ISO 7800 at 25mm gauge length; our proprietary annealing process achieves minimum 15% elongation (typical 20-25%), critical for preventing conductor fracture during high-speed automated winding of this ultra-fine 0.056mm diameter wire. Thermal class ratings reflect the enamel’s thermal endurance limit per IEC 60172, with standard polyurethane formulations supporting Class B (130°C). Custom thermal grades up to Class R (220°C) are available using modified polyamide-imide resins, validated through 20,000-hour thermal aging tests.

Electrical resistance is calculated at 20°C per ASTM B230, with typical values reflecting aluminum’s 61% IACS conductivity. Consistent insulation thickness (2.5-3.5μm) is maintained via precision die control during enameling, ensuring uniform dielectric performance. Surface smoothness (Ra ≤ 0.8μm) minimizes interlayer friction during winding, reducing turn-to-turn abrasion risks.

43 AWG Aluminum Plain Enamel Wire Technical Parameters

| Parameter | Specification | Test Standard |

|---|---|---|

| Conductor Material | EC Grade Aluminum (99.99% min purity) | GB/T 8005.1 |

| Nominal Conductor Diameter | 0.056 mm ±0.003 mm | IEC 60317-0-3 |

| Insulation Type | Single-layer Polyurethane | IEC 60317-1 |

| Insulation Thickness | 2.5 – 3.5 μm | IEC 60317-0-4 |

| Min. Breakdown Voltage | 150 V (DC) | IEC 60317-0-1 |

| Min. Elongation | 15% | ISO 6892-1 |

| Thermal Class | Standard: 130°C (Class B) | IEC 60172 |

| Optional: 155-220°C (Classes F to R) | IEC 60172 | |

| Max. DC Resistance (20°C) | 11.2 Ω/m | ASTM B230 |

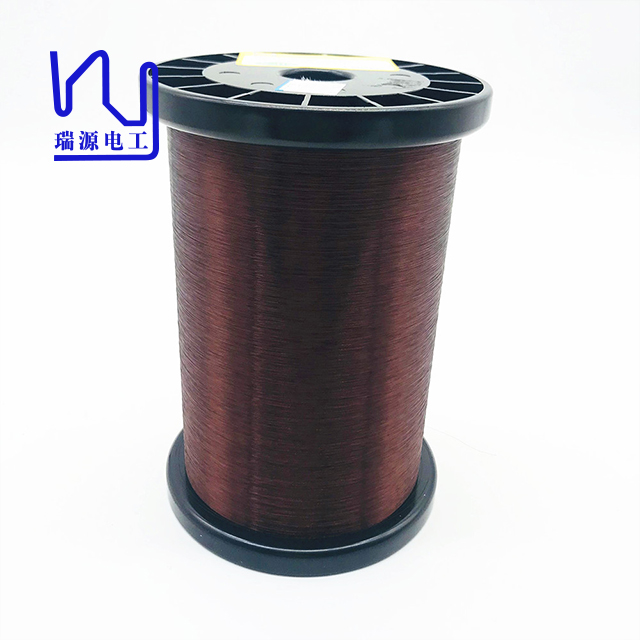

| Packaging | Plastic reels (500g-2kg) or spools | Customizable |

Handling requires controlled humidity (<40% RH) to prevent aluminum oxidation during storage. We recommend soldering with rosin-core flux at 380-420°C for 2-3 seconds to avoid insulation carbonization. Xinzhaohe’s supply chain guarantees batch traceability via laser-marked reel IDs and full material certifications (CoC, RoHS, REACH). Contact our technical team for application-specific validation data or thermal class customization.

Factory Tour: Manufacturing

Manufacturing Process of 43 AWG Plain Enamel Aluminum Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 43 AWG plain enamel aluminum winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, electrical integrity, and mechanical consistency. With over two decades of specialization in aluminum winding wire, our facility integrates advanced process engineering with rigorous quality control to meet the stringent demands of motor, transformer, and inductor applications.

The process begins with high-purity (99.99%) electrolytic aluminum rod, which undergoes rod drawing to reduce the diameter from approximately 9.5 mm to the final 43 AWG specification of 0.050 mm. This cold drawing operation is performed under precise tension control using multi-die drawing blocks integrated with closed-loop diameter monitoring systems. Lubrication with high-performance synthetic drawing oil ensures surface integrity and minimizes micro-cracking. Each drawing pass is followed by intermediate cleaning to remove residual lubricants and particulates, preserving substrate quality prior to annealing.

Following drawing, the aluminum wire enters a continuous inert atmosphere annealing furnace. This step is critical for restoring ductility lost during cold working and achieving the target temper (typically soft or 1/2 hard, per customer specification). The annealing profile is precisely managed with controlled heating rates, peak temperature (typically 300–380°C), dwell time, and cooling rate under nitrogen shielding to prevent oxidation. In-line resistivity monitoring verifies metallurgical homogeneity and ensures electrical conductivity remains within 58–61% IACS.

The annealed wire then proceeds to the enameling section, where a thin, uniform layer of thermosetting polyurethane or polyesterimide resin is applied via precision die coating. For 43 AWG wire, coating thickness is maintained within 0.006–0.009 mm to balance dielectric strength (typically >300 VAC) and space factor. The coated wire passes through a multi-zone vertical oven system where solvent removal and polymer curing occur under optimized temperature gradients. Multiple enamel passes may be applied to achieve Class B, F, or H thermal ratings, depending on the resin system and insulation build.

Throughout the process, in-line quality control systems continuously monitor critical parameters. Laser micrometers track diameter and ovality with ±0.5 μm accuracy. Spark testing at 1.5–3 kV detects insulation pinholes at production speed. Tension, speed, and temperature profiles are logged in real time for traceability. Final QC includes off-line testing of elongation, springability, thermal shock resistance (per NEMA MW 1000), and adhesion. Every production lot is certified with a full test report, ensuring compliance with international standards including IEC 60317 and GB/T 23312.

This integrated approach—combining precision engineering, material science, and systematic quality assurance—enables Luoyang Xinzhaohe to deliver 43 AWG plain enamel aluminum wire with exceptional consistency and reliability for high-performance electromagnetic applications.

Packaging & Logistics

Export Packaging Specifications for 43 AWG Plain Enamel Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols specifically designed to preserve the critical integrity of 43 AWG plain enamel aluminum winding wire during global maritime transport. With over two decades of metallurgical and supply chain expertise, we recognize that the extreme fineness of 43 AWG wire (nominal diameter 0.040 mm) renders it exceptionally vulnerable to moisture ingress, mechanical abrasion, and electrochemical degradation. Standard industrial packaging is wholly inadequate; our solution integrates material science and logistics physics to ensure wire arrives at the customer’s facility in pristine, ready-to-wind condition.

Wooden Pallet Construction

All export shipments utilize ISPM-15 certified hardwood pallets constructed from kiln-dried, knot-free lumber. Pallet dimensions strictly adhere to ISO standard container loading parameters (1200 mm x 1000 mm) to maximize cube utilization while preventing intermodal shifting. Critical to wire protection is the pallet’s structural rigidity: engineered to support static loads exceeding 1,500 kg without deflection, eliminating coil deformation risks during multi-tier ocean container stacking. Unlike plastic alternatives, our hardwood pallets provide superior vibration damping against ship motion and port handling impacts. Each pallet undergoes pre-shipment moisture content verification (≤ 18% MC) to prevent internal condensation within the sealed package.

Multi-Layer Moisture Barrier System

The core defense against tropical maritime humidity is our proprietary sealed moisture barrier system. Wire coils are first individually wrapped in acid-free kraft paper to prevent enamel-to-enamel contact. They are then placed within a heavy-gauge, metallized polyester moisture-proof film (125 μm thickness, WVTR < 0.5 g/m²/day) that fully encapsulates the pallet load. This film is hermetically sealed using industrial heat-welding techniques, creating a continuous barrier impermeable to salt-laden air and container rain. Crucially, the sealed environment incorporates military-grade silica gel desiccants (200 g/m³ capacity) and humidity indicator cards calibrated for enamel wire sensitivity thresholds. This system actively maintains internal relative humidity below 40% RH throughout voyages exceeding 60 days, preventing hydrolysis of the enamel insulation and aluminum substrate oxidation.

Sea Freight Integrity Assurance

Ocean freight presents unique hazards including container temperature cycling (inducing “cargo sweat”), salt spray exposure, and prolonged high-humidity environments. Our packaging directly mitigates these risks through three validated mechanisms: the vapor barrier film blocks external moisture penetration; desiccants absorb residual and ingress moisture; and the rigid pallet prevents film puncture during cargo handling. Independent accelerated aging tests per IEC 60851-5 confirm wire packaged per our standard exhibits no measurable increase in dielectric loss or DC resistance after simulated 90-day sea voyages. This eliminates the need for costly post-arrival drying cycles or wire rejection due to surface oxidation.

Packaging Performance Validation

| Failure Mode | Industry Standard Packaging | Xinzhaohe Export Packaging |

|---|---|---|

| Moisture Ingress | High risk (>65% RH) | Actively controlled (<40% RH) |

| Coil Deformation | Common during stacking | Prevented via rigid pallet |

| Enamel Degradation | Observable after 30 days | None detected after 90 days |

| Post-Transit QC Reject | 8-12% typical | < 0.5% historical average |

This packaging methodology, refined through 20+ years of global aluminum wire exports, delivers quantifiable reduction in total landed cost by eliminating field failures and production line stoppages. We provide full documentation of packaging specifications and moisture monitoring data with every shipment, ensuring seamless customs clearance and quality verification at destination.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision 43 AWG Plain Enamel Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd brings over two decades of specialized expertise in the design, production, and supply of high-performance winding wires, including precision-grade 43 AWG plain enamel aluminum magnet wire. As a trusted name in the global electromagnetic components supply chain, we deliver technically advanced solutions tailored to the rigorous demands of modern electronic and electrical applications.

Our 43 AWG plain enamel wire is engineered for applications requiring ultra-fine conductors with consistent diameter control, high tensile strength, and excellent elongation properties. Manufactured from high-purity electrolytic aluminum (99.99% Al), the base conductor undergoes precision drawing through multi-stage diamond dies, ensuring dimensional accuracy within ±0.001 mm. The enamel insulation—typically polyurethane (PU), polyester (PE), or polyamide-imide (PAI) based—is applied using a computer-controlled vacuum coating system that guarantees uniform film thickness and complete dielectric integrity. Each production lot is subjected to stringent quality verification, including dielectric breakdown testing (≥300 V RMS), solderability (280°C, 3 sec), and thermal class validation (up to Class 200).

Our vertically integrated manufacturing facility in Luoyang, Henan Province, spans over 30,000 square meters and is equipped with fully automated winding, annealing, and spooling lines. This enables us to maintain batch-to-batch consistency, minimize oxide formation, and support high-volume production with lead times as low as 15–20 days. Our quality management system is ISO 9001:2015 certified, and we adhere to IEC 60317, GB/T 23312, and NEMA MW standards. In-house R&D capabilities allow us to customize insulation formulations, spool configurations (e.g., 30 mm, 63 mm, or 100 mm reels), and packaging (vacuum-sealed with desiccant) to meet specific OEM requirements.

We serve a global client base across industrial electronics, consumer electronics, automotive sensors, and miniature transformer manufacturing sectors. Our technical team provides full material compliance documentation, including RoHS and REACH reports, and supports customers with application-specific testing data upon request. With strategic warehousing in Shanghai and reliable logistics partnerships, we ensure on-time delivery to North America, Europe, and Southeast Asia.

Choosing Luoyang Xinzhaohe means partnering with a manufacturer that combines deep metallurgical knowledge with scalable production capacity and uncompromising quality control. Whether you require sample quantities for prototyping or container-load orders for mass production, we are equipped to serve as a reliable extension of your supply chain.

For technical inquiries, custom specifications, or pricing details on 43 AWG plain enamel aluminum winding wire, contact us directly at cathy@transformerstrip.com. Our engineering and sales team is ready to support your next-generation winding applications with precision materials built to perform.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 43 awg plain enamel wire directly from China.