Table of Contents

Market Insight: Copper Vs Aluminum Motor Winding

Market Analysis: Winding Wire for Transformer Applications

The global transformer winding wire market exhibits a strategic bifurcation between copper and aluminum conductors, driven by distinct cost, performance, and application requirements. Historically dominated by copper due to its superior electrical conductivity (100% IACS baseline), the industry increasingly adopts aluminum for specific transformer segments, particularly distribution transformers above 50 kVA and certain large power units. This shift is primarily motivated by aluminum’s significant cost advantage—typically 30-40% lower raw material cost per unit weight—and its critical 65% density reduction versus copper, directly impacting transformer weight, transportation logistics, and structural support requirements. However, aluminum necessitates approximately 56% larger cross-sectional area to achieve equivalent DC resistance, influencing core window design and overall transformer footprint. Market analysis indicates aluminum now commands over 70% share in new distribution transformer production globally, reflecting sustained industrial demand for economical, lightweight solutions where space constraints are manageable.

Material selection profoundly impacts transformer lifecycle reliability and total cost of ownership. While copper offers inherent advantages in conductivity and termination simplicity, aluminum’s viability hinges entirely on stringent metallurgical control and manufacturing precision. Aluminum’s lower mechanical strength and susceptibility to creep under sustained pressure demand exacting control over tensile strength and elongation properties during wire drawing and annealing. Crucially, aluminum forms a highly resistive oxide layer (Al₂O₃) almost instantaneously upon exposure to air. Poor surface quality or inadequate cleaning at termination points creates high-resistance interfaces, leading to localized overheating, accelerated insulation degradation, and potential failure. Furthermore, aluminum exhibits a 36% higher coefficient of thermal expansion than copper, increasing mechanical stress on windings during thermal cycling if not properly accommodated in design and manufacturing. These factors make aluminum winding wire quality non-negotiable; substandard material directly correlates with elevated failure rates in field operation.

The following comparative table highlights critical metallurgical properties influencing winding performance:

| Property | Copper (OFHC) | Aluminum (1350-O) | Significance for Windings |

|---|---|---|---|

| Conductivity (% IACS) | 100 | 61 | Aluminum requires larger cross-section |

| Density (g/cm³) | 8.96 | 2.70 | Aluminum offers 65% weight reduction |

| Tensile Strength (MPa) | 200-250 | 60-80 | Aluminum more prone to creep deformation |

| CTE (x10⁻⁶/K) | 17 | 23 | Higher thermal stress in aluminum windings |

| Oxide Resistivity (Ω) | Low (Cu₂O) | Very High (Al₂O₃) | Critical for termination reliability |

For aluminum windings to deliver performance parity with copper, suppliers must guarantee exceptional purity (99.7% min Al), precise dimensional tolerances, controlled grain structure via optimized annealing, and consistent surface finish free from scratches or contaminants. Luoyang Xinzhaohe Aluminum leverages two decades of specialized metallurgical expertise to produce aluminum winding wire meeting ANSI C57.12.00 and IEC 60204 standards, ensuring the necessary conductivity, mechanical stability, and surface integrity. Industrial buyers must prioritize suppliers with demonstrable process control and quality assurance protocols, as the inherent challenges of aluminum necessitate uncompromising material quality to achieve the reliability and efficiency demanded in modern transformer networks. The cost benefits of aluminum are only realized when paired with wire of the highest metallurgical standard.

Technical Specs: Copper Vs Aluminum Motor Winding

Technical Specifications: Copper vs Aluminum Motor Winding Wire

When selecting conductor materials for motor winding applications, understanding the key technical parameters of copper and aluminum is critical to ensuring long-term reliability, efficiency, and performance under operational stress. Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in aluminum wire production, provides this comparative analysis based on industry-standard testing and application data. The evaluation focuses on three core parameters: insulation breakdown voltage, elongation, and thermal class capability—each playing a pivotal role in motor design and durability.

Insulation breakdown voltage determines the maximum electric field strength that the insulation layer surrounding the conductor can withstand before electrical failure occurs. For both copper and aluminum winding wires, this value is primarily dependent on the insulation material (e.g., polyurethane, polyester, or polyamide-imide) rather than the base metal. However, due to aluminum’s lower density and higher coefficient of thermal expansion, precise control over insulation coating thickness and adhesion is required to prevent micro-cracking during winding or thermal cycling. Standard breakdown voltages for magnet wires range from 1,500 V to over 6,000 V AC depending on insulation class and wire diameter. Copper wires typically exhibit more consistent dielectric performance due to their mechanical stability, whereas aluminum requires optimized drawing and annealing processes to match comparable insulation integrity.

Elongation, measured as a percentage of original length at the point of fracture, reflects the ductility of the conductor and its ability to withstand mechanical stresses during coil winding. Copper generally exhibits elongation values between 2% and 10% in hard-drawn temper and up to 40% in fully annealed conditions. Aluminum, while inherently more ductile in pure form, must be alloyed and processed carefully to maintain strength without sacrificing flexibility. High-purity aluminum winding wire (e.g., 1350-O temper) typically achieves elongation in the range of 25% to 35%, making it suitable for tight-radius winding when proper handling procedures are followed. However, improper tension control during winding can lead to necking or premature fracture in aluminum due to its lower tensile strength.

Thermal class defines the maximum continuous operating temperature at which the insulation system retains its dielectric and mechanical properties. Both copper and aluminum windings are available with insulation systems rated from Class B (130°C) to Class H (180°C), with extended thermal endurance options reaching 200°C or 220°C using advanced polymer coatings. The thermal conductivity of the conductor itself influences heat dissipation within the motor; copper’s higher thermal conductivity (approximately 401 W/m·K) provides faster heat transfer compared to aluminum (approximately 237 W/m·K). However, aluminum compensates through larger cross-sectional sizing, enabling comparable thermal performance in well-designed systems.

| Parameter | Copper Winding Wire | Aluminum Winding Wire |

|---|---|---|

| Insulation Breakdown Voltage | 1,500 – 6,000 V AC | 1,500 – 6,000 V AC |

| Elongation (%) | 2 – 40 (annealed) | 25 – 35 (1350-O temper) |

| Thermal Class Range | 130°C – 220°C | 130°C – 220°C |

| Base Conductor Conductivity | ~100% IACS | ~61% IACS |

| Typical Insulation Types | PU, PE, PAI, Polyester-imide | PU, PE, PAI, Polyester-imide |

Design engineers must consider these specifications holistically, factoring in application environment, current density, space constraints, and lifecycle requirements. Luoyang Xinzhaohe Aluminum Co., Ltd. specializes in high-purity aluminum winding wire engineered to meet stringent global standards, offering a technically viable and cost-efficient alternative to copper in a wide range of motor applications.

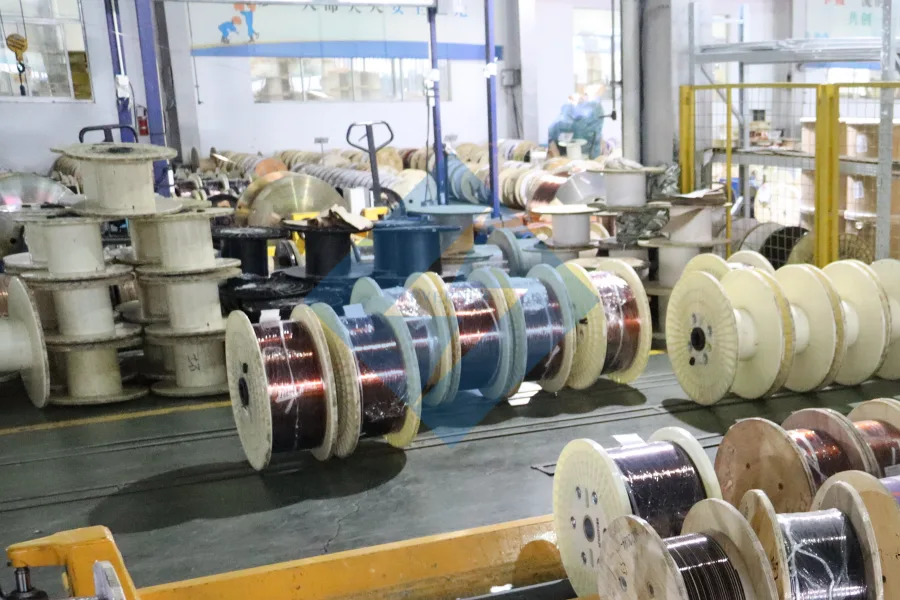

Factory Tour: Manufacturing

Aluminum Motor Winding Wire Production Process

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized metallurgical expertise to produce high-reliability aluminum motor winding wire. Our process rigorously addresses aluminum’s unique properties, ensuring performance parity with copper while optimizing for weight, cost, and conductivity targets. The sequence begins with high-purity aluminum rod (minimum 99.99% Al), sourced under stringent chemical certification protocols to minimize impurities detrimental to conductivity and formability.

Rod drawing transforms the rod into precise wire diameters. This cold working process occurs under controlled tension and speed parameters specific to aluminum’s lower work-hardening threshold compared to copper. Multi-die drawing blocks with precisely engineered reductions and constant lubricant flow prevent surface defects and micro-cracking. In-process diameter verification via laser micrometers ensures dimensional accuracy within ±0.005 mm, critical for consistent slot fill and thermal management in motor assemblies. Immediate attention to drawing speed prevents excessive strain hardening, which compromises subsequent processing.

Annealing follows drawing to restore ductility and electrical conductivity. Aluminum wire undergoes continuous in-line annealing in a precisely controlled inert atmosphere furnace (typically nitrogen-hydrogen mix) at 350-400°C. This eliminates residual stresses from drawing and achieves the target temper (typically soft or 1/2 hard per IEC 60122-1). Atmosphere purity is monitored continuously to prevent surface oxidation, which would impair enamel adhesion. Temperature uniformity across the wire cross-section is validated through thermocouple arrays, ensuring consistent recrystallization without grain growth that reduces mechanical strength.

Enameling applies the critical insulating layer. Prior to coating, aluminum undergoes proprietary surface activation to disrupt the native oxide layer, ensuring optimal enamel bonding—a step less critical for copper. Multiple enamel layers (typically polyester-imide basecoat with polyamide-imide topcoat) are applied via precision die systems with real-time viscosity and solids content control. Curing occurs in multi-zone ovens with oxygen-depleted atmospheres; temperature profiles are calibrated specifically for aluminum’s thermal expansion characteristics to prevent insulation cracking during thermal cycling in operation. Film thickness is maintained within ±2µm tolerance.

Inline testing provides continuous quality assurance. Every production meter undergoes high-voltage spark testing (per IEC 60851-5) at 3kV to detect pinholes. Simultaneous measurements include diameter (laser), elongation (capstan tester), and resistance (4-wire Kelvin method). Final reels undergo 100% rewind inspection with automated optical surface defect detection. Batch-level QC includes adhesion testing (mandrel wrap), thermal endurance (200-hour bake at 200°C), and accelerated aging per NEMA MW 1000. Hydrogen embrittlement susceptibility, unique to aluminum, is assessed via slow strain rate testing on critical batches.

This integrated approach, refined over 20 years, ensures our aluminum winding wire meets the exacting demands of modern motor manufacturing. Process parameters are continuously optimized using SPC data from inline sensors and final batch certification, guaranteeing the mechanical integrity, electrical performance, and long-term reliability required for efficient motor operation.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in aluminum winding wire, we recognize that product integrity extends beyond production. The export phase—particularly sea freight—presents significant environmental and mechanical challenges that demand a robust, technically sound packaging strategy. Our standard export packaging is engineered to preserve the metallurgical and electrical properties of aluminum motor winding wire throughout extended international transit.

All aluminum winding wire coils are wound onto high-strength cardboard or composite flanges and secured to prevent axial or radial movement. The core packaging unit is then mounted onto precision-machined wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to meet international phytosanitary standards, ensuring customs clearance across global markets. The structural rigidity of the wooden base provides critical protection against compression, vibration, and dynamic load shifts commonly encountered during containerized ocean transport.

Each loaded pallet undergoes a multi-layer moisture protection protocol. The entire assembly is first wrapped in industrial-grade moisture-proof film, which acts as a vapor barrier against humidity, salt air, and condensation—factors inherent in marine environments. This film exhibits low water vapor transmission rate (WVTR), maintaining internal relative humidity below 40% for prolonged periods. Overwrapping is performed using automated tension-controlled systems to ensure uniform coverage without mechanical stress on the wire coils.

For additional environmental shielding, desiccant packs are strategically placed within the sealed film envelope. These absorb any residual moisture and mitigate the risk of surface oxidation, which could compromise conductivity or lead to insulation adhesion issues during motor manufacturing. The sealed package is then labeled with orientation indicators, handling instructions, and moisture-sensitive warning labels to support proper logistics management.

Mechanical protection is further enhanced through optional corner boards and edge protectors made from laminated corrugated fiberboard. These components resist impact during loading/unloading and prevent film puncture from sharp container edges. For high-value or long-distance shipments, we offer vacuum-sealed packaging as an upgrade, which eliminates internal air volume and further reduces oxidation potential.

Our packaging design has been validated through accelerated aging tests and real-world shipping data across major trade lanes, including trans-Pacific and trans-Atlantic routes. This ensures compliance with IEC 60204 and ASTM D4169 standards for packaged product performance under simulated transport conditions.

By integrating structural stability, moisture control, and regulatory compliance, Luoyang Xinzhaohe Aluminum’s export packaging system guarantees that aluminum winding wire arrives at its destination in optimal condition—ready for precision processing in motor production environments. This technical approach underscores our commitment to reliability, consistency, and global supply chain excellence.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Advanced Aluminum Motor Winding Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance aluminum winding wire, engineered specifically to address the critical conductivity, weight, and cost challenges inherent in modern motor design. As a vertically integrated manufacturer, we control the entire production chain—from high-purity aluminum billet sourcing through precision drawing, annealing, and surface treatment—ensuring uncompromised material consistency and traceability. Our facility operates under stringent ISO 9001 quality management protocols, with in-line monitoring systems validating electrical conductivity (minimum 61.0% IACS per IEC 60138), dimensional tolerances (±0.005 mm), and mechanical properties at every process stage. This granular control eliminates historical aluminum winding failure modes, such as inter-turn insulation breakdown or thermal fatigue, by optimizing recrystallization kinetics during annealing and applying proprietary oxide layer stabilization for superior enamel adhesion.

Our production capacity exceeds 15,000 metric tons annually across fully automated drawing lines, enabling rapid fulfillment of tier-1 OEM volume requirements without sacrificing batch-to-batch uniformity. Advanced tension control systems and laser micrometry ensure wire ovality remains below 0.003 mm, critical for high-speed automatic winding equipment used in EV traction motors and industrial compressors. Unlike commodity suppliers, we specialize in aluminum alloys tailored for electromagnetic applications, including EC-grade (1350/1370) with enhanced creep resistance at 150°C+ operating temperatures. This metallurgical precision directly translates to motor efficiency gains of 1.5–3.0% compared to substandard aluminum alternatives, validated through third-party testing per IEEE 112 Method B.

Supply chain resilience is foundational to our partnership model. We maintain strategic billet inventories buffer-stocked for 90+ days of production, mitigating raw material volatility, while our dedicated logistics division coordinates JIT deliveries to global assembly plants via bonded warehousing in Rotterdam and Savannah. All shipments include full material test reports (MTRs) with batch-specific conductivity, tensile strength, and elongation data, alongside RoHS/REACH compliance documentation. For critical programs, we implement vendor-managed inventory (VMI) systems with real-time consumption tracking, reducing customer inventory carrying costs by up to 22%.

When evaluating copper versus aluminum windings, total cost of ownership—not just upfront material price—dictates optimal selection. Our engineering team collaborates directly with motor designers to model thermal performance, weight savings (35% lighter than Cu), and lifecycle costs, proving aluminum’s viability in applications from HVAC compressors to EV powertrains. Partner with Xinzhaohe to transform aluminum’s theoretical advantages into validated, field-proven motor performance.

Contact Senior Technical Sales Manager Cathy Zhang at cathy@transformerstrip.com to request conductivity validation data, sample reels, or a customized TCO analysis for your next motor platform. We respond to all technical inquiries within 4 business hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper vs aluminum motor winding directly from China.