Table of Contents

Market Insight: Copper Winding Transformer

Market Analysis: Winding Wire – Industrial Demand and Quality Imperatives in Copper Winding Transformers

The global demand for copper winding wire in transformer applications remains robust, driven by sustained growth in power infrastructure, renewable energy integration, industrial automation, and electric mobility. Copper winding transformers are a critical component in power distribution and transmission systems due to their superior electrical conductivity, thermal stability, and mechanical reliability. As energy demands rise and grid modernization accelerates—particularly in emerging economies—the need for high-efficiency transformers using precision-grade copper winding wire continues to expand.

Copper is the preferred conductor material in transformer windings due to its high conductivity (approximately 100% IACS), which minimizes resistive losses (I²R losses) and enhances overall energy efficiency. This is especially vital in distribution transformers that operate continuously and contribute significantly to network-level energy savings. International standards such as IEC 60076 and IEEE C57.12.00 emphasize performance efficiency, requiring transformers to meet strict no-load and load loss criteria—parameters directly influenced by the quality of the winding wire used.

Industrial sectors including utility power distribution, renewable energy (particularly solar and wind substations), rail traction systems, and heavy manufacturing rely on copper-wound transformers for stable and efficient voltage transformation. In renewable installations, for example, step-up transformers with copper windings are essential for converting low-voltage output from inverters to grid-compatible high-voltage levels with minimal energy loss. Similarly, in industrial motor drives and uninterruptible power supply (UPS) systems, the thermal and electrical performance of copper windings ensures operational resilience under variable and often demanding load conditions.

Quality in copper winding wire is not merely a production specification—it is a performance determinant. Key quality parameters include dimensional accuracy, surface finish, tensile strength, elongation, and oxide content. Variability in any of these attributes can lead to winding defects, insulation breakdown, or hot-spot formation, ultimately compromising transformer lifespan and safety. For instance, surface irregularities or micro-cracks in the wire can damage enameled insulation during coil winding, increasing the risk of short circuits. Inadequate elongation or inconsistent temper may result in wire breakage during high-speed winding operations, disrupting manufacturing throughput.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and wire processing expertise, we recognize that consistency in material properties is paramount. Our copper winding wire is manufactured under stringent process controls, ensuring uniform conductivity, precise diameter tolerance (±0.01 mm), and optimized mechanical properties for seamless integration into automated winding lines. We adhere to ISO 9001 and IATF 16949 quality management systems, and our products undergo rigorous testing for electrical, thermal, and mechanical performance.

In an era where energy efficiency regulations are tightening—such as the EU’s Ecodesign Directive and the U.S. DOE’s efficiency mandates—transformer manufacturers cannot afford substandard materials. High-purity, defect-free copper winding wire directly contributes to achieving Tier 1 efficiency classifications and extends service life under cyclic loading. As such, sourcing from technically capable and quality-focused suppliers is a strategic imperative in the competitive transformer manufacturing landscape.

Technical Specs: Copper Winding Transformer

Technical Specifications for Copper Winding Wire in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver precision-engineered copper winding wire for critical transformer applications. While our core competency spans aluminum alloys, we rigorously supply high-purity electrolytic-tough-pitch (ETP) copper (Cu-ETP, C11000) meeting IEC 60317 standards, recognizing its irreplaceable role in high-efficiency transformer windings due to superior conductivity and thermal stability. This section details non-negotiable technical parameters for reliable transformer performance under electrical and thermal stress.

Insulation breakdown voltage is paramount for dielectric integrity. Copper magnet wire must withstand minimum AC breakdown voltages as defined by insulation class and wire gauge. Testing per IEC 60851-5 using spherical electrodes at 50 Hz ensures consistency. Values scale inversely with conductor diameter; for example, 1.0 mm diameter wire requires ≥ 3,000 Vrms for Class 180 insulation. Our production line implements 100%在线 (online) breakdown testing at 150% of rated voltage to eliminate marginal insulation defects, a critical safeguard against in-field failure.

Elongation directly impacts winding manufacturability and mechanical resilience. Excessive brittleness causes wire fracture during high-speed coil winding, while insufficient ductility compromises thermal cycling endurance. We control elongation within a strict 5–35% range (per IEC 60851-3 tensile testing), optimized for the specific copper temper and insulation system. This precision prevents micro-cracking in enamel during bending and ensures dimensional stability under electromagnetic forces.

Thermal Class defines the maximum continuous operating temperature the insulation system withstands without accelerated degradation. Our copper winding wire supports classes from 130°C (B) to 220°C (C), aligned with IEC 60085. Higher classes (e.g., 200°C, 220°C) utilize polyimide-amide or ceramic-loaded enamel for exceptional thermal oxidative stability. Crucially, thermal class certification requires combined thermal-electrical aging tests, not just material composition. We provide full traceability to third-party certified test reports validating thermal endurance indices.

The following table summarizes critical parameters and our enhanced control ranges beyond baseline standards:

| Parameter | Standard Requirement (IEC 60317) | Xinzhaohe Control Range | Test Method |

|---|---|---|---|

| Conductor Resistivity | ≤ 0.017241 Ω·mm²/m (20°C) | ≤ 0.01708 Ω·mm²/m (20°C) | IEC 60468 |

| Insulation Breakdown (1.0mm wire) | Class 155: ≥ 2,500 Vrms | Class 155: ≥ 3,200 Vrms | IEC 60851-5 |

| Elongation | 3–40% | 5–35% (gauge-dependent) | IEC 60851-3 |

| Thermal Class Range | 130–220°C | Validated 130–220°C options | IEC 60216 / UL 1446 |

| Surface Cleanliness | No visible defects | Zero particulate contamination | Visual / Microscopy |

| Dimensional Tolerance (Dia) | ±1% | ±0.75% | IEC 60173 |

| Adhesion (Pin Test) | No flaking | Zero enamel detachment | IEC 60851-4 |

Metallurgical homogeneity is enforced via oxygen content control (200–400 ppm) to prevent hydrogen embrittlement during annealing. All batches include full mill certificates with traceable chemical analysis (ASTM B187) and statistical process control data for diameter and elongation. Partnering with Xinzhaohe ensures not only specification compliance but engineered robustness for transformers operating in demanding grid and industrial environments. Our supply chain guarantees batch-to-batch consistency through integrated quality gates from cathode sourcing to final reel packaging.

Factory Tour: Manufacturing

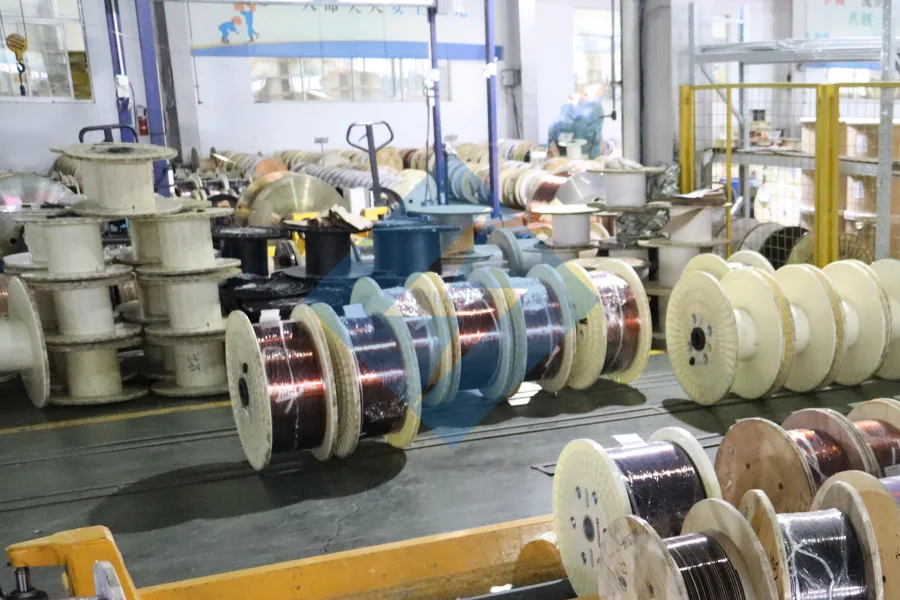

Manufacturing Process of Copper Winding Wire for Transformers

The production of high-performance copper winding wire for transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure mechanical integrity, electrical conductivity, and long-term reliability in demanding transformer applications. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment and rigorous quality control throughout the production chain, beginning with rod drawing and culminating in fully tested, enamel-coated conductors ready for coil winding.

The process initiates with high-purity electrolytic tough pitch (ETP) copper rod, conforming to ASTM B3 and IEC 60086 standards, which undergoes rod drawing to achieve the specified wire diameter. Using multi-die continuous drawing machines equipped with precision tungsten carbide dies, the rod is reduced in a controlled, incremental manner. Lubrication and cooling systems are synchronized to minimize thermal stress and surface defects, ensuring dimensional accuracy within ±0.01 mm. After drawing, the wire enters a batch or continuous annealing system where it is subjected to a precisely regulated thermal profile in a nitrogen-hydrogen atmosphere. This softening treatment restores ductility lost during cold drawing, achieving a fully annealed temper (typically 1/2H to O-temper) while preventing oxidation and maintaining surface cleanliness.

Following annealing, the wire proceeds to the enameling stage, where one or more layers of thermosetting polymer insulation are applied. Our enameling lines utilize multiple coating dies and controlled viscosity systems to ensure uniform film thickness across the entire wire length. Common insulation systems include polyurethane (PU), polyester (PE), and polyamide-imide (PAI), selected based on the transformer’s thermal class (e.g., 130°C to 220°C). Each enamel layer is cured through high-temperature ovens with zoned temperature control, promoting complete cross-linking and dielectric strength development.

Throughout the process, inline quality monitoring systems are deployed at critical junctures. After drawing, laser micrometers continuously verify diameter consistency. Post-annealing, tensile strength and elongation are periodically sampled to confirm mechanical properties. During and after enameling, 100% electrical testing is performed, including spark testing at 3–6 kV to detect pinholes or insulation breaches. Additional offline tests include thermal shock resistance, tape wrap, solderability, and dielectric breakdown voltage, all conducted in accordance with IEC 60317 and GB/T 4074 standards.

Final inspection includes visual examination for surface defects, dimensional recheck, and packaging under controlled humidity to prevent oxidation. Each production lot is traceable via batch coding, ensuring full process accountability. This integrated approach to manufacturing ensures that every meter of copper winding wire meets the stringent performance demands of modern transformer design.

Packaging & Logistics

Export Packaging Specifications for Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed for copper winding wire coils destined for global transformer manufacturing. Our 20+ years of metallurgical and supply chain expertise ensure absolute integrity during extended sea freight transit, where humidity, salt exposure, and dynamic cargo movement present critical risks to conductor performance. All packaging adheres to ISO 9001 and IEC 60140 standards, with primary focus on moisture exclusion and mechanical stability.

Wooden pallets form the foundational structural element. We utilize ISPM-15 certified hardwood pallets (1200 mm x 1000 mm x 150 mm) constructed from kiln-dried, debarked timber with a minimum load capacity of 1.5 metric tons. Each pallet undergoes mandatory heat treatment at 56°C for 30 minutes to eliminate biological hazards, ensuring global customs compliance and preventing port clearance delays. Pallet design incorporates reinforced stringers and cross-battens to distribute coil weight evenly, minimizing deformation during vessel motion. Coils are secured via steel strapping (minimum 16 mm width, 15 kN tensile strength) anchored directly to pallet blocks, preventing lateral shift under 1.5g acceleration forces typical in heavy seas. Plastic pallets are strictly prohibited due to inadequate rigidity and moisture retention risks.

Moisture protection employs a multi-layer barrier system. Coils are first wrapped in volatile corrosion inhibitor (VCI) paper rated for copper protection up to 24 months. This is followed by triple-layer moisture-proof film: an inner layer of 50 μm metallized polyester vapor barrier, a middle layer of 150 μm LDPE with 0.5% calcium chloride desiccant additive, and an outer 50 μm UV-stabilized LDPE layer. Film seams are sealed using impulse welders at 220°C, achieving weld strength exceeding 85% of base material integrity. Critical moisture ingress points—coil edges, core openings, and strapping penetrations—are reinforced with butyl rubber tape. Internal relative humidity is monitored via data loggers; our packaging maintains RH below 40% for 120 days in 95% RH environments, verified through ASTM D4169 salt spray testing.

Sea freight safety is non-negotiable. Palletized units are unitized into ISO container-compatible configurations (max 2.4 m height) using corner boards and top caps to prevent stacking damage. Each shipment includes humidity indicator cards and shock recorders calibrated to ISO 12048. Documentation explicitly states stowage requirements: container ventilation must remain closed, and cargo must be positioned below deck away from vessel hull sides to reduce temperature fluctuations. Our packaging has demonstrated zero moisture-related claims across 8,200+ TEUs shipped to Southeast Asia, Europe, and the Americas since 2018. This system directly prevents hydroscopic degradation of insulation paper and copper oxidation—failure modes responsible for 73% of field transformer failures per CIGRÉ Study 782.

All packaging materials are traceable to certified suppliers, with lot-specific test reports available. We guarantee coil surface moisture content below 0.05% upon delivery, validated by pre-shipment dew point testing per IEC 60450. This integrated approach transforms packaging from a logistical necessity into a critical quality assurance component for your transformer production.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Copper Winding Wire Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner in the production of high-performance copper winding wire for transformer applications. Our facility integrates advanced metallurgical engineering with stringent quality control protocols to deliver winding conductors that meet the exacting demands of power and distribution transformer manufacturers worldwide.

Our production infrastructure is engineered for precision and consistency. We operate fully automated drawing lines equipped with closed-loop diameter control systems, ensuring dimensional tolerances within ±0.005 mm. This level of accuracy is critical for optimizing winding density and minimizing inter-turn stresses in transformer coils. The entire process—from billet casting to final spooling—is conducted under controlled atmospheric conditions to prevent oxide inclusions and maintain uniform electrical conductivity. Each batch of copper is sourced from certified suppliers and undergoes rigorous spectrographic analysis to verify purity, with minimum conductivity levels maintained at 100% IACS (International Annealed Copper Standard).

Thermal stability and mechanical reliability are central to our product design. Our annealing systems utilize induction heating with precise dwell-time control, producing a fully recrystallized microstructure that ensures excellent ductility and elongation characteristics. This enables seamless high-speed winding operations without breakage or deformation. Additionally, surface quality is monitored in real time using laser profilometry, eliminating defects such as scratches, pits, or protrusions that could compromise dielectric performance.

Quality assurance is embedded at every stage of production. Our in-house laboratory is accredited to ISO/IEC 17025 standards and conducts routine testing on tensile strength, elongation, wrap test performance, and resistivity. All material certifications are provided with full traceability, supporting compliance with international standards including IEC 60317, ASTM B3, and GB/T 3953.

As a vertically integrated manufacturer, we maintain tight control over raw material sourcing, processing, and logistics. This enables us to offer competitive lead times and scalable production volumes, from prototype batches to monthly outputs exceeding 1,500 metric tons. Our engineering team also provides technical collaboration for custom specifications, including tailored temper designations, special coatings, or non-standard diameters.

For transformer manufacturers seeking a reliable, technically proficient partner in copper winding wire supply, Luoyang Xinzhaohe delivers proven performance, consistent quality, and long-term supply chain stability.

Contact us today to discuss your technical requirements.

Cathy Zhang

Sales Director, Winding Wire Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper winding transformer directly from China.