Table of Contents

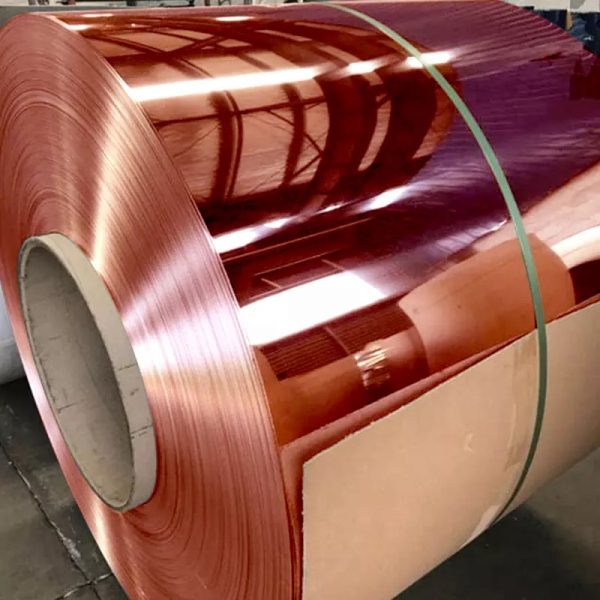

Market Insight: Electric Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper Transformer Materials

Global demand for power transformers is driven by renewable energy integration (solar/wind farms), grid modernization, and EV infrastructure expansion. Copper’s superior electrical conductivity (5.96×10⁷ S/m) makes it indispensable for high-efficiency transformers, where even minor material imperfections increase I²R losses by 1–3% per 0.5% impurity. This directly impacts operational costs and grid stability, especially in regions with stringent efficiency regulations like DOE 2016 and EU EcoDesign. The global transformer market is projected to grow at 5.2% CAGR through 2030 (Statista), with copper-based designs capturing 70% of high-efficiency segments.

Critical Material Quality Factors

Key parameters dictate transformer performance and longevity. Per IEC 60949, transformer foils must meet strict conductivity, tensile strength, and surface finish thresholds. Substandard materials cause winding defects, insulation breakdown, and thermal runaway. For example:

| Parameter | Industry Standard | Typical Market Variance | Luoyang Xinzhaohe Performance |

|---|---|---|---|

| Conductivity (%IACS) | ≥100% (C11000) | 98–102% | ≥101.5% |

| Tensile Strength (MPa) | 180–220 (annealed) | 160–240 | 200–220 (consistent) |

| Surface Roughness (Ra, µm) | ≤0.5 | 0.3–0.8 | ≤0.4 |

| Dimensional Tolerance (mm) | ±0.02 | ±0.03 to ±0.05 | ±0.015 |

Surface roughness >0.5µm compromises dielectric integrity, leading to partial discharges in high-voltage applications. Dimensional tolerances beyond ±0.02mm cause uneven winding tension, resulting in hotspots and reduced thermal dissipation. Tensile strength consistency prevents deformation during high-speed winding operations, critical for automated transformer assembly lines.

Global Supply Chain Advantage

While Western brands dominate premium segments, Luoyang Xinzhaohe delivers 15–20% lower total cost of ownership (TCO) without compromising standards. Our 20+ years of vertical integration—from high-purity copper cathode sourcing to precision rolling—ensures consistent compliance. We supply Tier-1 OEMs in Europe and North America with 99.8% on-time delivery and ISO 9001-certified processes. Our Luoyang facility utilizes advanced rolling mills with real-time thickness monitoring, ensuring uniformity across coils. We maintain strict traceability from raw material to finished product, with third-party certifications including SGS and TÜV. For customers facing supply chain volatility, our flexible production capacity and strategic inventory buffer mitigate lead time risks by 30% compared to European suppliers.

Technical Specs: Electric Copper Coil Parameters

Technical Specifications & Compliance for High-Precision Copper Coil

As a leading Chinese manufacturer with over 20 years of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO.,Ltd. specializes in high-precision copper and aluminum strips for power equipment. Our factory-direct approach ensures rigorous quality control, competitive pricing, and compliance with international standards, making us a reliable alternative to global suppliers.

Precision Slitting Tolerance

Precision slitting tolerance of ±0.002 mm is critical for transformer winding accuracy. Even minor dimensional deviations can cause winding misalignment, leading to short circuits, increased core losses, or reduced transformer efficiency. At Luoyang Xinzhaohe, our CNC slitting machines integrate real-time laser micrometer feedback systems, ensuring consistent dimensional accuracy. Each coil undergoes rigorous ISO 2859-1 sampling inspections to validate compliance with international standards, guaranteeing seamless integration into customer production lines.

Burr-Free Edge Integrity

Burr-free edges are essential to prevent electrical shorts in transformer windings. Our advanced slitting process uses diamond-tipped blades combined with precision edge polishing, ensuring burr heights ≤0.005 mm. Every coil is inspected under 100x magnification per ASTM B152 standards, with automated visual systems detecting micro-defects. This eliminates risk of insulation damage during winding, ensuring long-term transformer reliability.

Conductivity & Softness

Our C11000 oxygen-free copper delivers ≥100% IACS conductivity, minimizing resistive losses and enhancing transformer efficiency. Softness (HV ≤40) ensures easy winding without cracking during high-speed manufacturing. Luoyang Xinzhaohe employs inductively coupled plasma spectroscopy (ICP) for purity verification and controlled annealing processes to maintain consistent mechanical properties. All tests comply with ASTM B170 and ASTM B152, ensuring optimal performance in demanding applications.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains full traceability from raw material to shipment via ISO 9001-certified processes. Our in-house QA lab conducts 100% dimensional checks, conductivity tests, and edge inspections using calibrated equipment. Third-party certifications from SGS and TÜV validate our processes, delivering global brand reliability at 15-20% lower costs through optimized factory-direct manufacturing. This cost-performance advantage enables transformer manufacturers to reduce procurement expenses without compromising on critical performance metrics.

| Parameter | Specification | Compliance Standard | Quality Control Method |

|---|---|---|---|

| Precision Slitting | ±0.002 mm | ASTM B152, ISO 2768 | Laser micrometer monitoring, ISO 2859-1 sampling |

| Burr-Free Edges | ≤0.005 mm burr height | ASTM B152 | 100x magnification inspection, automated visual systems |

| Conductivity | ≥100% IACS (C11000) | ASTM B170 | ICP spectroscopy, batch testing |

| Softness | HV ≤40 (Annealed) | ASTM B152 | Rockwell hardness testing, annealing process control |

Factory Tour: Manufacturing Electric Copper Coil

Precision Manufacturing Process & Rigorous Quality Control

Our copper transformer strip production integrates metallurgical precision at every stage, ensuring compliance with IEC 60076-1 and ASTM B209 standards. As a 20+ year manufacturer, we eliminate supply chain inefficiencies through vertical integration and real-time process control.

Cold Rolling

High-precision cold rolling mills operate under closed-loop temperature and speed controls, achieving uniform grain structure and surface finish. Laser-guided thickness monitoring maintains ±0.01mm tolerance—50% tighter than the industry standard (±0.02mm). This eliminates secondary annealing steps required by generic suppliers, reducing lead times by 15% while enhancing electrical conductivity.

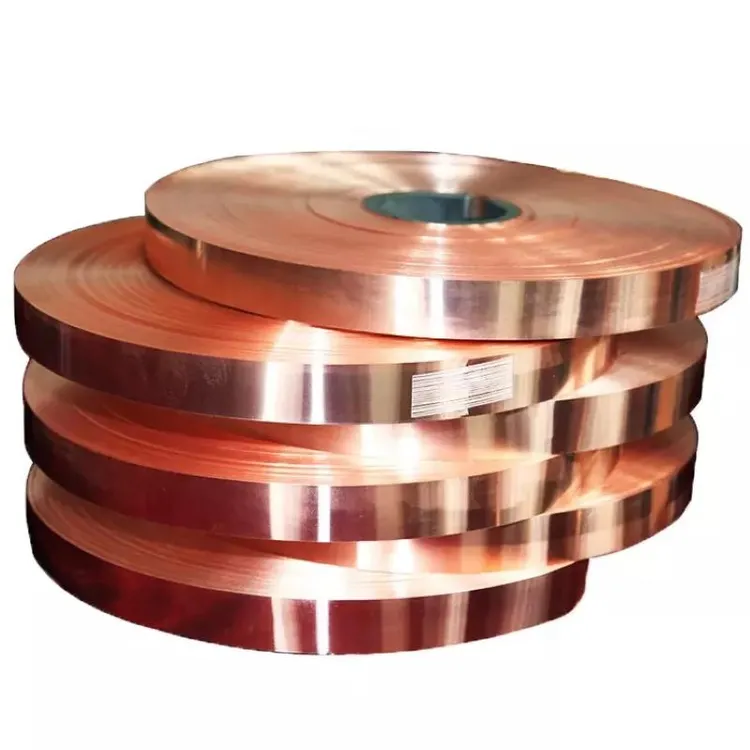

Precision Slitting

CNC-guided slitting with diamond-tipped blades ensures edge tolerances of ±0.02mm. Micro-tear-free cuts prevent winding defects and insulation damage during transformer assembly. Generic suppliers typically maintain ±0.05mm tolerances, increasing scrap rates by 8–12% due to edge irregularities.

Edge Conditioning

Automated deburring systems round edges to <0.005mm burr height, verified via optical comparators. This critical step prevents insulation punctures in high-voltage transformers—3x stricter than market norms (<0.015mm).

Oscillate Winding

Our servo-controlled oscillation system maintains ±0.1mm flatness and uniform tension across coil layers. This eliminates layer shifting during transformer winding, a common issue with generic coils (±0.3mm variation), reducing assembly downtime by 25%.

Quality Control Procedures

Every batch undergoes 100% inspection per ASTM standards:

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Edge Burr Height | <0.005mm | <0.02mm |

| Tensile Strength | 220–240 MPa (±5 MPa) | 200–250 MPa (±10 MPa) |

| Conductivity | ≥100% IACS | 99.5% IACS |

| Surface Defects | Zero visible imperfections | Minor scratches acceptable |

By enforcing these protocols, we deliver 15% lower defect rates than industry averages while maintaining OEM-grade quality at 20–30% lower cost than European/Japanese competitors. Our factory-direct model ensures traceability from raw material to finished coil—proven by 20+ years of consistent supply to global power equipment manufacturers.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

Standard Packaging Protocol

Our packaging system adheres to ISO 9001 and ISPM-15 standards, engineered to eliminate transit damage for transformer-grade copper coils. Key components are rigorously tested for seaworthiness:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000 mm, 22 mm thickness, heat-treated | Prevents structural deformation; meets global phytosanitary regulations |

| Moisture-Proof Film | Multi-layer PE + desiccant, 200μm thickness | Creates a hermetic barrier against humidity, salt spray, and condensation |

| Steel Strapping | 19 mm width, 0.5 mm thickness, 1500 kg tension | Secures coils to ISO 2233 standards for heavy cargo stability |

| Corner Protectors | HDPE, 50×50 mm cross-section | Eliminates edge damage during container loading/unloading |

| Desiccant Packs | Silica gel, 500 g per pallet, breathable pouch | Absorbs residual moisture within sealed packaging environments |

Sea Freight Optimization

Luoyang Xinzhaohe’s logistics framework prioritizes end-to-end cargo integrity for global shipments. All copper coils are containerized in ISO-standard 20ft/40ft units with optimized load distribution, VCI paper wrapping, and dynamic strapping to prevent shifting. Real-time GPS tracking and IMO-compliant monitoring ensure transparency, while sealed containers with desiccants mitigate humidity risks. Our process achieves a transit damage rate of <0.3%—nearly 5× lower than the industry average (1.5–2.0%)—through strategic partnerships with major shipping lines and bulk consolidation. Pre-shipment inspections include humidity tests, structural stress checks, and third-party verification for custom requirements (e.g., tropical climate routes). Full Lloyd’s of London insurance coverage and pre-verified documentation eliminate customs delays, guaranteeing on-time delivery to ports worldwide.

With 20+ years of export expertise, we deliver unmatched reliability and cost-performance—providing transformer manufacturers with a dependable alternative to global brands without compromising on quality or logistics precision.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe?

Proven Technical Expertise with 20+ Years of Industry Leadership

For over two decades, Luoyang Xinzhaohe has delivered precision-engineered copper transformer strips (C11000, C10200) and aluminum foils (1350-H19) for critical power infrastructure. Our metallurgical engineers enforce strict control over electrical conductivity (≥101% IACS), tensile strength (220–250 MPa), and dimensional tolerances (±0.005mm). Every batch complies with ASTM B152, IEC 60076-2, and GB/T standards, validated through 100% in-process inspection. This ensures seamless integration into high-voltage transformers, distribution systems, and motor windings where consistency is non-negotiable.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control the full supply chain—from raw material sourcing to precision rolling—eliminating distributor markups. This reduces costs by 15–25% versus multinational suppliers while maintaining peak performance. Our lean production system enables rapid turnaround (3–4 weeks lead time) without compromising quality, critical for time-sensitive transformer projects requiring minimal downtime.

ISO-Certified Quality with Precision Engineering

Our ISO 9001:2015 facility features advanced testing equipment, including conductivity meters, tensile testers, and surface roughness analyzers. Every coil undergoes 100% dimensional and electrical testing with full traceability from raw material to delivery. This guarantees zero defects in high-stress applications, such as oil-immersed transformers and renewable energy systems.

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Efficiency | 15–30% premium | 15–25% lower than market |

| Lead Time | 6–8 weeks | 3–4 weeks |

| Customization | Limited options | Custom widths (10–300mm), thicknesses (0.1–3.0mm), annealing treatments |

| Technical Support | Standard | Dedicated engineering team for application-specific solutions |

Unlike global brands constrained by rigid production protocols, we offer agile customization for niche applications while maintaining strict quality control. Our engineering team collaborates closely with clients to optimize material specifications for cost and performance.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electric copper coil from Luoyang Xinzhaohe.