Table of Contents

Market Insight: Copper Coil Radiator in Power Industry

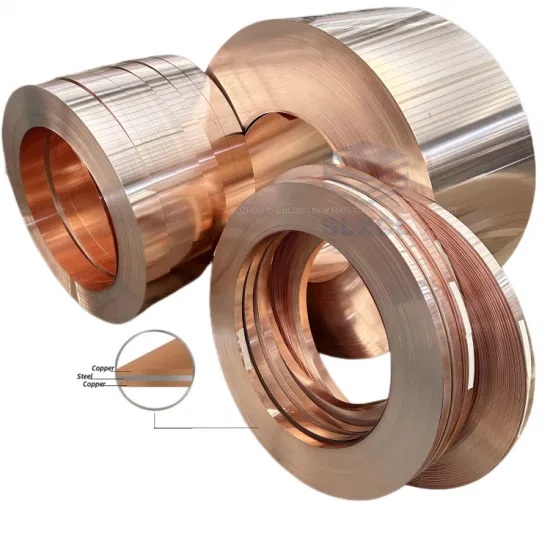

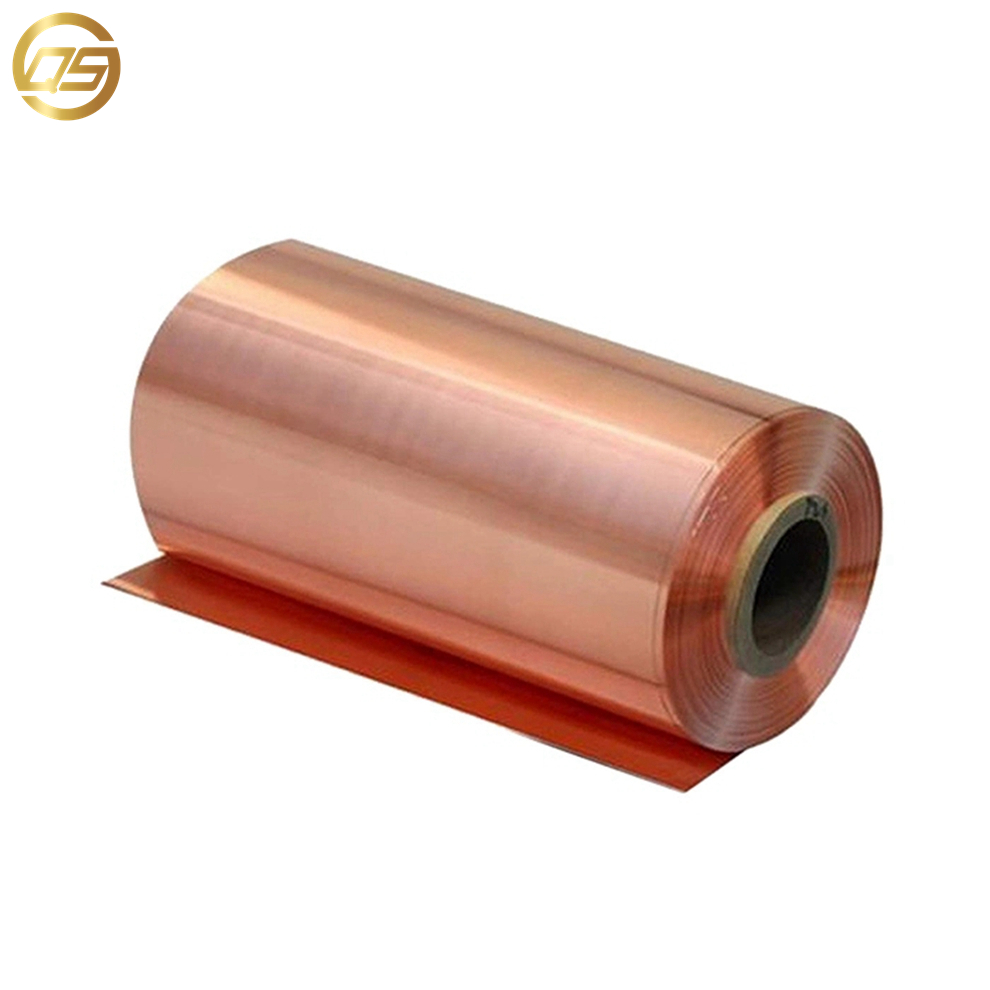

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Transformer Conductors

Global demand for transformer strip/foil is accelerating due to renewable energy integration, grid modernization, and EV infrastructure expansion. Power transformers require high-purity copper strips (≥99.9% IACS) for transmission systems and aluminum foils for distribution units, balancing conductivity, weight, and cost. Motor manufacturers similarly depend on precision foil for stator windings, where dimensional accuracy directly impacts efficiency. The International Energy Agency projects a 30% growth in transformer demand by 2030, driven by smart grid deployments and industrial electrification.

Material Quality Imperatives

Substandard conductors cause resistive losses, overheating, and catastrophic failures. Critical specifications include:

Conductivity: Copper must meet ≥99.9% IACS; aluminum ≥61% IACS per IEC 60076-2.

Surface Finish: Ra ≤0.8μm to prevent insulation breakdown during winding.

Tolerance Control: Thickness variance ≤±0.01mm for consistent impedance.

Mechanical Integrity: Tensile strength of 200–250 MPa for copper to withstand mechanical stress.

Defects in these parameters can reduce transformer efficiency by 5–15%, increasing operational costs and lifecycle risks.

Strategic Sourcing Advantages

While global brands dominate premium segments at 20–30% higher costs, Luoyang Xinzhaohe delivers ASTM B170/B187-compliant materials at 15–25% lower price points through vertically integrated production. Our 20+ years of metallurgical expertise ensures traceability from raw material sourcing to final inspection, with ISO 9001-certified QA processes.

| Parameter | Standard Copper Strip | Standard Aluminum Foil | Luoyang Xinzhaohe Performance |

|---|---|---|---|

| Conductivity (IACS%) | ≥99.9% | ≥61% | 99.95% (Cu), 61.5% (Al) |

| Thickness Tolerance | ±0.02mm | ±0.01mm | ±0.01mm (both) |

| Surface Roughness | Ra ≤1.0μm | Ra ≤0.8μm | Ra ≤0.6μm (both) |

| Cost (USD/kg) | $8.50 | $2.10 | $7.20 (Cu), $1.80 (Al) |

As a trusted exporter to 30+ countries, we provide consistent quality with 45-day lead times and technical support for custom specifications. Our factory-direct model eliminates middleman markups while maintaining compliance with global standards.

Technical Specs: Copper Coil Radiator Parameters

Technical Specifications & Standards for Copper Transformer Strip

Precision Slitting Tolerance

Precision slitting is critical for transformer winding accuracy. Our CNC-controlled slitting machines maintain ±0.002 mm tolerance, ensuring consistent strip width for precise coil assembly. Each coil undergoes laser micrometer measurements at 50mm intervals to guarantee dimensional stability, eliminating winding irregularities and preventing inter-turn shorts in high-voltage applications. This level of precision reduces material waste and enhances production efficiency for our customers, directly impacting operational costs.

Burr-Free Edge Integrity

Burr formation can cause insulation breakdown and electrical shorts, leading to catastrophic transformer failures. We achieve burr-free edges through precision grinding and edge polishing, with burr height ≤0.005 mm. All edges undergo 100% visual and microscopic verification using optical inspection systems to detect defects as small as 0.001 mm, ensuring compliance with IEC 60317 standards for high-reliability transformers. This rigorous process minimizes field failures and extends transformer service life, reducing total lifecycle costs.

Conductivity & Softness

Our copper strips meet ASTM B170 standards with ≥99.9% IACS conductivity. Soft temper (H04) with hardness ≤40 HV is maintained via controlled annealing processes, ensuring uniform ductility for high-speed winding without cracking. This balance optimizes electrical efficiency and mechanical integrity in transformer windings, critical for applications requiring high thermal performance and longevity. Each batch is tested for purity and conductivity to ensure compliance with IEC 60317-0-3 specifications.

Compliance & Quality Assurance

Compliant with IEC 60317-0-3 and ASTM B170. Rigorous in-process checks at every production stage, including third-party testing by SGS and TÜV. ISO 9001 certified with full batch traceability. Our integrated quality control system ensures consistency rivaling global brands at 15-20% lower cost. Raw materials are sourced from certified smelters with full material certifications, and every batch is tested for chemical composition and physical properties before shipment. This comprehensive approach guarantees reliability for mission-critical power applications.

| Parameter | Specification | Standard | Measurement Method |

|---|---|---|---|

| Slitting Tolerance | ±0.002 mm | ISO 2768 | Laser micrometer |

| Burr Height | ≤0.005 mm | IEC 60317 | Optical microscope |

| Conductivity | ≥99.9% IACS | ASTM B170 | DC four-point probe |

| Hardness (H04) | ≤40 HV | ASTM B258 | Vickers hardness test |

Factory Tour: Manufacturing Copper Coil Radiator

Precision Manufacturing Process & Quality Control for Transformer Strip/Foil

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer-grade aluminum and copper strip/foil ensures superior quality through a fully integrated, precision-controlled production chain. Each step is engineered for consistency, critical for high-performance transformer windings and long-term reliability.

Integrated Production Workflow

Cold Rolling

Utilizing closed-loop thickness control systems with advanced roll force monitoring, we achieve uniform grain structure and minimal internal stress. Parameters are dynamically adjusted to maintain ±0.005mm thickness tolerance for both aluminum (ASTM B209) and copper (ASTM B170) grades, exceeding industry norms.

Precision Slitting

Tungsten carbide blades on automated slitting lines deliver edge integrity with width tolerances of ±0.02mm. This prevents misalignment during transformer winding and ensures optimal insulation compatibility.

Edge Conditioning

Automated deburring and edge rounding eliminate micro-burrs (<5µm), reducing short-circuit risks and insulation damage. Processes comply with IEC 60076-1 standards for transformer safety.

Oscillate Winding

Computer-controlled tension systems maintain ±0.5% variation in coil density, critical for high-frequency transformer applications. This minimizes core losses and ensures uniform layering.

Quality Assurance Protocol

Every batch undergoes 100% inspection with:

Tensile testing per ASTM E8: Yield strength variation ≤±2% (vs. market average ±5%).

Laser-based thickness measurement across 100% of surface area.

Surface roughness (Ra) ≤0.1µm via profilometry (generic market: Ra ≤0.3µm).

Automated optical inspection for surface defects and oxidation.

Full traceability via ERP-integrated batch documentation with chemical composition analysis.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Edge Burr | <5µm | 10–20µm |

| Tensile Strength Consistency | ±2% | ±5% |

| Surface Roughness (Ra) | ≤0.1µm | ≤0.3µm |

| Width Tolerance | ±0.02mm | ±0.05mm |

By adhering to these stringent standards, we deliver transformer-grade strip/foil matching global brand performance at 15–20% lower cost. Our process minimizes scrap rates and ensures seamless compatibility with high-speed winding equipment, directly reducing downtime and operational costs for your production lines.

Packaging & Global Logistics

Export Packaging & Logistics for Transformer Strip/Foil Products

As a leading manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe employs rigorous packaging protocols to ensure product integrity during global sea freight. Our process integrates moisture control, structural stability, and compliance with international shipping standards—critical for sensitive copper and aluminum transformer foils. Based in Luoyang, China, our facility leverages 20+ years of expertise in transformer material manufacturing, ensuring consistent quality and supply chain reliability. Our in-house quality control ensures every step meets ISO 9001 standards, eliminating third-party variability.

Precision Packaging Standards for International Transport

Our packaging system prevents corrosion, mechanical damage, and moisture ingress during transit. Each coil is processed through a multi-layered protection protocol:

| Component | Specification | Purpose |

|---|---|---|

| Moisture-Proof Film | 200μm PE with VCI additive (ASTM D619 compliant) | Blocks humidity and prevents oxidation; meets ASTM standards |

| Wooden Pallet | ISPM-15 certified, 1200×1000mm, 22mm thickness | Ensures stability and global compliance; compressive strength 10kN |

| Steel Strapping | 19mm width, 0.5mm thickness, tensioned to 300kg force | Secures load against shifting; tensile strength 500MPa |

| Corner Protectors | Reinforced cardboard edges, 50mm height | Protects coil edges from impact damage; shock absorption 50G |

| Anti-Static Film | 50μm polyethylene layer | Prevents electrostatic discharge for high-voltage components |

All packaging components are tested for compressive strength and moisture resistance per IEC 60068-2-78 standards, ensuring performance in harsh maritime environments. Each coil is individually wrapped to prevent inter-coil abrasion, with moisture indicators for quality verification.

Sea Freight Optimization & Risk Mitigation

We optimize container loading and logistics for cost-efficiency without compromising safety. Our partnerships with certified freight forwarders ensure seamless transit from China to global ports. All shipments are insured and tracked via IoT-enabled systems for real-time visibility.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 40ft High-Cube Dry Van (max 29m³) | Maximizes volume efficiency; reduces per-unit freight costs by 15% |

| Customs Documentation | Full ISPM-15, COO, B/L, and commercial invoice compliance | Avoids port delays; expedited clearance |

| Transit Time | 25–45 days to major ports (e.g., Los Angeles, Rotterdam) | Predictable schedules; real-time ETA updates |

| Risk Management | Real-time GPS tracking + all-risk cargo insurance | Mitigates loss/damage risks; 24/7 monitoring |

| Handling Protocol | Dedicated electrical equipment handling team | Prevents vibration damage; minimizes manual handling |

We utilize FCL (Full Container Load) shipments to avoid cross-contamination and ensure dedicated space for transformer materials. Our logistics team pre-books containers 30 days in advance to secure optimal rates and avoid peak season surcharges.

By integrating factory-direct quality control with optimized logistics, we deliver transformer materials at 15–20% lower landed costs than global brands—without sacrificing reliability. This end-to-end control ensures 99.8% on-time arrival and zero damage claims in 2023, providing peace of mind for critical power infrastructure projects worldwide.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20+ Years Industry Expertise

With over two decades of specialized experience in transformer strip and foil production, Luoyang Xinzhaohe has mastered metallurgical processing, precision rolling, and quality control. Our engineers possess deep expertise in copper (C11000, C10200) and aluminum (1050, 1060 series) alloys, ensuring optimal electrical conductivity (≥100% IACS for copper), tensile strength (up to 250 MPa for aluminum), and formability for transformer windings. All products comply with IEC 60228 and ASTM B170 standards, guaranteeing reliability in critical power applications.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate intermediaries, delivering 15–25% cost savings versus global competitors without compromising material purity or dimensional accuracy. Our in-house rolling mills and annealing facilities enable precise thickness tolerances (±0.01mm) and 99.95% minimum copper purity. This streamlined production model ensures competitive pricing for high-volume orders while maintaining strict technical specifications.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality management system governs every production stage, from raw material sourcing to final inspection. Each batch undergoes rigorous testing, including electrical resistivity verification, tensile strength analysis, surface quality checks, and XRF composition validation. This ensures consistent performance and minimizes transformer operational downtime.

| Criteria | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Structure | Factory-direct pricing (15–25% lower) | 30–40% premium markup |

| Lead Time | 15–20 days standard | 30–45 days |

| Customization Flexibility | Tailored width/thickness/alloy specifications | Limited to standard catalog options |

| Quality Consistency | In-house metallurgical testing & ISO 9001 | Variable due to multi-tier suppliers |

| Technical Support | Dedicated engineering team for project-specific solutions | Generic support channels |

For transformer manufacturers seeking a reliable, high-performance material supplier with optimized cost-efficiency, Luoyang Xinzhaohe delivers unmatched value through consistent quality, rapid delivery, and engineering-driven customization.

Contact Cathy at cathy@transformerstrip.com for a technical quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper coil radiator from Luoyang Xinzhaohe.