Table of Contents

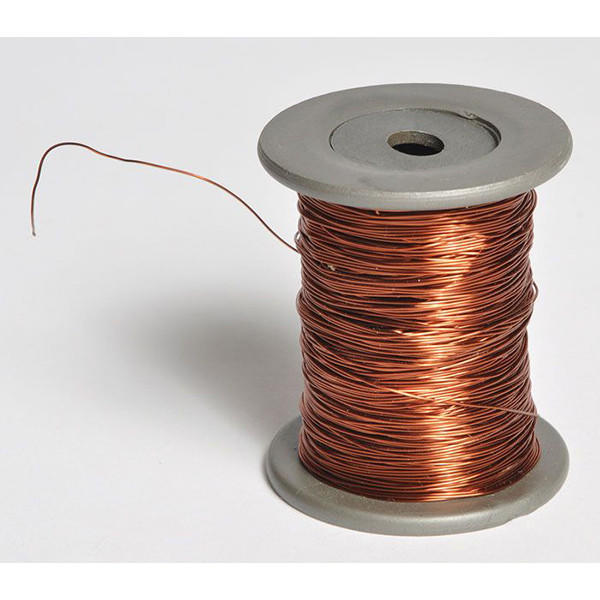

Market Insight: 24 Awg Copper Enameled Wire

Market Analysis: Winding Wire – Industrial Demand for 24 AWG Copper Enameled Wire in Transformers

The global demand for 24 AWG copper enameled wire remains robust, driven primarily by its widespread application in small to medium power transformers used across industrial automation, consumer electronics, renewable energy systems, and power distribution infrastructure. As a core component in electromagnetic winding systems, 24 AWG (0.5106 mm diameter) offers an optimal balance between electrical conductivity, mechanical flexibility, and space efficiency, making it particularly suitable for compact transformer designs where thermal management and winding density are critical.

In transformer manufacturing, 24 AWG enameled copper wire is frequently employed in control transformers, isolation transformers, and switch-mode power supplies (SMPS). These applications require consistent electrical performance under variable load conditions, necessitating wire with precise dimensional tolerances, high thermal class insulation, and excellent dielectric strength. The increasing miniaturization of electronic systems has further intensified the need for fine-gauge wires like 24 AWG that can deliver reliable performance within constrained physical footprints.

Quality is a decisive factor in the performance and longevity of transformers utilizing 24 AWG enameled wire. Substandard wire with inconsistent enamel coating thickness or poor thermal endurance can lead to inter-turn short circuits, premature insulation breakdown, and transformer failure. High-quality enameled wire must meet or exceed international standards such as IEC 60317, GB/T 6109, and NEMA MW 1000, ensuring compatibility with varnish impregnation processes and resistance to thermal aging, humidity, and mechanical stress during winding.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in winding wire production and supply chain management, we emphasize material purity, coating uniformity, and rigorous in-process testing. Our 24 AWG copper enameled wire is manufactured using high-conductivity electrolytic tough pitch (ETP) copper (Cu ≥ 99.97%) and advanced polymer insulation systems—typically polyurethane, polyester, or polyamide-imide—engineered to achieve thermal classes ranging from 130°C to 220°C. This ensures compatibility with automated winding equipment and resilience in harsh operating environments.

Market trends indicate growing demand from emerging sectors such as electric vehicle (EV) charging stations, solar inverters, and industrial IoT devices, all of which rely on high-efficiency, compact transformers. As energy efficiency regulations tighten globally (e.g., DOE 2016, EU Ecodesign Directive), transformer manufacturers are under pressure to reduce copper and core losses, further elevating the importance of high-purity, low-resistance winding materials.

The table below summarizes key technical and market parameters for 24 AWG copper enameled wire in transformer applications:

| Parameter | Value/Specification |

|---|---|

| Conductor Diameter | 0.5106 mm (±0.005 mm) |

| Material | ETP Copper (Cu ≥ 99.97%) |

| Insulation Type | Polyurethane, Polyester, Polyamide-Imide |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C |

| Standards Compliance | IEC 60317, GB/T 6109, NEMA MW 1000 |

| Typical Applications | Control Transformers, SMPS, Isolation Transformers |

In conclusion, the industrial demand for 24 AWG copper enameled wire in transformer applications is sustained by technological advancement and regulatory pressures toward higher efficiency. Ensuring consistent quality in material composition, dimensional accuracy, and insulation integrity is not merely a manufacturing concern—it is a fundamental requirement for system reliability and performance.

Technical Specs: 24 Awg Copper Enameled Wire

Technical Specifications for 24 AWG Copper Enameled Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of precision manufacturing expertise in winding wire production to deliver 24 AWG copper enameled wire meeting stringent global industrial standards. This grade utilizes 100% electrolytic tough pitch (ETP) copper per IEC 60028, ensuring optimal electrical conductivity and mechanical integrity for demanding motor, transformer, and inductor applications. Critical performance parameters are rigorously controlled through in-line monitoring and batch validation testing, with key specifications detailed below.

Insulation breakdown voltage represents a fundamental safety and reliability metric for enameled wire. Our 24 AWG product achieves a minimum DC breakdown voltage of 1500 V under IEC 60317-0-1 testing conditions, measured at a ramp rate of 500 V/s on wound samples. Premium grades consistently exceed 1800 V, validated through 100% spark testing during production. This high dielectric strength ensures robust insulation performance under transient voltage spikes and continuous operating stresses, directly contributing to extended component lifespan in high-efficiency electromagnetic devices.

Elongation percentage is a critical indicator of the wire’s ductility and resistance to fracture during high-speed winding processes. Our 24 AWG copper conductor achieves a minimum elongation of 20% per ASTM B3/B3M test methods, measured on a 250 mm gauge length. This value is maintained through precise annealing control and copper purity management, preventing micro-cracking of the insulation layer during tight-radius coiling. Consistent elongation performance minimizes wire breakage in automated winding machinery, directly improving production yield for our clients.

Thermal classification defines the maximum continuous operating temperature at which the insulation retains ≥50% of its original mechanical and electrical properties after 20,000 hours of service. We offer 24 AWG enameled wire across multiple thermal classes, with standard production supporting Class 130°C (B), 155°C (F), 180°C (H), and 220°C (C). Each class undergoes thermal endurance testing per IEC 60172, establishing the temperature index through Arrhenius curve analysis. It is imperative to note that the thermal class rating (e.g., 220°C) denotes the insulation system’s thermal capability, not the recommended continuous operating temperature; actual application limits must consider combined thermal, electrical, and mechanical stresses per IEC 60034-22.

The following table summarizes essential technical parameters for our standard 24 AWG copper enameled wire offerings:

| Parameter | Symbol | Unit | Min Value | Max Value | Test Standard |

|---|---|---|---|---|---|

| Conductor Diameter | d | mm | 0.511 | 0.511 | IEC 60317-0-1 |

| Overall Diameter | D | mm | 0.550 | 0.580 | IEC 60317-0-1 |

| DC Resistance (20°C) | R | Ω/km | 84.21 | 84.21 | IEC 60028 |

| Breakdown Voltage | Vb | V | 1500 | – | IEC 60317-0-1 |

| Elongation | ε | % | 20 | – | ASTM B3/B3M |

| Thermal Class | – | °C | 130 | 220 | IEC 60172 |

| Solderability (260°C) | – | s | – | 3 | IEC 60317-0-1 |

All products undergo 100% continuity and spark testing, with full traceability from copper cathode sourcing through enameling and spooling. Thermal class validation includes mandatory thermal aging at multiple temperature points to confirm the insulation’s thermal endurance exponent. Solderability performance is guaranteed per IEC 60317-0-1, ensuring reliable termination in automated soldering processes. This comprehensive specification framework ensures compatibility with high-volume manufacturing while meeting the evolving efficiency and reliability demands of modern electromechanical systems.

Factory Tour: Manufacturing

Manufacturing Process of 24 AWG Copper Enameled Wire

The production of 24 AWG copper enameled wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled sequence of metallurgical and coating processes designed to ensure high electrical performance, mechanical durability, and consistency across batches. With over two decades of specialization in winding wire technologies, our manufacturing workflow integrates precision engineering with rigorous quality control to meet international standards including IEC 60317 and GB/T 23312.

The process begins with high-purity electrolytic tough pitch (ETP) copper rod, typically grade Cu-ETP1 (99.95% minimum Cu), sourced from certified suppliers and verified through incoming material inspection. The rod undergoes a multi-stage rod drawing operation, where it is progressively reduced in diameter through diamond or tungsten carbide dies under controlled tension and lubrication. For 24 AWG wire, the final conductor diameter is precisely drawn to 0.511 mm (±0.003 mm tolerance), ensuring dimensional accuracy essential for tight coil winding applications. Throughout drawing, surface integrity is maintained by continuous cleaning and drying to eliminate particulate or oxide contamination.

Following drawing, the wire enters a continuous annealing system. This step restores ductility lost during cold working by subjecting the copper to a controlled thermal cycle in an inert atmosphere (typically nitrogen or nitrogen-hydrogen mix) to prevent oxidation. The annealing temperature is maintained between 450°C and 600°C, depending on line speed and desired mechanical properties. Post-annealing, the wire is rapidly cooled and dried to stabilize its microstructure and tensile strength, achieving an elongation of 10–15% and a tensile strength range of 250–320 MPa.

The enameled coating application follows immediately in a single-pass or multi-pass configuration, depending on insulation class. For 24 AWG wire, common insulation types include polyurethane (PU), polyester (PE), or polyamide-imide (PAI), applied via precision die coating or fluidized bed systems. Each pass is followed by thermal curing in a series of temperature-zoned ovens, where solvent evaporation and polymer cross-linking occur under precisely regulated conditions. Film build is maintained within ±0.003 mm, with typical total diameter reaching approximately 0.57–0.59 mm depending on insulation type and grade.

Inline quality control is embedded at every stage. During enameling, optical diameter monitoring systems provide real-time feedback, while spark testing at 1.5–3 kV detects pinholes or insulation defects. Additional inline tests include continuity monitoring and winding tension control. Off-line QC includes adhesion testing (tape test), thermal shock resistance (bend around mandrel at specified temperatures), and dielectric strength verification (minimum 3 kV RMS for 1 minute). All batches are traceable through lot numbering, with material test reports available upon request.

This integrated manufacturing and quality assurance approach ensures that our 24 AWG copper enameled wire delivers reliable performance in motors, transformers, solenoids, and other electromagnetic devices demanding precision and durability.

Packaging & Logistics

Export Packaging System for 24 AWG Copper Enameled Wire: Ensuring Integrity During Ocean Transit

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and supply chain expertise to implement a rigorously engineered export packaging system specifically designed for the safe ocean freight of 24 AWG copper enameled winding wire. This system addresses the critical vulnerabilities of fine-gauge enameled wire—susceptibility to moisture ingress, mechanical shock, and corrosion—during extended maritime exposure. Our methodology prioritizes absolute product integrity upon arrival, minimizing the risk of dielectric failure or handling damage for the end-user.

All export shipments utilize robust, ISPM-15 compliant wooden pallets constructed from kiln-dried, heat-treated lumber. Pallet dimensions are standardized to maximize container cube utilization while ensuring structural stability under dynamic load conditions encountered during vessel movement. Each pallet base incorporates reinforced stringers capable of supporting the concentrated weight of densely wound 24 AWG wire coils without deflection. Crucially, pallet surfaces are meticulously sanded to eliminate splinters or protrusions that could compromise the primary moisture barrier. Coils are securely unitized to the pallet using polypropylene strapping applied at calibrated tension; excessive force is avoided to prevent coil deformation, a critical consideration for the precise dimensional tolerances of 24 AWG product.

The primary defense against maritime humidity is a multi-layer moisture-proof barrier film. We employ a co-extruded, metallized polyester film with a minimum thickness of 1.2mm, featuring a high-barrier aluminum oxide layer. This film provides an oxygen transmission rate (OTR) below 5 cm³/m²/day and a water vapor transmission rate (WVTR) under 0.5 g/m²/day at 38°C and 90% RH, significantly exceeding standard polyethylene films. Each coil, or consolidated unit load, is hermetically sealed within this film using industrial-grade impulse sealers, ensuring continuous, leak-proof seams. Prior to sealing, a calculated quantity of high-capacity silica gel desiccant, conforming to ASTM D1014, is placed within the enclosure to absorb any residual ambient moisture and buffer against potential minor film breaches. The sealed unit is then overwrapped with a secondary layer of UV-stabilized polyethylene for abrasion resistance during handling.

Verification is integral to our process. Film seal integrity is tested using vacuum decay methods per ASTM F2095. Desiccant placement and quantity are validated against predicted moisture load calculations based on shipment volume, transit duration, and historical port climate data. Palletized loads undergo ISTA 3A simulation testing, replicating the vibration, shock, and compression forces of global sea freight routes. Documentation includes a packing list detailing pallet dimensions, film specifications, desiccant type/quantity, and seal test results, providing full chain-of-custody transparency.

This integrated packaging approach directly mitigates the primary risks of ocean freight: salt-laden air penetration, condensation during temperature fluctuations, and physical impact. By exceeding IEC 60317 environmental protection standards for enameled wire, Luoyang Xinzhaohe ensures that the critical electrical and mechanical properties of the 24 AWG copper enameled wire—surface smoothness, dielectric strength, and solderability—remain uncompromised from factory gate to customer production line. This commitment to packaging science underpins our reliability as a strategic global supplier.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance 24 AWG Copper Enameled Wire

With over two decades of specialized expertise in the production and supply of winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industry leader in the global electromagnetic wire market. Our comprehensive manufacturing capabilities, rigorous quality assurance protocols, and deep technical knowledge position us as the preferred partner for sourcing 24 AWG copper enameled wire that meets the exacting demands of modern electrical and electronic applications.

Our state-of-the-art production facility integrates advanced wire drawing, annealing, and enamel coating technologies to ensure consistent dimensional accuracy and superior electrical insulation properties. The 24 AWG copper enameled wire produced at our plant conforms to international standards including IEC 60317, GB/T 6109, and NEMA MW series, guaranteeing reliable performance in transformers, inductors, motors, and other precision-wound components. Each batch undergoes stringent testing for dielectric strength, thermal endurance (Class 130, 155, 180, and 200), elongation, and thermal shock resistance, ensuring compliance with the highest industry benchmarks.

We utilize high-purity electrolytic tough pitch (ETP) copper with a minimum conductivity of 100% IACS, drawn to precise 24 AWG specifications (0.5106 mm ± 0.005 mm diameter). Our enamel coatings—available in polyurethane (PU), polyester (PE), polyester-imide (PEI), and polyamide-imide (PAI)—are applied using precision metering systems to achieve uniform film thickness and excellent thermal stability. This enables our wire to perform reliably under continuous operating temperatures up to 200°C, depending on insulation class.

Vertical integration is a cornerstone of our operational model. By maintaining control over raw material sourcing, wire drawing, insulation application, and final inspection, we ensure product traceability and reduce lead times. Our supply chain is optimized for both volume efficiency and customization, allowing us to support OEMs, contract manufacturers, and distributors with flexible MOQs and on-time delivery rates exceeding 98%.

Quality management is certified under ISO 9001:2015, with in-house laboratories equipped for continuous monitoring of mechanical, electrical, and thermal properties. Our technical team, with extensive experience in electromagnetic materials, provides application-specific support, including wire selection, spooling configuration, and troubleshooting for winding processes.

When you partner with Luoyang Xinzhaohe, you gain more than a supplier—you gain a long-term collaborator committed to engineering excellence and supply chain reliability. We serve clients across Asia, Europe, and the Americas, consistently delivering high-performance enameled wire solutions that enhance product efficiency and durability.

For technical inquiries, sample requests, or customized quotations for 24 AWG copper enameled wire, contact us directly at cathy@transformerstrip.com. Let our expertise become your competitive advantage.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 24 awg copper enameled wire directly from China.