Table of Contents

Market Insight: Transformer Fuse Wire

Market Analysis: Winding Wire – Transformer Fuse Wire Demand and Quality Imperatives

The global demand for transformer fuse wire, a specialized subset of winding wire used in electrical transformers, continues to grow in alignment with expanding power infrastructure, industrial automation, and renewable energy integration. As a critical component in transformer protection systems, fuse wire functions as a sacrificial element designed to interrupt excessive current during fault conditions, thereby safeguarding more expensive core components such as windings and magnetic cores. This application places stringent performance requirements on the material composition, dimensional consistency, and thermal-electrical characteristics of the fuse wire.

Transformer fuse wire is predominantly manufactured from high-purity aluminum or aluminum alloys due to their favorable conductivity-to-weight ratio, corrosion resistance, and cost efficiency compared to copper. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in aluminum-based winding wire production, we emphasize metallurgical precision in the fabrication of fuse wire tailored for medium and high-voltage transformers. The material must exhibit a precisely controlled melting point, predictable time-current characteristics, and minimal oxidation during service life to ensure reliable operation under transient overloads.

Industrial demand for high-quality transformer fuse wire is driven by several key sectors. Power distribution networks, particularly in emerging economies, are investing in robust transformer fleets that require dependable internal protection mechanisms. Similarly, the rise of solar and wind power installations has increased the deployment of step-up and grid-interface transformers, all of which rely on effective overcurrent protection. In industrial settings, transformers powering heavy machinery must operate continuously under variable loads, making fuse wire reliability a critical factor in minimizing unplanned downtime.

Quality in transformer fuse wire is not a secondary attribute—it is foundational to system safety and longevity. Substandard materials or inconsistent wire dimensions can lead to premature fusing, erratic response times, or failure to clear faults, all of which compromise the integrity of the entire transformer system. Poor surface finish or inclusion of impurities in the aluminum matrix can initiate localized hot spots, accelerating degradation. Furthermore, improper annealing or tensile strength control may result in mechanical failure during winding or installation.

At Luoyang Xinzhaohe Aluminum, our production process integrates strict quality control protocols, including continuous casting, precision drawing, and in-line resistivity monitoring, to ensure batch-to-batch uniformity. Each coil of fuse wire is tested for diameter tolerance (±0.01 mm), elongation, and electrical resistance to meet IEC 60264 and GB/T 3953 standards. This commitment to technical excellence enables our clients to integrate fuse wire solutions that enhance transformer reliability and reduce lifecycle costs.

The following table summarizes key performance parameters for high-grade aluminum transformer fuse wire:

| Parameter | Typical Value | Standard Reference |

|---|---|---|

| Aluminum Purity | ≥ 99.7% | GB/T 8170 |

| Diameter Tolerance | ±0.01 mm | IEC 60173 |

| Electrical Resistivity | ≤ 0.0283 Ω·mm²/m at 20°C | IEC 60468 |

| Tensile Strength | 60–90 MPa | GB/T 4909.3 |

| Elongation | ≥ 30% | GB/T 4909.4 |

In conclusion, the industrial demand for transformer fuse wire is inextricably linked to the global push for resilient and efficient power systems. As transformers become more integral to smart grids and distributed energy resources, the role of high-performance fuse wire will only increase. Partnering with a technically proficient supplier ensures that this small but vital component meets the rigorous demands of modern electrical engineering.

Technical Specs: Transformer Fuse Wire

Technical Specifications: Transformer Fuse Wire

Transformer fuse wire represents a specialized metallurgical product distinct from standard winding wire, engineered to sacrificially interrupt fault currents in power transformers. Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of aluminum alloy expertise to deliver fuse elements with rigorously controlled electrical, thermal, and mechanical properties. Critical specifications ensure reliable operation under transient overloads while preventing catastrophic transformer failure.

Insulation Breakdown Voltage Requirements

The dielectric strength of the wire’s oxide layer and any supplementary coating must withstand transient overvoltages without puncture. For aluminum-based fuse wire, the minimum AC breakdown voltage is 2.5 kV RMS at 50 Hz, tested per IEC 60243-1 on 100 mm immersed samples. DC breakdown voltage tolerance is maintained at ≥3.2 kV. This parameter directly correlates with oxide layer integrity; deviations indicate inconsistent anodization or surface contamination during drawing. Our process controls oxide thickness to 80–120 nm via electrolytic passivation, ensuring breakdown consistency across 0.15–1.20 mm diameters.

Elongation and Mechanical Integrity

Elongation at break is critical for fuse wire to withstand winding stresses without microfractures that alter fusing characteristics. Values must remain tightly constrained between 1.0% and 3.0% per ASTM E8, measured at 25°C on 50 mm gauge lengths. Excessive elongation (>3.5%) indicates inadequate cold work, risking premature deformation during coil insertion. Insufficient elongation (<0.8%) suggests over-annealing, increasing brittleness. Xinzhaohe achieves this balance through precision rod homogenization and multi-pass drawing with intermediate annealing, maintaining grain structure uniformity to ±0.5 µm.

Thermal Class and Operational Limits

Transformer fuse wire operates within thermal classes 130 (B), 155 (F), and 220 (C), corresponding to maximum continuous operating temperatures of 130°C, 155°C, and 220°C. The thermal index (TI) must exceed the class rating by 10°C to accommodate thermal runaway scenarios. Key material responses include:

| Parameter | Standard Value | Test Method | Critical Tolerance |

|---|---|---|---|

| Thermal Class | 130°C to 220°C | IEC 60505 | ±5°C |

| Resistivity (20°C) | 0.02826 Ω·mm²/m | ASTM B193 | ±0.0005 Ω·mm²/m |

| Melting Point | 658–662°C | ASTM E793 | ±2°C |

| Annealing Stability | No recrystallization at 200°C/168h | IEC 60216-2 | Max. 5% grain growth |

Aluminum alloy 1350-O (99.5% Al minimum) forms our baseline, with controlled iron (0.40–0.60%) and silicon (0.15–0.30%) for optimal fusing time-current characteristics. Higher thermal classes (e.g., 220°C) require proprietary scandium/zirconium microalloying to suppress grain growth at elevated temperatures.

All parameters undergo batch-level validation via in-line eddy current testing and destructive sampling. Diameter tolerance is held to ±0.005 mm for wires <0.50 mm and ±0.01 mm for larger gauges, directly impacting fusing accuracy per I²t calculations. Consistency in these specifications prevents nuisance tripping or failure to clear faults—critical for grid stability. Luoyang Xinzhaohe’s integrated smelting-to-drawing facility ensures traceability from billet metallurgy to final spool, eliminating supply chain variability in high-reliability transformer protection systems.

Factory Tour: Manufacturing

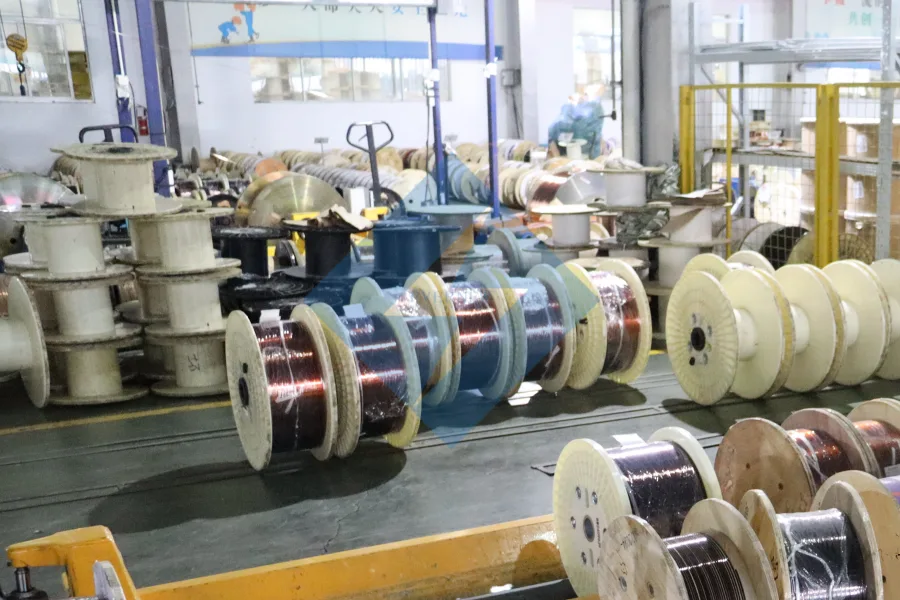

Transformer Fuse Wire Manufacturing Process at Luoyang Xinzhaohe Aluminum Co., Ltd

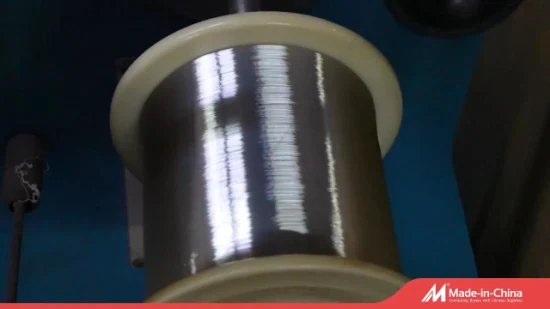

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of high-performance transformer fuse wire begins with precision rod drawing, a critical phase that establishes dimensional accuracy and mechanical consistency. High-purity aluminum rods, meeting ASTM B233 or equivalent standards, are fed into multi-die drawing machines where they are reduced incrementally to the specified wire diameter. This cold drawing process enhances tensile strength and ensures uniform cross-sectional geometry, essential for predictable fusing characteristics under overcurrent conditions. All drawing parameters—including reduction ratio, drawing speed, and die alignment—are monitored in real time to maintain tight tolerances, typically within ±0.02 mm.

Following drawing, the wire undergoes a controlled continuous annealing process to restore ductility and optimize electrical conductivity. The annealing line employs an induction heating system with precise temperature regulation, typically operating between 300°C and 450°C depending on the alloy and final temper requirements. A protective nitrogen atmosphere prevents surface oxidation, preserving the metallurgical integrity of the aluminum. The cooling zone utilizes a multi-stage water spray system to ensure rapid and uniform quenching, minimizing grain coarsening and maintaining a homogeneous microstructure. This step is crucial for achieving the required elongation (typically 18–25%) and conductivity (≥58% IACS), which directly influence the fuse wire’s thermal response and reliability.

The annealed wire then proceeds to the enameling stage, where a dielectric polymer coating is applied to provide electrical insulation. Utilizing a multi-pass dip-and-cure system, the wire is coated with modified polyester or polyamide-imide resins, selected for their thermal stability (Class 130°C to Class 200°C) and dielectric strength (>8 kV AC). Each pass includes precise viscosity control, oven curing at 450–550°C, and thickness monitoring via laser gauges to ensure coating uniformity within ±2 µm. The final build diameter is verified inline to ensure compatibility with winding equipment used by transformer manufacturers.

Throughout the production line, comprehensive quality control protocols are integrated at every stage. Dimensional checks are performed using laser micrometers, while electrical conductivity is validated via eddy current testing. The enamel coating undergoes 100% spark testing at 3 kV to detect pinholes or insulation defects. Sample wires are routinely extracted for destructive testing, including tensile strength, elongation, thermal shock (200°C for 1 hour), and dielectric breakdown. All data are logged in our traceability system, enabling batch-level quality audits.

This end-to-end manufacturing process, refined over 20 years of specialization in aluminum winding wire, ensures that our transformer fuse wire delivers consistent performance, superior thermal response, and long-term reliability in critical power applications.

Packaging & Logistics

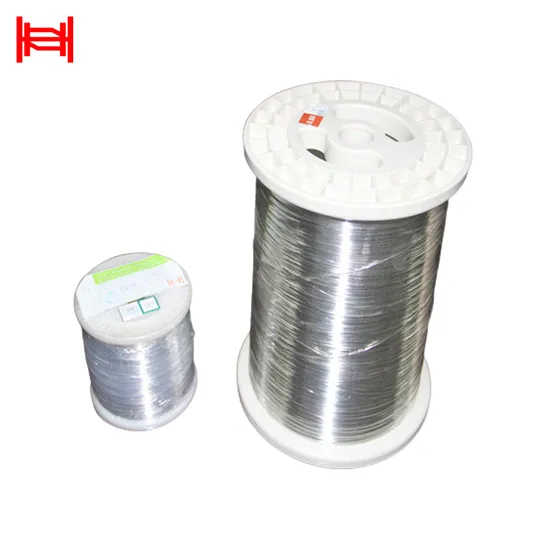

Export Packaging Specifications for Transformer Fuse Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard the metallurgical integrity and dimensional precision of aluminum alloy transformer fuse wire during international sea freight. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging is a primary cause of in-transit degradation, leading to oxidation, coil deformation, and compromised electrical performance upon arrival. Standardized solutions fail to address the unique hygroscopic nature of high-purity aluminum alloys and the extreme environmental stresses encountered in maritime logistics. Our methodology prioritizes absolute moisture exclusion and structural resilience.

Wooden Pallet Specifications

All shipments utilize ISPM-15 certified heat-treated wooden pallets constructed from kiln-dried hardwood. Pallet dimensions strictly adhere to ISO container optimization standards (1200mm x 1000mm or 1100mm x 1100mm) to ensure secure stowage and prevent shifting within shipping containers. Load-bearing capacity exceeds 2500 kg per pallet, incorporating double stringers and reinforced deck boards to eliminate flexure under stack loading during multi-tier container storage. Edge protectors made from high-density polyethylene are affixed to all coil perimeters to distribute point loads and prevent core collapse or wire buckling during handling. Pallet base treatment includes a corrosion-inhibiting sealant to counteract potential exposure to salt-laden container atmospheres.

Multi-Layer Moisture Barrier System

The critical defense against humidity-induced corrosion employs a triple-layer moisture barrier system. Coils are first wrapped in vapor corrosion inhibitor (VCI) paper, releasing controlled molecules that form a molecular shield on the aluminum surface. This is followed by hermetic sealing within 100-micron thick co-extruded polyethylene film (LDPE/LLDPE blend), specifically engineered for ultra-low moisture vapor transmission rates (MVTR < 0.5 g/m²/24hr @ 38°C, 90% RH). The film is heat-sealed using industrial impulse sealers to eliminate micro-perforations. A final outer layer of UV-stabilized polypropylene woven cloth provides abrasion resistance during cargo handling and protects the primary moisture barrier from puncture. All sealing operations occur within climate-controlled environments (<45% RH) to prevent encapsulation of ambient moisture.

Sea Freight Validation and Compliance

Our packaging system undergoes mandatory validation per ASTM D4169-21 Distribution Cycle 17, simulating 45 days of open-ocean transit including 85% relative humidity exposure, 40°C temperature cycling, and 15G shock testing. Documentation includes pallet load certification reports, VCI paper material safety data sheets (MSDS), and MVTR test certificates from SGS. This integrated approach ensures compliance with IMDG Code requirements for non-hazardous metal products while mitigating the dominant failure modes observed in transformer fuse wire shipments: intergranular corrosion from chloride ingress and plastic deformation from inadequate lateral support. The result is guaranteed product conformance to IEC 60228 Class 1 conductivity standards upon discharge, eliminating costly rework or rejection at destination ports. This packaging integrity directly translates to predictable landed costs and supply chain reliability for our global partners.

Core Packaging Component Specifications

| Component | Material Specification | Performance Standard |

|---|---|---|

| Primary Pallet | ISPM-15 HT Hardwood | ISO 18606, Load Capacity >2500 kg |

| Moisture Barrier Film | 100μm Co-extruded LDPE/LLDPE | MVTR <0.5 g/m²/24hr (ASTM F1249) |

| VCI Protection | Neutral pH VCI Paper | ASTM D6098, 18-month protection |

| Edge Protection | High-Density Polyethylene (HDPE) | Impact Resistance >50 J |

| Outer Cover | UV-Stabilized Polypropylene Woven Cloth | Tensile Strength >30 kN/m |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Transformer Fuse Wire Solutions

With over two decades of specialized expertise in aluminum winding wire manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for high-performance transformer fuse wire. Our facility integrates advanced metallurgical processing, precision drawing, and stringent quality assurance systems to deliver products that meet the exacting demands of power distribution and electrical protection applications.

Our production infrastructure is centered on continuous casting and rolling, ensuring consistent microstructural homogeneity in aluminum feedstock. This foundational control enables superior electrical conductivity, typically exceeding 61% IACS, while maintaining precise mechanical properties such as tensile strength and elongation. All raw materials are sourced from certified suppliers and subjected to rigorous incoming inspection, including spectral analysis and mechanical testing, to guarantee compliance with GB/T 3954 and international standards.

The transformer fuse wire production line at Xinzhaohe is engineered for dimensional accuracy and surface integrity. We offer diameters ranging from 0.15 mm to 3.0 mm, with tight tolerances down to ±0.005 mm, critical for predictable fusing characteristics under overload conditions. The wire is processed under controlled atmosphere annealing to eliminate residual stresses and ensure uniform softness, a key factor in reliable short-circuit response. Surface quality is monitored in-line using high-resolution optical inspection systems to detect defects such as scratches, pits, or oxide inclusions that could compromise performance.

Quality assurance is embedded throughout our manufacturing workflow. Each production batch undergoes comprehensive testing, including DC resistance measurement, tensile testing, bend testing, and thermal cycling to simulate real-world operating environments. Our ISO 9001-certified quality management system ensures traceability from ingot to finished coil, with full material test reports (MTRs) provided with every shipment.

We specialize in custom solutions for OEMs and electrical component manufacturers, including tailored temper specifications, spooling configurations, and packaging for export logistics. Our R&D team collaborates closely with clients to optimize wire performance for specific fuse designs, particularly in medium-voltage distribution transformers and protective devices where reliability is non-negotiable.

As a vertically integrated manufacturer, we maintain control over cost efficiency without compromising quality, enabling competitive pricing and stable supply continuity. Our logistics network supports just-in-time delivery to global markets, backed by responsive technical support and supply chain coordination.

For engineers and procurement managers seeking a dependable source of high-purity, high-consistency aluminum transformer fuse wire, Luoyang Xinzhaohe offers the technical depth, production capability, and long-term reliability required in critical electrical systems.

Contact us at cathy@transformerstrip.com to discuss your technical requirements and discover how our manufacturing excellence can support your product performance and supply chain goals.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer fuse wire directly from China.