Table of Contents

Market Insight: Transformer Core Lamination Material

Market Analysis: Silicon Steel for Transformer Core Lamination Applications

Global transformer manufacturing drives sustained demand for high-grade non-oriented and grain-oriented silicon steel, the critical material for core laminations. This demand is intrinsically linked to electrical grid expansion, modernization initiatives, and the accelerating integration of renewable energy sources requiring robust power conversion infrastructure. Utilities and industrial end-users increasingly prioritize energy efficiency, directly governed by core material performance. Regulatory frameworks like the DOE 2016 efficiency standards in the US and similar EU Ecodesign directives mandate significant reductions in no-load losses, compelling transformer designers to specify silicon steel with exceptionally low core loss characteristics. Consequently, the market exhibits strong growth, particularly for high-permeability, ultra-low-loss grain-oriented electrical steel (GOES) in distribution and power transformers above 50 kVA, where core losses constitute a major operational cost factor over the asset’s 30+ year lifespan.

Material quality is non-negotiable in transformer core laminations, directly impacting performance, reliability, and total cost of ownership. Substandard silicon steel introduces critical failure modes. Elevated core loss (W/kg) at operational flux densities (typically 1.5-1.7 T) translates directly to wasted energy, increased operating temperature, and reduced transformer efficiency. This not only incurs higher lifetime energy costs but also accelerates insulation degradation, shortening equipment life. Inconsistent magnetic permeability leads to unpredictable excitation currents and potential voltage regulation issues. Poor lamination insulation coating integrity causes interlaminar short circuits, significantly increasing eddy current losses and localized heating, creating hotspots that risk catastrophic failure. Furthermore, excessive magnetostriction generates audible noise and mechanical vibration, violating stringent environmental noise regulations and inducing fatigue stresses within the core structure. Dimensional inaccuracies or burrs on stamped laminations impede tight core stacking, increasing the effective air gap and further degrading magnetic performance.

The supply chain requires stringent metallurgical control to meet these demands. Key quality parameters include precise chemical composition control (especially silicon content 2.9-3.3% for GOES), exact grain orientation (Goss texture {110}<001>), ultra-smooth surface finish, and highly uniform, adherent insulating coatings (e.g., C3 or laser-scribed types per IEC 60404-8-7). Achieving consistent core loss values below 1.00 W/kg at 1.7 T and 50 Hz (P1.7/50) demands advanced production capabilities from melt refining through continuous annealing and coating application. Variability in any process step cascades into field performance issues. Luoyang Xinzhaohe Aluminum CO., Ltd leverages its two decades of specialized focus on electrical steel processing to ensure this consistency. Our integrated quality management system, encompassing rigorous incoming coil inspection, in-process monitoring of coating weight and adhesion, and final core loss validation testing against international standards, mitigates supply risk. This precision engineering capability is essential for transformer manufacturers seeking to comply with global efficiency mandates while ensuring long-term operational reliability and minimizing lifecycle costs for their customers. The procurement of silicon steel is not merely a cost exercise; it is a fundamental investment in the transformer’s electromagnetic integrity and economic viability.

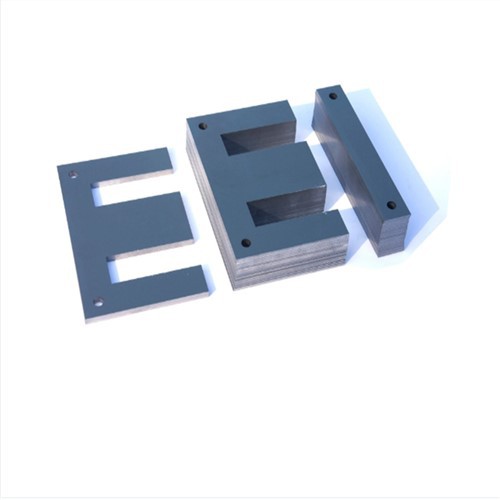

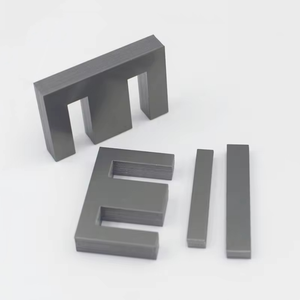

Technical Specs: Transformer Core Lamination Material

Transformer core lamination material selection is critical to achieving high-efficiency performance in power and distribution transformers. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in electrical steel processing and supply, we emphasize precision in material specifications to ensure optimal magnetic performance, thermal stability, and structural integrity. The technical parameters governing core lamination performance are primarily defined by core loss (iron loss), magnetic flux density, and geometric tolerances such as flatness. These factors directly influence transformer efficiency, noise levels, and operational lifespan.

Core loss, also referred to as iron loss, is a fundamental performance indicator and is measured in watts per kilogram (W/kg) under standardized test conditions (typically at 1.5 T and 50 Hz or 60 Hz). It comprises hysteresis loss and eddy current loss, both of which are minimized in high-grade grain-oriented silicon steel (GOES). Lower core loss translates to reduced heat generation and higher energy efficiency, particularly important in large-scale power transformers where regulatory standards such as IEC 60404-2 and GB/T 31357 impose strict efficiency benchmarks. Our supplied materials comply with these international standards and are available in core loss grades ranging from 0.90 W/kg to 1.25 W/kg, depending on the application requirements.

Magnetic flux density, expressed in Tesla (T), determines the magnetic loading capacity of the core. Grain-oriented electrical steel typically exhibits a nominal induction (B₈) of 1.88 T to 1.95 T when measured at a magnetic field strength of 800 A/m. Higher flux density allows for reduced core cross-sectional area, leading to compact transformer designs and material savings. However, operating near saturation must be carefully evaluated to avoid excessive losses and harmonic distortion. Our material portfolio includes high-permeability grades that optimize the balance between flux density and core loss, particularly suitable for high-efficiency distribution and traction transformers.

Flatness is a critical geometric specification in lamination stacks. Poor flatness leads to air gaps between laminations, increasing reluctance and localized eddy currents, which degrade magnetic performance and elevate temperature. We maintain flatness tolerances within 2 mm over a 1-meter span, ensuring uniform stacking pressure and minimal interlaminar losses. This is achieved through precision leveling and tension leveling processes during slitting and blanking operations.

The following table summarizes key technical specifications for transformer core lamination materials supplied by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Symbol | Standard Value Range | Test Condition | Standard Reference |

|---|---|---|---|---|

| Core Loss (Iron Loss) | P₁.₅/50 | 0.90 – 1.25 W/kg | 1.5 T, 50 Hz | IEC 60404-2 |

| Magnetic Flux Density | B₈ | 1.88 – 1.95 T | H = 800 A/m | IEC 60404-2 |

| Specific Total Loss | P₁.₇/60 | 1.00 – 1.35 W/kg | 1.7 T, 60 Hz | ASTM A876 |

| Flatness Tolerance | — | ≤ 2 mm per 1 m length | Free state, no load | Internal QC Standard |

| Thickness Tolerance | — | ±0.01 mm to ±0.03 mm | Depending on grade | GB/T 31357 |

| Coating Resistivity | — | ≥ 10 Ω·mm² | Post-insulation coating | IEC 60404-11 |

All materials are subject to rigorous quality control, including Epstein frame testing and single sheet testing (SST), to validate magnetic performance. We recommend material selection based on the transformer’s operating frequency, cooling method, and efficiency class to achieve optimal total owning cost.

Factory Tour: Manufacturing

Transformer Core Lamination Material Manufacturing Process

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in electrical steel processing to deliver transformer core lamination materials meeting stringent international performance standards. Our integrated manufacturing sequence ensures optimal magnetic properties, dimensional accuracy, and long-term operational reliability for critical power applications.

The process initiates with precision slitting of cold-rolled non-oriented or grain-oriented silicon steel coils. Utilizing computer-controlled tension management and high-precision rotary shear blades, master coils are longitudinally divided into narrow strips with widths conforming to lamination stack requirements. Critical process parameters include maintaining strip edge squareness within ±0.05 mm and controlling burr formation to less than 2% of material thickness. In-line laser micrometers continuously monitor strip width and thickness uniformity, with automatic feedback systems adjusting blade positioning to sustain tolerances of ±0.02 mm. Edge quality inspection via optical profilometry ensures minimal micro-cracking that could degrade core loss performance.

Subsequent continuous annealing is performed in a controlled hydrogen-nitrogen atmosphere furnace. This critical thermal treatment achieves decarburization to levels below 30 ppm carbon while promoting optimal grain growth and stress relief. Temperature profiles are meticulously managed across distinct zones: preheating at 700°C, rapid heating to 820-860°C for grain refinement, and slow cooling under tension to minimize magnetic domain disruption. Atmosphere dew point is maintained at -50°C or lower to prevent surface oxidation. Post-annealing, magnetic properties are verified using Epstein frame testing per IEC 60404-2, confirming core loss (W10/400) and permeability values against customer specifications.

Insulation coating application follows annealing to electrically isolate individual laminations. We apply either organic-based C3 coatings or inorganic C5/C6 coatings via roll-coating systems, achieving uniform dry film thicknesses of 0.5-1.0 μm. Coating weight is precisely controlled between 0.8-1.5 g/m² per side through real-time gravimetric measurement. Adhesion is validated per ASTM D3359 cross-hatch testing, while insulation resistance is measured at 500 V DC to ensure values exceed 5 Ω·m². Curing occurs in dedicated ovens at 450-550°C to fully polymerize the coating without degrading magnetic properties.

Final precision cutting transforms coated strips into individual laminations using high-speed progressive dies or laser cutting systems. Stamping operations maintain positional accuracy of ±0.01 mm for key features like teeth and yoke sections, with punch-die clearances optimized to 4-6% of material thickness to minimize burrs. Laser cutting provides burr-free edges for complex geometries at speeds up to 30 m/min. All cut parts undergo 100% automated optical inspection for dimensional conformity, burr height (<5% material thickness), and edge integrity. Final quality verification includes stack factor measurement, interlaminar resistance testing, and destructive sampling for core loss validation per IEC 60404-3.

Our integrated quality control framework embeds inspection at every stage, from incoming coil certification to final lamination validation. This systematic approach guarantees lamination materials that minimize eddy current losses, maintain structural stability under electromagnetic forces, and deliver transformer efficiency exceeding IE4/IE5 standards. Luoyang Xinzhaohe’s process discipline ensures consistent material performance essential for modern high-efficiency power infrastructure.

Packaging & Logistics

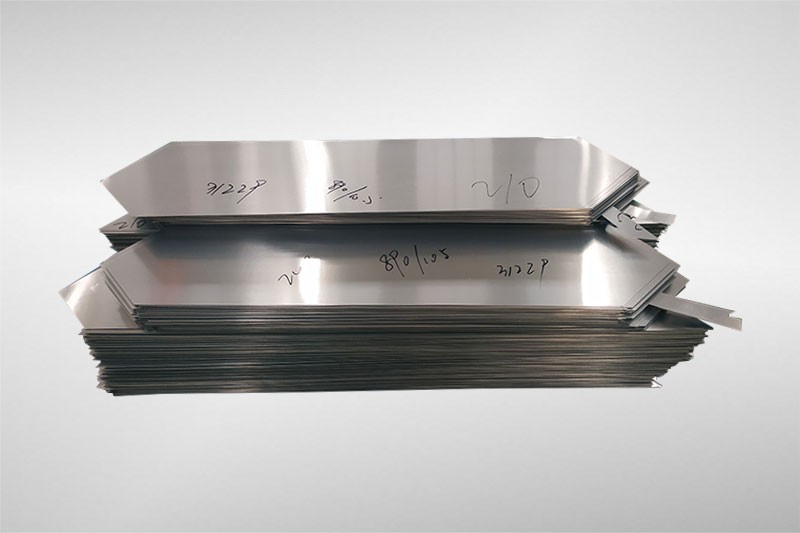

Export Packaging for Silicon Steel Used in Transformer Core Lamination Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international supply of high-grade silicon steel, we maintain rigorous standards in material integrity throughout the entire logistics chain. A critical component of this commitment is our engineered export packaging system, specifically designed to preserve the metallurgical and dimensional stability of electrical steel during extended sea freight transportation.

All silicon steel coils and cut-to-length laminations are systematically secured on custom-fabricated wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are engineered to support the substantial unit weight of densely wound steel coils, typically ranging from 5 to 12 metric tons, while ensuring compatibility with standard containerized shipping protocols. The structural integrity of each pallet is verified to meet ISO 12192 and ISTA 3A performance criteria for compression and load-bearing capacity, minimizing deformation risks during stacking and transshipment.

Immediately following palletization, the material undergoes a multi-layer moisture protection process. The primary barrier consists of heat-shrink polyethylene film with a minimum thickness of 125 microns, applied using automated wrapping systems to ensure 100% coverage. This is followed by an intermediate vapor corrosion inhibitor (VCI) film layer, which actively suppresses electrochemical oxidation by releasing passivating molecules into the enclosed environment. The outermost layer is a heavy-duty, UV-resistant polyethylene tarpaulin, sealed with waterproof adhesive tape to form a hermetic enclosure resistant to saltwater exposure and tropical humidity.

This tripartite wrapping system is essential for maritime transport, where cargo may be exposed to relative humidity levels exceeding 90% and temperature fluctuations between 0°C and 50°C across multiple climate zones. The packaging design mitigates the risk of white rust formation, interlamellar corrosion, and surface degradation—failures that can compromise core loss performance and magnetic permeability upon end-use processing.

Each packaged unit is labeled with permanent, weather-resistant markings indicating batch number, grade (e.g., M470-50A, M350-35A), coating type, and handling instructions compliant with IMDG Code and IATA Dangerous Goods Regulations where applicable. Lifting points are reinforced to meet ASME B30.20 standards, ensuring safe crane and forklift operations at ports and receiving facilities.

Our packaging methodology has been validated through accelerated salt spray testing (ASTM B117) and real-world shipment data across major trade lanes, including trans-Pacific and Europe-Asia routes. This systematic approach ensures that silicon steel arrives at the transformer manufacturing site in the same condition as it left our facility, supporting consistent stamping, annealing, and stacking operations downstream.

For global clients, this level of packaging assurance translates into reduced material rejection rates, lower insurance premiums, and uninterrupted production schedules—all integral to reliable supply chain performance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Silicon Steel Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise and industrial-scale manufacturing to deliver superior non-oriented and grain-oriented silicon steel for critical transformer core lamination applications. Our integrated production facility, operating at an annual capacity exceeding 200,000 metric tons, is engineered for stringent consistency and adherence to global electrical steel standards including IEC 60404-2 and JIS C 2550. We provide transformer manufacturers with the material foundation necessary to achieve optimal core efficiency, thermal stability, and long-term operational reliability in demanding power systems.

Our core strength resides in precise microstructural control and advanced processing capabilities. Dedicated hot and cold rolling lines, coupled with proprietary continuous annealing and decarburization processes, ensure exceptional grain orientation development in GOES grades and uniform magnetic properties in NOES grades. Critical parameters such as core loss (W/kg) and magnetic induction (T) are rigorously managed through real-time process analytics and closed-loop thickness control systems maintaining tolerances within ±0.002mm. All electrical steel undergoes stringent final inspection via automated laser measurement and Epstein frame testing, guaranteeing compliance with customer-specified performance bands. Our metallurgical team actively optimizes steel chemistry and processing parameters to minimize anomalous eddy current losses, directly contributing to transformer efficiency gains.

Supply chain resilience and technical collaboration define our partnership model. We operate a just-in-time (JIT) logistics framework supported by dedicated containerized shipping lanes and strategic inland warehousing, consistently achieving 99.5% on-time delivery performance globally. Our engineering support extends beyond material supply; we provide comprehensive technical data packages including full mill test reports, B-H curve analysis, and lamination stack loss modeling assistance. This enables seamless integration into your core manufacturing process and supports design validation. Crucially, our surface treatment systems apply industry-standard insulating coatings (C3, C5) with verified adhesion strength exceeding 30N/cm², ensuring lamination integrity during punching, stacking, and transformer operation.

Key Material Performance Specifications

| Parameter | Typical Range (GOES) | Typical Range (NOES) | Test Standard |

| :———————– | :————————- | :———————— | :—————- |

| Thickness (mm) | 0.23, 0.27, 0.30 | 0.35, 0.50, 0.65 | IEC 60404-9 |

| Core Loss P1.7/50 (W/kg) | ≤ 0.85 (0.23mm) | ≤ 3.20 (0.35mm) | IEC 60404-2 |

| Magnetic Polarization B8 | ≥ 1.89 T | ≥ 1.65 T | IEC 60404-4 |

| Coating Weight (g/m²) | 0.5 – 4.0 (C3/C5) | 0.8 – 5.0 (C3/C5) | IEC 60404-11 |

| Interlaminar Resistance | > 3.0 Ω·cm² (min 80% H₂O) | > 2.5 Ω·cm² (min 80% H₂O) | IEC 60404-12 |

Partnering with Luoyang Xinzhaohe means securing a reliable source of high-performance electrical steel backed by deep process metallurgy knowledge and responsive supply chain execution. We mitigate material risk for transformer OEMs through documented quality assurance, scalable production, and proactive technical engagement. Contact our engineering team directly for a detailed technical consultation and material qualification support tailored to your specific core lamination requirements. Initiate the process by emailing Cathy at cathy@transformerstrip.com to discuss your project specifications and receive comprehensive performance data.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer core lamination material directly from China.