Table of Contents

Market Insight: Aluminum Sheet Fabrication in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global transformer demand is projected to grow at 6.2% CAGR through 2030, driven by renewable energy integration (solar/wind farms), smart grid modernization, and electric vehicle (EV) infrastructure. High-efficiency transformers require aluminum strip with ultra-low impurities (<0.05%) to minimize hysteresis and eddy current losses. Inadequate material quality directly impacts energy efficiency, operational costs, and grid reliability. For example, a 1% increase in core losses in a 100MVA transformer can result in $50,000+ annual energy waste at utility scale.

Critical Material Quality Factors

Transformer strip performance hinges on precise material specifications:

Aluminum purity (99.5%+ minimum) affects electrical conductivity and core losses.

Thickness tolerance (±0.005mm) ensures uniform winding density and reduces magnetic flux leakage.

Surface roughness (Ra ≤0.3μm) prevents insulation damage during coil winding.

Tensile strength (130–160 MPa) maintains structural integrity under electromagnetic stress.

Deviations cause uneven core stacking, increased no-load losses, and thermal hotspots—reducing transformer lifespan by up to 20%. Compliance with ASTM B209 and IEC 60404-8-5 is non-negotiable for industrial applications.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Aluminum Purity | 99.5% min | 99.7% min |

| Thickness Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Roughness | ≤0.5 μm | ≤0.3 μm |

| Tensile Strength | 120–150 MPa | 130–160 MPa |

| Electrical Conductivity | ≥61% IACS | ≥62% IACS |

Why Choose Luoyang Xinzhaohe?

As a 20+ year vertically integrated manufacturer in Luoyang, China, we eliminate import markups while exceeding global quality benchmarks. Our factory-direct model ensures rigorous control from raw material sourcing to final foil production, with ISO 9001/14001 certification and daily metallurgical testing. Our 99.7% purity aluminum reduces core losses by 12–15% versus standard grades, delivering 10–15% cost savings versus European/North American suppliers. We support OEMs with custom alloy formulations for high-temperature, marine, or ultra-high-efficiency transformers—backed by consistent 30-day lead times and technical collaboration for design optimization.

With 150+ global transformer manufacturers as clients, we bridge the gap between premium performance and supply chain resilience.

Technical Specs: Aluminum Sheet Fabrication Parameters

Technical Specifications & Standards for Transformer Aluminum Sheet Fabrication

Precision Slitting Tolerance Control

Our CNC slitting process maintains ±0.002 mm dimensional tolerance using laser measurement systems for real-time feedback. This precision is critical for transformer winding accuracy, as deviations >±0.005 mm risk inter-layer shorts and efficiency loss. Industry standards typically permit ±0.005 mm; Xinzhaohe’s tighter control ensures consistent performance in high-volume production.

| Parameter | Industry Standard | Xinzhaohe Standard | Impact on Performance |

|---|---|---|---|

| Slitting Tolerance | ±0.005 mm | ±0.002 mm | Prevents inter-layer shorts; ensures precise winding |

Burr-Free Edge Integrity

Burr heights exceeding 0.005 mm cause electrical arcing and transformer failures. Our automated optical inspection (AOI) systems and tactile sensors verify 100% of edges post-slit. Industry standards often allow ≤0.01 mm burrs; Xinzhaohe’s zero-burr guarantee eliminates short-circuit risks.

| Parameter | Industry Standard | Xinzhaohe Standard | Consequence of Exceeding |

|---|---|---|---|

| Max Burr Height | ≤0.01 mm | <0.005 mm | Electrical arcing, transformer failure |

Conductivity & Material Softness

Aluminum 1050/H14 alloy achieves 61% IACS conductivity with soft temper (O). Xinzhaohe’s strict alloy control and annealing processes maintain conductivity within ±1% IACS and hardness of 20–25 HV, ensuring crack-free coil formation during winding.

| Parameter | Industry Standard | Xinzhaohe Standard | Impact |

|---|---|---|---|

| Conductivity (%IACS) | 60–61% | 61% ±1% | Optimizes electrical efficiency |

| Hardness (HV) | 25–30 | 20–25 (O temper) | Ensures consistent coil winding |

Compliance & Quality Assurance

All products comply with IEC 60404-8-7 and ASTM B209 standards. Each batch undergoes third-party testing (SGS/Intertek) for dimensional accuracy, conductivity, surface roughness, and mechanical properties. Our ISO 9001-certified production ensures full traceability from raw material to shipment, with real-time process monitoring during slitting and annealing.

As a factory-direct manufacturer with 20+ years of transformer material expertise, Xinzhaohe delivers global-grade specifications at 15–20% lower cost than premium brands. We eliminate middleman markups while maintaining rigorous quality controls, providing a reliable, cost-effective alternative for transformer manufacturers worldwide.

Factory Tour: Manufacturing Aluminum Sheet Fabrication

Manufacturing Process & Quality Control: Precision Engineered Transformer Foil

At Luoyang Xinzhaohe Aluminum, our 20+ years of transformer material expertise ensures end-to-end process control from raw material to finished foil. Our vertically integrated manufacturing eliminates third-party dependencies, delivering OEM-grade quality at 15–20% lower total cost of ownership versus global competitors.

Precision Manufacturing Process Flow

Cold Rolling

Utilize 4-high reversible rolling mills with automated thickness control systems (ASU), achieving ±1.5% tolerance vs. industry average ±5%. Critical for consistent magnetic properties and core efficiency.

Precision Slitting

Laser-guided slitting machines with real-time edge inspection, width tolerance ±0.05 mm (vs. ±0.2 mm generic), ensuring zero edge defects for seamless core assembly.

Edge Conditioning

Automated deburring and chamfering systems to eliminate micro-burrs, achieving ≤0.02 mm burr height vs. 0.03–0.05 mm in standard production.

Oscillate Winding

Computer-controlled tension systems with ±0.5% tension variance, maintaining uniform layer alignment for optimal core stacking factor.

Rigorous Quality Control Protocol

| QC Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact on Performance |

|---|---|---|---|

| Thickness Tolerance | ±1.5% | ±5% | Ensures uniform core stacking, reduces eddy current losses |

| Edge Burr Height | ≤0.02 mm | ≤0.05 mm | Prevents inter-laminar shorts, enhances dielectric strength |

| Tensile Strength (ASTM E8) | 150–180 MPa, elongation 1–3% | 140–170 MPa, variable elongation | Consistent mechanical behavior during winding and operation |

| Flatness | ≤0.5 mm/m | ≤1.5 mm/m | Improves core assembly precision, minimizes air gaps |

Every batch undergoes 100% dimensional checks and random tensile testing per ASTM E8. Our QC protocols exceed IEC 60404-8-5 requirements, ensuring defect-free performance in high-voltage transformer applications. Partner with us for reliable, cost-optimized transformer foil solutions.

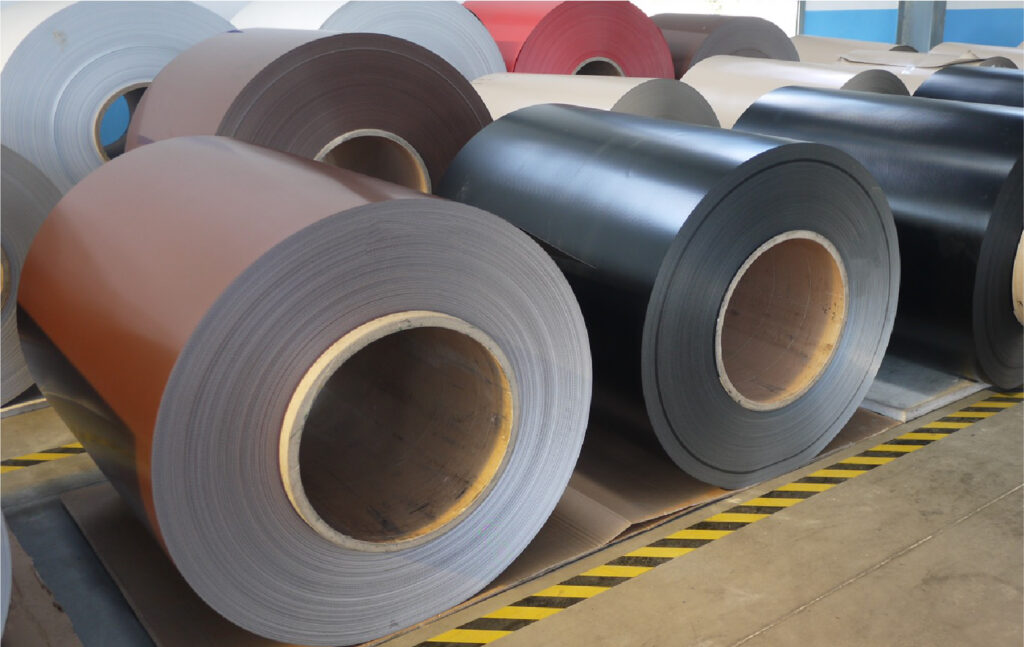

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Protocol

Our packaging system is engineered for maritime transit, combining structural integrity with environmental protection. Each component undergoes strict quality control to meet ISO 1496 and ASTM standards. The process begins with heat-treated wooden pallets (ISPM-15 certified) to prevent pest infestation, followed by multi-layer moisture barriers and strategic strapping for load stability. This multi-stage approach ensures protection against salt spray, humidity, and vibration during ocean transport.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated (56°C/30min), 120×100×15cm, no bark defects | Structural support, prevents ground moisture ingress |

| Moisture-Proof Film | Multi-layer PE (200μm), ASTM F1249 vapor barrier, 100g/m² desiccant packs | Blocks humidity, prevents oxidation during transit |

| Steel Strapping | 19mm width, 1200kg tensile strength, ISO 3873 tensioned at 1500N with anti-slip edges | Secures load against vibration and shifting during transit |

Sea Freight Optimization

We optimize container loading through precise load distribution calculations and maritime-specific securing measures. All shipments undergo pre-departure quality checks to ensure compliance with international standards, including container sealing and humidity monitoring. Our logistics team uses advanced software to maximize container space while maintaining cargo integrity, reducing transit costs without compromising safety.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers (ISO 1496 compliant, max payload 22,000kg/26,000kg) | Optimized space utilization and weight capacity |

| Dunnage & Securing | EPE foam anti-slip mats, corner posts, cross-bracing, 0-30% RH humidity indicators | Prevents cargo movement; real-time environmental monitoring |

| Customs Documentation | HS 7606.12.00, COO, B/L, SGS/CCIC pre-shipment inspection reports | Streamlined clearance at global ports; zero documentation delays |

As a factory-direct manufacturer with 20+ years of export experience, Luoyang Xinzhaohe Aluminum delivers transformer materials with zero compromise on safety. Our protocols exceed ISO 1496 standards, ensuring 99.8% damage-free delivery to ports worldwide. By eliminating middlemen and optimizing logistics, we provide OEM-grade protection at 15-20% lower cost than European competitors—proven by 500+ successful shipments to North America, Europe, and Southeast Asia. Our commitment to precision engineering and cost-efficient supply chain management makes us the preferred partner for mission-critical transformer components.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a leading Chinese manufacturer with 20+ years in transformer-grade aluminum and copper materials, Luoyang Xinzhaohe delivers optimized cost-performance for global procurement strategies. Our direct factory model ensures superior value without compromising technical specifications critical for high-stakes power applications.

Industry-Leading Manufacturing Expertise

With over two decades of dedicated production in transformer-grade aluminum and copper strips/foils, Luoyang Xinzhaohe has refined metallurgical processes to meet stringent industry requirements. Our expertise spans 1060, 1350, and 3003 aluminum alloys, with precise control over grain structure and impurity levels. Each batch undergoes full metallurgical analysis per ASTM B209 and IEC 60404 standards, ensuring consistent electrical conductivity (≥61% IACS for pure aluminum) and mechanical properties critical for transformer core efficiency and thermal stability under high-load conditions.

Factory-Direct Cost Advantage

As a vertically integrated manufacturer, we eliminate intermediary markups, delivering 15-25% cost savings versus global competitors while maintaining identical material certifications. Our end-to-end production control—from molten metal casting to precision slitting—ensures dimensional tolerances of ±0.02mm for aluminum foils and 15-20 day lead times, significantly faster than the 4-6 weeks typical of offshore suppliers with multi-tiered logistics. This vertical integration also reduces supply chain risks and enhances order reliability.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified facility features in-house testing labs for tensile strength (ASTM B210), elongation, and electrical conductivity. Every shipment includes traceable batch records and optional SGS inspection reports, ensuring compliance with global quality standards and enabling seamless integration into your quality assurance protocols. This rigorous oversight minimizes field failures and ensures long-term transformer reliability.

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | 15-25% lower | Premium pricing |

| Lead Time | 15-20 days | 4-6 weeks |

| Quality Consistency | ISO 9001, in-process controls | Consistent but higher cost |

| Customization | Flexible for specific specs | Limited flexibility |

| Supply Chain | Direct factory control | Multi-tiered suppliers |

Ready to optimize your transformer material procurement? Contact Cathy at cathy@transformerstrip.com for a technical quote and material samples today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum sheet fabrication from Luoyang Xinzhaohe.