Table of Contents

Market Insight: Transformer Tape

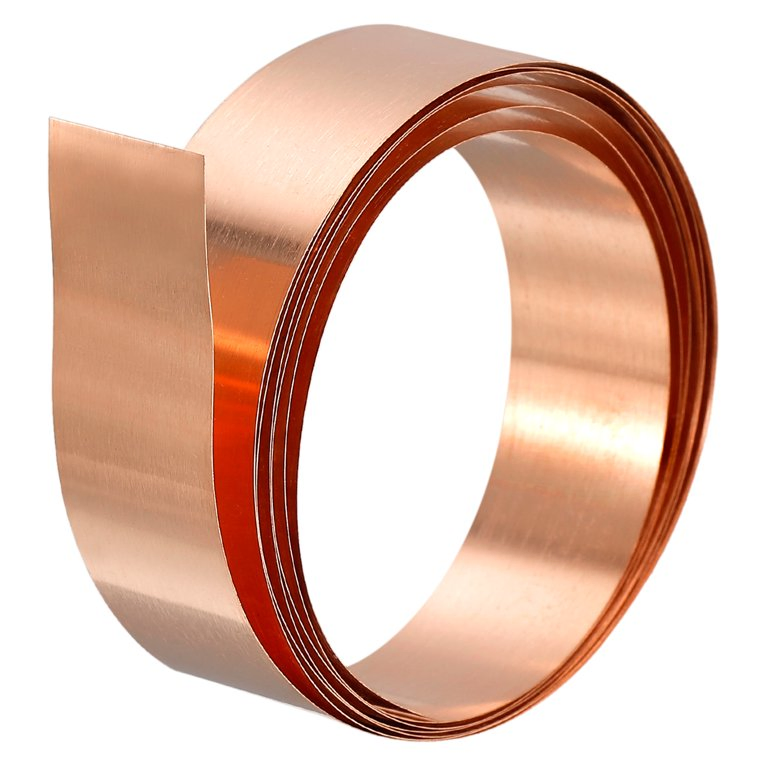

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for precision transformer strip and foil, commonly referred to as transformer tape within winding operations, is intrinsically linked to the expansion and modernization of electrical power infrastructure. This critical material forms the conductive windings in power and distribution transformers, directly impacting efficiency, reliability, and lifecycle cost. Primary demand drivers include the worldwide push for grid stability, integration of renewable energy sources requiring robust transmission infrastructure, replacement of aging transformers, and stringent energy efficiency regulations (e.g., DOE 2016, EU Ecodesign). Distribution transformers, heavily utilizing aluminum strip due to its favorable conductivity-to-weight ratio and cost efficiency, represent the largest volume segment. High-efficiency power transformers often employ copper foil for its superior conductivity in critical applications, though advanced aluminum alloys are increasingly competitive. Current market analysis indicates sustained growth, particularly in Asia-Pacific and emerging economies, driven by urbanization and industrialization.

Material selection between aluminum and copper involves critical engineering trade-offs. Aluminum strip (typically 1xxx or 6xxx series alloys) offers significant weight reduction (approximately 50% lighter than copper for equivalent conductance) and lower raw material cost, making it dominant in distribution transformers where size and weight are major logistical factors. Copper foil provides higher inherent conductivity, advantageous in space-constrained high-power units or where absolute minimal resistive losses are paramount. However, the performance gap narrows significantly with high-purity, precisely engineered aluminum strip meeting international standards (IEC 60138, ASTM B417). Quality is non-negotiable; substandard material introduces systemic risks. Inconsistent electrical conductivity directly increases I²R losses, reducing transformer efficiency and increasing operational costs over its 25-40 year lifespan. Imperfect surface finish or residual contaminants act as nucleation points for partial discharges, accelerating insulation degradation and risking catastrophic failure. Dimensional inaccuracies in thickness or width tolerance disrupt automated winding processes, causing layer misalignment, increased mechanical stress, and potential short circuits. Crucially, inadequate grain structure uniformity in the metal strip elevates core losses (hysteresis and eddy current), undermining the transformer’s fundamental energy conversion efficiency and violating regulatory standards.

The following table summarizes key regional demand growth projections and drivers for transformer strip/foil:

| Region | Projected CAGR (2024-2029) | Primary Demand Drivers |

|---|---|---|

| Asia-Pacific | 6.8% | Massive grid expansion (India, SE Asia), renewable integration, urbanization |

| North America | 4.2% | Grid modernization, aging infrastructure replacement, EV charging network growth |

| Europe | 3.9% | Renewable energy targets, EU Green Deal compliance, grid interconnection |

| Rest of World | 5.5% | Industrialization, rural electrification programs |

Supply chain resilience is increasingly vital. Geopolitical factors and raw material volatility necessitate robust supplier partnerships with demonstrable metallurgical control and consistent quality assurance protocols. Procurement decisions must extend beyond initial material cost to encompass total cost of ownership, where premium strip quality directly translates to lower operational losses, extended transformer lifespan, reduced maintenance, and compliance assurance. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production expertise to deliver strip and foil meeting the most stringent electrical and dimensional specifications, ensuring optimal transformer performance and reliability for global infrastructure.

Technical Specs: Transformer Tape

Transformer tape, specifically aluminum and copper strip used in winding applications for electrical transformers, demands stringent technical specifications to ensure optimal electrical performance, mechanical stability, and process efficiency during coil winding. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, our transformer tape is engineered to meet the highest industry standards for precision, conductivity, and edge quality. Each parameter is controlled through advanced cold rolling, precision slitting, and in-line inspection systems to deliver consistent product performance across high-volume production environments.

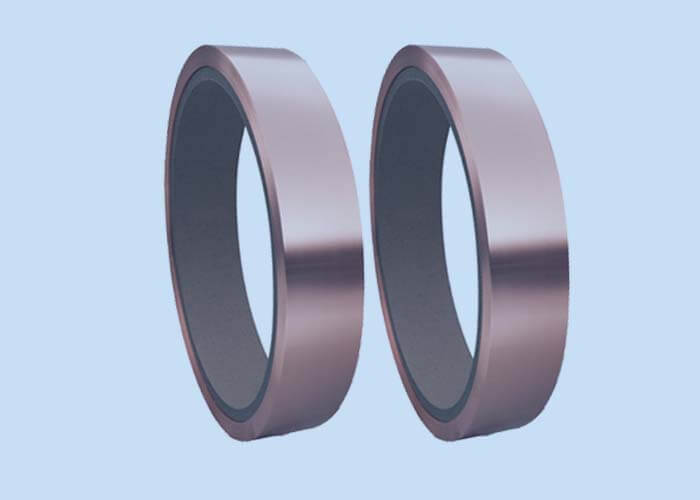

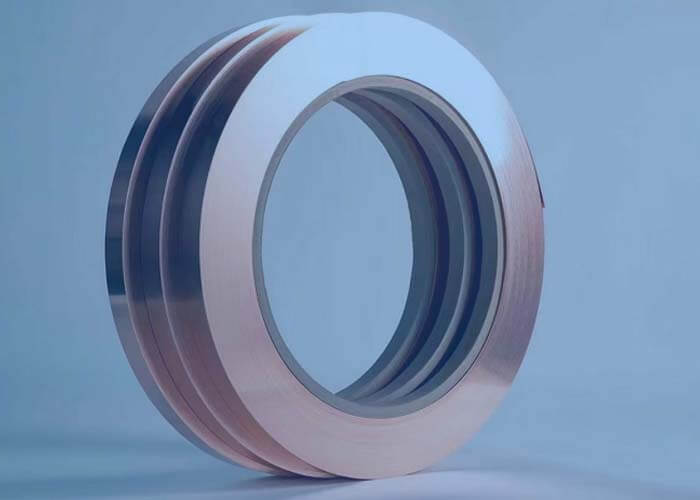

A critical attribute of transformer tape is dimensional accuracy, particularly in slit width and thickness tolerance. Our precision slitting process maintains a width tolerance of ±0.002 mm, achieved using servo-guided rotary shear slitters with automatic edge tracking. This level of accuracy ensures uniform winding tension and prevents layer misalignment in coil packs, which is essential for minimizing partial discharge and thermal hotspots in transformer operation. Thickness tolerances are maintained within ±0.005 mm for aluminum and ±0.003 mm for copper, depending on nominal gauge, verified through non-contact laser gauging systems integrated into the production line.

Edge quality is paramount to prevent damage to insulation coatings during winding and to avoid electrical field concentration at sharp burrs. All transformer tapes produced at our facility are burr-free, with edge protrusions controlled to less than 2% of material thickness. This is achieved through optimized roll tooling geometry, in-process edge inspection via high-magnification imaging, and scheduled tool maintenance protocols. The resulting smooth, square-cut edge enhances winding integrity and reduces the risk of dielectric breakdown.

Electrical conductivity is a core performance metric, directly influencing transformer efficiency. Aluminum transformer tape is supplied in O-temper (fully annealed) condition with a minimum conductivity of 61.0% IACS at 20°C, conforming to GB/T 17049 and IEC 60115 standards. Copper tape achieves a minimum of 98.0% IACS, utilizing high-purity electrolytic tough pitch (ETP) copper with oxygen content controlled between 200–400 ppm. Conductivity is verified through four-point probe resistivity measurements on every batch, with full traceability maintained from ingot to finished coil.

Surface finish is maintained to minimize friction during high-speed winding. A uniform, clean surface free of scratches, pits, or residual rolling oil is ensured through controlled cleaning and passivation processes. Coils are supplied in master rolls with protective interleafing and core-plug sealing to prevent transit damage.

The following table summarizes key technical parameters for our transformer tape products:

| Parameter | Aluminum Tape | Copper Tape | Test Standard |

|---|---|---|---|

| Thickness Range | 0.05 – 3.0 mm | 0.05 – 2.5 mm | GB/T 3880 |

| Width Tolerance | ±0.002 mm | ±0.002 mm | GB/T 15102 |

| Thickness Tolerance | ±0.005 mm | ±0.003 mm | ISO 11495 |

| Edge Burr | < 2% of thickness | < 2% of thickness | ASTM E3 |

| Conductivity (min) | 61.0% IACS | 98.0% IACS | GB/T 3048.2 |

| Temper | O (Annealed) | O (Annealed) | GB/T 17049 |

| Surface Roughness (Ra) | ≤ 0.45 µm | ≤ 0.35 µm | ISO 4287 |

| Winding Defects | None visible under 10x | None visible under 10x | Internal QC Procedure |

All materials are subject to full certification, including mill test reports (MTRs) and conductivity validation. Luoyang Xinzhaohe Aluminum Co., Ltd. maintains ISO 9001 and IATF 16949 certifications, ensuring traceability, process control, and compliance with global supply chain requirements.

Factory Tour: Manufacturing

Transformer Strip Manufacturing Process: Precision Engineering for Critical Applications

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages two decades of specialized metallurgical expertise to produce transformer strip and foil meeting stringent global electrical industry standards. Our manufacturing sequence ensures dimensional stability, surface integrity, and electromagnetic performance critical for transformer efficiency and longevity. The core process comprises three integrated stages: Cold Rolling, Precision Slitting, and Edge Conditioning, each governed by rigorous quality control protocols.

Cold Rolling initiates the production sequence, transforming cast aluminum or copper ingots into precise strip geometries. Ingots undergo homogenization and hot rolling to intermediate gauges before entering 4-high or 6-high cold rolling mills. Here, controlled reduction ratios (typically 85–92% total reduction) are applied under precise tension and temperature parameters. Interpass annealing in continuous galvanizing lines (CGL) or batch furnaces eliminates work hardening, ensuring optimal grain structure and ductility. Critical parameters monitored include roll force uniformity (±1.5%), strip flatness (I-Units < 20), and surface roughness (Ra 0.3–0.8 µm). Inline laser micrometers and X-ray fluorescence systems verify thickness tolerance (±0.005 mm) and alloy composition in real time.

Precision Slitting follows, converting master coils into narrow transformer tape widths ranging from 10 mm to 250 mm. High-tension payoff and rewind systems maintain constant strip tension (±2% deviation) to prevent edge waviness or center buckling. Tungsten carbide rotary knives operate at 0.02–0.05 mm knife clearance, adjusted per material grade and thickness. Width tolerance is held to ±0.05 mm for aluminum and ±0.03 mm for copper strips. Automated edge guiding systems with CCD cameras correct positional drift within 0.01 mm. Slit edges undergo immediate visual inspection via high-resolution cameras detecting micro-tears or burrs exceeding 5 µm.

Edge Conditioning constitutes the final critical stage, eliminating microscopic imperfections that could initiate corona discharge in transformer windings. Strips pass through precision brushing or plasma deburring units, removing raised edges and surface contaminants. For aluminum alloys, controlled chemical etching may supplement mechanical processing to achieve edge radii of 10–25 µm. Copper strips receive electrochemical smoothing to prevent oxidation-induced roughness. This stage directly impacts dielectric strength; edge defects >10 µm can reduce breakdown voltage by 15–20%.

Quality control is embedded throughout the process. Key verification steps include:

| Parameter | Test Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Thickness Profile | Laser Micrometer Array | ±0.005 mm (Al), ±0.003 mm (Cu) | 100% Inline |

| Edge Burrs | Optical Profilometry | ≤ 8 µm | Every 30 min |

| Tensile Strength | ASTM E8 Tensile Testing | Per IEC 60138 Spec | Per Coil Batch |

| Surface Defects | Eddy Current + AI Vision | Zero class 3 defects | 100% Inline |

Final coils undergo 100% eddy current testing for subsurface flaws and are packaged in moisture-controlled environments with desiccants. Documentation includes material traceability certificates, dimensional reports, and electrical resistivity data. This integrated approach ensures transformer tape meets IEC 60138 and ASTM B209/B3 standards, delivering consistent performance in high-efficiency transformer windings. Luoyang Xinzhaohe’s process discipline minimizes field failures through metallurgical precision at every production phase.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer strip and foil—fabricated in both aluminum and copper—we adhere to stringent export packaging standards designed to maintain material integrity throughout international logistics, particularly during sea freight transportation. The inherent sensitivity of these precision materials to environmental exposure, mechanical stress, and contamination necessitates a robust, multi-layered packaging system centered on wooden pallets and high-performance moisture-proof film.

All transformer strip and foil coils are first wound under controlled conditions to prevent surface defects and dimensional variance. Each coil is then fitted with protective end discs made from fiberboard or steel to safeguard the outer and inner wraps from edge deformation during handling. This foundational layer of mechanical protection is critical when loading and unloading in port facilities where automated equipment may induce lateral forces.

The primary structural component of our export packaging is the fumigated wooden pallet, compliant with International Standards for Phytosanitary Measures No. 15 (ISPM-15). These pallets are engineered to support the full weight of densely packed coils, typically ranging from 500 kg to 5,000 kg per unit load, without flexural failure. The use of nailed, multi-stringer wooden bases ensures stability during stacking and prevents slippage in containerized shipping environments subject to pitch, roll, and vibration.

Once secured to the pallet, the coil assembly is completely enveloped in a laminated moisture-proof film composed of aluminum foil and polyethylene layers. This vapor barrier provides a water vapor transmission rate (WVTR) of less than 0.1 g/m²·24hr, effectively isolating the metal surface from ambient humidity, salt spray, and condensation—common hazards in maritime transport across tropical and temperate zones. The film is heat-sealed at all seams and mechanically strapped to resist puncture and wind uplift during transit.

For added protection, desiccant packs are strategically placed beneath the film to absorb any residual moisture, and humidity indicator cards are included for post-arrival verification of internal conditions. Each packaged unit is labeled with orientation arrows, handling instructions, and moisture-sensitive warnings to guide port operators.

This integrated packaging methodology has been validated across thousands of shipments to markets in Southeast Asia, the Middle East, Europe, and South America. It ensures that transformer strip and foil arrive at destination facilities with preserved surface quality, dimensional accuracy, and electrical performance characteristics—critical for downstream slitting, winding, and transformer core assembly operations.

Luoyang Xinzhaohe Aluminum Co., Ltd treats packaging not as a logistical afterthought but as an extension of our metallurgical quality control system, ensuring that every meter of strip or foil meets the exacting demands of the global transformer manufacturing sector.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd for Precision Transformer Strip Solutions

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver mission-critical aluminum and copper transformer strip and foil. Our vertically integrated facility in Luoyang, China, is engineered for the exacting demands of the global power transmission and distribution sector, where material consistency directly impacts transformer efficiency, thermal management, and operational lifespan. We operate beyond standard commodity production, functioning as a technical extension of your engineering and sourcing teams.

Our core manufacturing strength resides in advanced cold rolling technology capable of producing aluminum strip from 0.05mm to 3.0mm thickness with tolerances held to ±0.005mm. Utilizing high-precision Sendzimir mills and continuous annealing lines, we achieve exceptional surface finish (Ra ≤ 0.2µm) and microstructural homogeneity essential for low-loss transformer cores. For copper applications, we maintain stringent oxygen-free processing to ensure optimal electrical conductivity (≥ 100% IACS) and formability. All alloys, including 1060, 1070, 1350, and specialty tempers, undergo rigorous in-house metallurgical analysis to guarantee purity levels exceeding 99.99% Al and precise mechanical properties per ASTM B498/B548 and IEC 60404-8-6 standards.

Supply chain resilience is engineered into our operations. We maintain dedicated production lines for transformer materials, minimizing cross-contamination risks and ensuring batch traceability from raw material smelting to final slitting. Strategic partnerships with primary aluminum smelters provide direct access to high-purity feedstock, while our 20,000-ton annual capacity for transformer-specific alloys enables reliable fulfillment of large-volume contracts. Real-time production monitoring systems track dimensional stability, coil integrity, and edge quality, ensuring every shipment meets the narrow specification windows required by modern transformer design.

Quality assurance is non-negotiable. Our ISO 9001 and IATF 16949 certified laboratory conducts comprehensive testing on every production lot, including:

Tensile strength and elongation measured per ASTM E8

Electrical resistivity verified via four-point probe

Surface defect analysis using automated optical inspection

Coating weight verification for insulated strip variants

Interlaminar resistance validation per IEC 60404-11

This systematic approach minimizes field failures and supports your compliance with international energy efficiency regulations like DOE 2016 and EU Ecodesign Lot 20. We provide full material test reports (MTRs) with chemical composition, mechanical properties, and process documentation for seamless audit trails.

Partnering with Luoyang Xinzhaohe means securing a supplier with deep process metallurgy knowledge and scalable production infrastructure. We collaborate proactively on material optimization for amorphous metal or nanocrystalline core designs, offering technical consultation on annealing profiles and surface treatments to enhance your transformer performance metrics. Our engineering team works directly with your specifications to resolve complex material challenges, from reducing magnetostriction in grain-oriented alloys to achieving ultra-thin foil stability.

For technical specifications, production scheduling, or custom alloy development support, contact our Transformer Materials Division. Cathy Zhang leads global sourcing coordination and ensures seamless integration with your procurement workflows. Reach out directly to discuss how our precision manufacturing capabilities can enhance your transformer supply chain reliability and product performance.

Contact Cathy Zhang: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer tape directly from China.