Table of Contents

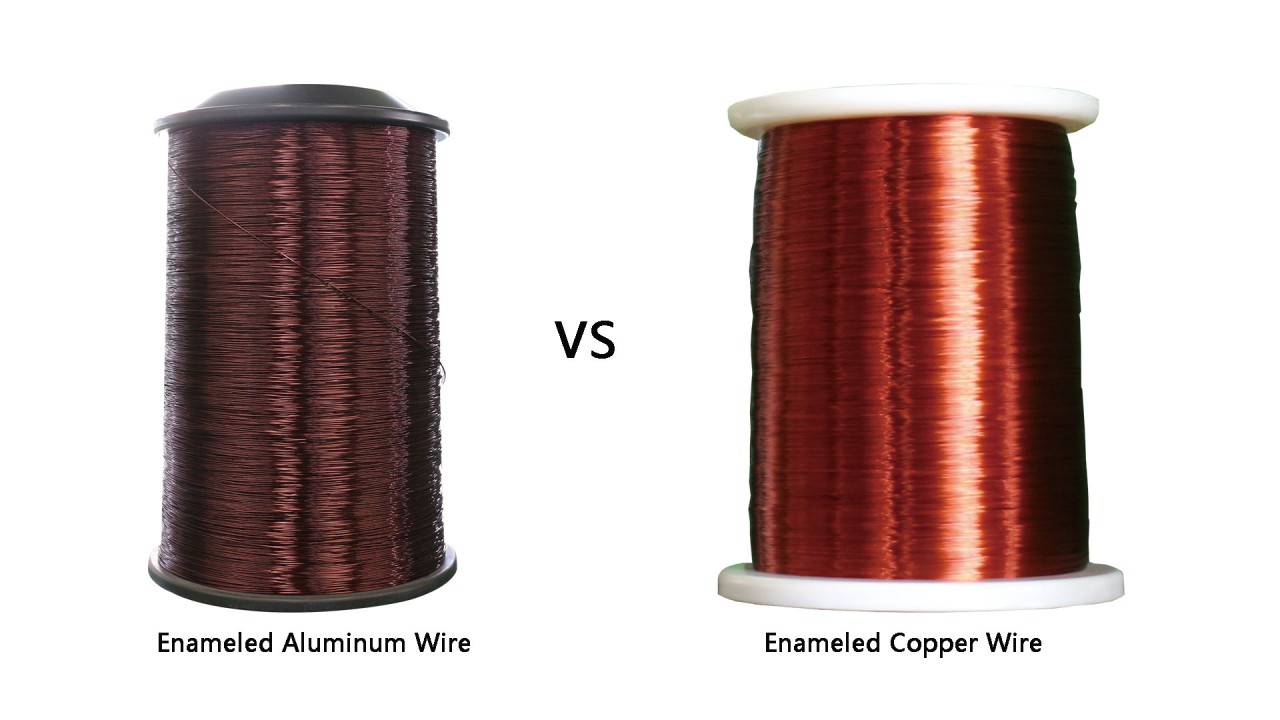

Market Insight: Aluminum Winding Vs Copper Winding

Market Analysis: Winding Wire – Aluminum vs Copper in Transformer Applications

The global transformer industry continues to exhibit a strategic shift in conductor material selection, with aluminum winding wire increasingly competing with traditional copper windings. This transition is driven by economic, logistical, and material efficiency considerations, particularly in distribution and power transformers used in utility, industrial, and renewable energy infrastructure. While copper has historically dominated due to its superior electrical conductivity (approximately 100% IACS), aluminum offers a compelling alternative with conductivity around 61% IACS, offset by significant advantages in weight and cost.

Aluminum winding wire typically weighs approximately one-third that of copper for equivalent electrical performance when adjusted for cross-sectional area. This density advantage reduces the overall mass of transformer cores and coils, simplifying transportation and installation—particularly critical in rural electrification projects and large-scale solar or wind substations. Additionally, aluminum is more abundant in the Earth’s crust than copper, leading to greater price stability and reduced exposure to geopolitical supply chain disruptions. For manufacturers aiming to optimize bill-of-materials (BOM) costs without compromising performance, high-purity aluminum winding wire (Grade 1350-O or 1370-O) presents a technically viable and economically efficient solution.

However, the performance parity between aluminum and copper is contingent upon material quality and manufacturing precision. Substandard aluminum wire—characterized by impurities, inconsistent tensile strength, or poor surface finish—can lead to increased resistive losses, thermal instability, and joint degradation due to galvanic corrosion or creep under prolonged mechanical stress. These risks are particularly pronounced at termination points where aluminum-to-copper connections are required. Therefore, adherence to international standards such as ASTM B398/B398M and IEC 60104 is essential to ensure dimensional accuracy, elongation properties, and oxide layer control.

Copper remains the preferred choice in high-efficiency, compact transformers where space and energy losses are critical constraints, such as in urban substations or industrial motor drives. Nevertheless, the performance gap has narrowed significantly due to advancements in aluminum alloying, annealing processes, and insulation technologies. Modern aluminum windings, when properly engineered and installed, can achieve life-cycle performance comparable to copper in many medium-voltage applications.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience in aluminum electrical conductors, we emphasize that material quality is non-negotiable. Our aluminum winding wires undergo rigorous refining, continuous annealing, and surface treatment to ensure consistent conductivity, mechanical reliability, and compatibility with standard winding and splicing practices. As the market evolves toward cost-effective and sustainable solutions, the choice between aluminum and copper must be informed not only by initial conductivity metrics but by total cost of ownership, system longevity, and supply chain resilience.

Technical Specs: Aluminum Winding Vs Copper Winding

Technical Specifications: Aluminum vs Copper Winding Conductors

Material selection for electromagnetic windings requires precise evaluation of electrical, mechanical, and thermal properties. As a metallurgical specialist with Luoyang Xinzhaohe Aluminum Co., Ltd. (20+ years in conductor manufacturing), we emphasize that aluminum and copper exhibit distinct behaviors under operational stress. Key differentiators include density, mechanical resilience, and thermal expansion characteristics, directly impacting winding integrity and longevity. Below is a comparative analysis of critical parameters per IEC 60228 and ASTM B3/B230 standards.

| Parameter | Aluminum Conductor | Copper Conductor | Notes |

|---|---|---|---|

| Density (kg/m³) | 2700 | 8960 | Aluminum offers 68% weight reduction. |

| Tensile Strength (MPa) | 60–150 | 200–350 | Copper provides higher mechanical rigidity; aluminum requires optimized annealing for ductility. |

| Elongation (%) | 15–30 | 3–10 | Aluminum’s superior elongation enhances flexibility during high-speed winding, reducing breakage risk. |

| Coefficient of Thermal Expansion (μm/m°C) | 23.1 | 16.5 | Aluminum’s higher expansion necessitates design allowances for thermal cycling. |

| Insulation Breakdown Voltage (kV) | 3–10 (insulation-dependent) | 3–10 (insulation-dependent) | Identical for equivalent insulation systems (e.g., polyester-imide); material does not inherently alter dielectric strength. |

| Thermal Class Range | 130°C to 220°C | 130°C to 220°C | Achieved via matching insulation (e.g., Class H = 180°C); conductor material does not limit class. |

Critical Interpretation

Elongation is a decisive factor in manufacturing efficiency. Aluminum’s 15–30% elongation (vs. copper’s 3–10%) allows tighter bending radii without microcracking, particularly advantageous in complex coil geometries. However, aluminum’s lower tensile strength demands precise tension control during winding to prevent deformation. Density differences directly influence system weight—critical in aerospace or EV applications where aluminum reduces mass by over 50% at equivalent conductivity.

Thermal class compatibility relies entirely on insulation chemistry, not conductor material. Both metals achieve Classes B (130°C) through C (220°C) using identical insulating varnishes or films. Nevertheless, aluminum’s higher coefficient of thermal expansion (23.1 vs. 16.5 μm/m°C) induces greater dimensional stress during thermal cycling. Designs must incorporate strain relief at terminations to prevent fatigue failure.

Insulation breakdown voltage remains insulation-system-dependent. For example, a 0.2 mm polyester-imide coating typically withstands 5–8 kV regardless of conductor. However, aluminum’s susceptibility to oxidation requires inert atmosphere processing during insulation curing to maintain interface integrity—unlike copper, which forms a conductive oxide.

Operational Considerations

Aluminum windings necessitate specialized termination techniques (e.g., ultrasonic welding) to mitigate galvanic corrosion. Copper’s higher conductivity (58 MS/m vs. aluminum’s 35 MS/m) allows smaller cross-sections for identical current loads, but aluminum’s cost-to-performance ratio often offsets this in large-scale deployments. Thermal class validation must include thermal aging per IEC 60172, with aluminum systems requiring additional cyclic stress testing due to expansion differentials.

Consult Luoyang Xinzhaohe’s application engineers to optimize conductor grade (e.g., 1350-O for flexibility vs. 6201-T81 for strength) and insulation pairing for your thermal duty cycle. Our metallurgical expertise ensures compliance with NEMA MW-1000 and IEC 60317 specifications across 130–220°C operational envelopes.

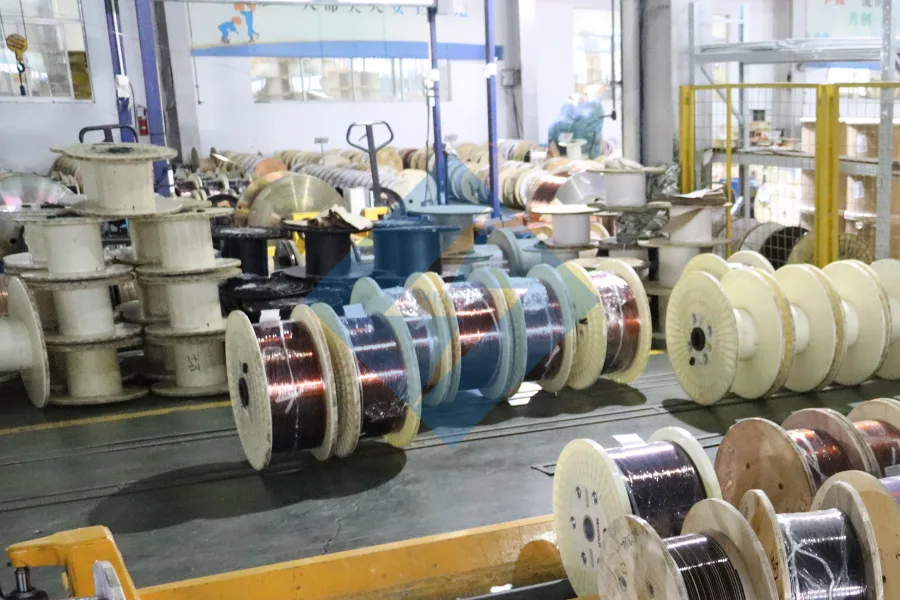

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, mechanical integrity, and electrical reliability. With over two decades of metallurgical and industrial expertise, our facility integrates advanced process engineering with rigorous quality control to meet the demanding requirements of the electromechanical and transformer industries.

The process begins with rod drawing, where high-purity aluminum rods (typically 9.5 mm in diameter, meeting GB/T 3954 standards) are reduced to precise wire diameters ranging from 0.08 mm to 5.0 mm. This is achieved through multi-die drawing machines operating under controlled tension and lubrication conditions. The drawing process is critical for achieving uniform surface finish and consistent cross-sectional geometry, both of which directly influence subsequent coating adhesion and winding performance. Each drawing line is monitored in real time for line speed, reduction ratio, and temperature to prevent microstructural defects.

Following drawing, the wire undergoes continuous annealing in an inert atmosphere furnace. This step restores ductility lost during cold working by promoting recrystallization of the aluminum microstructure. Our annealing system operates at precisely calibrated temperatures between 300°C and 450°C, depending on alloy grade and final application requirements. Oxygen content is maintained below 50 ppm to prevent oxide formation, ensuring superior conductivity and bondability in the enameling stage.

The annealed wire then proceeds to the enameling section, where one or multiple layers of polymer insulation—commonly polyurethane (PU), polyester (PE), or polyamide-imide (PAI)—are applied via precision die coating. The coating thickness is tightly controlled within ±5% of nominal values to meet dielectric strength specifications. Each layer is immediately cured in a series of high-efficiency UV or thermal curing ovens, ensuring complete cross-linking and thermal class compliance (up to Class 200). Dual or triple coatings can be applied for enhanced mechanical and thermal endurance.

Throughout the production line, inline testing systems continuously monitor key parameters. These include diameter measurement via laser gauges, insulation continuity testing at 3 kV, and tension control within ±2%. Additional quality checks include elongation (minimum 15%), tensile strength (80–120 MPa), and thermal shock resistance per IEC 60317 standards. Samples are extracted hourly for laboratory verification of adhesion, dielectric strength, and thermal aging performance.

All process data is logged and traceable to batch numbers, ensuring full compliance with ISO 9001 and customer-specific quality management systems. This integrated approach to manufacturing enables Luoyang Xinzhaohe Aluminum Co., Ltd to deliver aluminum winding wire with performance characteristics that rival copper equivalents, while offering significant advantages in weight and cost.

Packaging & Logistics

Export Packaging Specifications for Winding Wire Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorous export packaging protocols specifically engineered to safeguard aluminum and copper winding wire integrity during global maritime transport. Sea freight exposes sensitive conductor materials to significant environmental stressors including high humidity, salt air, condensation, and mechanical shock. Our packaging system is designed as a critical barrier against these risks, ensuring product arrives in optimal condition for immediate processing. This is particularly vital for aluminum winding wire, which requires enhanced protection against oxidation compared to copper due to its higher susceptibility to surface corrosion under adverse conditions.

All export shipments utilize ISPM 15 certified wooden pallets as the foundational structural element. These pallets are constructed from kiln-dried hardwood or engineered plywood, providing essential load stability and resistance to compression forces encountered during container stacking and handling. Pallet dimensions strictly adhere to international containerization standards, maximizing cube utilization while preventing internal cargo movement. Each pallet undergoes thorough inspection for splinters, protrusions, or structural weaknesses that could compromise wire reels or subsequent handling equipment. Reels are securely fastened to the pallet base using high-tensile steel strapping applied with calibrated tensioners, eliminating lateral shift during transit.

The primary moisture barrier consists of multiple layers of high-density polyethylene (HDPE) film with a minimum thickness of 120μm. This film possesses a low water vapor transmission rate (WVTR), critical for preventing atmospheric moisture ingress over extended voyages. The wrapping process employs a multi-stage methodology: initial tight wrapping around the reel core, followed by overlapping layers covering the entire wire surface and flanges, culminating in a final hermetic seal heat-welded at the film overlap points. Desiccant packs rated for the specific shipment volume and expected transit duration are strategically placed within the sealed enclosure to absorb any residual moisture trapped during packaging. For aluminum wire shipments, an additional internal vapor corrosion inhibitor (VCI) film layer is integrated beneath the primary HDPE barrier, providing electrochemical protection against oxidation initiation.

The following table outlines key packaging requirements for each material:

| Parameter | Aluminum Winding Wire | Copper Winding Wire |

|---|---|---|

| Pallet Standard | ISPM 15 Hardwood/Plywood | ISPM 15 Hardwood/Plywood |

| Primary Film | 120μm HDPE + VCI Layer | 120μm HDPE |

| Desiccant Capacity | 150g/m³ minimum | 100g/m³ minimum |

| Seal Integrity | Double Heat-Welded Seams | Single Heat-Welded Seam |

| Corrosion Mitigation | Mandatory VCI + Desiccant | Desiccant Only |

This integrated packaging system directly addresses the core vulnerabilities of sea freight: prolonged humidity exposure, salt contamination, and temperature fluctuations causing cargo sweat. By maintaining a stable, dry microclimate around the wire, we prevent interlayer adhesion, surface pitting, and oxide layer formation that would necessitate costly cleaning or lead to winding machine downtime at the customer facility. Compliance with these specifications is non-negotiable in our quality management system, verified through pre-shipment humidity monitoring and visual inspection. Proper export packaging is not a cost center but a strategic investment in supply chain resilience, ensuring the metallurgical properties and dimensional tolerances of our conductors remain uncompromised from factory gate to production line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Aluminum Winding Solutions

With over two decades of specialized expertise in aluminum winding wire production, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of high-purity, high-conductivity aluminum winding materials. As a vertically integrated manufacturer, we maintain full control over the metallurgical and processing stages—from billet sourcing and continuous casting to precision drawing, annealing, and final inspection. This comprehensive oversight ensures exceptional consistency in mechanical and electrical properties, meeting the stringent demands of transformer, motor, and inductor manufacturers worldwide.

Our production facility spans over 50,000 square meters and is equipped with state-of-the-art German and Italian wire drawing lines, automated annealing furnaces, and inline resistivity monitoring systems. These capabilities allow us to produce aluminum winding wire in diameters ranging from 1.0 mm to 6.0 mm, with conductivity consistently exceeding 61% IACS and tensile strength tailored to application-specific requirements. We specialize in 1350, 1370, and 8030 aluminum alloys, all processed under strict ISO 9001-certified quality management protocols. Every coil undergoes rigorous testing for elongation, ovality, surface finish, and electrical continuity to ensure defect-free performance in high-stress winding environments.

One of our core differentiators lies in our proprietary homogenization and annealing technology, which significantly enhances grain uniformity and reduces residual stress in the final product. This results in superior formability and reduced springback during coil winding—critical factors in automated manufacturing lines where precision and repeatability are paramount. Furthermore, our aluminum wire exhibits excellent thermal stability and oxidation resistance, making it an ideal alternative to copper in applications where weight reduction, cost efficiency, and long-term reliability are key design drivers.

We understand that B2B sourcing decisions are based on more than product specifications—they depend on supply chain resilience, technical support, and responsive collaboration. At Luoyang Xinzhaohe, we maintain a dedicated technical service team that works closely with clients during material qualification, process integration, and failure analysis. Our logistics network ensures on-time delivery to North America, Europe, Southeast Asia, and the Middle East, supported by just-in-time inventory programs for high-volume partners.

For engineering teams evaluating aluminum versus copper windings, we offer comprehensive comparative data, sample coils for prototyping, and metallurgical reports to support material substitution initiatives. Our goal is to enable seamless transition to high-efficiency aluminum solutions without compromising performance or reliability.

Contact us today to discuss your winding wire requirements. Partner with a manufacturer that combines deep metallurgical expertise with industrial-scale reliability.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum Co., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum winding vs copper winding directly from China.