Table of Contents

Market Insight: Rectangular Magnet Wire

Market Analysis: Industrial Demand for Rectangular Magnet Wire in Transformers

Global transformer manufacturing exhibits sustained growth in rectangular magnet wire consumption, driven by critical infrastructure modernization and electrification trends. Key demand sectors include renewable energy integration (solar/wind farm step-up transformers), electric vehicle charging networks, high-voltage direct current (HVDC) transmission systems, and industrial motor efficiency upgrades mandated by international standards like IE4 and IE5. The shift toward compact, high-efficiency transformer designs directly increases reliance on rectangular cross-section magnet wire. This geometry maximizes copper or aluminum fill factor within stator and rotor slots, significantly improving thermal management and power density compared to round wire alternatives. Space constraints in urban substations and mobile applications further amplify the necessity for optimized winding configurations achievable only with precision rectangular profiles.

Quality parameters for rectangular magnet wire are non-negotiable in transformer applications due to severe operational consequences of substandard material. Dimensional tolerances—specifically width, thickness, and edge radius—must adhere strictly to IEC 60317 specifications. Inconsistent cross-sections create uneven magnetic flux distribution, leading to localized hotspots, increased eddy current losses, and premature insulation degradation. Surface smoothness is equally critical; microscopic imperfections from improper drawing or handling act as stress concentrators during winding, compromising enamel integrity and initiating partial discharges under operational voltage stress. Thermal aging resistance of the insulation system must withstand continuous operation at 180°C (Class H) or higher, particularly in干式 transformers where convective cooling is limited. Aluminum alloy composition and temper uniformity directly impact conductivity stability and mechanical springback behavior during coil formation—variables Xinzhaohe controls through proprietary homogenization and annealing protocols developed over two decades.

The operational cost of quality failure extends far beyond initial procurement savings. Substandard wire induces higher no-load and load losses, violating energy efficiency regulations and increasing lifetime ownership costs for utilities and industrial users. Insulation breakdown from poor surface quality or inadequate thermal endurance causes catastrophic transformer failures, incurring extended downtime, expensive replacements, and potential grid instability. Recent industry data correlates transformer field failures with magnet wire dimensional variance exceeding ±0.02mm in critical width dimensions. As grid resilience becomes paramount, procurement specifications now mandate traceable material certifications, rigorous batch testing for elongation consistency (min. 2.5% for aluminum), and third-party validation of thermal shock performance. Luoyang Xinzhaohe Aluminum prioritizes these failure-mode mitigations through in-line laser micrometry monitoring and accelerated life testing protocols exceeding IEC 62399 requirements, ensuring wire integrity throughout the transformer lifecycle. Transformer manufacturers increasingly recognize that magnet wire quality is not a line-item cost but a foundational element of asset reliability and total cost of ownership.

Technical Specs: Rectangular Magnet Wire

Technical Specifications for Rectangular Magnet Wire

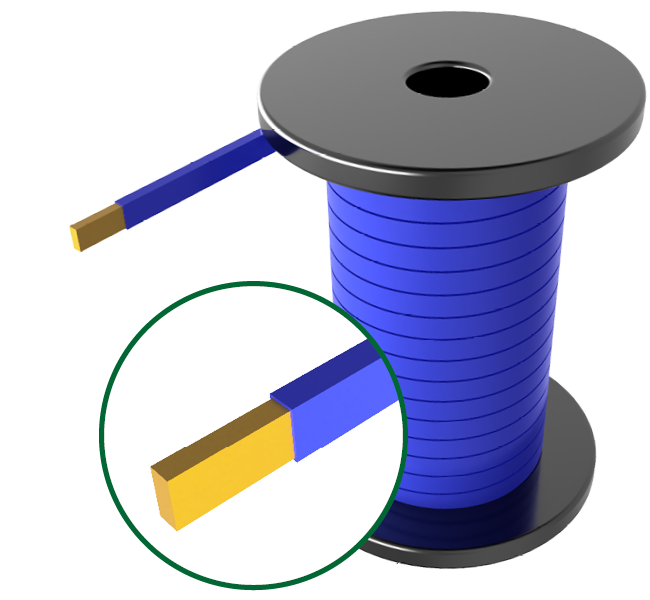

Rectangular magnet wire, a critical component in high-efficiency electromagnetic windings, is engineered to meet stringent performance demands in motors, transformers, and inductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and wire-drawing expertise, our rectangular aluminum magnet wire is manufactured to exacting international standards, ensuring reliability, thermal stability, and electrical integrity under operational stress. The performance of this wire is governed by key technical parameters, including insulation breakdown voltage, elongation, and thermal class rating—each of which directly influences the wire’s suitability for specific industrial applications.

Insulation breakdown voltage is a primary indicator of dielectric strength, defining the maximum electric field the insulation layer can withstand before failure. For rectangular magnet wire, this value is measured perpendicular to the insulation surface and is critical in preventing inter-turn short circuits in tightly wound coils. Our standard insulation systems achieve breakdown voltages ranging from 2,500 V to 6,000 V, depending on insulation thickness and grade. Enhanced dielectric performance is achieved through multi-layer polymer coatings, including polyurethane, polyester-imide, and polyamide-imide, applied via precision extrusion and cured under controlled thermal profiles.

Elongation, expressed as a percentage, reflects the ductility of the conductor material and is essential for ensuring formability during winding operations. Aluminum rectangular wire typically exhibits elongation values between 15% and 25%, depending on the temper (e.g., H14, H16, or O-soft temper). Higher elongation reduces the risk of cracking during sharp bending or compaction in slot-filled windings. Our wire undergoes controlled annealing and drawing processes to optimize mechanical properties, ensuring consistent elongation across production batches.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Our rectangular magnet wire is available in thermal classes from 130°C to 220°C, with higher classes utilizing advanced polymer chemistries to resist thermal aging and maintain dielectric strength. Operating within the specified thermal class ensures extended service life and minimizes the risk of insulation embrittlement or thermal runaway in high-load environments.

The following table summarizes the key technical parameters for our rectangular aluminum magnet wire:

| Parameter | Standard Range | Test Method | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 2,500 V – 6,000 V (rms) | IEC 60317, ASTM D4355 | Measured at 50 Hz, perpendicular to insulation |

| Elongation (Aluminum Core) | 15% – 25% | GB/T 4909.4, ASTM B562 | Depends on temper and cross-sectional area |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60172, ASTM D2307 | Based on insulation system thermal endurance |

| Conductor Material | Aluminum (1350-O, 1060-O) | GB/T 3954, ASTM B233 | High purity, low oxygen content |

| Cross-Section Tolerance | ±0.02 mm (width), ±0.01 mm (thickness) | IEC 60122, custom specifications | Precision rolled and drawn profiles |

These specifications are validated through in-house quality control systems, including continuous electrical testing, thermal aging ovens, and mechanical tensile testing. Luoyang Xinzhaohe Aluminum Co., Ltd. ensures full traceability and compliance with ISO 9001 and IATF 16949 standards, supporting OEMs with reliable, high-performance magnet wire solutions.

Factory Tour: Manufacturing

Manufacturing Process for Rectangular Aluminum Magnet Wire

Luoyang Xinzhaohe Aluminum CO.,LTD employs a rigorously controlled sequence for producing high-performance rectangular aluminum magnet wire, leveraging two decades of metallurgical expertise to ensure compliance with IEC 60317 and customer-specific specifications. The process initiates with Rod Drawing, where high-purity aluminum rod (typically 99.7% min. Al) undergoes multi-stage cold drawing through precision tungsten carbide dies. This reduces the rod diameter while elongating the cross-section into precise rectangular profiles. Critical parameters include die geometry calibration, lubricant viscosity control (using synthetic ester-based compounds), and tension management to achieve dimensional tolerances of ±0.005 mm on width and thickness. In-process diameter verification via laser micrometers occurs at each reduction stage to prevent ovality or surface defects.

Annealing follows drawing to restore ductility and electrical conductivity degraded by cold work. Wire passes through a continuous inert-atmosphere furnace (N₂/H₂ mix, dew point <-40°C) at 300–500°C, with residence time calibrated to aluminum’s recrystallization kinetics. This step eliminates residual stresses and ensures uniform grain structure, directly impacting subsequent enamel adhesion and flexural endurance. Conductivity is validated post-annealing via eddy current testing, targeting 55–61% IACS. Any deviation triggers real-time furnace parameter adjustment to maintain consistency.

The Enameling stage applies multiple polymer insulation layers via precision die coating. Aluminum’s native oxide layer necessitates proprietary surface activation pre-treatment to ensure enamel-metal bonding. Solvent-based polyurethane, polyester-imide, or polyamide-imide resins are applied in 2–4 layers, with each pass cured in staged ovens (280–450°C). Critical controls include resin viscosity (measured hourly), oven temperature profiling, and coating thickness monitoring via beta-gauge sensors to achieve ±2 μm tolerance per layer. Solvent recovery systems minimize VOC emissions while maintaining coating integrity.

Inline Testing integrates non-destructive verification throughout production. Key checkpoints include: breakdown voltage testing (per IEC 60851-5) at 3x operating voltage; scrape abrasion resistance; thermal shock compliance at 200°C; and dimensional stability after thermal cycling. Automated optical inspection scans for pinholes, bubbles, or coating irregularities at line speeds up to 15 m/min. Final reels undergo 100% continuity checks and megger testing. All data is logged to digital batch records, traceable to raw material heat numbers.

This end-to-end process, refined over 20 years, ensures rectangular aluminum magnet wire meets the demanding thermal, electrical, and mechanical requirements of EV traction motors, transformers, and high-efficiency industrial windings. Our integrated QC framework—spanning raw material certification to finished goods—delivers <50 ppm defect rates, underpinning reliability in mission-critical applications.

Packaging & Logistics

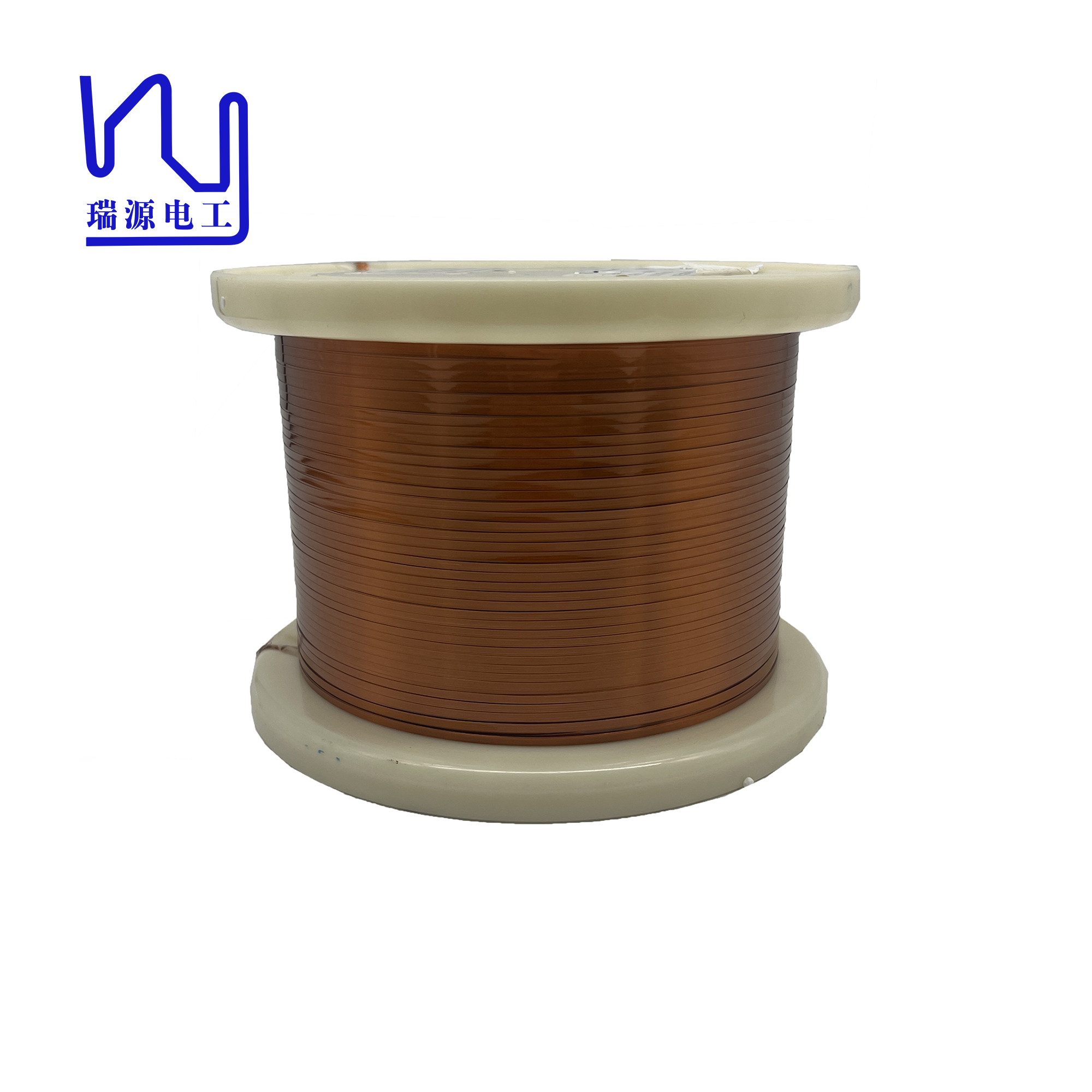

Export Packaging for Rectangular Magnet Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wire solutions, we recognize that proper export packaging is critical to maintaining product integrity during international logistics. For rectangular magnet wire—characterized by its precise dimensional tolerances and sensitive insulation systems—packaging is not merely a logistical consideration but a technical necessity. Our export packaging protocol is engineered to ensure mechanical stability, moisture resistance, and compliance with global freight standards, particularly for sea transport, which remains the dominant mode for bulk industrial shipments.

All rectangular magnet wire coils are wound on precision-machined spools constructed from high-strength composite materials or kiln-dried plywood, ensuring dimensional stability under load. These spools are mounted securely onto robust wooden pallets that meet ISPM 15 (International Standards for Phytosanitary Measures No. 15) requirements. The use of heat-treated, non-contaminated hardwood ensures compliance with biosecurity regulations across major markets, including the United States, European Union, and Southeast Asia. Each pallet is designed to support the full weight of the coiled wire while distributing stress evenly to prevent deformation during stacking and transit.

Following spooling and inspection, the entire assembly is wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier is critical in preventing condensation ingress during prolonged sea voyages, where fluctuating temperature and humidity levels can lead to corrosion of aluminum conductors and degradation of insulation systems. The wrapping process is conducted in a climate-controlled environment to eliminate pre-sealing moisture entrapment. Seams are heat-sealed to ensure continuity of the protective envelope, and additional desiccant packs may be included within the sealed package for extended voyages or high-humidity destinations.

To further enhance load stability, strapping in accordance with ISO 1745:2016 standards is applied using UV-resistant polyester bands. These straps are tensioned to industry-specific specifications to prevent loosening during vessel motion without inducing deformation on the spool or wire. Corner boards made from laminated kraft paper or reinforced plastic are often affixed to protect edges from forklift damage during handling.

Each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch number, net weight, handling instructions, and orientation markers (e.g., “This Side Up”). These labels comply with international labeling conventions to facilitate customs clearance and warehouse logistics.

Our packaging design has been validated through extensive real-world shipment data and accelerated environmental testing, confirming its efficacy over transit durations exceeding 45 days under tropical maritime conditions. By integrating material science, structural engineering, and supply chain expertise, Luoyang Xinzhaohe ensures that every coil of rectangular magnet wire arrives at its destination in optimal condition—ready for immediate integration into transformer, motor, or reactor production lines.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Rectangular Magnet Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver high-performance rectangular aluminum magnet wire, engineered specifically for demanding transformer and inductor applications. Our vertically integrated facility in Luoyang, China, provides unparalleled control over the entire production chain, ensuring consistency and reliability from raw material input to finished coil. This deep process mastery is fundamental to meeting the stringent electrical and mechanical requirements inherent in modern winding wire specifications.

Metallurgical precision forms the cornerstone of our product excellence. We utilize high-purity aluminum ingot (99.70% min Al) processed through controlled casting and homogenization to achieve optimal grain structure and electrical conductivity. Our proprietary drawing and annealing sequences, developed through extensive R&D and field validation, consistently produce rectangular wire with exceptional surface smoothness, precise dimensional tolerances (±0.02mm on width/thickness), and stable mechanical properties critical for high-density winding. We strictly adhere to IEC 60317-0-7 and equivalent international standards, with capabilities to customize alloys and tempers for specific customer voltage class and thermal endurance needs.

Our dedicated magnet wire production line features advanced tension control systems and precision rolling mills, enabling efficient manufacturing of complex rectangular profiles across a broad cross-sectional range (typically 1.0mm x 3.0mm up to 6.0mm x 15.0mm). Annual capacity exceeds 8000 metric tons, supported by flexible scheduling to accommodate both large volume contracts and urgent prototype requirements without compromising quality. This scale and agility are backed by rigorous in-process monitoring at every critical control point.

Quality assurance is non-negotiable. We implement a comprehensive testing regime far exceeding baseline industry requirements. Key performance metrics consistently achieved include:

| Test Parameter | Luoyang Xinzhaohe Standard | Typical Industry Baseline |

|---|---|---|

| Elongation (min %) | 25 | 20 |

| Bend Test Cycles (min) | 12 | 8 |

| Pinhole Density (max) | 0.5 per 100m | 1.5 per 100m |

| Adhesion (min cycles) | 10 | 6 |

This data-driven approach ensures minimal winding defects, superior thermal stability under load, and extended product lifespan in the end application. Our integrated supply chain, managing everything from billet production to final annealing and spooling internally, eliminates third-party variability and guarantees traceability from melt to shipment. Stringent logistics protocols, including custom packaging solutions and certified shipping partners, ensure product integrity throughout global delivery.

For engineering teams requiring magnet wire that delivers on electrical efficiency, manufacturability, and long-term reliability, Luoyang Xinzhaohe provides a technically robust and supply-secure partnership. We collaborate closely with clients during the specification phase to optimize wire parameters for your specific core design and manufacturing process. Contact our technical sales team today to discuss your project requirements and request a detailed technical dossier. Initiate a precision supply partnership by emailing Cathy directly at cathy@transformerstrip.com. Let our metallurgical expertise become your competitive advantage.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing rectangular magnet wire directly from China.