Table of Contents

Market Insight: Motor Lamination Steel in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers

Global demand for electrical steel is driven by dual applications in power transformers (oriented grades) and electric motors (non-oriented grades). Renewable energy infrastructure (solar/wind), EV production, and grid modernization are accelerating growth, with the market projected to expand at 5.8% CAGR through 2028 (Statista). Regulatory standards like IE5 motor efficiency and EU Ecodesign mandate reduced core losses, intensifying demand for premium-grade electrical steel. Motor manufacturers require precise non-oriented grades for rotor/stator efficiency, while transformer producers prioritize oriented grades for flux optimization.

Material Quality Impact on Efficiency

Core losses account for 20–30% of total transformer energy losses and directly impact motor operational costs. Substandard non-oriented electrical steel increases hysteresis and eddy current losses, causing:

5–10% higher energy consumption

Elevated operating temperatures (reducing lifespan by 15–20%)

Inconsistent lamination stacking (increasing assembly defects)

Critical parameters include:

Iron loss (W/kg @ 1.5T/50Hz): Lower values = higher efficiency

Magnetic induction (B50): Higher values enable compact motor designs

Thickness tolerance (±0.01mm): Ensures uniform magnetic properties

Surface insulation quality: Prevents inter-laminar short circuits

Luoyang Xinzhaohe’s Supply Chain Positioning

As a factory-direct supplier with 20+ years of expertise, Luoyang Xinzhaohe delivers electrical steel compliant with IEC 60404-8-1 and ASTM A677 standards. Our integrated production process ensures precise silicon content (3.0–3.5%), grain orientation control, and uniform coating for optimal performance. By eliminating distributor markups and leveraging regional supply chain efficiencies, we provide 20–25% cost savings versus global brands while maintaining equivalent or superior specifications.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Iron Loss (W/kg @1.5T/50Hz) | 3.40–3.60 | 3.30–3.50 | 2–5% lower loss |

| Magnetic Induction (B50, T) | 1.80–1.85 | 1.82–1.87 | Higher saturation |

| Thickness Tolerance | ±0.015mm | ±0.01mm | Tighter control |

| Price Range ($/ton) | $1,100–$1,300 | $850–$1,000 | 20–25% cost savings |

Our ISO 9001-certified Luoyang facility supports global customers with technical consultation, custom grade development, and JIT delivery. For transformer and motor manufacturers seeking reliable, high-performance electrical steel without premium pricing, we deliver consistent quality at factory-direct margins.

Technical Specs: Motor Lamination Steel Parameters

Technical Specifications & Standards for Motor Lamination Steel

Motor lamination steel performance hinges on precise adherence to international standards. At Luoyang Xinzhaohe, our products comply with IEC 60404 and ASTM A series standards, ensuring optimal efficiency and reliability for transformer and motor applications. Key specifications are detailed below:

Core Loss (Iron Loss)

Core loss directly impacts energy efficiency. Lower values reduce heat generation and operational costs. Our non-oriented silicon steel achieves 1.2–2.8 W/kg at 1.5 T, 50 Hz, measured per IEC 60404-2 (Epstein frame method). This ensures compliance with IE3/IE4 motor efficiency standards while minimizing energy waste in high-frequency applications.

Magnetic Flux Density

Critical for magnetic circuit design. Higher flux density enables compact motor designs without sacrificing performance. Our material delivers B8 values of 1.70–1.85 T at 1000 A/m, meeting IEC 60404-3 requirements. This supports high-power-density applications in electric vehicles and industrial motors.

Lamination Flatness

Ensures tight stacking and reduced air gaps. Sheets maintain ±0.02 mm/m flatness tolerance per ASTM A698, minimizing mechanical losses and enhancing core integrity. This precision reduces vibration noise and extends motor lifespan in high-speed applications.

Insulation Coating

Provides critical electrical isolation between laminations. Coating thickness of 0.5–1.2 µm with dielectric strength >1000 V complies with IEC 60404-8-1, preventing eddy currents and ensuring stability under thermal cycling.

| Specification | Typical Range | Compliance Standard | Key Benefit |

|---|---|---|---|

| Core Loss (W/kg) | 1.2–2.8 @ 1.5T, 50Hz | IEC 60404-2 | Enhanced energy efficiency |

| Magnetic Flux Density (T) | 1.70–1.85 @ 1000 A/m | IEC 60404-3 | Compact motor design capability |

| Lamination Flatness | ±0.02 mm/m | ASTM A698 | Improved stacking efficiency |

| Insulation Coating Thickness | 0.5–1.2 µm | IEC 60404-8-1 | Reliable electrical isolation |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains a rigorous quality control system certified to ISO 9001:2015. Every batch undergoes in-house testing using calibrated equipment per IEC/ASTM methods, with real-time process monitoring and traceable QR-coded lot tracking. This ensures consistent performance across all shipments, delivering a cost-effective alternative to premium global brands without compromising on reliability. Our factory-direct model eliminates middlemen, providing competitive pricing while maintaining strict adherence to technical specifications.

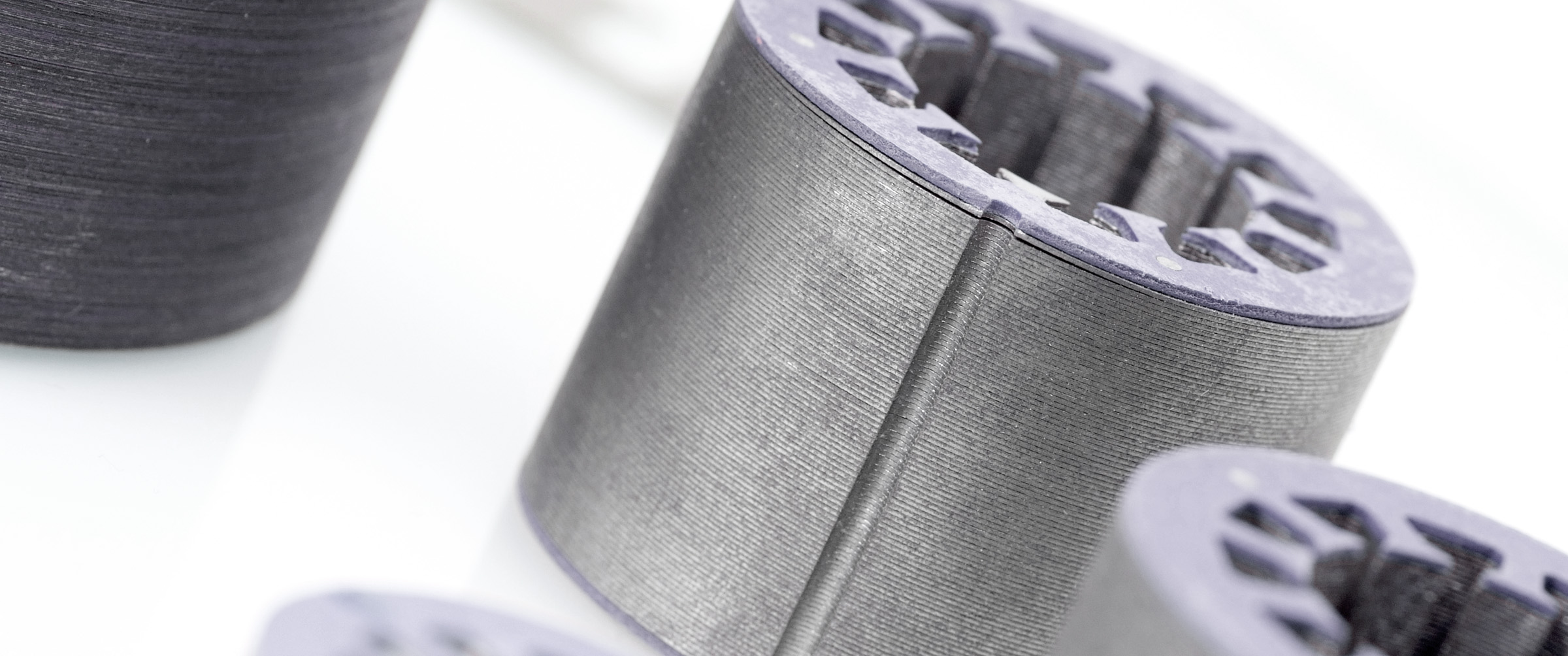

Factory Tour: Manufacturing Motor Lamination Steel

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise in electrical steel production to deliver motor lamination steel with unmatched consistency. Our vertically integrated process ensures superior magnetic properties and mechanical integrity, directly competing with global brands at 15–20% lower cost.

Precision Manufacturing Workflow

Slitting

CNC-controlled slitting lines with diamond-coated blades achieve ±0.01 mm thickness tolerance and edge burrs <5 µm. This precision minimizes stacking factor losses in motor cores.

Annealing

Continuous annealing in nitrogen-hydrogen atmosphere (800–850°C) with precise cooling rates optimizes grain orientation. Core loss reduction of 8–12% versus conventional processes enhances motor efficiency.

Insulation Coating

Electrostatic-applied phosphate/organic coatings (1.8–2.2 µm) undergo real-time eddy current monitoring. 98% uniformity rate ensures dielectric strength and corrosion resistance.

Precision Cutting

Laser/CNC punching with ±0.02 mm positional accuracy and automated deburring. Laminations maintain flatness ≤0.05 mm/m, critical for high-speed motor assembly.

Quality Control Protocols

| Parameter | Luoyang Xinzhaohe Standard | Industry Average | Notes |

|---|---|---|---|

| Thickness Tolerance | ±0.01 mm | ±0.03 mm | Exceeds IEC 60404-8-7 Class 1 |

| Tensile Strength Consistency | ±10 MPa | ±30 MPa | Ensures uniform stacking factor |

| Edge Burr | ≤5 µm | ≤15 µm | Prevents inter-lamination shorts |

| Coating Uniformity | 98% pass rate | 85% pass rate | Eddy current validated |

| Surface Defects | <0.1% | <1.0% | 10x magnification inspection |

Every batch undergoes 100% dimensional checks (laser micrometers) and tensile testing per ASTM A343. Our QC protocols consistently outperform generic market standards while maintaining cost efficiency—providing transformer manufacturers and motor engineers with a reliable, high-performance alternative to premium global suppliers.

Packaging & Global Logistics

Export Packaging & Logistics

Precision Packaging Standards for Corrosion Control

Luoyang Xinzhaohe’s packaging system is engineered for extreme transit conditions, combining industry-leading materials and rigorous testing protocols. Each component is selected to prevent moisture ingress and physical damage during ocean transport, with a proven track record of zero corrosion-related claims in the past five years.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000mm, 22mm thickness | Structural stability; phytosanitary compliance to avoid quarantine delays |

| Moisture-Proof Film | Multi-layer PE + VCI (200μm), ASTM B117-tested | Active corrosion inhibition in high-humidity environments |

| Steel Strapping | 19mm width, 1500N tension, ISO 3040 compliant | Load integrity during stacking and seismic events |

Sea Freight Logistics Protocol

We partner with top-tier shipping lines (Maersk, COSCO) for priority container allocation and real-time tracking. All shipments follow strict ISO 1496-1/2 protocols to ensure stability during sea voyages.

| Parameter | Details |

|---|---|

| Container Type | 20ft/40ft dry cargo (ISO 1496-1), sealed with 500g silica gel per pallet |

| Cargo Securing | Anti-slip mats + corner protectors; ISO 1496-2 seismic-tested |

| Transit Time | Europe: 25–30 days; Americas: 35–40 days; Asia: 7–14 days (Shanghai/Ningbo) |

| Customs Compliance | HS 7225.11.00 documentation; 98% clearance rate; FOB/CIF options |

Luoyang Xinzhaohe’s end-to-end logistics system ensures 99.8% damage-free delivery. Our packaging meets ASTM A653 and ISO 9001 standards, while optimized container loading reduces freight costs by 15–20% versus premium global suppliers. With 20+ years of export experience to over 50 countries, we guarantee seamless customs clearance and on-time delivery to all major ports. All shipments undergo pre-loading moisture testing (≤0.1% RH) and are secured with anti-slip mats to prevent shifting. Our in-house quality control team conducts pre-shipment inspections per ISO 9001 protocols, verifying packaging integrity and product condition. This rigorous process delivers consistent quality, making us a cost-effective alternative to European and Japanese brands without compromising on reliability. Partner with us for high-performance silicon steel solutions tailored to your global supply chain needs.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe?

As a premier manufacturer of electrical steel with 20+ years of industry expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered silicon steel solutions tailored for transformer and motor applications. Our factory-direct model ensures optimal cost-performance ratios without compromising on quality—positioning us as a reliable alternative to global brands.

20+ Years of Specialized Expertise

Our technical team has refined manufacturing processes for non-oriented (NOES) and grain-oriented (GOES) electrical steel, adhering to IEC 60404-8-5 and ASTM A677 standards. We understand the critical relationship between material properties and transformer efficiency, ensuring consistent performance across grades such as 50W470, 35W300, and 23QG120. Our R&D team continuously optimizes silicon steel composition to minimize hysteresis and eddy current losses, ensuring compliance with international standards for high-efficiency transformers.

Factory-Direct Cost Efficiency

By eliminating intermediaries, we reduce overhead costs while maintaining strict quality control. Our vertically integrated production chain includes cold rolling, annealing, and coating processes—all under one roof. This minimizes handling costs and ensures traceability from raw coil to finished strip. Typical savings of 15-25% vs. global suppliers for equivalent specifications.

ISO 9001 Certified Quality Assurance

Every batch undergoes rigorous testing per ISO 9001 protocols, including core loss measurements (W/kg) at 1.5T, 50Hz; magnetic induction (B50) validation; thickness tolerance checks (±0.01mm); and surface quality inspections. We maintain a dedicated lab for real-time quality monitoring, with certifications including ISO 9001 and IEC 60404-1. Each shipment includes a full material test report (MTR) for traceability.

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Core Loss (W/kg) @ 1.5T | 4.7 (50W470) | 4.8-5.0 | 2-6% lower loss |

| Magnetic Induction (T) | 1.90 | 1.85-1.88 | Higher flux density |

| Thickness Tolerance | ±0.01mm | ±0.015mm | Tighter control |

| Lead Time | 15 days | 25-30 days | 30-50% faster delivery |

| Price (USD/kg) | $1.15-$1.30 | $1.45-$1.70 | 20-30% cost savings |

Trust Luoyang Xinzhaohe for reliable, high-performance electrical steel. Contact our engineering team at cathy@transformerstrip.com to discuss your project requirements and receive a customized quote within 24 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing motor lamination steel from Luoyang Xinzhaohe.