Table of Contents

Market Insight: E Steel Inc

Market Analysis Silicon Steel Electrical Steel for Transformer Applications

Global demand for high-grade silicon steel remains fundamentally tied to electrical infrastructure expansion and modernization. Transformer manufacturers face sustained pressure to deliver units meeting stringent efficiency standards driven by regulatory frameworks like DOE 2016 in the US and EU Ecodesign Directive 2014/51/EC. This directly translates to increased procurement requirements for grain-oriented electrical steel (GOES) with precisely controlled magnetic properties. Key demand drivers include renewable energy integration necessitating grid-strengthening transformers, urbanization driving substation deployment, and the global push for energy-efficient distribution transformers (DETs) reducing no-load losses. The shift towards higher operating frequencies in certain specialty applications further intensifies the need for advanced non-oriented electrical steel (NOES) grades. Supply chain resilience is critical as transformer lead times directly impact grid project schedules worldwide.

Material quality in silicon steel is non-negotiable for transformer performance and lifecycle cost. Core losses—comprising hysteresis and eddy current losses—directly determine a transformer’s no-load energy consumption over its 30-40 year operational lifespan. Minor deviations in key parameters incur significant financial penalties. For instance, a 0.5 W/kg increase in specific core loss (P1.7/50) for a 100 MVA power transformer can equate to approximately 40,000 kWh of wasted energy annually, translating to over $4,000 in operational costs per year at industrial electricity rates. Critical quality factors include precise silicon content (2.9-3.3% for Hi-B GOES), tight control of grain orientation (Goss texture {110}<001>), minimal carbon and sulfur residuals (<30 ppm), and consistent lamination thickness tolerance (±0.005 mm). Surface insulation coating integrity is equally vital to prevent interlaminar short circuits, which drastically increase eddy current losses.

Substandard material manifests in measurable operational deficiencies. Inconsistent magnetic domain structure elevates core loss beyond specification, forcing derating or premature failure. Poor coating adhesion causes vibration-induced core degradation and audible noise exceeding regulatory limits (e.g., 55 dB(A) for urban substations). Thickness variations disrupt core stacking factor, reducing effective cross-sectional area and magnetic flux density (B800 typically 1.88-1.92 T for premium GOES). These defects trigger costly field failures, warranty claims, and reputational damage for OEMs. The table below summarizes critical quality parameters and their operational impact:

| Parameter | Target Value (Premium GOES) | Consequence of Deviation |

|---|---|---|

| Specific Core Loss (P1.7/50) | ≤ 0.78 W/kg | Increased no-load losses; higher lifetime energy costs |

| Magnetic Induction (B8) | ≥ 1.89 T | Reduced power handling capacity; potential core saturation |

| Stacking Factor | ≥ 97.5% | Lower effective core area; increased magnetizing current |

| Interlaminar Resistance | ≥ 3.0 Ω·mm² | Elevated eddy current losses; localized heating |

Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise to address these critical quality demands. Our production rigor ensures silicon steel meets or exceeds IEC 60404-2 and ASTM A976 standards through advanced slab reheating control, precision cold rolling, and laser-scribed domain refinement. For ‘e steel inc’, partnering with a supplier possessing deep process understanding of the steel-to-core performance relationship is essential to mitigate lifecycle cost risks and ensure compliance with evolving global efficiency mandates. Material consistency is not merely a specification—it is the foundation of grid reliability.

Technical Specs: E Steel Inc

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance silicon steel (electrical steel) products engineered for precision applications in power transformers, electric motors, and high-efficiency electrical systems. Our manufacturing process adheres to international standards, including IEC 60404-8, GB/T 2521, and JIS C 2550, ensuring consistent material performance across critical magnetic and mechanical parameters. The following technical specifications outline key performance indicators essential for B2B sourcing decisions, particularly with respect to core loss, magnetic flux density, and flatness—parameters that directly influence energy efficiency, thermal management, and manufacturability.

Core loss, also known as iron loss, is a fundamental metric in evaluating the energy efficiency of electrical steel under alternating magnetic fields. It comprises hysteresis loss and eddy current loss, both of which contribute to heat generation during operation. Lower core loss values translate into higher system efficiency and reduced operational costs. Our non-oriented and grain-oriented silicon steel grades are optimized to minimize total core loss at standard test conditions of 1.5 T and 50/60 Hz. For grain-oriented materials, core loss (P1.7/50) is typically controlled below 0.90 W/kg, while non-oriented grades range from 2.50 to 4.00 W/kg (P1.5/50), depending on silicon content and processing techniques. These values are validated through Epstein frame testing per IEC 60404-2.

Magnetic flux density (B) determines the maximum magnetic induction a material can achieve under a given magnetizing force. It is a critical factor in the design of compact and high-output electromagnetic devices. Our grain-oriented silicon steel achieves a peak magnetic flux density (B800) of no less than 1.90 T, with high-permeability grades reaching up to 1.96 T. Non-oriented grades exhibit B50 values ranging from 1.55 T to 1.75 T, tailored to meet application-specific demands in rotating machinery and small transformers. High flux density allows for reduced core volume and material usage without compromising performance.

Flatness is a dimensional quality parameter that significantly impacts stackability, core lamination, and air gap control in assembled magnetic circuits. Poor flatness leads to increased vibration, noise, and localized eddy current losses. At Luoyang Xinzhaohe, flatness is rigorously controlled through precision rolling and tension leveling processes. We define flatness as the maximum deviation from a reference plane over a specified length, measured in I-units. Our standard flatness specification for grain-oriented steel is ≤ 15 I-units, while non-oriented grades are maintained within ≤ 20 I-units. Tighter tolerances are available upon request for high-precision applications.

The table below summarizes the typical technical parameters for our standard silicon steel product lines.

| Parameter | Test Condition | Grain-Oriented (Typical) | Non-Oriented (Typical) |

|---|---|---|---|

| Core Loss (P) | P1.7/50 (W/kg) | ≤ 0.90 | – |

| Core Loss (P) | P1.5/50 (W/kg) | – | 2.50 – 4.00 |

| Magnetic Flux Density (B800) | mT | ≥ 1900 | – |

| Magnetic Flux Density (B50) | mT | – | 1550 – 1750 |

| Thickness Range | mm | 0.23 – 0.30 | 0.35 – 0.65 |

| Flatness | I-units | ≤ 15 | ≤ 20 |

| Insulating Coating | Type | C3, C4, C5 (IEC 60404-11) | C2, C3 |

These specifications reflect our commitment to delivering silicon steel products that meet the evolving demands of energy-efficient electrical systems. Custom formulations and testing protocols are available to support specialized engineering requirements.

Factory Tour: Manufacturing

Silicon Steel Manufacturing Process at Luoyang Xinzhaohe Aluminum CO.,Ltd

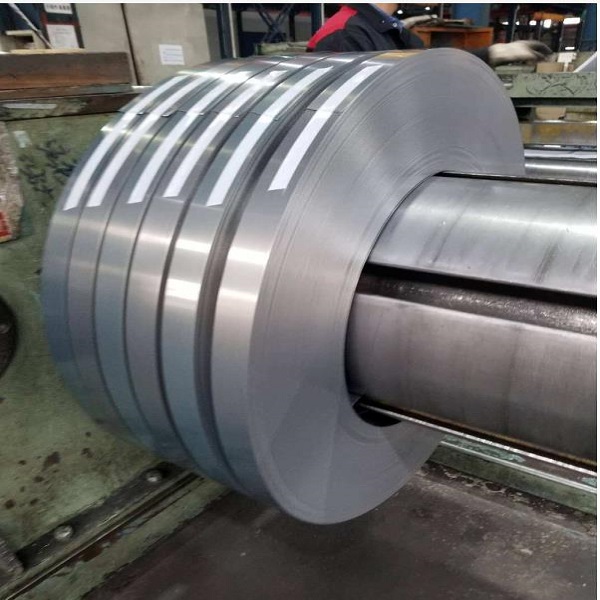

Luoyang Xinzhaohe Aluminum CO.,Ltd employs a rigorously controlled, sequential manufacturing process for high-performance silicon steel (electrical steel), honed over 20+ years of specialized production. This process ensures optimal magnetic properties, dimensional accuracy, and surface integrity critical for electric motor and transformer cores. The core sequence begins with precision slitting of incoming master coils. Utilizing computerized tension control and high-speed rotary knives, we slit coils to exact customer-specified widths, typically ranging from 50mm to 1000mm. Critical QC at this stage involves continuous monitoring of edge burr height (<0.02mm) and width tolerance (±0.1mm) via laser measurement systems, alongside periodic tensile testing to verify mechanical properties remain unaffected by the slitting operation.

Subsequent continuous annealing is fundamental for stress relief and grain growth optimization. Coils undergo controlled atmosphere annealing in continuous furnaces at precise temperatures between 700°C and 850°C, depending on the specific alloy grade (e.g., M19, M43). This decarburization and recrystallization step is meticulously managed to achieve target core loss (W/kg) and permeability values per IEC 60404-2 or ASTM A664 standards. Real-time atmosphere composition monitoring (H₂, N₂, dew point) and strict thermal profile validation via thermocouples ensure metallurgical integrity. Post-anneal QC includes Epstein frame testing for core loss and permeability, along with surface inspection for oxidation or scale defects.

Application of a uniform, adherent insulation coating follows annealing. We apply a thin, inorganic-based insulating layer (typically 0.5-1.5μm dry film thickness) via roll coating or spraying. This coating minimizes interlamination eddy current losses and provides electrical resistance between laminations. Precise control of coating viscosity, application rate, and curing temperature is maintained. QC verifies coating weight (mg/m²), electrical resistance (>70 Ω·cm²), adhesion (cross-hatch test), and absence of pinholes through automated optical inspection and destructive sampling.

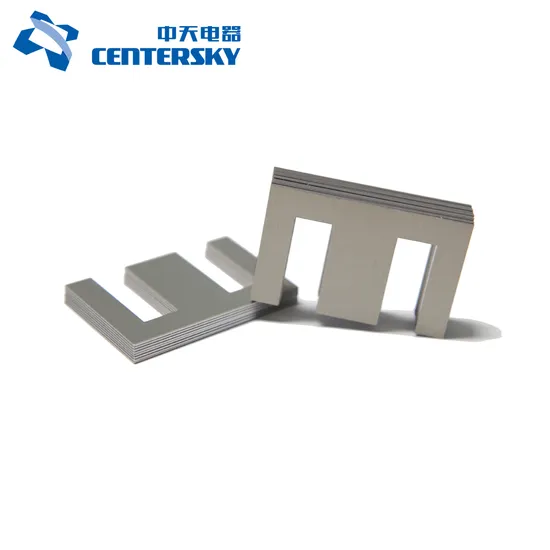

The final stage is precision cutting to shape. Utilizing state-of-the-art CNC turret presses, laser cutters, or progressive dies, we produce laminations or strips to exact geometric specifications. Cutting parameters (clearance, speed) are optimized for each steel grade to minimize burr formation and magnetic property degradation at edges. Dimensional tolerances are held to ±0.05mm for critical features. Final QC encompasses comprehensive dimensional verification via CMM, rigorous burr inspection (<0.03mm), magnetic property spot checks on finished parts, and 100% visual inspection for surface defects before packaging and shipment.

Key Process Control Parameters Summary

| Process Stage | Critical Parameter | Target Tolerance | Primary QC Method |

|---|---|---|---|

| Slitting | Width | ±0.1 mm | Laser Width Gauge |

| Edge Burr Height | <0.02 mm | Optical Microscopy | |

| Annealing | Core Loss (P1.5/60) | Per Grade Standard | Epstein Frame Tester |

| Atmosphere Dew Point | -40°C to -50°C | In-line Dew Point Analyzer | |

| Insulation Coating | Coating Weight | ±0.1 mg/m² | Gravimetric Analysis |

| Electrical Resistance | >70 Ω·cm² | 4-Point Probe Tester | |

| Precision Cutting | Dimensional Tolerance | ±0.05 mm | CMM |

| Edge Burr | <0.03 mm | Optical Comparator |

This integrated process, underpinned by stringent in-process and final QC protocols, guarantees the consistent delivery of silicon steel meeting the highest global performance and reliability standards demanded by the electrical equipment industry.

Packaging & Logistics

Export Packaging for Silicon Steel Coils – Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of high-performance silicon steel, we recognize that packaging is a critical component in preserving material integrity throughout global logistics. Our export packaging system for silicon steel coils is engineered to meet the rigorous demands of sea freight, ensuring product safety, dimensional stability, and protection against environmental degradation during prolonged maritime transit.

All silicon steel coils are secured on custom-fabricated wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are designed to support the substantial weight of steel coils, typically ranging from 5 to 25 metric tons, while maintaining structural rigidity under dynamic loading conditions encountered during vessel movement and container stacking. The wood is treated in compliance with ISPM 15 regulations to prevent the spread of pests, ensuring seamless customs clearance across international ports. Each pallet is reinforced with steel base plates and corner bracing to prevent deformation and to distribute load evenly, minimizing the risk of coil collapse or edge damage during handling.

Immediately after slitting or shearing operations, coils are wrapped with multi-layer moisture-proof composite film, consisting of aluminum foil laminates and high-density polyethylene (HDPE). This barrier system provides a vapor transmission rate of less than 0.1 g/m²·day, effectively shielding the silicon steel from humidity, salt air, and condensation—common challenges in marine environments. The film is heat-sealed at all seams and extends beyond the coil’s outer diameter to prevent lateral ingress of moisture. Additionally, desiccant packets are strategically placed between wrapping layers to absorb residual humidity trapped during packaging.

To further enhance protection, each coil is fitted with steel edge protectors made from galvanized steel profiles. These protectors maintain coil shape during transit and prevent mechanical damage from forklift operations or contact with container walls. The entire packaged unit is then strapped with high-tensile steel or polyester bands, tensioned to industrial standards, ensuring the coil remains fixed to the pallet under inertial forces up to 1.5g in all directions, as per IMDG Code recommendations for cargo securing.

All packaged coils undergo final inspection prior to containerization, including verification of wrapping integrity, label accuracy, and load stability. Standard export containers (20’ or 40’ dry freight) are lined with anti-slip mats and moisture-absorbing liners when required, depending on destination climate profiles.

Our packaging protocol is validated through accelerated salt spray testing and real-world shipment monitoring across routes including Asia to North America, Europe, and Southeast Asia. This systematic approach ensures that silicon steel arrives at customer facilities with preserved surface quality, magnetic performance, and dimensional accuracy—critical for downstream processing in transformer and motor manufacturing.

Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001 and ISO 14001 standards in all packaging operations, integrating quality and environmental responsibility into every shipment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Silicon Steel Manufacturing Expertise

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized metallurgical engineering and high-volume production experience to the global silicon steel (electrical steel) supply chain. As a vertically integrated manufacturer, we control the entire process from coil processing through precision slitting and quality assurance, ensuring consistent material performance critical for transformer and motor core applications. Our dedicated facility in Luoyang, Henan Province, leverages strategic logistics within China’s industrial heartland, enabling reliable delivery to domestic and international markets while maintaining stringent cost efficiency.

Our core strength lies in advanced production capabilities specifically engineered for non-oriented and grain-oriented electrical steel. We operate state-of-the-art continuous annealing lines (CAL) with precise atmosphere control, essential for achieving optimal magnetic properties and minimizing core loss. Downstream, our high-precision slitting lines, featuring 5-layer tension leveling and laser-guided edge control, consistently deliver strip widths within ±0.05mm tolerance and edge camber below 0.15mm/m. This dimensional accuracy is non-negotiable for high-speed core stacking and lamination processes. Comprehensive coating application systems ensure uniform insulation layers (C3, C5, C6 per IEC 60404-8-7), directly impacting core efficiency and interlaminar resistance.

Quality assurance is embedded at every process stage through rigorous in-line and offline testing. Our ISO 17025 accredited laboratory utilizes Epstein frame testers, single-sheet testers (SST), and precision thickness gauges to validate magnetic induction (B50, B800), specific total loss (W10/400, W15/50), and coating weight against international standards including IEC 60404, JIS C 2550, and ASTM A664. Real-time statistical process control (SPC) monitors critical parameters, guaranteeing lot-to-lot consistency demanded by Tier-1 transformer and motor manufacturers.

Key Production Specifications

| Parameter | Capability Range | Tolerance/Standard |

|——————–|————————————–|—————————–|

| Thickness | 0.18 mm – 0.65 mm | ±0.003 mm (typical) |

| Width | 80 mm – 1250 mm | ±0.05 mm |

| Coating Types | C3, C5, C6 (Phosphate/Organic) | IEC 60404-8-7 compliant |

| Core Loss (W15/50) | As low as 0.85 W/kg (50PN35A grade) | Certified per batch |

| Surface Inspection | 100% Automated Optical Inspection | Defects >0.1mm detected |

Partnering with Luoyang Xinzhaohe mitigates supply chain risk through our robust production capacity exceeding 150,000 metric tons annually and flexible scheduling for urgent requirements. We provide full material traceability via comprehensive mill test reports (MTRs) and collaborate closely with engineering teams to resolve application-specific challenges, from optimizing stacking factors to resolving lamination burr issues. Our technical sales group possesses deep metallurgical knowledge to support material selection and qualification processes.

For sourcing managers requiring dependable, high-performance silicon steel with certified quality and responsive logistics, Luoyang Xinzhaohe offers a proven manufacturing partnership. Contact Cathy Zhang, International Sales Manager, directly to discuss your technical specifications and volume requirements. Provide your target grades, annual volume, and dimensional tolerances for a tailored capability assessment and quotation.

Contact Cathy Zhang: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing e steel inc directly from China.