Table of Contents

Market Insight: Copper Motor Winding

Market Analysis: Copper Motor Winding Demand in Transformer Applications

Global transformer manufacturing represents a critical and sustained market segment for high-purity copper winding wire. Driven by escalating electricity demand, grid modernization initiatives, renewable energy integration requiring power conversion, and stringent international efficiency regulations (such as IEC 60076 and DOE 2016 standards), the industrial requirement for premium copper conductors in transformer windings remains robust. Power transformers, distribution transformers, and specialized industrial units collectively consume vast quantities of electrolytic-tough-pitch (ETP) or oxygen-free electronic (OFE) copper wire, where electrical conductivity directly impacts operational efficiency, thermal management, and service life. The shift towards higher efficiency classes (e.g., IE4, IE5) further intensifies demand for conductors meeting exacting conductivity and dimensional specifications, as even marginal resistive losses translate into significant cumulative energy waste and heat generation over decades of operation.

Material quality is non-negotiable in transformer windings due to the extreme operational stresses involved. Substandard copper wire introduces critical failure risks. Inconsistent conductivity increases I²R losses, elevating operating temperatures beyond design parameters. This accelerates insulation degradation (typically paper-oil or synthetic systems), potentially leading to dielectric breakdown and catastrophic failure. Dimensional inaccuracies—such as out-of-tolerance diameter or ovality—compromise winding tightness and layer uniformity, creating localized hotspots and mechanical instability under short-circuit forces. Surface imperfections, burrs, or residual oxides can puncture delicate turn-to-turn insulation during the winding process, initiating internal faults. Furthermore, inadequate ductility or inconsistent mechanical properties hinder manufacturability, causing wire breakage during high-speed winding and increasing scrap rates. The consequences of compromised wire quality extend far beyond initial manufacturing costs; they directly threaten transformer reliability, safety, and the multi-decade asset lifecycle expected in power infrastructure.

The performance requirements necessitate adherence to strict metallurgical and dimensional standards. Key parameters include:

| Parameter | Critical Standard Range | Primary Impact |

|---|---|---|

| Conductivity | ≥ 100% IACS (ASTM B3) | Minimizes resistive losses, heat rise |

| Diameter Tolerance | ±0.002 mm to ±0.005 mm | Ensures winding density, thermal paths |

| Tensile Strength | 150-250 MPa (annealed) | Balances formability & short-circuit strength |

| Elongation | ≥ 40% | Prevents breakage during winding |

| Surface Cleanliness | Mirror finish, oxide-free | Protects insulation integrity |

Sourcing decisions must prioritize certified material traceability, rigorous in-process quality control (including continuous conductivity monitoring and automated diameter inspection), and proven manufacturing consistency. Luoyang Xinzhaohe Aluminum Co., Ltd., with over 20 years of metallurgical process expertise, emphasizes that while aluminum conductors serve specific applications, copper remains the unequivocal standard for high-reliability transformer windings due to its superior conductivity-to-weight ratio stability and established manufacturing protocols. Selecting a supplier with deep technical understanding of copper’s role in electromagnetic and thermal performance is paramount; it mitigates lifecycle risks and ensures transformers meet the demanding efficiency and longevity requirements of modern power systems. Quality assurance in copper winding wire is not a cost factor—it is the foundation of grid resilience.

Technical Specs: Copper Motor Winding

Technical Specifications for Copper Motor Winding Wire

Copper motor winding wire is a critical component in the construction of electric motors, generators, and transformers, where electrical conductivity, thermal resilience, and mechanical durability are paramount. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in winding wire manufacturing and supply, we emphasize adherence to international standards and precise technical parameters to ensure optimal performance and longevity in demanding industrial applications.

A key performance indicator for copper motor winding wire is insulation breakdown voltage, which defines the maximum voltage the insulation layer can withstand before electrical failure occurs. This parameter is essential for ensuring operational safety and reliability under high-voltage conditions. Our standard offering achieves a minimum breakdown voltage of 3,000 V AC at room temperature, with high-grade variants exceeding 5,000 V AC, suitable for heavy-duty industrial motors and high-efficiency systems. Testing is performed in accordance with IEC 60317 and ASTM D2307 standards using step-voltage methods to validate dielectric integrity.

Elongation, measured as a percentage of original length before fracture, reflects the wire’s ductility and ability to endure mechanical stress during winding processes. Insufficient elongation can lead to wire breakage, inconsistent coil formation, and reduced manufacturing yield. Our copper winding wire maintains a minimum elongation of 8%, with premium grades achieving up to 12%, ensuring compatibility with high-speed automatic winding equipment and complex coil geometries. This mechanical property is tested per ASTM B3 and IEC 60228 to guarantee consistency across production batches.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For copper motor winding wire, thermal classes range from 130°C to 220°C, aligning with insulation materials such as polyurethane, polyester, polyamide-imide, and silicone. Higher thermal classes enhance motor efficiency and lifespan, particularly in applications involving frequent thermal cycling or elevated ambient temperatures. Our product portfolio includes wires rated at 155°C (Class F), 180°C (Class H), and 220°C (Class C), all tested under thermal endurance protocols per IEC 60172 and UL 1446.

The following table summarizes the core technical parameters for our copper motor winding wire series:

| Parameter | Standard Value | Test Standard | Notes |

|---|---|---|---|

| Conductor Material | Electrolytic Tough Pitch (ETP) Copper | ASTM B3, IEC 60028 | Oxygen content ≤ 0.04% |

| Insulation Breakdown Voltage | ≥ 3,000 V AC (min) | IEC 60317, ASTM D2307 | Up to 5,000 V AC for high-performance grades |

| Elongation | 8–12% | ASTM B3, IEC 60228 | Measured on bare copper conductor |

| Thermal Class | 130°C to 220°C | IEC 60172, UL 1446 | Classes B, F, H, and C available |

| Insulation Material | Polyester, Polyamide-imide, Silicone | IEC 60317 | Solvent-resistant, thermal shock tested |

| Diameter Tolerance | ±0.01 mm to ±0.03 mm | IEC 60127 | Depends on nominal diameter |

These specifications are engineered to meet the rigorous demands of modern motor manufacturing, including energy efficiency standards (IE3, IE4), compact design requirements, and extended service intervals. All products undergo 100%在线 testing for continuity, insulation defects, and diameter consistency to ensure zero-defect delivery.

Factory Tour: Manufacturing

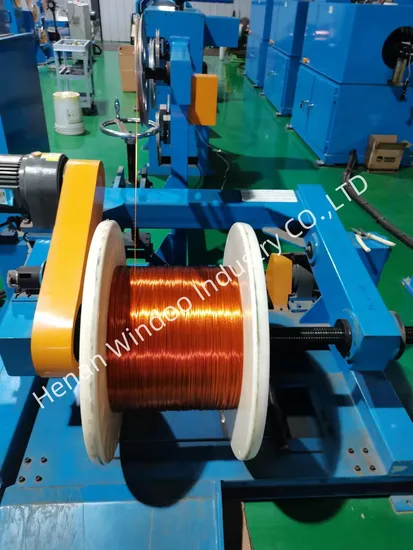

Manufacturing Process for High-Performance Copper Motor Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in electromagnetic wire production to deliver copper motor winding wire meeting the most stringent global performance and reliability standards. Our integrated manufacturing process ensures consistent dimensional accuracy, optimal electrical properties, and robust insulation integrity essential for efficient motor operation. The core sequence comprises Rod Drawing, Annealing, Enameling, and rigorous Inline Testing, each stage incorporating critical quality control checkpoints.

The process initiates with high-conductivity electrolytic tough pitch (ETP) copper rod, certified to IACS standards exceeding 101%. Precision rod drawing reduces the diameter to the target specification through multiple dies under controlled tension and lubrication. This cold working significantly increases tensile strength but reduces ductility, necessitating the subsequent annealing stage. Continuous annealing occurs in a precisely controlled inert atmosphere furnace. Temperature profiles are meticulously calibrated based on wire gauge and required mechanical properties, typically ranging from 450°C to 550°C, to restore optimal ductility and conductivity while eliminating residual stresses. Strict atmosphere control prevents surface oxidation, ensuring a clean substrate for insulation adhesion. Key QC checkpoints include real-time monitoring of drawing speed, tension, and rod surface quality, coupled with periodic tensile and elongation testing on drawn samples to verify mechanical property targets.

The annealed conductor then enters the enameling line. Multiple layers of thermosetting polymer insulation, commonly polyurethane, polyester, or advanced polyesterimide formulations, are applied via precision die coating. Each layer undergoes immediate curing in high-temperature ovens with precisely managed dwell times and temperature gradients to achieve complete cross-linking without degrading the polymer or conductor. Layer thickness is continuously monitored and adjusted to meet exact class requirements (e.g., Class 155, 180, 200). Critical QC during enameling involves automated optical measurement of coating diameter and concentricity, solvent extraction tests for cure degree, and adhesion testing per IEC 60851 standards.

Inline testing is fundamental to our zero-defect philosophy. Every meter of wire undergoes 100% spark testing at voltages significantly exceeding operational requirements to detect microscopic pinholes or thin spots in the insulation. Simultaneously, laser micrometers provide continuous, non-contact measurement of overall wire diameter, ensuring compliance with tight tolerance bands, typically ±0.002mm for fine gauges. Breakage monitoring systems track tension and spooling integrity in real-time. Final inspection before shipment encompasses comprehensive verification against customer specifications:

| Test Parameter | Standard Method | Typical Tolerance/Requirement |

|---|---|---|

| Conductor Diameter | IEC 60122 | ±0.002mm to ±0.005mm |

| Overall Diameter | IEC 60851-3 | ±0.005mm to ±0.020mm |

| Insulation Resistance | IEC 60851-5 | >1000 MΩ·km @ 20°C |

| Dielectric Breakdown | IEC 60851-5 | Min. 2x Rated Voltage + 1kV |

| Elongation | IEC 60851-4 | ≥15% (Typical) |

| Thermal Shock | IEC 60851-6 | Pass @ Specified Temp/Class |

This tightly integrated process, governed by ISO 9001-certified procedures and advanced statistical process control (SPC), guarantees copper motor winding wire that maximizes motor efficiency, thermal endurance, and operational lifespan. Our commitment to process transparency and documented quality provides sourcing professionals with the assurance of supply chain reliability and product performance consistency demanded by modern electric motor manufacturing.

Packaging & Logistics

Export Packaging for Copper Motor Winding Wire – Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international distribution of high-performance winding wires, we recognize that effective export packaging is as critical as material quality in ensuring product integrity upon delivery. For copper motor winding wire, which is highly sensitive to mechanical stress, moisture, and environmental contamination during transit, our export packaging system is engineered to meet the rigorous demands of global sea freight logistics.

All copper motor winding wire shipments are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support heavy coil loads while maintaining structural stability under dynamic loading conditions typical in containerized ocean transport. The use of treated wood ensures compliance with international phytosanitary standards, eliminating the risk of customs delays due to non-conforming dunnage materials. Each coil is precisely positioned and mechanically fastened to the pallet using steel strapping, preventing axial or radial displacement during vessel movement, port handling, or intermodal transfers.

A primary concern in maritime transport is humidity exposure, particularly in tropical and high-salinity environments. To mitigate oxidation and surface degradation of copper conductors, every palletized load is hermetically wrapped with multi-layer moisture-proof film. This film consists of a laminated aluminum-polyethylene composite barrier that provides a vapor transmission rate of less than 0.1 g/m²·day, effectively isolating the wound copper wire from ambient humidity. The sealing process includes heat-welded seams and overlapping wraps, verified through visual inspection to ensure continuity and absence of punctures or gaps.

Additionally, desiccant packs are strategically placed within the sealed film enclosure to absorb any residual moisture and maintain an internal relative humidity below 40% throughout the shipment duration. This dual-defense strategy—barrier film and active desiccation—preserves the surface cleanliness and electrical performance of the copper winding wire, which is essential for downstream processing in motor and transformer manufacturing.

All packaged units are labeled with durable, weather-resistant identification tags indicating product specification, batch number, net weight, handling instructions, and storage conditions. These labels are affixed externally on multiple sides to ensure visibility regardless of orientation during handling.

Our packaging protocol has been validated through long-term shipments to markets across Southeast Asia, Europe, and South America, consistently achieving zero moisture-related claims. By integrating structural resilience with advanced environmental protection, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that copper motor winding wire arrives in the same technical condition as it left our facility, supporting reliable performance in high-efficiency electromechanical applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Motor Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver copper motor winding wire meeting the most stringent global performance and reliability standards. Our core strength resides in precise metallurgical process control, ensuring consistent material properties critical for high-efficiency motor operation. We utilize high-purity electrolytic tough pitch (ETP) copper cathode (C11000) or oxygen-free electronic (OFE) copper (C10100/C10200) as feedstock, subjected to rigorous in-house rod casting and continuous annealing processes. This vertical integration from raw material to finished product guarantees unparalleled traceability and eliminates supply chain vulnerabilities inherent in fragmented sourcing models.

Our production facility employs advanced continuous annealing and straightening lines with real-time monitoring of key parameters including tensile strength, elongation, and electrical conductivity. This granular process control ensures every coil of wire adheres to exact specifications for motor winding applications, typically achieving conductivity levels of 100% to 101% IACS with tightly controlled mechanical properties. Dimensional accuracy is paramount; we maintain outer diameter tolerances within ±0.01mm and surface finish standards that minimize insulation damage during high-speed winding operations. Statistical process control (SPC) methodologies are embedded throughout manufacturing, supported by comprehensive in-house laboratory testing for chemical composition, mechanical properties, and dimensional verification per ASTM B3, IEC 60122, and customer-specific requirements.

Supply chain resilience and technical collaboration define our partnership approach. We operate a robust inventory management system optimized for just-in-time delivery schedules, mitigating production disruption risks for our clients. Our engineering team provides direct technical support for winding process optimization, material selection guidance based on motor design parameters (voltage class, thermal class, duty cycle), and rapid root-cause analysis for any field performance inquiries. This proactive engagement ensures our copper winding wire integrates seamlessly into your manufacturing process, enhancing final motor efficiency and longevity. Certifications including ISO 9001 and adherence to IATF 16949 principles underpin our commitment to quality management and continuous improvement.

Partnering with Luoyang Xinzhaohe means securing a supplier whose metallurgical rigor and supply chain discipline directly contribute to your motor’s performance and production stability. We transform copper purity and process science into your competitive advantage. Contact our Technical Sales Manager Cathy immediately at cathy@transformerstrip.com to discuss your specific winding wire requirements and receive a detailed capability statement. Initiate a technical consultation to optimize your sourcing strategy with a proven industry specialist.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper motor winding directly from China.