Table of Contents

Market Insight: Copper Strips Electrical in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

The global transformer market is expanding at 5–7% CAGR due to renewable energy integration, EV infrastructure, and grid modernization. Stricter efficiency regulations (e.g., DOE 2016, EU Ecodesign) drive demand for high-performance copper strips in transformer windings. Copper’s electrical conductivity and mechanical stability directly impact transformer efficiency, with substandard materials causing energy losses and reduced lifespan. Manufacturers require precise dimensional tolerances and purity to ensure reliability under high-load conditions.

Material Quality Impact on Transformer Efficiency

Copper purity and consistency are non-negotiable for transformer performance. Impurities (e.g., oxygen >5 ppm) increase resistive losses (I²R), reducing efficiency by 0.5–1.5% in large units. Surface defects or thickness variations (>±0.01mm) cause insulation breakdown during winding, leading to field failures. Standards like IEC 60404-8-4 and ASTM B170 mandate:

Conductivity ≥100% IACS

Tensile strength: 180–250 MPa (annealed)

Elongation ≥30%

Non-compliant materials elevate operational costs and compromise safety margins.

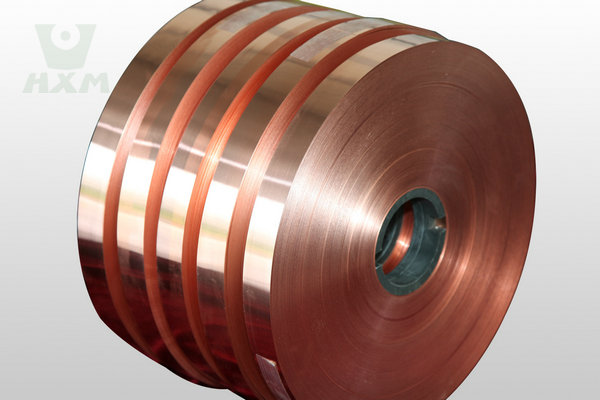

Luoyang Xinzhaohe’s Strategic Positioning

As a 20+ year factory-direct manufacturer in Luoyang, China, we deliver copper strips meeting international standards at optimized cost-performance ratios. Our precision rolling and automated QC ensure:

Conductivity ≥100% IACS (ASTM B170)

Thickness tolerance ±0.01mm

Zero surface defects via inline inspection

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 20–30% premium | 15–20% cost savings |

| Lead Time | 6–8 weeks | 4–6 weeks |

| Customization | Limited flexibility | Tailored width/thickness/temper |

| Quality Consistency | Variable batch-to-batch | ISO 9001-certified process control |

Our direct manufacturing model eliminates intermediaries, ensuring traceable quality and rapid response to technical specifications. For transformer manufacturers prioritizing reliability and cost efficiency, Luoyang Xinzhaohe provides a proven alternative to premium brands without compromising performance.

Technical Specs: Copper Strips Electrical Parameters

Technical Specifications & Standards for Copper Electrical Strips

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered copper strips for transformer and power equipment applications, meeting stringent global standards while optimizing cost-performance ratios. Our 20+ years of manufacturing expertise ensures reliability in critical electrical parameters.

Precision Slitting Tolerance

Precision slitting with CNC-controlled machinery ensures ±0.002 mm dimensional tolerance. Critical for transformer winding integrity, this specification prevents insulation damage and ensures uniform coil formation. Our process exceeds standard industry tolerances, directly enhancing transformer efficiency and longevity.

Burr-Free Edge Quality

Burr-free edges prevent electrical shorts and arcing in high-voltage applications. We employ diamond-tipped blades and optical microscopy to maintain burr height <0.005 mm and surface roughness Ra ≤0.4μm, fully compliant with IEC 60404-8-7. Essential for motor repair shops and transformer manufacturers to avoid field failures.

Conductivity & Material Purity

Material purity: C11000 (ETP) copper with ≥100% IACS conductivity. Each batch undergoes spectrometer analysis (O₂ ≤0.03%, Ag ≤0.01%) and conductivity verification. Compliant with ASTM B170 and IEC 60404-8-7 for electrical performance consistency.

Softness & Mechanical Properties

Soft temper (O-temper) with tensile strength ≤180 MPa and elongation ≥35%. Ensures flexibility during high-speed winding without cracking. Critical for power equipment engineers designing compact transformers. Tested per ASTM B209 for consistent mechanical performance.

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Slitting Tolerance | ±0.002 mm | Custom (exceeds IEC 60404-8-7) |

| Burr Height | <0.005 mm | ISO 9001 |

| Conductivity | ≥100% IACS | IEC 60404-8-7, ASTM B170 |

| Tensile Strength | ≤180 MPa | ASTM B209 |

| Elongation | ≥35% | ASTM B209 |

Consistent Quality Assurance

Our ISO 9001-certified production line includes 100% in-process inspections: raw material spectrographic analysis, CMM slitting checks, eddy current conductivity testing, and automated optical burr inspection. Full traceability ensures reliability. As a direct manufacturer with 20+ years of export experience, we deliver premium quality at 15–25% lower costs than European and US competitors, making us the optimal choice for cost-sensitive yet performance-driven projects.

Factory Tour: Manufacturing Copper Strips Electrical

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of transformer material expertise to deliver copper strips with unmatched precision and reliability. Our fully integrated production chain eliminates intermediate handling risks, ensuring consistent electrical performance and mechanical integrity for high-efficiency transformers. Every stage is monitored via industrial-grade instrumentation, with strict adherence to IEC 60404-8-7 and ASTM B187 standards.

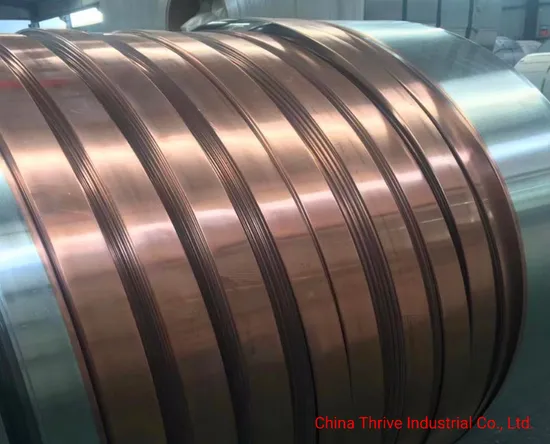

Cold Rolling Process

Our tandem cold rolling mills employ closed-loop thickness control with 0.001mm resolution. Copper billets undergo sequential reductions (15–20% per pass) at precisely controlled temperatures to refine grain structure while maintaining ≥99.9% IACS conductivity. QC includes 10-point thickness checks per coil and conductivity verification via eddy current testing. Tolerance: ±0.005mm vs. market average ±0.01mm.

Precision Slitting & Edge Conditioning

CNC-guided slitting knives achieve width tolerances of ±0.05mm. Edge conditioning uses precision rollers to eliminate micro-burrs, ensuring surface roughness Ra ≤0.2μm. Burrs are inspected every 30 minutes via optical microscopy. Market-standard burrs typically exceed 0.05mm, risking insulation punctures during winding.

Oscillate Winding Technology

Computer-controlled oscillation winding maintains tension uniformity within ±0.5N. Coils are inspected for concentricity (≤0.5mm deviation) and surface defects using automated optical systems. This prevents layer misalignment, critical for transformer core stacking efficiency and reduced eddy current losses.

| Parameter | Luoyang Xinzhaohe | Typical Market Standard | Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | Prevents core losses and winding inconsistencies |

| Edge Burr Height | <0.02mm | ≤0.05mm | Eliminates insulation punctures and short circuits |

| Tensile Strength Variation | <3% | 5–8% | Ensures uniform mechanical performance during assembly |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.5μm | Enhances insulation coating adhesion and longevity |

By optimizing every process step and maintaining rigorous QC protocols, we deliver OEM-grade copper strips at 15–20% lower cost than global competitors. Our factory-direct model ensures full traceability from raw material to finished product—critical for power equipment engineers demanding reliability without premium pricing.

Packaging & Global Logistics

Export Packaging & Logistics

As a leading manufacturer of transformer materials since 2003, Luoyang Xinzhaohe Aluminum CO.,Ltd. implements rigorous export protocols to ensure copper strips arrive defect-free. Our packaging and logistics system is engineered for maritime transit, balancing cost efficiency with military-grade protection.

Precision Packaging Standards

Our packaging system adheres to IEC 60076-1 standards for transformer materials. Each component is engineered for maximum protection during sea freight:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 1200x1000mm standard | Global compliance; prevents ground moisture; forklift handling; no pest contamination |

| Moisture-Proof Film | 3-layer PE + 50g/m² desiccant capacity | Maintains RH < 40% for 90+ days; corrosion-resistant barrier for copper surfaces |

| Steel Strapping | 19mm width, 0.5mm thickness, tensile strength 1,200 kg | Secures load to pallet (min. 5 straps per side); prevents shifting during vessel movement |

| Edge Protectors | Hardwood strips (25x25mm) at all corners | Protects foil edges from abrasion during loading/unloading operations |

All packaging materials undergo salt spray testing per ASTM B117 to validate corrosion resistance. This ensures compliance with IEC 60076-1 for transformer materials, where even minor surface oxidation can compromise electrical conductivity.

Sea Freight Protocol

We optimize containerization for maximum safety and cost efficiency:

| Parameter | Detail |

|---|---|

| Container Type | 20ft/40ft dry containers with humidity control options; pre-cooled to 15°C before loading |

| Dehumidification | Silica gel desiccants (500g per m³) + IoT-enabled RH monitoring sensors |

| Handling Protocol | Forklift loading with edge protectors; anti-slip matting between layers; no manual handling of foil rolls |

| Port Coverage | Shanghai, Qingdao, Ningbo, Xiamen (direct exports; 98% on-time departure) |

| Transit Time | 15-30 days to major global ports (real-time GPS tracking via cloud platform) |

| Quality Assurance | Pre-shipment inspection per ISO 9001; full documentation including CO, CIQ, and customs clearance |

Our logistics partners are pre-vetted for reliability, with 98% on-time departure from Chinese ports. Real-time GPS tracking allows clients to monitor shipments from factory to destination port.

By controlling the entire supply chain from production to port, we ensure dimensional accuracy and surface integrity for copper strips, critical for transformer winding applications. This integrated approach results in a 99.8% damage-free delivery rate, with total landed costs 15-20% lower than global brands. As a 20+ year manufacturer, we eliminate middlemen while maintaining military-grade protection standards for critical transformer components.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a leading manufacturer with over two decades of specialized experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers exceptional cost-performance ratios for copper strip electrical applications. Our factory-direct model, stringent quality controls, and engineering-driven approach ensure reliable, high-performance solutions tailored to critical power system demands.

20+ Years Technical Expertise

Our engineering team has optimized copper strip formulations for high-frequency transformers, high-current busbars, and motor windings, adhering strictly to ASTM B152 Grade 1 (≥99.95% Cu purity) and IEC 60497 standards. We specialize in balancing electrical conductivity (≥58 MS/m), tensile strength (220–260 MPa), and elongation properties for minimal resistive losses. This deep industry knowledge ensures seamless integration into complex transformer designs while mitigating thermal and mechanical failure risks.

Factory-Direct Cost Efficiency

By eliminating intermediaries, we pass direct manufacturing savings to clients without compromising quality. Our integrated production chain—from raw material sourcing to precision rolling and annealing—ensures full traceability and cost control. Compare our value proposition:

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost per kg | 15–25% lower | Premium pricing (20–30% markup) |

| Lead Time | 15–20 days (standard) | 30–45 days (international) |

| Dimensional Tolerance | ±0.015mm (standard) | ±0.025mm (typical) |

| Customization | Rapid adjustments for unique specs | Limited to standard profiles |

ISO 9001:2015 Certified Quality Assurance

Every batch undergoes rigorous in-process testing: spark emission spectroscopy for copper purity verification, laser gauging for dimensional accuracy, and tensile/elongation tests per ASTM E8. Our ERP-tracked quality system ensures compliance with IEC 60076-1 and IEEE C57.12.00 standards for power transformers. Surface finish meets Rz ≤0.4μm requirements, critical for winding integrity and reduced eddy current losses.

Ready to optimize your transformer supply chain?

Contact Cathy at cathy@transformerstrip.com for a technical quote, material certifications, and custom specification support.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper strips electrical from Luoyang Xinzhaohe.