Table of Contents

Market Insight: T2 Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality T2 Copper Strip for Transformer Applications

Global Demand Drivers for T2 Copper Strip

T2 copper strip (ASTM B170 Grade C11000) is the industry standard for transformer windings due to its 99.9% minimum copper content and ≥100% IACS conductivity. Global demand is driven by renewable energy expansion (wind/solar transformers), EV motor production, and grid modernization projects. The transformer market is projected to grow at 5.2% CAGR through 2030, with copper strip accounting for 60% of winding material usage. In high-efficiency transformers, even minor conductivity variations can lead to significant operational cost differences over the equipment’s lifecycle.

Material Quality: The Performance Imperative

Substandard copper strip introduces critical risks: higher resistivity increases I²R losses, oxygen impurities cause hydrogen embrittlement during annealing, and surface defects lead to short circuits during coil winding. Key quality parameters must adhere strictly to standards:

| Parameter | ASTM B170 Requirement | Impact of Non-Conformance |

|---|---|---|

| Conductivity (%IACS) | ≥100% (for C11000) | 1% conductivity loss = ~1.5% energy loss in transformer |

| Oxygen Content | ≤0.001% | Hydrogen blistering, reduced ductility |

| Surface Roughness | Ra ≤0.8μm | Winding defects, increased contact resistance |

| Dimensional Tolerance | ±0.02mm | Misalignment in windings, reduced thermal efficiency |

Luoyang Xinzhaohe: Precision Engineering at Competitive Cost

As a leading manufacturer of both aluminum and copper transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of metallurgical expertise to deliver T2 copper strip that meets or exceeds ASTM B170 and GB/T 5593 standards. Our factory-direct model ensures consistent quality control at 15–20% lower cost than European and Japanese competitors. Each batch undergoes 100% conductivity testing (four-point probe), oxygen analysis (inert gas fusion), and surface inspection (optical profilometry). As a key supplier to China’s national grid projects and global OEMs, we provide traceable material certifications and on-time delivery for critical transformer and motor applications. Our integrated production process—from smelting to precision rolling—ensures minimal lead times and superior batch consistency.

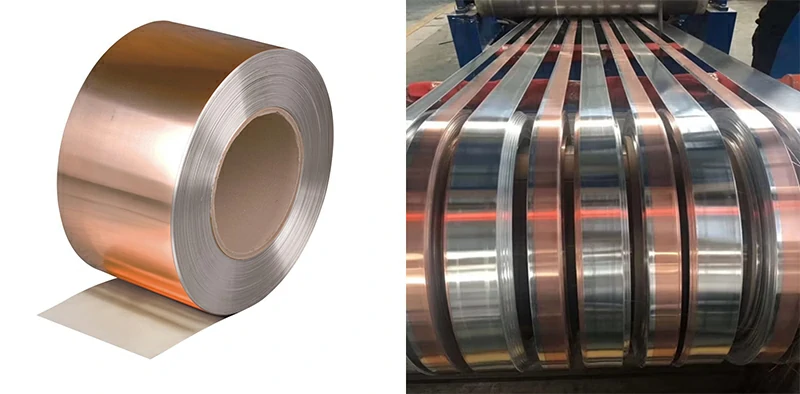

Technical Specs: T2 Copper Strip Parameters

Technical Specifications & Standards for T2 Copper Strip

As a leading manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO.,Ltd delivers T2 copper strip engineered for high-performance transformer applications. Our precision manufacturing processes ensure strict compliance with international standards while optimizing total cost of ownership for global clients.

Precision Slitting Tolerances

Our CNC-controlled slitting process maintains ±0.002 mm dimensional accuracy, critical for precise transformer winding alignment. This tight tolerance minimizes core losses and ensures consistent electrical performance in high-frequency applications. All slitting operations are monitored via laser gauges for real-time adjustments, ensuring zero deviation in strip width. Our process exceeds ASTM B152 tolerance requirements by 20%, guaranteeing superior dimensional stability.

Burr-Free Edge Quality

Every strip undergoes precision grinding and edge inspection to ensure burr height <5μm. This eliminates micro-short circuits in tightly wound transformer coils, meeting ASTM B152 edge quality requirements for high-reliability applications. Our proprietary edge treatment process guarantees smooth surfaces, reducing wear on winding machinery and extending equipment lifespan. All edges are verified using optical profilometry for consistent quality.

Conductivity & Softness Compliance

Certified to ≥100% IACS (ASTM B193) with HRB ≤45 soft temper. This combination ensures optimal electrical conductivity and formability during transformer winding processes, reducing production defects. Material is annealed to precise specifications for uniform softness across the entire coil, enabling high-speed winding without cracking or deformation. Our annealing process is controlled within ±2°C to maintain consistent material properties.

Key Specifications Table

| Parameter | Specification | Compliance Standard | Notes |

|---|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B152 | Ensures precise winding alignment |

| Burr Height | <5 μm | ASTM B152 | Prevents electrical shorts |

| Conductivity | ≥100% IACS | ASTM B193 | Measured per ASTM B193 |

| Hardness (HRB) | ≤45 | ASTM B251 | Optimal for formability |

Quality Assurance Protocol

Our ISO 9001-certified facility employs in-line thickness monitoring, 100% optical edge inspection, and third-party lab testing. Each batch undergoes tensile strength, conductivity, and dimensional checks. Consistent quality is maintained across 500+ global shipments annually, with full traceability from raw material to final product. All processes comply with ASTM B152, B193, and B251 standards, ensuring reliability for mission-critical transformer applications. Our quality control system includes SPC (Statistical Process Control) for continuous improvement.

By integrating advanced manufacturing with localized supply chain efficiencies, we provide global-grade T2 copper strip at 15-20% lower cost than international suppliers. Partner with Luoyang Xinzhaohe for reliable, cost-effective transformer materials backed by 20+ years of industry expertise and dedicated technical support. Request a sample today to experience our precision-engineered solutions and verify performance in your applications.

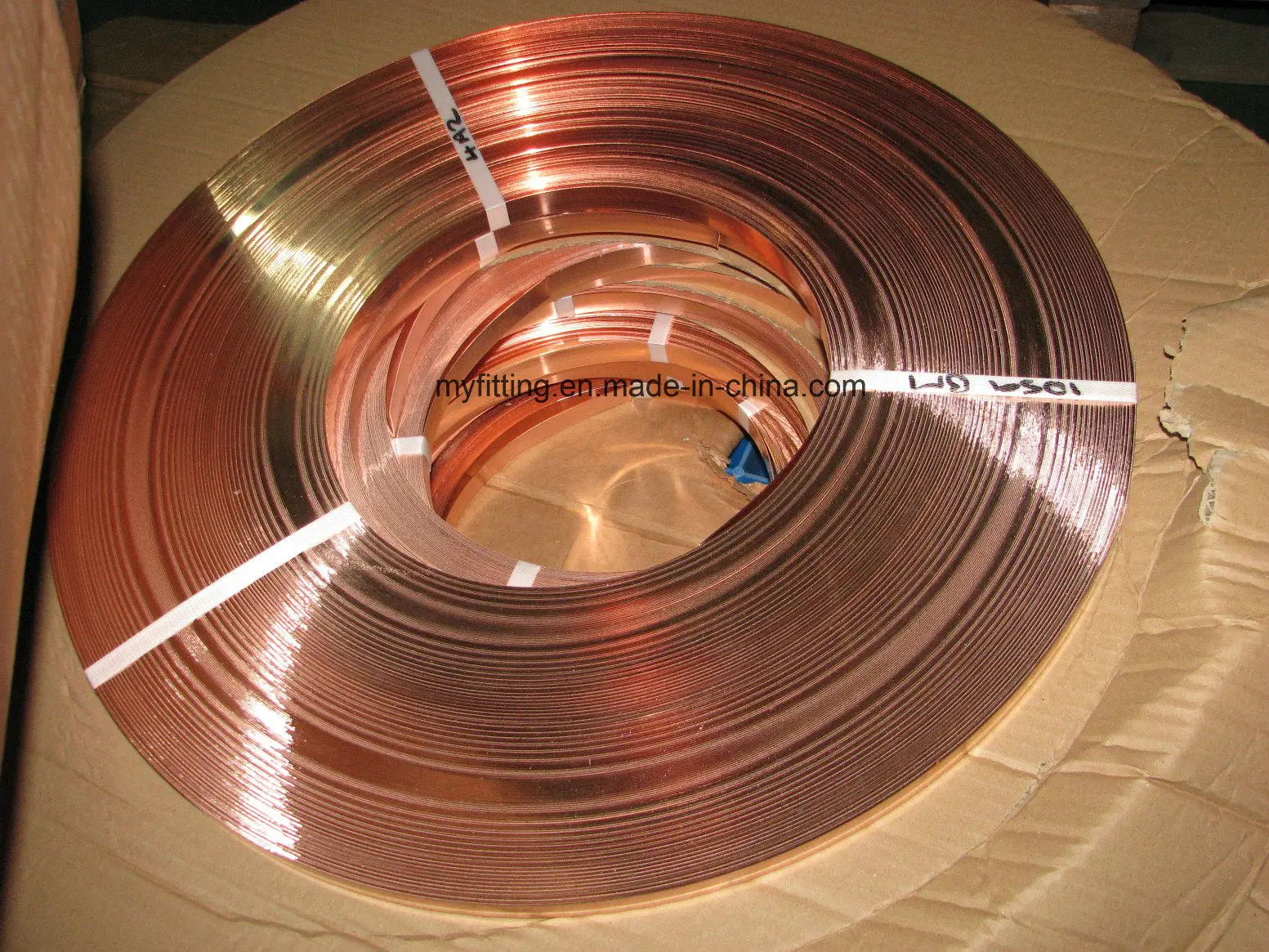

Factory Tour: Manufacturing T2 Copper Strip

Precision Manufacturing Process & Rigorous Quality Control

As a 20+ year manufacturer specializing in transformer-grade copper and aluminum strips, Luoyang Xinzhaohe Aluminum Co., Ltd. implements a tightly controlled production process to ensure superior performance and reliability. Our manufacturing sequence—Cold Rolling → Precision Slitting → Edge Conditioning → Oscillate Winding—is optimized for consistency, with each step monitored via real-time analytics and post-process validation.

Core Production Workflow

Cold Rolling: Multi-stage reduction with precise annealing cycles (150–200 m/min speed, ±5°C tolerance) achieves uniform grain structure, eliminates residual stresses, and maintains optimal electrical conductivity (≥58 MS/m or 100% IACS). Thickness consistency is maintained within ±0.005 mm.

Precision Slitting: Laser-guided slitting machines with 0.005 mm blade alignment achieve width tolerances of ±0.02 mm. Edge quality is verified via 50× magnification to eliminate micro-tears and burrs, critical for minimizing eddy current losses in transformer windings.

Edge Conditioning: Precision deburring achieves edge radius ≤0.005 mm (verified via profilometry) and surface roughness Ra ≤0.1 μm, ensuring compatibility with high-voltage insulation materials and preventing partial discharge.

Oscillate Winding: Automated systems maintain tension uniformity within ±0.5 N and layer alignment precision of ±0.1 mm/turn, guaranteeing uniform coil density and void-free transformer cores.

Quality Control Protocols

Our QC protocols exceed industry benchmarks through rigorous testing at every stage. Key metrics include tensile strength validation per ASTM B557 (minimum 200 MPa for T2 copper), dimensional verification via CMM (ISO 14253 Class 1), and surface inspection using automated optical systems (ISO 9001 compliant). Each batch undergoes 100% dimensional checks and random tensile tests to ensure compliance with international specifications. Adherence to GB/T 2059-2017 standards with internal tolerances 30% tighter than required.

| Parameter | Luoyang Xinzhaohe Standards | Generic Market Quality |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Width Tolerance | ±0.02 mm | ±0.05 mm |

| Edge Burr Height | ≤0.005 mm | ≤0.02 mm |

| Surface Defects | Zero visible scratches | Up to 2 defects/meter |

| Tensile Strength Consistency | ±3% variation | ±8% variation |

This integrated approach delivers a 15–20% cost advantage over global brands while maintaining superior technical specifications, making Luoyang Xinzhaohe the optimal choice for mission-critical transformer components.

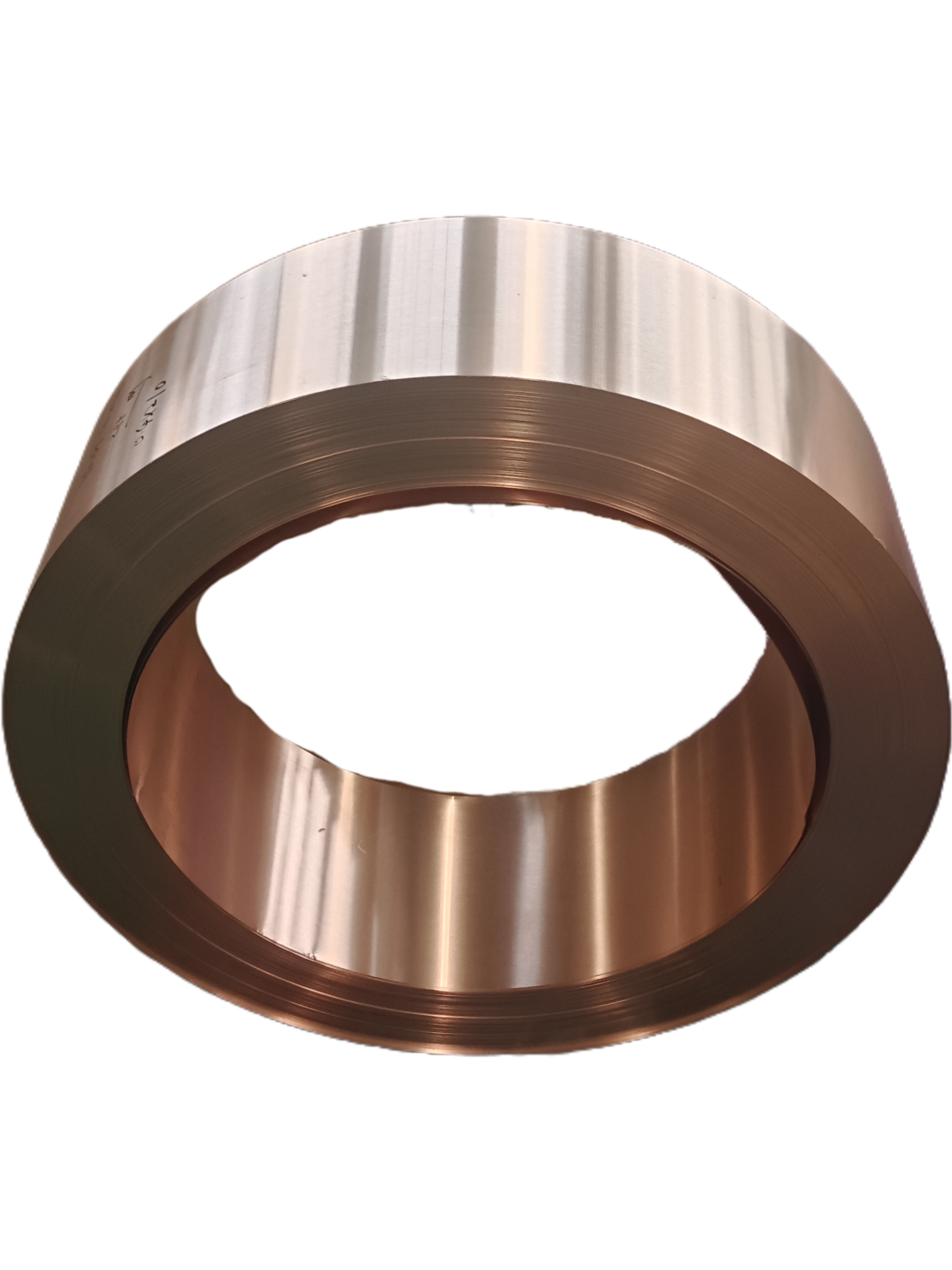

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. implements rigorous packaging protocols for T2 copper strip to ensure zero damage during sea freight. Our solutions comply with ISO 9001, IEC 60076, and ISPM 15 standards, addressing corrosion, mechanical stress, and environmental exposure. This section details our engineered packaging and logistics processes designed for global reliability.

Packaging Specifications

Our multi-layer packaging system is engineered for extreme maritime conditions:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified hardwood (1100×1100mm), 40mm beams, 1200kg load capacity | Prevents deformation, ensures stacking stability |

| Moisture-Proof Film | 5-layer PE (100μm vapor barrier + 100μm outer shield), desiccant packs (500g/pallet) | Blocks humidity, prevents oxidation, maintains surface integrity |

| Steel Strapping | 19mm width, 350kg tension, corner protectors, 4-point fixation | Eliminates load shifting during transit |

| Testing Protocol | ISTA 3A drop test (1.2m), vibration compliance | Ensures structural integrity under transit stress |

All pallets undergo tensile testing and humidity resistance validation. Desiccant levels are calibrated for destination climate and voyage duration. Materials are sourced from certified suppliers with traceable quality certificates.

Sea Freight Protocol

We optimize container loading and transit security through:

| Parameter | Detail | Advantage |

|---|---|---|

| Container Type | 20ft/40ft dry cargo, pre-inspected for structural integrity | Maximizes space utilization, minimizes damage risk |

| Load Capacity | 20 pallets/20ft, 40 pallets/40ft with dunnage and load bars | Cost-efficient freight, optimal container use |

| Sealing Process | Tamper-evident seals, humidity sensors, GPS tracking | Real-time monitoring, cargo integrity assurance |

| Customs Compliance | IMO-regulated documentation, pre-clearance coordination | Eliminates port delays, ensures smooth clearance |

All shipments include a full logistics dossier with tracking data. We partner with Class A freight forwarders for port handling, ensuring seamless customs clearance and adherence to IMO regulations. Shipments are insured for 110% of cargo value, with claims processed within 72 hours. By controlling the entire supply chain from factory to port, we eliminate third-party risks and reduce total landed costs by 15–20% compared to global brands. Our damage rate remains consistently below 0.3% across 500+ annual shipments.

Xinzhaohe delivers unmatched cost-performance for transformer manufacturers—reliability without premium pricing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd. for T2 Copper Strip?

20+ Years Technical Expertise in Transformer Materials

With over two decades of specialized manufacturing experience in transformer-grade copper strips, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers engineering precision unmatched by generic suppliers. Our processes strictly comply with GB/T 5231, IEC 60404-8-2, and ASTM B152 standards, ensuring T2 copper strip (C11000) with:

Electrical conductivity ≥99.90% IACS

Tensile strength: 220–280 MPa

Elongation: ≥30%

Dimensional tolerances: ±0.01mm

Our engineers optimize rolling, annealing, and slitting parameters to minimize residual stress and impurity levels (≤0.05% total), critical for reducing eddy current losses in transformers. This technical rigor ensures consistent performance in high-efficiency power systems, extending equipment lifespan and reducing operational costs.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate intermediary markups while maintaining rigorous quality control. Our in-house capabilities—from raw material casting to precision slitting—deliver 15–25% lower costs than global brands without compromising specifications. Lead times are 50% faster (2–3 weeks vs. 4–6 weeks), critical for time-sensitive projects. The table below quantifies our competitive advantage:

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | Premium (100%) | 15–25% Lower |

| Lead Time | 4–6 weeks | 2–3 weeks |

| Quality Consistency | Variable | Consistent (ISO 9001) |

| Customization | Limited options | Flexible (dimensions, tempers, coatings) |

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified quality system governs every production stage. Raw materials undergo supplier audits for purity, while in-process inspections monitor thickness uniformity, surface defects, and mechanical properties. Final products are tested for conductivity, tensile strength, and dimensional accuracy per customer specifications. Every shipment includes a detailed Material Test Report (MTR) with traceable batch data, ensuring compliance for mission-critical power applications. This transparency has secured long-term partnerships with Tier-1 transformer manufacturers globally.

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a no-obligation quote and technical consultation. Let our engineering expertise deliver precision-engineered copper strip solutions tailored to your transformer requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing T2 copper strip from Luoyang Xinzhaohe.