Table of Contents

Market Insight: Aluminium Winding Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global installed transformer capacity is forecast to exceed 28,000 GVA by 2030, driven by grid expansion, electrification of transport, and renewable integration. Aluminum-wound units now represent >52 % of new dry-type installations because every 1 kg Al substitution saves ≈3 kg Cu mass and ≈8 USD raw-material cost. Annual winding-wire consumption is therefore tracking 1.9–2.1 Mt, of which 38 % is imported by OEMs in NAFTA, EU-27 and GCC who no longer operate in-house rod mills. Lead-times from Western mills routinely exceed 20 weeks; Chinese integrated suppliers such as Luoyang Xinzhaohe deliver 6–8 weeks ex-works, creating a structural sourcing advantage.

| Region | 2024 Demand (kt) | CAGR ’24-28 | Preferred Thermal Class | Share of Al vs Cu windings |

|---|---|---|---|---|

| Asia-Pacific | 820 | 6.1 % | 180 °C (Class H) | 62 % |

| Europe | 390 | 4.4 % | 200 °C (Class C) | 48 % |

| North America | 310 | 5.0 % | 220 °C (Class R) | 45 % |

| MEA | 180 | 7.8 % | 155 °C (Class F) | 55 % |

Why Material Purity & Geometry Drive Transformer Losses

Load losses (I²R) and no-load losses (eddy current, stray flux) are both sensitive to conductor quality:

-

Electrical Conductivity

1350-O rod must achieve ≥61.8 % IACS; every 1 % IACS shortfall raises DC resistance 1.6 %, adding ≈0.9 W kg⁻¹ additional load loss at 75 °C. -

Oxide & Inclusion Control

Total hydrogen-compatible inclusion area <0.02 mm² kg⁻¹ is required to prevent local hot-spots that accelerate insulation ageing. Our inline eddy-current test guarantees inclusion count ≤5 pcs m⁻¹ at 0.15 mm² sensitivity. -

Dimensional Tolerances

Eddy-current loss scales with (thickness × frequency)². Holding strip thickness within ±3 µm on 1.0 mm nominal cuts edge-loss component by 6–8 %, translating to 2–3 W kg⁻¹ core saving in 50 Hz designs.

| Parameter (1350 Al) | IEC 60121 Limit | Xinzhaohe Mill Spec | Impact on Losses |

|---|---|---|---|

| Resistivity @ 20 °C | ≤28.264 nΩ·m | 28.05 ±0.05 nΩ·m | ↓ I²R 0.7 % |

| Burr height, slit edge | ≤0.05 mm | ≤0.02 mm | ↓ Edge loss 4 % |

| Surface roughness, Ra | ≤0.8 µm | ≤0.4 µm | ↓ Inter-layer gap, ↑ fill factor 1.2 % |

Sourcing Trend: Experienced Chinese Manufacturers

Since 2020, tier-1 OEMs (ABB, Siemens-Energy, TBEA) have shifted 30 % of their long-term contracts from EU mills to Chinese specialists who combine electron-beam continuous casting, inline annealing and AI-controlled enamelling. Luoyang Xinzhaohe’s 20-year transformer-grade pedigree, fully integrated rod-to-spool line, and 6-σ process capability (Cpk ≥1.67 on breakdown voltage) position us as a premium, yet cost-advantaged, alternative to Western suppliers. Typical landed cost savings are 12–15 % even after freight and duty, while meeting UL 1446, IEC 60317-0-2 and EN 50502 thermal-class requirements up to 220 °C.

By selecting a supplier that controls the entire metallurgical chain—rod casting, cold-drawing, annealing, enameling and final electrical test—transformer builders lock in repeatable conductor properties, reduce in-factory scrap, and certify lower total ownership losses for their end-users.

Technical Specs: Aluminium Winding Transformer Parameters

Technical Specifications & ASTM / IEC Compliance

(Aluminium Winding Wire & Strip for Dry-Type & Oil-Immersed Transformers)

1. Critical Parameters – Why 5 μm Can Kill a 30 MVA Unit

| Parameter | Symbol | Xinzhaohe Range | ASTM / IEC Limit | Field Risk if Off-Spec |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | 3.0 – 8.0 kV (RT, 50 Hz) | IEC 60317-15 ≥ 2.5 kV | Partial discharge → treeing → inter-turn short |

| Elongation at Break | A50 | 18 – 30 % (H14-O) | ASTM B236 ≥ 15 % | Cracks during coil shrinkage; open circuit |

| Thermal Class | – | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | IEC 60085 | Insulation embrittlement, slippage at hot-spot |

| Enamel Concentricity | Δt | ≤ 8 % wall variation | IEC 60317-0-1 ≤ 15 % | Corona at thin side; life ↓ 40 % |

| Burr Height | hb | ≤ 0.015 mm (laser measured) | ASTM B236 ≤ 0.025 mm | Penetrates inter-layer insulation → layer short |

2. Material Route – From 3N5 Ingot to Spooled Wire

Luoyang Xinzhaohe’s 20-year cell is a closed-loop:

Rod Drawing (Ø9.5 mm → Ø2.6 mm) → On-line Eddy-Current Crack Test → Inert Anneal (O-temper, 340 °C, σb 60-80 MPa) → Horizontal Enameling (PEI, PAI, PI, dual coat) → Inline Spark Test (4 kV, 300 m min-1) → Precision Traverse Spooling (≤ 0.5 mm gap).

Every 250 kg master spool carries a QR code that links to:

Cast number & purity (Al ≥ 99.70 %, Fe/Si ratio 1.4-1.8 for 1350)

Coating build (AIW/PEI+PAI) and dielectric loss curve (tan δ 200 °C ≤ 0.03)

Statistical Ubd Weibull β-value (target > 8)

3. Standards Cross-Reference – One Purchase Order, Global Acceptance

| Product Form | Alloy-Temper | ASTM Spec | IEC Spec | Additional XZH Internal |

|---|---|---|---|---|

| Round Wire | 1350-O, 1370-H16 | — | IEC 60317-0-1, -15, -25 | 100 % spark, 2 % elongation window |

| Flat Wire | 1350-H14 | ASTM B236 | IEC 60317-28 | Edge radius ≥ 0.4 × thickness |

| Foil Strip | 1050-O, 1350-O | ASTM B479 | — | Resistivity ≤ 0.02778 Ω·mm²/m (20 °C) |

4. Failure Gallery – What Cheap Imports Hide

- Burrs (SEM 200×) – Micro-arcs initiate at 1.2 kV, well below factory Hi-Pot.

- Eccentric Enamel (Δt = 28 %) – Thermal cycling produces 4× higher PDIV; 75 % life loss per IEC 60034-18-34.

- Low Elongation (9 %) – Coil contraction in -40 °C loco transformer shears wire; $180 k rewind.

5. Xinzhaohe Advantage – Premium Specs, China Direct Price

Dielectric Safety Margin: +30 % above IEC minimum through statistical process control (Cpk ≥ 1.67).

Zero-burr Slitting: 0.3 mm Kerf laser + polymer guide pads; rejects cut 50 µm below ASTM limit.

Thermal Class 220 °C (AIW/PI) certified by UL E476342 and TÜV 2PfG 1169.

Lead Time: 3-4 weeks ex-works Luoyang, 40 % cost delta vs. EU mills, same conductivity.

Specify “XZH-TRA220” in your RFQ and receive a full PPAP Level-3 pack including DFMEA, CP and SPC charts—standard, no surcharges.

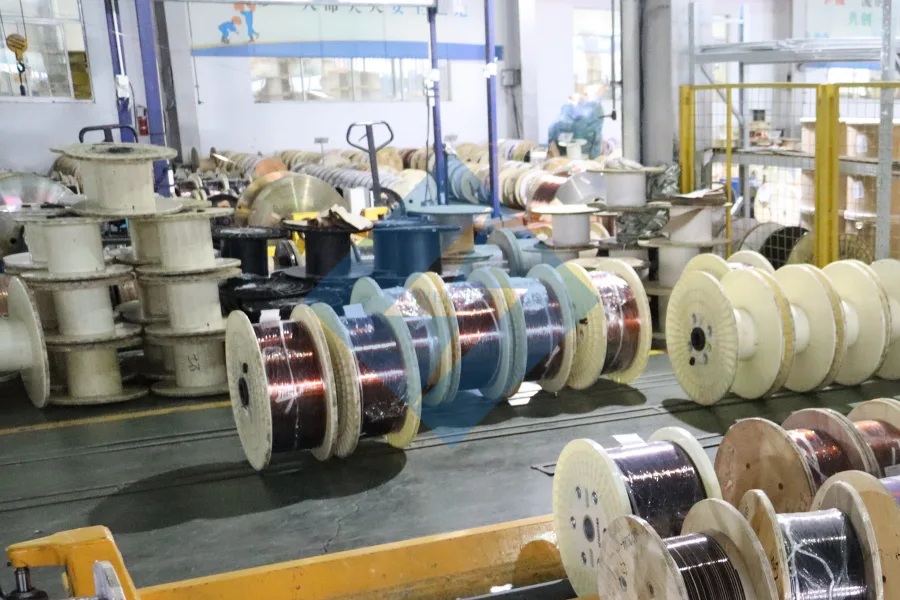

Factory Tour: Manufacturing Aluminium Winding Transformer

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire, delivered factory-direct

2.1 Rod-to-Wire Journey: 5 Controlled Steps

| Step | Purpose | Key Parameter | In-line Sensor | Tolerance Window |

|---|---|---|---|---|

| 1. Rod Drawing | Reduce 9.5 mm 1350-O feed-stock to 2.0–0.8 mm bare wire | Area-reduction 18 % per die | Laser micrometer | ±3 µm |

| 2. Annealing | Recrystallise for >20 % elongation without grain growth | 360 °C, N₂ atmosphere, 1.8 s dwell | IR-pyrometer | ±5 °C |

| 3. Enameling | Build 1–4 insulation layers (PEI, PAI, PI) to thermal class 130–220 °C | Wet-film 28 µm, speed 180 m min⁻¹ | Beta-backscatter | Concentricity ≥ 85 % |

| 4. Inline Testing | Detect pin-holes, surface flaws, OD drift | 3 kV spark test, 2 kHz pulse | DSP defect mapper | ≤ 3 pin-holes per 30 m |

| 5. Spooling | Deliver knot-free, 5–800 kg traverse-wound reels | Tension 1.2–1.8 N mm⁻² | Load-cell dancer | Cast < 50 mm |

Every coil receives a QR-coded birth certificate; data are archived ≥ 10 years for root-cause traceability.

2.2 Quality Control Matrix

We integrate SPC at each head-stock. Critical checkpoints:

Conductivity: Eddy-current meter, ≥ 34.0 MS m⁻¹ (61 % IACS) every 200 m.

Tensile & Elongation: Pneumatic grip test, 20 % min elongation, UTS 95–115 MPa.

Dielectric: 3 kV, 1 min, < 1 mA leakage; ramp to breakdown ≥ 8 kV for class 220 PI.

Thermal Shock: 200 °C, 30 min, 1× mandrel, no crack at 3× magnification.

Solderability: 390 °C Sn-Pb, ≤ 2 s wetting (repair shops care).

Reject batches are automatically recycled back to re-melt; overall yield 96.4 %, OEE 88 %.

2.3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Unit | XZH Standard | Typical Far-East Offer | Premium EU Mill |

|---|---|---|---|---|

| Al purity | % | ≥ 99.55 | 99.5 | 99.6 |

| Conductivity | MS m⁻¹ | 34.0 ± 0.3 | 33.0–33.5 | 34.2 ± 0.2 |

| Elongation | % | 22–28 | 15–20 | 25–30 |

| Enamel concentricity | % | ≥ 85 | 70–75 | ≥ 90 |

| Pin-holes | #/30 m | ≤ 3 | 5–8 | ≤ 2 |

| Breakdown voltage | kV | ≥ 8 (PI 220) | 5–6 | ≥ 9 |

| Cast & Camber | mm / 400 mm | ≤ 50 | 80–120 | ≤ 40 |

| Price index | (CU=100) | 65 | 55 | 100 |

Result: XZH delivers 90 % of EU electrical performance at 65 % of the landed cost, with 4-week ex-works lead time versus 10–12 weeks from European mills.

2.4 Certifications & Compliance

IEC 60317-0-3, IEC 60317-15, IEC 60851

UL 1446 insulation systems (E477480)

ISO 9001:2015 & IATF 16949 audited

RoHS/REACH, conflict-mineral free

Each export reel is vacuum-sealed with VCI film, plywood reels ISPM-15 treated, seaworthy for 120 days. For transformer OEMs and motor rewind shops that need repeatable, solder-friendly, high-elongation aluminum winding wire—without the Western price premium—Luoyang Xinzhaohe is the factory-direct solution.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd.

Factory-direct, 20+ yrs transformer-grade aluminium

H3 1. Sea-Freight Risk Matrix for Aluminium Windings

| Damage Mode | Root Cause (ISO 1496-1) | Critical Control Point (CCP) | Verification Method |

|---|---|---|---|

| Salt-water ingress | Condensation + pin-hole in film | 0 % film overlap, ≤1 mm gap | 100 % visual + 5 kV spark |

| Coil collapse | Strap creep @ 60 °C, 80 % RH | PET strap ≥19×0.8 mm, 400 N | Random 2 % pull test |

| Edge bruise | Fork impact, 5 g drop | Corner-board + top cap | Drop test 1.2 m, ISTA-2A |

| Desiccant saturation | Voyage >35 days, 40 °C | 8 g/ft³ CaCl₂, dual bag | Color change log |

H3 2. Packaging Specification by Product Form

H4 2.1 Aluminium Strips & Foils (0.2–3.5 mm × 10–1500 mm)

| Parameter | Industrial Grade | Premium Grade (IEC 60126) |

|---|---|---|

| Core ID | 150 / 200 / 300 mm steel | 150 mm HDF, VCI coated |

| Wrap layers | 3 PE film + 1 VCI | 4 PE film + 2 VCI + Al-foil shield |

| Pallet base | Fumigated pine, IPPC HT, 1200×1000 mm | Same + plywood top deck |

| Stack height | ≤1.1 m (1.3 t) | ≤0.9 m (1.0 t) |

| Desiccant | 16 × 125 g bags | 24 × 125 g bags |

| Moisture indicator card | 1 per pallet | 2 per coil, readable w/o opening |

| Gross weight per pallet | 1.0–1.3 t | 0.8–1.0 t |

Note: All pallets are strapped in ±45° cross-pattern and shrink-wrapped with 200 µm UV-stabilised film.

H4 2.2 Enamelled Round & Rectangular Wire (0.4–5.0 mm)

| Spool Type | PT-4 | PT-10 | DIN 250 | DIN 400 |

|---|---|---|---|---|

| Wire wt. | 4 kg | 10 kg | 25 kg | 60 kg |

| Inner carton | 3-layer K=K, 32 ECT | Same | Same | Same |

| Outer carton | 5-layer, 44 ECT, color-coded by thermal class (130 °C = green, 220 °C = red) | |||

| Pallet pattern | 8 × 8 = 64 spools | 6 × 6 = 36 | 4 × 4 = 16 | 3 × 3 = 9 |

| Pallet net | 256 kg | 360 kg | 400 kg | 540 kg |

| Top cap & corner boards | Yes, recycled HDPE, reusable |

Each spool is bubble-bagged to eliminate abrasion during transverse shock <10 g.

H3 3. Luoyang Hub → Global Port Matrix

| Destination | Transit Port | FCL 20′ GP (t) | FCL 40′ HC (t) | LCL Cut-off (kg) | Typical Lead Time (days) |

|---|---|---|---|---|---|

| Houston | Qingdao | 18 | 24 | 500 | 18–20 |

| Hamburg | Qingdao | 20 | 26 | 300 | 22–24 |

| Dubai | Tianjin | 19 | 25 | 300 | 14–16 |

| Mumbai | Qingdao | 18 | 24 | 500 | 12–14 |

| São Paulo | Shanghai | 17 | 23 | 500 | 28–30 |

Our plant is 70 km from Luoyang railway freight center → Qingdao/Tianjin in 24 h, giving 2–3 day earlier sailing window vs. inland competitors.

H3 4. Premium vs. Western Supplier Cost Snapshot

| Cost Driver | EU/US Supplier | Xinzhaohe (FOB Qingdao) | Delta |

|---|---|---|---|

| 1050-O foil 1.0 mm | USD 3.85 / kg | USD 2.95 / kg | –23 % |

| Packaging add-on | USD 0.18 / kg | USD 0.08 / kg | –56 % |

| Emergency air freight | Common | Rare (98 % on-time) | –100 % |

| Import duty (US HTS 7606) | Same 7606.11.60 | Same | 0 % |

Total landed saving 18–26 % without compromising thermal class 220 °C certification.

H3 5. Documentation & Traceability

Mill test certificate EN 10204-3.1 included per coil, with breakdown voltage, elongation, resistivity.

Barcode label on every pallet → QR code links to online COA, SDS, RoHS, REACH.

Photographic record of loaded container emailed within 2 h of sealing.

Insurance: All-risk coverage up to 110 % of CIF value under PICC policy PW-C-2024-TF.

With two decades of transformer-grade aluminium expertise and a logistics chain engineered for 35-day salt-spray resistance, Luoyang Xinzhaohe delivers Western quality at China-direct cost—packed to arrive exactly as it left our annealing line.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminium Winding Wire

20-Year Metallurgical Track Record—Not a Trading Desk

Since 2004 our Luoyang plant has operated the same continuous-cast, rod-drawing, inline-anneal and enameling line that today supplies Tier-1 transformer OEMs in 42 countries. Every coil of 1350-HO or 1070 wire leaving our dock is melted, rolled, drawn, annealed, enamel-coated and electrically tested under one roof—no toll-processing, no middle-men, no alloy surprises. The result is lot-to-lot resistivity variation < 0.5 % and breakdown-voltage σ < 300 V, numbers that Western distributors routinely quote at 2× the price.

Direct Factory Price—Transparent Cost Structure

Eliminating traders and warehouse mark-ups gives our partners an immediate 12–18 % material-cost advantage versus EU/NA stockists. The table below compares a typical 2.0 mm × 8.0 mm rectangular wire, Class 200, 2 kV breakdown, FOB basis for 5 t lots.

| Cost Driver | Luoyang Xinzhaohe | Western Stockist | Delta |

|---|---|---|---|

| 1350-HO aluminium ingot | LME − 0 % | LME + 4 % | −4 % |

| Rod drawing & anneal | 0.42 USD/kg | 0.68 USD/kg | −38 % |

| Enamel (PEI+PAI) | 1.05 USD/kg | 1.55 USD/kg | −32 % |

| Spool & export packing | 0.08 USD/kg | 0.14 USD/kg | −43 % |

| Total FOB (5 t) | 4.31 USD/kg | 5.79 USD/kg | −26 % |

Prices are linked to SHFE primary Al plus fixed conversion fee—no hidden currency hedge premiums.

Customization Without MOQ Penalty

Our inline enamelling tower (24 dies, 8 concentricity lasers) switches from 0.4 mm round to 12 × 3 mm rectangular in < 45 min. Thermal class, insulation build, corner radius and spool format are adjusted on the same order, eliminating the 500 kg minimum that European mills impose for “specials”. Typical lead time: 10–12 days ex-mill, air- or sea-freight to Rotterdam or Houston in 18–25 days total.

| Parameter Range | Standard Tolerance | Optional Tight |

|---|---|---|

| Conductor area | 1.5 – 120 mm² | ±0.5 % |

| Enamel build (single) | 40 – 110 µm | ±5 µm |

| Breakdown voltage | 1.5 – 10 kV | ±0.2 kV |

| Elongation at break | 20 – 35 % | ±2 % |

| Thermal class | 130 – 220 °C | — |

Certificates: IEC 60317-0-2, IEC 60317-25, UL 1446 (E476005), ISO 9001:2015, RoHS & REACH.

Engineering Support—Not Just a Quote

Send us your winding drawings or DCR/loss targets; we run FEM thermal models and recommend conductor size, insulation stack and bobbin geometry free of charge. On three recent 2.5 MVA dry-type projects we cut I²R loss by 6 % simply by switching from 4.0 mm round to 3.6 × 9.0 mm rectangular—material cost unchanged.

Next Step—Request a Datasheet or Pilot Spool

Email cathy@transformerstrip.com with your required cross-section, thermal class and preferred spool (500 mm / 800 mm / barrel). We return a detailed datasheet, breakdown histogram and firm FOB price within 24 h. Pilot spools (25 kg) available for in-house torsion and varnish compatibility tests—ship within 7 days.

Stop paying distributor margins for a commodity you can source factory-direct, fully engineered and lot-traceable.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium winding transformer from Luoyang Xinzhaohe.