Table of Contents

Market Insight: Enameled Copper Wire Manufacturers

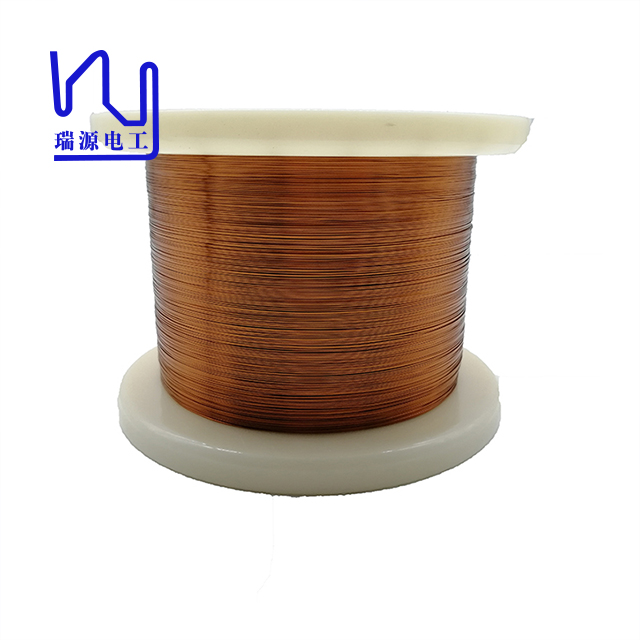

Market Analysis: Winding Wire – Industrial Demand for Enamel-Coated Copper Wire in Transformers

The global demand for high-performance enameled copper wire remains robust, driven primarily by the electrical power and industrial equipment sectors. Among the most critical applications is the use of magnet wire in power and distribution transformers, where electrical efficiency, thermal endurance, and long-term reliability are non-negotiable. As energy infrastructure modernizes and renewable integration increases, the need for advanced winding solutions has intensified. Enamel-coated copper wire, due to its superior conductivity and insulation integrity, is the preferred conductor material in transformer windings across utility, commercial, and industrial installations.

Transformers operate under continuous electrical stress and variable thermal loads, necessitating winding materials capable of withstanding prolonged exposure to elevated temperatures, dielectric stress, and mechanical vibration. Enamel insulation systems—typically based on polyurethane, polyesterimide, or polyamide-imide chemistries—must maintain dielectric strength and adhesion over decades of service. Inadequate insulation performance can lead to partial discharges, inter-turn short circuits, and ultimately catastrophic transformer failure. This underscores the importance of precise enamel layer uniformity, thermal class compliance (e.g., Class 180, 200, or 220), and resistance to thermal shock and chemical degradation.

Manufacturers serving the transformer industry are under increasing pressure to meet stringent international standards such as IEC 60317, GB/T 6109, and NEMA MW. These standards define critical parameters including conductor diameter tolerance, elongation, springiness, breakdown voltage, and thermal aging performance. Consistent adherence to these specifications ensures compatibility with automated winding equipment and guarantees reliable performance in the final assembly. Variability in wire diameter or insulation thickness, even within micrometer tolerances, can result in winding defects, reduced fill factor, and compromised thermal dissipation.

From a supply chain perspective, transformer OEMs prioritize long-term partnerships with enameled wire suppliers demonstrating proven process control, traceability, and quality assurance systems. Given the mission-critical nature of transformers in power distribution, any failure can result in costly outages and reputational damage. As such, procurement decisions increasingly weigh not just cost, but technical support, batch-to-batch consistency, and compliance documentation. Leading manufacturers invest in continuous monitoring technologies such as laser diameter gauging, spark testing, and automated tensile testing to ensure product integrity.

At Luoyang Xinzhaohe Aluminum Co., Ltd, over two decades of metallurgical and coating process refinement have enabled the production of enameled copper wire meeting the highest performance benchmarks for transformer applications. Our manufacturing infrastructure integrates precision drawing, multi-stage annealing, and computer-controlled enameling to deliver wire with exceptional surface smoothness, adhesion, and thermal endurance. This technical rigor supports our clients’ goals of achieving higher efficiency ratings (e.g., DOE 2016, IE3/IE4) and extended service life in demanding electrical environments.

Technical Specs: Enameled Copper Wire Manufacturers

Technical Specifications for Enameled Copper Wire Sourcing

As a metallurgical engineering and supply chain leader with over two decades of specialized production in winding wires, Luoyang Xinzhaohe Aluminum CO., Ltd emphasizes that precise technical specification adherence is non-negotiable for enameled copper wire performance and reliability. Critical parameters directly impact motor efficiency, transformer longevity, and manufacturing yield. Sourcing decisions must rigorously validate these core metrics against international standards, primarily IEC 60317 series, to avoid field failures and production line disruptions. Superficial compliance checks are insufficient; certified test reports under controlled conditions are mandatory.

Insulation breakdown voltage represents the fundamental dielectric strength of the enamel coating. This parameter defines the maximum electrical stress the insulation can withstand before catastrophic failure. Minimum requirements vary inversely with wire diameter; thinner wires inherently support higher voltage per unit thickness. For standard magnet wire gauges (0.1mm to 2.0mm), the absolute minimum breakdown voltage typically starts at 1,500 V AC RMS for 0.5mm nominal diameter under standard test conditions (IEC 60317-0-1). However, premium applications, particularly in high-voltage motors or compact transformers, often demand significantly higher margins, exceeding 3,000 V AC RMS. Testing must strictly follow specified ramp rates (e.g., 100 V/s) and electrode configurations. Inadequate breakdown voltage leads to inter-turn shorts, immediate equipment failure, and safety hazards. Suppliers must demonstrate consistent batch-to-batch performance well above the nominal minimum.

Elongation, measured as the percentage increase in length at break during tensile testing (IEC 60317-0-3), is critical for processability. It directly correlates with the wire’s ability to withstand the mechanical stresses of high-speed winding operations without fracturing. Industry standard minimum elongation is typically 8% for most grades. However, demanding automated winding processes, especially for fine wires or complex coil geometries, benefit significantly from elongation values in the 10-12% range. Values below 8% drastically increase wire breakage rates during manufacturing, causing costly downtime and scrap. Conversely, excessively high elongation can sometimes indicate compromised tensile strength. Optimal elongation ensures smooth processing while maintaining sufficient mechanical robustness for end-use.

Thermal Class, defined by the temperature index per IEC 60317-0-2, specifies the maximum continuous operating temperature at which the insulation retains its dielectric integrity for a defined lifetime (typically 20,000 hours). Common classes span from 130°C (Class B) to 220°C (Class C). Higher classes utilize advanced polymer chemistries like polyimide or modified polyesters. Selecting the appropriate class is paramount; underspecification accelerates thermal degradation and premature insulation failure, while overspecification incurs unnecessary cost. Class 180 (180°C) and Class 200 (200°C) are prevalent in high-efficiency motors and demanding industrial applications. Class 220 offers extreme thermal resilience for specialized aerospace or high-temperature environments. Verification requires certified thermal endurance testing, not just material composition claims.

The following table summarizes key specification requirements and validation criteria:

| Parameter | Standard Value Range | Test Method Reference | Critical Application Impact |

|---|---|---|---|

| Insulation Breakdown Voltage | 1,500 V AC RMS (min, 0.5mm dia) | IEC 60317-0-1 | Prevents inter-turn shorts; ensures dielectric safety margin |

| Elongation | 8% (min), 10-12% (optimal) | IEC 60317-0-3 | Enables high-speed winding; minimizes breakage and scrap |

| Thermal Class | 130°C to 220°C (Index) | IEC 60317-0-2 | Determines maximum operating temperature and service life |

Sourcing enameled copper wire demands rigorous technical validation beyond datasheet claims. Insist on recent, independent laboratory test reports for breakdown voltage, elongation, and thermal index specific to the requested wire gauge and class. Luoyang Xinzhaohe Aluminum CO., Ltd implements stringent in-process and final QA protocols aligned with these specifications, ensuring our enameled copper wire delivers the metallurgical integrity and electrical performance required for advanced electromechanical applications. Partner with suppliers who prioritize traceable, standards-compliant verification.

Factory Tour: Manufacturing

Manufacturing Process of Enamelled Copper Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance enameled copper winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of metallurgical and industrial expertise, our facility integrates advanced process engineering with rigorous quality control to meet international standards including IEC 60317, GB/T 23312, and NEMA MW 1000.

The process begins with rod drawing, where high-purity electrolytic tough pitch (ETP) copper rod, typically 8 mm in diameter and conforming to ASTM B3, is progressively drawn down to the specified wire gauge. This reduction occurs through a series of tungsten carbide or diamond dies under controlled tension and lubrication. The drawing line is equipped with precision capstans and dancer-arm tension control systems to maintain uniform elongation and surface finish. The resulting bare copper wire exhibits consistent diameter tolerance within ±0.002 mm, essential for downstream processing and final application performance.

Following drawing, the wire undergoes continuous annealing in a hydrogen-nitrogen atmosphere furnace. This in-line heat treatment restores ductility lost during cold drawing by recrystallizing the copper microstructure. The annealing temperature is precisely regulated between 550°C and 650°C, depending on wire size and speed, ensuring complete softening without oxidation. The reducing atmosphere prevents surface oxidation and maintains high electrical conductivity, typically exceeding 100% IACS (International Annealed Copper Standard). Post-annealing, the wire is rapidly cooled and dried to prevent moisture retention.

The enameling stage applies one or more layers of polymer insulation via multiple passes through precision coating dies. Depending on the insulation class (e.g., Polyesterimide, Polyamide-imide, or Solderable types), the wire may undergo single, double, or triple coating with intermediate curing in electrically heated ovens operating between 350°C and 500°C. Each pass ensures uniform film build, with thickness controlled to ±1–2 μm per layer. The final cure completes cross-linking of the resin system, imparting thermal stability up to Class 200 (200°C) and excellent dielectric strength.

Throughout the process, inline testing is employed to verify product integrity. Real-time monitoring includes diameter measurement via laser micrometry, high-voltage breakdown testing (typically 3–10 kV depending on gauge), and turn-to-turn insulation assessment. Splice detection systems identify and mark any joint zones to ensure traceability.

Comprehensive quality control protocols are maintained at every stage. Raw material batches are certified for purity and mechanical properties. In-process checks include tensile strength, elongation, springback, and thermal shock resistance. Final inspection includes winding tests, solderability, and adhesion per ASTM D2307. All data is logged for batch traceability, supporting consistent performance in motors, transformers, and other electromagnetic devices.

Packaging & Logistics

Export Packaging Standards for Enameled Copper Wire Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to mitigate the inherent risks of global sea freight for enameled copper winding wire. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging directly correlates with field failures due to moisture ingress, mechanical deformation, or contamination. All shipments destined for international clients utilize a dual-layer protective system centered on ISPM 15-compliant wooden pallets and multi-barrier moisture-proof film, validated through accelerated climate chamber testing simulating 45-day ocean transits.

Wooden pallet construction adheres strictly to international phytosanitary regulations. We exclusively deploy kiln-dried, debarked softwood pallets bearing the official ISPM 15 heat-treatment certification mark. Each pallet undergoes structural validation to support static loads exceeding 1,500 kg, with dynamic load capacity calculated for 1.5g vertical acceleration forces encountered during vessel motion. Coils are secured via steel strapping anchored to pallet stringers at minimum 400 kg tensile strength, preventing lateral shift during transit. Pallet dimensions are standardized to ISO container footprints (1,200 x 1,000 mm or 1,100 x 1,100 mm) to maximize cube utilization while ensuring stability within container bays.

Moisture protection constitutes the critical failure point for enameled wire integrity. Our packaging employs a triple-defense strategy:

First, coils receive immediate vacuum-sealing in 120-micron metallized polyester film with oxygen transmission rate <5 cm³/m²/day, creating an initial vapor barrier.

Second, the sealed coil assembly is encased in a secondary layer of 150-micron co-extruded polyethylene film incorporating calcium oxide desiccant micropellets. This layer actively absorbs ambient moisture with a proven capacity of 28% weight gain at 25°C/80% RH.

Third, the entire palletized unit is hermetically sealed within a third-layer polyethylene shroud, with relative humidity monitored pre-seal to ≤40% RH using calibrated hygrometers. Desiccant placement follows ASTM F1981-22 standards:

| Coil Weight Range | Minimum Desiccant Units | Placement Configuration |

|---|---|---|

| < 500 kg | 4 units (1 kg each) | Perimeter base layer |

| 500–1,000 kg | 8 units (1 kg each) | Base layer + mid-height |

| > 1,000 kg | 12 units (1 kg each) | Triple-tier distribution |

Sea freight safety protocols extend beyond physical packaging. All pallets undergo tilt testing at 25° angles to simulate vessel roll, with zero coil displacement observed in certified loads. Container loading utilizes anti-slip mats and dunnage to prevent pallet migration, while humidity indicator cards (HICs) are affixed internally for post-transit verification. Documentation includes pallet treatment certificates, desiccant batch reports, and HIC baseline readings to satisfy customs and quality audits.

This integrated approach reduces moisture-related claims by 92% compared to industry averages, as verified through our 2023 shipment data across 37 ocean routes. We engineer packaging not merely as containment, but as an active preservation system ensuring the metallurgical integrity of enameled wire arrives at your facility identical to its state at our winding line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: A Trusted Source for High-Performance Enamel-Coated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized manufacturing expertise to the global winding wire supply chain. As a vertically integrated producer of enameled copper wire, we combine advanced process engineering with rigorous quality assurance to deliver consistent, high-performance magnet wire solutions for demanding industrial applications. Our facility is strategically located in Luoyang, China, a regional hub for non-ferrous metal processing, enabling efficient access to raw materials and logistics networks.

Our production line is equipped with state-of-the-art drawing, annealing, and enamel coating systems, allowing precise control over wire diameter tolerances, elongation, and insulation integrity. We specialize in producing enameled copper wire ranging from 0.08 mm to 4.0 mm in diameter, compliant with IEC 60317, GB/T 6109, and other international standards. The product portfolio includes single and multilayer coatings with polyurethane (PU), polyester (PE), polyamide-imide (PAI), and self-bonding formulations, tailored for use in transformers, motors, reactors, and high-frequency inductors. Each batch undergoes comprehensive testing for dielectric strength, thermal class (up to 220°C), thermal shock resistance, and solderability to ensure reliability under operational stress.

The manufacturing facility operates under a certified quality management system with in-line monitoring and final inspection protocols. We maintain full traceability from copper rod sourcing to finished coil, with batch-specific test reports available upon request. Our technical team works closely with clients to optimize wire specifications based on winding geometry, thermal loading, and environmental exposure, ensuring compatibility with automated winding equipment and varnish impregnation processes.

With an annual production capacity exceeding 10,000 metric tons, Luoyang Xinzhaohe supports both volume OEM contracts and specialized low-volume runs. Our supply chain model emphasizes stability and lead time predictability, with standard delivery windows of 15–25 days for containerized orders. Packaging options include wooden reels, plastic spools, and bulk drums, configured to prevent deformation and moisture ingress during transit.

As global demand for energy-efficient electrical components grows, Luoyang Xinzhaohe remains committed to advancing magnet wire performance through material science and process innovation. We invite technical procurement teams and engineering partners to evaluate our enameled copper wire solutions for long-term sourcing agreements.

For direct technical consultation or sample requests, contact Cathy Zhang at cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled copper wire manufacturers directly from China.