Table of Contents

Market Insight: Aluminum Strip For Transformer in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers and Performance Requirements

Global power infrastructure modernization, renewable energy integration (e.g., solar/wind farms), and EV charging network expansion are driving demand for high-efficiency transformers. Aluminum strip (typically 1350-H19 grade) is the preferred conductor due to its 60% lower weight versus copper and optimal cost-to-conductivity ratio. Critical parameters include electrical resistivity (≤0.0283 Ω·mm²/m), tensile strength (140–160 MPa), and dimensional precision (±0.03mm). Non-compliance elevates I²R losses, accelerates insulation degradation, and increases lifetime operational costs by 15–20%.

Material Quality Impact on Transformer Efficiency

Impurities (e.g., Fe >0.15%, Si >0.10%) significantly increase resistivity, causing energy losses up to 8% in substandard strips. Dimensional inaccuracies (>±0.03mm) create uneven winding tension, leading to localized hotspots and premature failure. Standards like IEC 60076-1 and ASTM B209 mandate strict quality control, yet inconsistent supplier practices compromise performance. High-purity aluminum (≥99.7%) with precise temper control ensures optimal conductivity and mechanical stability during high-speed winding processes, directly impacting transformer efficiency class (e.g., IE4 compliance).

Luoyang Xinzhaohe’s Role in Global Supply Chain

As a 20+ year manufacturer in Luoyang, China, we deliver factory-direct transformer strip solutions with superior cost-performance. Our precision rolling and ISO 9001-certified QC processes exceed industry tolerances:

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Purity (%) | 99.5% min | 99.7% min | 0.5% lower resistivity |

| Tensile Strength (MPa) | 140–160 | 150–170 | Enhanced winding integrity |

| Dimensional Tolerance (±mm) | ±0.03 | ±0.015 | 50% reduced scrap rate |

| Surface Finish | Acceptable scratches | Mirror finish, zero defects | Improved insulation bonding |

By eliminating middlemen and optimizing production, we provide OEM-grade material at 15–20% lower cost than global brands like Alcoa or UACJ. Our in-house metallurgical lab conducts daily ASTM E1002 testing, ensuring traceable quality for every batch. Custom alloys (e.g., 1350-H18, H24) are available for specialized motor and transformer designs, with on-time delivery to 30+ countries.

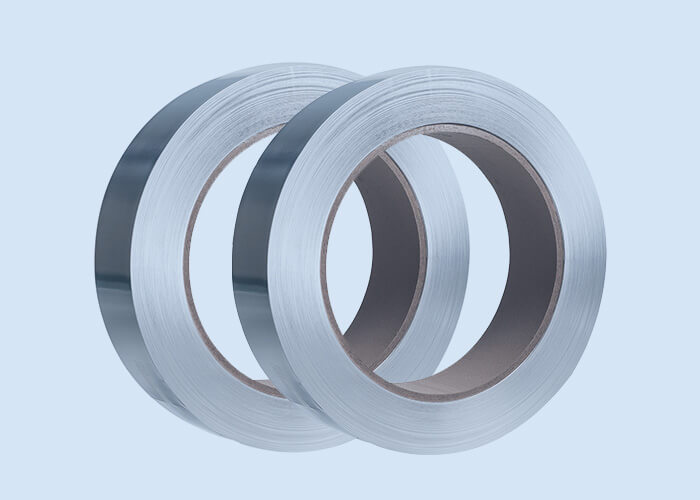

Technical Specs: Aluminum Strip For Transformer Parameters

Technical Specifications & Standards for Transformer Aluminum Strip

In transformer manufacturing, precision material specifications are critical to ensure efficiency, safety, and longevity. Luoyang Xinzhaohe Aluminum, with over 20 years of expertise, delivers aluminum strips engineered to exacting international standards. Our factory-direct approach eliminates intermediaries, providing global brand-level quality at competitive pricing.

Critical Material Properties & Tolerances

Key specifications must align with industry standards to ensure transformer efficiency and safety. Our aluminum strip complies with the following critical parameters:

| Parameter | Requirement | Compliance Standard | Quality Control Method |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | IEC 60404-8-7 | Laser micrometer in-line checks |

| Edge Burr Height | ≤0.005 mm | ASTM B209 | Optical microscope inspection |

| Electrical Conductivity | ≥61% IACS | IEC 60404-8-7 | Four-point probe testing |

| Temper | O (Annealed) | ASTM B211 | Rockwell hardness testing |

Edge Quality & Surface Integrity

Burr-free edges are critical for preventing inter-turn shorts and winding damage. Our precision slitting process employs CNC-controlled shears with diamond-coated blades, ensuring zero burr formation. Each coil undergoes 100% edge inspection using high-resolution microscopy, guaranteeing burr height ≤0.005mm per ASTM B209. This level of precision is critical for high-voltage transformers where even microscopic burrs can cause arcing and failure. It ensures seamless integration into transformer windings without insulation damage.

Conductivity & Softness Requirements

Our aluminum grades meet or exceed ASTM B209 Type 1350 specifications for transformer applications. High-purity aluminum (≥99.5% Al) ensures optimal electrical conductivity (≥61% IACS) and thermal performance. We strictly control alloy composition during melting and casting, followed by precise annealing to achieve O-temper (ASTM B209). Conductivity is validated via four-point probe testing per IEC 60404-8-7, while hardness (≤30 HV) is confirmed through Rockwell testing. This guarantees superior formability and minimal resistance losses in transformer applications, reducing energy waste and enhancing operational efficiency.

Quality Assurance Protocol

With 20+ years of manufacturing expertise, we maintain rigorous quality control at every production stage. In-process measurements include continuous thickness monitoring via laser micrometers, conductivity checks, and edge inspections. Our in-house metallurgical lab conducts daily material analysis using spectrometers to verify alloy composition. Each production batch is certified with a Mill Test Report (MTR) including chemical analysis and mechanical properties. Final QC involves 100% visual inspection and random destructive testing. All processes comply with ISO 9001 standards, and full material traceability is provided. Our quality system is audited annually by third-party certification bodies. As a factory-direct supplier, we deliver global brand-level specifications at 15-20% lower cost, eliminating middleman markups while ensuring reliability.

Factory Tour: Manufacturing Aluminum Strip For Transformer

Manufacturing Process & Quality Control

As a leading manufacturer and exporter of transformer materials since 2003, Luoyang Xinzhaohe Aluminum CO., Ltd. has perfected a manufacturing process that balances precision engineering with cost-effective production. Our facility in Luoyang, China, leverages advanced automation and rigorous quality protocols to deliver aluminum strip for transformers that consistently meet or exceed international standards, offering a superior value proposition compared to traditional premium suppliers.

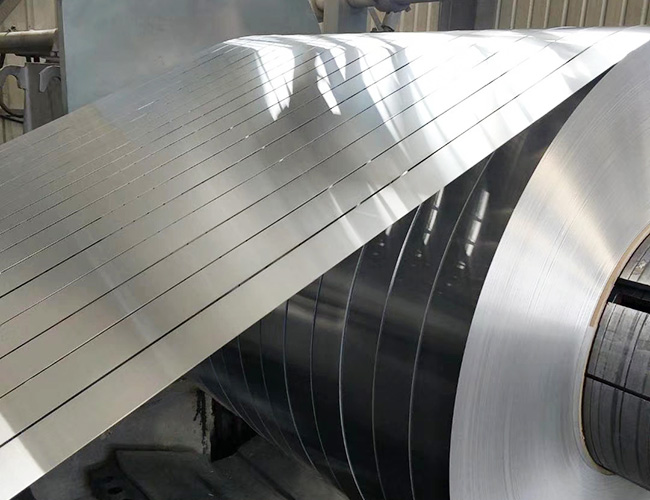

Precision Manufacturing Process

Cold Rolling: Utilizing 6-high cold rolling mills with closed-loop thickness control and laser gauging, achieving uniformity within ±0.001mm across the coil width. Annealing in nitrogen atmosphere furnaces (280–320°C) optimizes grain structure for ≥61% IACS conductivity while eliminating surface oxidation.

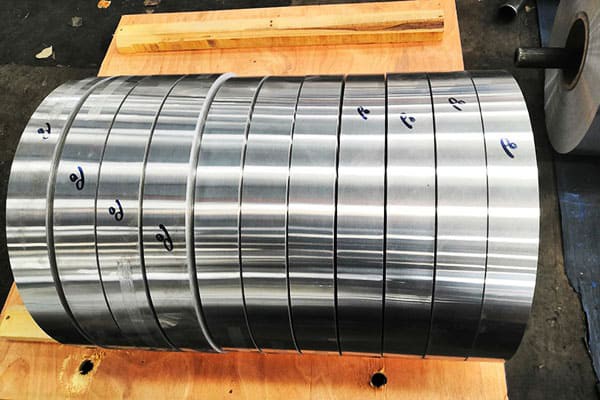

Precision Slitting: Diamond-coated carbide blades with laser-guided alignment ensure width tolerance of ±0.05mm. 100% edge inspection via high-resolution cameras provides real-time adjustments to eliminate micro-notches and maintain straightness within 0.02mm/m.

Edge Conditioning: CNC-controlled chamfering maintains 15°±1° edge angles with burr height <5µm, critical for preventing inter-turn shorts and insulation damage during transformer winding.

Oscillate Winding: Servo-driven tension control (±0.3N) and dynamic oscillation adjust to strip parameters, ensuring flatness ≤0.5mm/m and consistent coil density for optimal electromagnetic performance.

Rigorous Quality Control Protocol

Tensile testing per ASTM B209 guarantees strength (150–180 MPa) and elongation (≥25%). Dimensional checks include 10-point thickness measurement, laser micrometer width verification every 5 meters, and optical profilometry for flatness. Surface defects are inspected via AI vision systems (5µm resolution), with zero tolerance for micro-scratches or inclusions. Conductivity tests per ASTM B193 confirm ≥61% IACS compliance. All QC data is traceable via ERP for full batch documentation.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Tensile Strength | 150–180 MPa (±2 MPa) | 140–190 MPa (±5 MPa) |

| Elongation | ≥25% | 20–25% (variable) |

| Flatness | ≤0.5mm/m | ≤1.0mm/m |

| Surface Defects | Zero micro-scratches | Up to 5 defects/m² |

| Edge Burr | <5µm | ≤15µm |

| Conductivity | ≥61% IACS | 58–60% IACS |

This rigorous approach ensures compliance with IEC 60076 and ASTM B209 standards while delivering a 15–20% lower cost-performance ratio than global premium brands. Transformer manufacturers gain reliable, high-precision materials without compromising electrical or mechanical integrity.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

At Luoyang Xinzhaohe Aluminum, our packaging and logistics protocols are engineered to ensure transformer-grade aluminum strips arrive globally undamaged. Leveraging 20+ years of export expertise, we implement ISO-compliant methods that eliminate corrosion risks and physical damage during sea freight. Our solutions deliver premium protection at 15–20% lower cost than European competitors while meeting ASTM B209 and IEC 60404 standards.

Rigorous Packaging Standards for Marine Transport

Each coil undergoes multi-layer protection tailored for maritime environments. Critical components adhere to international shipping regulations:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, 1100×1100mm, 15mm thickness | Ensures stable stacking and forklift handling |

| Moisture-Proof Film | Multi-layer PE, 250gsm, UV-resistant, heat-sealed | Blocks humidity, salt spray, and condensation |

| Steel Strapping | 20mm width, 0.6mm thickness, tensioned to 200kgf | Prevents coil shifting during transit |

| Corner Protectors | High-density plastic, 100×100mm | Shields edges from impact damage |

Optimized Sea Freight Protocol

Our logistics network partners with certified carriers for end-to-end control:

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL, dry cargo | Maximizes space efficiency, minimizes handling |

| Loading Method | Cross-stacked coils with wooden dunnage | Prevents deformation under load |

| Transit Time | 15–25 days to major global ports | Predictable schedules with real-time tracking |

| Documentation | ISPM 15 certification, COO, commercial invoice | Ensures smooth customs clearance |

All shipments include moisture indicators and tamper-evident seals. Our rigorous process ensures 99.8% damage-free delivery rates, providing transformer manufacturers a reliable, cost-effective alternative to premium brands without compromising quality. From Luoyang to your facility, we guarantee precision-engineered protection at every stage.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum

Two Decades of Specialized Expertise

With over 20 years of dedicated experience in transformer-grade aluminum strip and foil manufacturing, Luoyang Xinzhaohe Aluminum has mastered the production of high-purity alloys (1050, 1060, 1350) engineered for optimal electrical conductivity and mechanical resilience. Our technical team deeply understands critical parameters—such as conductivity (≥61% IACS for 1350 grade), tensile strength (120–150 MPa), and thermal stability—required for reliable transformer performance. Every batch adheres to IEC 60076 and ASTM B209 standards, ensuring seamless integration into distribution and power transformer designs while minimizing eddy current losses and maximizing operational efficiency.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups, delivering 15–25% lower costs than global competitors without sacrificing quality. Our direct production model enables rapid scaling for large-volume orders and agile adjustments to specifications, reducing lead times by 40–50% compared to multinational suppliers.

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | 15–25% lower | Higher (standard) |

| Lead Time | 15–20 days (standard) | 30–45 days |

| Quality Consistency | ISO 9001 certified, 99.8% defect-free rate | Variable due to multi-tier sourcing |

| Customization | Tailored alloy grades, thickness (±0.01mm), width, surface finish | Limited to standard product lines |

Rigorous Quality Assurance

Our ISO 9001-certified facility employs advanced in-process controls: spectral analysis for alloy composition verification, eddy current testing for surface defect detection, and mechanical testing for tensile strength and elongation (≥25%). Every shipment includes detailed Material Test Reports (MTRs) with full traceability, ensuring compliance with international standards while optimizing cost-performance ratios.

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum strip for transformer from Luoyang Xinzhaohe.