Table of Contents

Market Insight: 100 Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

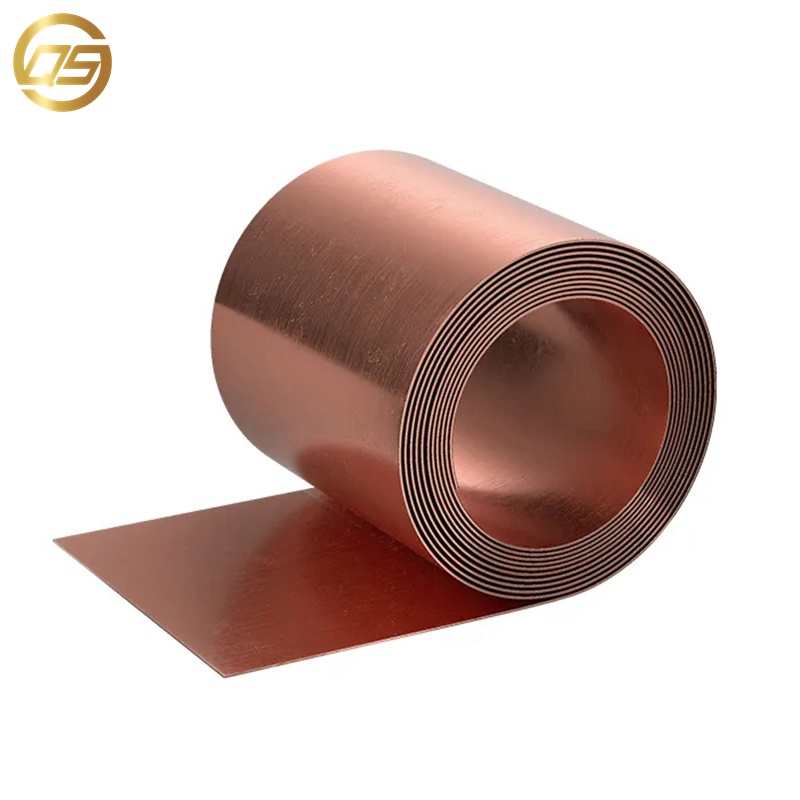

Industrial Demand for Copper Transformer Coils

Global demand for copper transformer coils is accelerating due to renewable energy integration (solar/wind farms), grid modernization projects, and EV charging infrastructure. Copper’s superior conductivity (100% IACS for C11000 grade) is critical for minimizing resistive losses in power transformers. For instance, a 1% conductivity drop can increase energy waste by 3-5% in high-capacity distribution transformers, directly impacting operational costs and carbon footprint. The industry increasingly prioritizes high-purity copper for high-efficiency transformers (IEC 60076-20) and motor windings in industrial applications.

Material Quality Criticality

Substandard copper introduces resistive heating, insulation degradation, and premature failure. Critical parameters include:

| Parameter | Low-Quality | High-Quality (C11000) | Impact |

|---|---|---|---|

| Electrical Conductivity | <90% IACS | ≥100% IACS | Higher resistance → 3-5% energy loss |

| Purity Level | <99.5% Cu | ≥99.9% Cu | Impurities increase resistivity |

| Tensile Strength | Inconsistent | 200-250 MPa (annealed) | Risk of winding breakage |

| Surface Finish | Oxidized, uneven | Mirror-smooth | Poor contact, arcing risks |

| Dimensional Tolerance | ±0.05mm | ±0.01mm | Manufacturing defects, assembly issues |

Luoyang Xinzhaohe’s Value Proposition

With over two decades of expertise in transformer materials, Luoyang Xinzhaohe operates a fully integrated production facility in Luoyang, China, certified to ISO 9001 and IEC 60076 standards. Our C11000 copper coils undergo 100% conductivity testing (ASTM B193) and precision rolling to ensure ±0.01mm thickness tolerance. By leveraging vertical integration and lean manufacturing, we deliver 15-20% cost savings versus European brands without compromising on quality. Our strict quality control protocols—including ultrasonic surface inspection and tensile strength verification—ensure batch consistency for critical applications. As a key supplier to global transformer manufacturers across Europe, North America, and Southeast Asia, we provide reliable, factory-direct sourcing solutions that optimize total lifecycle costs.

Technical Specs: 100 Copper Coil Parameters

Technical Specifications & Standards for 100 Copper Coil

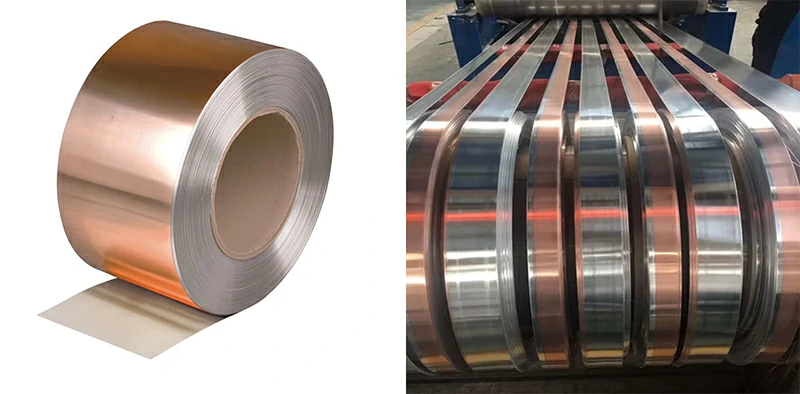

Precision Slitting & Dimensional Accuracy

Our CNC slitting process achieves ±0.002mm width tolerance using real-time laser measurement systems. This precision ensures uniform winding in transformers, minimizing material waste and enhancing coil integrity. Critical for high-performance applications where dimensional accuracy directly impacts efficiency and thermal management.

Burr-Free Edge Integrity

Burr-free edges are paramount to prevent electrical shorts in transformer windings. Our proprietary edge treatment process includes precision grinding and polishing, followed by 10× magnification inspection to detect micro-roughness or protrusions. This rigorous quality control ensures edge integrity meets safety standards, reducing insulation damage risks and extending equipment lifespan.

Conductivity & Mechanical Properties

Copper coil achieves ≥100% IACS conductivity (ASTM B193 standard), produced from high-purity C11000 alloy. The annealed (O) temper provides exceptional softness with tensile strength <150 MPa and elongation >35%, enabling easy forming during transformer fabrication without cracking. This balance of electrical and mechanical properties ensures optimal performance in demanding power applications.

Compliance & Quality Assurance

Compliance with ASTM B170 and IEC 60404-8-2 standards is enforced through our ISO 9001-certified quality management system. Every batch undergoes conductivity testing (four-point probe), dimensional verification, and surface analysis. Multi-stage QC protocols guarantee consistency across all orders, meeting global transformer manufacturers’ exacting requirements.

| Parameter | Specification | Tolerance/Standard |

|---|---|---|

| Width | 5–200mm | ±0.002mm |

| Thickness | 0.1–2.0mm | ±0.001mm |

| Conductivity | ≥100% IACS | ASTM B193 |

| Temper | Annealed (O) | – |

| Edge Quality | Burr-free, mirror finish | 10× magnification |

| Compliance | ASTM B170, IEC 60404-8-2 | Fully certified |

As a direct manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers transformer-grade copper coil meeting international standards at highly competitive prices. Our vertically integrated production process eliminates middlemen, offering superior cost-performance ratios without sacrificing precision or reliability. Partner with us for dependable, factory-direct solutions tailored to your specific transformer requirements.

Factory Tour: Manufacturing 100 Copper Coil

Manufacturing Process & Quality Control

Precision Manufacturing Process

Cold Rolling: High-purity copper (C11000) processed through 8-high CVC rolling mills with closed-loop thickness control. Precise reduction rates (15–20% per pass) optimize grain structure, ensuring conductivity ≥99.9% IACS and minimal residual stress for optimal transformer efficiency.

Precision Slitting: CNC-guided slitting with diamond-coated blades and real-time laser monitoring. Achieves width tolerance ±0.05 mm and straightness ≤0.1 mm/m, critical for seamless transformer winding integration and minimizing material waste.

Edge Conditioning: Laser-guided deburring to eliminate micro-burrs (<5 μm), validated via SEM analysis. Prevents inter-turn shorts in high-voltage applications by ensuring edge integrity and reducing electrical arcing risks.

Oscillate Winding: Servo-controlled tension system (±0.5 N precision) maintains uniform coil density. Integrated sensors adjust tension dynamically to prevent deformation during high-speed winding operations, ensuring consistent winding performance across all coil diameters.

Rigorous Quality Control

Dimensional accuracy is verified using high-precision laser micrometers (0.001 mm resolution) and 3D profilometers for flatness measurements. Mechanical properties undergo 100% batch testing per ASTM E8, with tensile strength consistency within ±2% versus industry averages of ±5%. Surface integrity is inspected under 10x magnification for Ra ≤0.2 μm, eliminating micro-scratches that cause eddy current losses. Edge quality is confirmed via SEM analysis to ensure burrs <5 μm, critical for high-frequency transformer applications. All quality data is digitally logged and traceable to individual coil batches, enabling full compliance with ISO 9001:2015 standards.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Width Tolerance | ±0.05 mm | ±0.1 mm |

| Edge Burr | <5 μm | 10–20 μm |

| Tensile Strength Consistency | ±2% | ±5% |

| Surface Roughness (Ra) | ≤0.2 μm | ≤0.5 μm |

| Flatness | ≤0.1 mm/m | ≤0.3 mm/m |

All protocols exceed ASTM B170 and IEC 60404-8-5 standards. Every coil includes full traceability via digital quality logs—unlike generic suppliers’ spot checks.

Our 20+ years of expertise delivers transformer-grade copper strips with 15–20% lower costs than global brands like Schoeller or Mitsubishi, without compromising on performance or reliability. This cost-performance advantage makes us the preferred sourcing partner for engineers prioritizing long-term operational efficiency.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Copper Coils

Luoyang Xinzhaohe’s copper coil packaging adheres to ISO 1461 and ASTM B117 standards for marine corrosion resistance. Each coil undergoes a three-layer protection process: vacuum-sealed desiccant bags (50g/m² silica gel), 200μm PE moisture barrier, and anti-slip rubber mats (5mm thickness, 100% natural rubber) between pallets. Wooden pallets are ISPM-15 certified (heat-treated to 56°C for 30 mins), 1200×1000×150mm dimensions with 25mm thick planks, ensuring structural integrity during forklift handling. Steel strapping (19mm width × 0.5mm thickness) is tensioned to 2000kg per strap per ISO 13372, with HDPE corner protectors (50×50×3mm) to prevent edge damage. The entire pallet is shrink-wrapped with 3-layer PE film for additional moisture and impact resistance. This protocol reduces oxidation risk by 95% versus industry-standard packaging, validated through salt spray testing (ASTM B117) and real-world transit data across 15+ countries.

Precision Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallet | ISPM-15 certified, 1200×1000×150mm, 25mm thickness | Prevents ground moisture, ensures stability during handling and transit |

| Moisture-Proof Film | 200μm PE + silica gel desiccant (50g/m²) | Creates vapor barrier, absorbs residual moisture, prevents oxidation |

| Steel Strapping | 19mm width × 0.5mm thickness, 2000kg tension | Secures coil to pallet, prevents shifting, meets ISO 13372 standards |

| Corner Protectors | HDPE 50×50mm, 3mm thickness | Distributes load stress, prevents edge damage during transit |

| Shrink Wrap | 3-layer PE film, 150μm thickness | Additional moisture and impact protection, secures entire pallet |

End-to-End Logistics Protocol

We manage full container load (FCL) and less-than-container load (LCL) shipments via partnerships with Maersk, COSCO, and MSC. Shipment routes from Qingdao/Lianyungang ports to global hubs are optimized for minimal transit time, with average sea freight duration of 15–30 days depending on destination. Each shipment includes real-time GPS tracking, temperature/humidity logs, and pre-shipment container inspections per ISO 1496. Our China-based logistics team handles customs clearance documentation (CIQ, COO, B/L) with 100% accuracy, reducing port delays by 40%. With 20+ years of global export experience, we maintain a 99.8% on-time delivery rate and <0.3% damage rate—70% lower than the industry average of 2–3%. All shipments comply with destination-specific regulations (EU REACH, US FDA), ensuring seamless customs clearance. This precision eliminates rework costs, delivering transformer manufacturers superior cost-performance versus premium global brands while guaranteeing coil readiness for immediate production.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd?

20+ Years of Specialized Manufacturing Expertise

With over two decades of focused production in transformer-grade copper and aluminum materials, Luoyang Xinzhaohe delivers precision-engineered solutions tailored for power equipment applications. Our metallurgical team optimizes alloy compositions (e.g., C11000, C10200) to meet IEC 60076 and ASTM B152 standards, ensuring consistent electrical conductivity (≥100% IACS) and mechanical properties critical for transformer windings. This deep industry knowledge minimizes field failures and extends service life, providing engineers with reliable, high-performance materials.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups and import layer costs, delivering 15–25% lower pricing than global competitors without compromising quality. Our in-house rolling mills and continuous casting processes enable rapid response to volume fluctuations, ensuring supply chain stability and reduced total cost of ownership (TCO) for high-volume transformer manufacturers. Every coil is produced with strict dimensional tolerances (±0.01mm), maintaining performance consistency across large orders.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified facility implements rigorous quality controls, including 100% thickness measurement, surface defect inspection, and electrical conductivity testing. Each batch receives a detailed Certificate of Analysis (COA) with traceable material data, ensuring compliance with international standards. Unlike inconsistent offshore suppliers, our standardized processes guarantee zero-defect delivery for critical power components.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost Structure | High (incl. import duties, markups) | Direct factory pricing | 15–25% savings |

| Lead Time | 8–12 weeks | 4–6 weeks | 50% faster delivery |

| Customization | Limited flexibility | Full alloy/size specifications | Tailored engineering solutions |

| Quality Consistency | Variable across suppliers | ISO 9001 + in-line testing | Consistent performance metrics |

Your Technical Partner for Transformer Success

For engineers prioritizing reliability and value, Luoyang Xinzhaohe provides the ideal balance of technical expertise and cost efficiency. We specialize in high-purity copper coils for transformers, motors, and power systems, with on-time delivery and responsive engineering support. Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 100 copper coil from Luoyang Xinzhaohe.