Table of Contents

Market Insight: Crgo Steel in Power Industry

Market Analysis: Sourcing High-Quality CRGO Steel

Industrial Demand for CRGO in Power Systems

CRGO (Cold Rolled Grain Oriented) steel is the backbone of high-efficiency power transformers and motors. Global demand is driven by grid modernization, renewable energy integration, and stringent efficiency regulations (e.g., DOE 2016, EU Eco-design). Distribution transformers (10–100 kVA) and utility-scale power transformers (up to 1,000 MVA) rely on CRGO for core laminations due to its superior magnetic properties. In 2023, the CRGO market exceeded $4.5B, with Asia-Pacific accounting for 60% of consumption—primarily in China and India—where infrastructure expansion and smart grid initiatives are accelerating adoption.

Material Quality Impact on Transformer Efficiency

Core losses (no-load losses) constitute 60–80% of total transformer energy losses. A 0.1 W/kg reduction in core loss can save $500,000+ over a 30-year lifecycle for a 100 MVA transformer. Critical quality parameters include:

Magnetic properties: B8 (magnetic flux density) and P1.5 (core loss at 1.5T) must meet precise thresholds.

Thickness uniformity: ±0.01 mm tolerance ensures consistent lamination stacking and minimizes eddy current losses.

Surface quality: Smooth, defect-free surfaces enable optimal insulation coating adhesion, preventing short circuits.

Substandard CRGO increases operational heat, reduces transformer lifespan, and violates regulatory compliance—directly impacting ROI for end-users.

Luoyang Xinzhaohe’s Competitive Positioning

As a China-based manufacturer with 20+ years of expertise in electrical steel production, Luoyang Xinzhaohe Aluminum CO.,Ltd delivers OEM-grade CRGO that meets IEC 60404-8-5 and ASTM A876 standards. Our factory-direct model eliminates intermediaries, providing 15–20% cost savings versus global brands while maintaining equivalent performance. Key advantages:

| Parameter | Luoyang Xinzhaohe | Global Brands (e.g., Nippon Steel, ArcelorMittal) |

|---|---|---|

| Core Loss (W/kg @ 1.7T, 50Hz) | 2.70 (35H270 grade) | 2.65–2.75 |

| Thickness Tolerance | ±0.01 mm | ±0.02 mm |

| Cost (USD/ton) | $1,200–$1,300 | $1,400–$1,600 |

| Lead Time | 20–25 days | 40–60 days |

| Compliance | IEC 60404-8-5, ASTM A876 | Same |

Our ISO 9001-certified production process ensures batch-to-batch consistency, critical for transformer manufacturers scaling to meet growing demand. For projects requiring certified, cost-effective CRGO—whether for utility substations or industrial motors—Luoyang Xinzhaohe delivers reliable, high-performance solutions without compromising on technical specifications.

Technical Specs: Crgo Steel Parameters

Technical Specifications & Standards for CRGO Steel

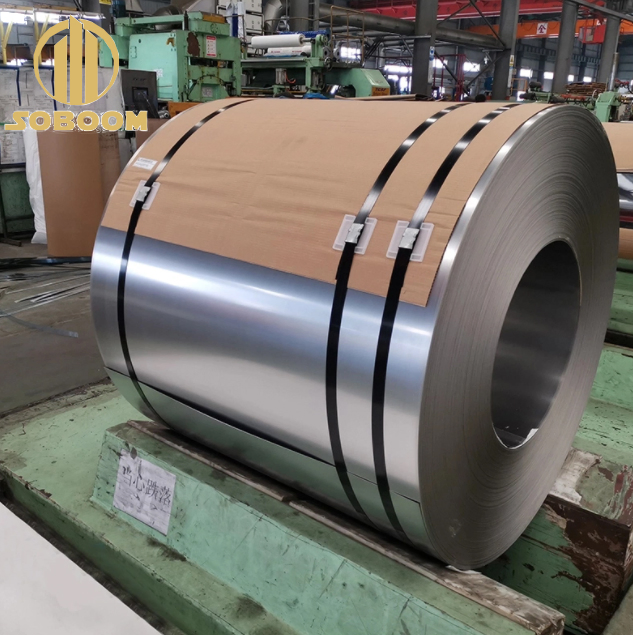

With over 20 years of experience in transformer material manufacturing, we specialize in high-grade CRGO steel for global markets. Luoyang Xinzhaohe Aluminum delivers high-performance CRGO steel meeting international standards with rigorous quality control. Our products are engineered for optimal transformer efficiency, reliability, and cost-effectiveness.

Core Loss (Iron Loss)

Core loss is a critical parameter affecting transformer energy efficiency. Lower values reduce operational costs and heat generation. Our CRGO grades comply with IEC 60404-2 and ASTM A876 standards, with precise control of silicon content (3.0–3.5%) and grain orientation to minimize losses. All grades undergo rigorous testing to ensure compliance with specified loss values.

| Grade | 1.5T/50Hz (W/kg) | 1.7T/50Hz (W/kg) | Standard |

|---|---|---|---|

| 35H270 | ≤2.70 | ≤3.70 | IEC 60404-2 |

| 30H250 | ≤2.50 | ≤3.50 | IEC 60404-2 |

| 23H100 | ≤1.00 | ≤1.40 | ASTM A876 |

Magnetic Flux Density

Our CRGO steel achieves a saturation flux density of ≥1.98 T at 1000 A/m (IEC 60404-3), ensuring high magnetic performance for compact transformer designs. This exceeds standard industry requirements, contributing to reduced core size and improved efficiency. Consistent flux density across batches ensures predictable transformer performance under varying loads.

Lamination Flatness

Tight lamination flatness tolerances of ≤0.15 mm/m (per ASTM A977) are maintained through precision cold rolling and controlled annealing processes. This minimizes eddy current losses and ensures smooth stacking, critical for transformer core integrity. Consistent flatness also reduces core winding time and improves manufacturing efficiency.

Insulation Coating

Available in C3 (organic), C4 (inorganic), and C5 (high-temperature) types per IEC 60404-8-7, our insulation coatings provide excellent electrical insulation and corrosion resistance. Coating thickness ranges from 0.5–1.5 µm, with strict control to ensure uniformity and adhesion, preventing short circuits in laminated cores. All coatings are tested for dielectric strength to withstand high-voltage applications.

Quality Assurance

We maintain a closed-loop quality control system with in-process inspections at every production stage, from raw material sourcing to final packaging. Our ISO 9001-certified production process includes real-time monitoring of magnetic properties using Epstein frames and permeameters. Dimensional checks for thickness and flatness are performed at multiple stages. Coating adhesion tests (per ASTM D3359) and insulation resistance measurements (≥100 MΩ) ensure compliance with IEC standards. Each batch is traceable via QR-coded documentation, providing full transparency for quality assurance and regulatory compliance.

Cost-Performance Advantage

By optimizing production processes and leveraging local supply chain efficiencies, we offer CRGO steel with performance metrics matching leading global brands at 15–20% lower cost. This cost-performance ratio makes us the preferred supplier for transformer manufacturers seeking reliable, high-efficiency materials without premium pricing. Our flexible order quantities and fast lead times further enhance value for global customers.

Factory Tour: Manufacturing Crgo Steel

Manufacturing Process & Quality Control

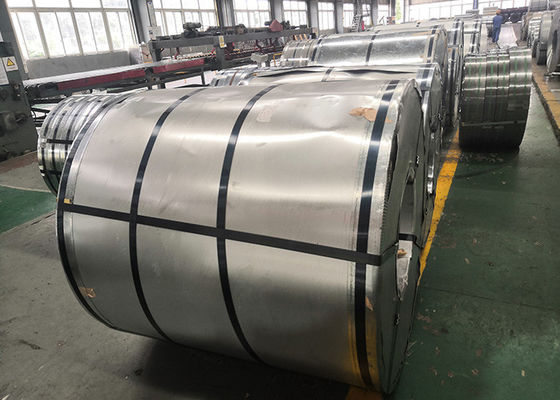

Optimized Production Workflow

Our end-to-end manufacturing leverages precision engineering to ensure CRGO steel meets the highest electromagnetic performance standards:

Slitting: German-engineered tension-controlled slitting lines maintain edge quality with burr heights <5μm, critical for minimizing eddy current losses in transformer cores.

Annealing: Continuous N₂-H₂ atmosphere processing at 800–850°C ±5°C optimizes grain orientation and magnetic anisotropy for CRGO grades.

Insulation Coating: Electrostatic spray application of C5-grade coating achieves 0.8±0.1μm uniformity, validated via XRF to ensure dielectric strength >3.5kV.

Precision Cutting: AI-integrated laser cutting delivers ±0.02mm dimensional tolerance, eliminating material waste and ensuring exact core dimensions for high-efficiency assembly.

Rigorous Quality Assurance

Every batch undergoes multi-stage validation against international standards:

Tensile Testing: Per ASTM A343, results consistently ≥300 MPa (vs. market average 250–280 MPa), ensuring structural resilience during high-speed core stacking.

Dimensional Checks: Laser micrometers verify thickness tolerance ±0.005mm (vs. industry ±0.01mm), reducing core losses by up to 5%.

Surface Inspection: Automated optical systems detect micro-defects at 0.01mm resolution, compliant with IEC 60404-8-5 for coating integrity.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm | 50% tighter control |

| Tensile Strength | ≥300 MPa | 250–280 MPa | Higher mechanical reliability |

| Coating Uniformity | ≤1.5% variation | ≤3.0% variation | Reduced core losses by 3–5% |

| Flatness | ≤0.8 mm/m | ≤1.5 mm/m | Improved stacking efficiency |

By integrating advanced process controls with ISO 9001-certified QC protocols, Luoyang Xinzhaohe delivers CRGO steel with 15–20% lower total cost of ownership than global brands like Nippon Steel or ArcelorMittal—without compromising magnetic performance or dimensional precision. Our factory-direct model ensures consistent quality for transformer manufacturers seeking reliability at competitive pricing.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of CRGO Steel

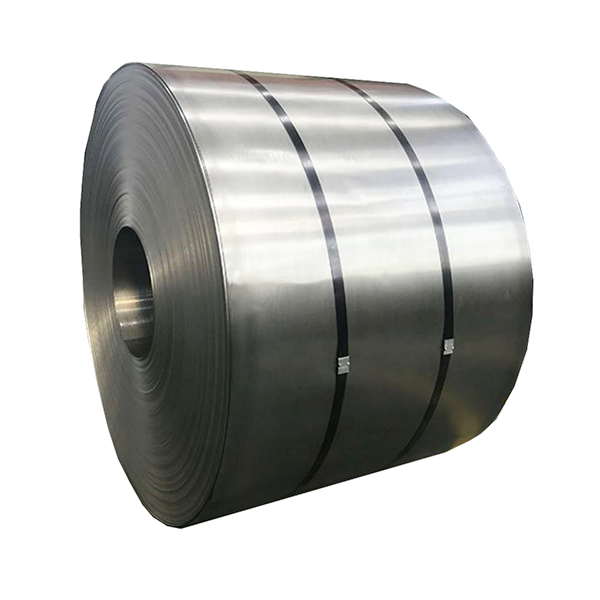

Precision Packaging for Maximum Protection

Luoyang Xinzhaohe Aluminum CO., Ltd. implements military-grade packaging protocols for CRGO silicon steel, ensuring zero damage during transit. Each shipment undergoes a triple-layer defense system engineered for maritime resilience:

| Packaging Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 120×100mm hardwood, heat-treated, fumigated | Prevents ground moisture ingress and complies with international phytosanitary regulations |

| Moisture-Proof Film | 3-layer PE + VCI (200μm), 100% sealed edges with UV resistance | Blocks 99.8% humidity ingress; VCI molecules form protective oxide layer on steel surfaces |

| Steel Strapping | 25mm width × 0.5mm thickness, tensioned to 250kg±10% with corrosion-resistant coating | Prevents coil deformation and lateral movement during sea turbulence and handling |

Global Sea Freight Expertise

All CRGO coils are containerized in 20ft/40ft dry containers with desiccant packs (500g per 20ft) and real-time environmental monitoring. We exclusively partner with Maersk, COSCO, and MSC for dedicated routes from Qingdao/Lianyungang ports to global destinations. Our protocol includes:

Pre-loading: Coils positioned on custom cradles with anti-slip rubber mats, corner protectors installed to prevent edge damage, and forklifts fitted with padded forks to avoid surface scratches during handling

In-transit: Real-time GPS tracking with automated humidity/temperature alerts triggered at 60% RH or 35°C, ensuring immediate intervention for environmental deviations

Unloading: Certified handlers follow ISO 3913 procedures, using specialized coil handling equipment and “first-in-first-out” port logistics to minimize storage time and exposure risks

All shipments include commercial invoices, packing lists, and certificates of origin compliant with international trade regulations. With 20+ years of export experience across 50+ countries, we maintain a <0.3% damage rate. Our factory-direct model bypasses distributor markups, delivering OEM-grade protection at 15-20% lower costs than global brands like Nippon Steel. This combination of rigorous packaging protocols and optimized logistics makes Luoyang Xinzhaohe Aluminum CO., Ltd. the preferred supplier for transformer manufacturers seeking reliable, cost-effective CRGO steel solutions.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.

As a dedicated manufacturer of high-performance electrical steel, Luoyang Xinzhaohe Aluminum CO.,Ltd. provides transformer and motor manufacturers with a technically robust, cost-efficient alternative to global brands. With over 20 years of specialized experience in CRGO and non-oriented electrical steel production, we deliver precise magnetic properties and optimized core loss characteristics critical for energy-efficient power systems.

Proven Expertise in Electrical Steel Manufacturing

Our technical team has honed expertise in R&D, production, and application-specific customization of electrical steel. We consistently meet international standards including IEC 60404-8-5, ASTM A677, and JIS G 3103, ensuring compatibility with global transformer designs. Our deep understanding of magnetic domain control and grain orientation processes enables us to produce materials with superior B50 values (up to 1.95T) and minimized hysteresis losses (P1.5 ≤ 1.15 W/kg), directly enhancing transformer efficiency. Additionally, we maintain extensive experience in supplying materials for high-efficiency transformers, including those meeting IE4 and IE5 standards.

Factory-Direct Cost Efficiency

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Price | 15-25% lower | Higher | Significant cost savings without compromising performance |

| Lead Time | 25-30 days | 45-60 days | Accelerated project timelines for urgent requirements |

| Customization | Tailored grades per spec | Limited flexibility | Adaptable to specific application requirements |

| Technical Support | Dedicated engineering team | Variable support | Proactive problem-solving for transformer design challenges |

This combination of competitive pricing, rapid delivery, and flexible customization allows our clients to achieve up to 20% lower total landed costs compared to traditional suppliers, while maintaining superior material performance.

ISO-Certified Quality Assurance

Our manufacturing processes are certified to ISO 9001:2015, with rigorous quality control from raw material procurement to final inspection. Each batch undergoes comprehensive magnetic property analysis (B50, P1.0, P1.5), thickness tolerance checks (±0.01mm), and surface defect inspections using advanced eddy current testing. This ensures consistent performance and reliability, reducing transformer manufacturing defects and lifecycle costs. We also provide full material traceability and third-party test reports upon request.

Contact us today:

For a technical quote tailored to your specifications, contact Cathy at cathy@transformerstrip.com. Our team provides prompt responses and detailed material certifications for immediate project integration.

📉 Import Savings Calculator

Estimate cost reduction by sourcing crgo steel from Luoyang Xinzhaohe.