Table of Contents

Market Insight: Copper Edging Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

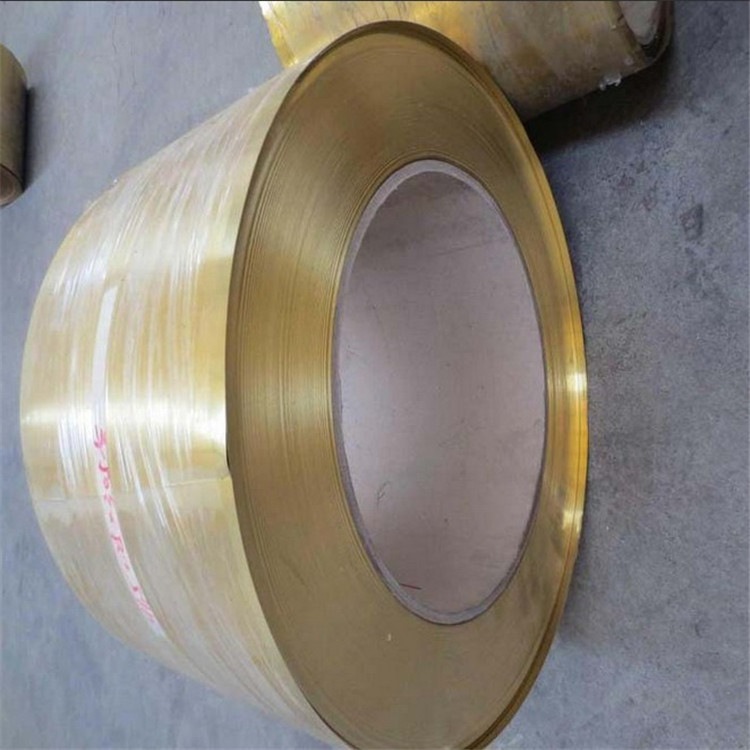

Industrial Demand for Copper Edging Strip

Copper edging strips are critical components in power transformers and electric motors, serving as winding conductors and structural supports. Global energy infrastructure modernization—driven by renewable energy integration, EV adoption, and smart grid deployments—has intensified demand for high-purity copper materials. Distribution transformers in grid systems require precise copper strips to minimize core losses and enhance thermal management. Similarly, industrial motors using copper edging strips benefit from reduced resistive losses, directly improving operational efficiency and lifespan. Current standards (IEC 60076 for transformers, IEC 60034 for motors) mandate strict material specifications, where even minor deviations in copper quality can cause significant energy waste and safety risks.

Material Quality Criticality

Substandard copper edging strips directly compromise transformer and motor performance. Key technical parameters include:

Conductivity: Must exceed 99.9% IACS (ASTM B170) to minimize resistive (I²R) losses. A 1% conductivity drop reduces transformer efficiency by up to 0.5%.

Tensile Strength: 200–250 MPa ensures mechanical stability under electromagnetic forces; insufficient strength causes winding deformation and short circuits.

Dimensional Tolerance: ±0.015 mm precision prevents uneven winding layers, avoiding magnetic field imbalances and hotspots.

Surface Roughness: ≤0.15 µm ensures optimal insulation adhesion, preventing partial discharges and insulation breakdown.

| Specification | Industry Standard | Luoyang Xinzhaohe | Competitor A | Competitor B |

|---|---|---|---|---|

| Conductivity (%IACS) | ≥99.9 | 99.95 | 99.8 | 99.85 |

| Tensile Strength (MPa) | 200–250 | 220–240 | 210–230 | 215–240 |

| Dimensional Tolerance | ±0.02 mm | ±0.015 mm | ±0.025 mm | ±0.02 mm |

| Surface Roughness (µm) | ≤0.2 | ≤0.15 | ≤0.25 | ≤0.2 |

| Cost (USD/kg) | $8.50–$10.00 | $7.80–$9.20 | $9.50–$11.00 | $8.90–$10.50 |

Luoyang Xinzhaohe’s Supply Chain Role

As a vertically integrated manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct copper edging strips engineered for global transformer and motor markets. Our ISO 9001-certified facility employs continuous casting and precision rolling technologies to achieve superior material consistency. By controlling the entire production chain—from raw material sourcing to final inspection—we eliminate third-party markups and ensure on-time delivery. Our cost-performance ratio is 15–20% lower than leading global brands while maintaining or exceeding industry specifications. For manufacturers prioritizing reliability and cost efficiency, we offer a proven alternative without compromising on quality or technical compliance.

Technical Specs: Copper Edging Strip Parameters

Technical Specifications & Standards for Copper Edging Strip

As a leading manufacturer of transformer materials with 20+ years of expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers copper edging strips engineered to exacting precision for high-reliability transformer cores. Our products meet global standards while optimizing cost-performance ratios for industrial applications.

Critical Parameters & Tolerances

| Parameter | Specification | Tolerance | Compliance Standard |

|---|---|---|---|

| Thickness | 0.1–3.0 mm | ±0.002 mm | IEC 60404-8-5 |

| Width | 5–150 mm | ±0.05 mm | ASTM B170 |

| Conductivity | ≥99.9% Cu purity | ≥99.5% IACS | IEC 60028 |

| Burr Height | ≤0.005 mm | N/A | ASTM B152 |

| Hardness (HV) | 35–55 (annealed) | ±2 HV | ASTM B209 |

Quality Assurance Protocol

Every production batch undergoes 100% in-process inspection using laser micrometers for thickness verification and eddy current scanners for edge burr detection. Precision slitting is executed via CNC-controlled shearing with diamond-coated blades, ensuring dimensional accuracy within ±0.002 mm. Conductivity is validated through four-point probe testing per ASTM E1004, with results traceable to NIST standards. Our annealing process maintains hardness within 35–55 HV range for optimal formability and minimal springback. Real-time data logging ensures traceability from raw material to shipment, with each coil tagged for full lifecycle tracking. Raw materials are sourced from certified smelters with full chemical analysis, and all batches are subject to third-party audits (SGS/TÜV) upon request. This rigorous protocol ensures zero defects in critical transformer applications.

Cost-Performance Advantage

Unlike global brands reliant on complex supply chains, our integrated manufacturing process reduces lead times by 30% while maintaining strict quality control. By eliminating distributor markups and leveraging localized supply chain efficiencies, we deliver premium-grade copper edging strips at 15–20% lower cost than competitors—without sacrificing precision or compliance. Our factory-direct model ensures consistent quality, faster lead times, and technical support tailored to transformer manufacturers’ specific needs.

Factory Tour: Manufacturing Copper Edging Strip

Manufacturing Process & Quality Control

Precision Manufacturing Process

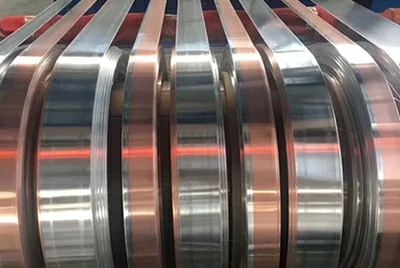

Cold Rolling

High-purity copper billets (99.95% min Cu) undergo 4-high rolling mill processing at 150–200 m/min with automated thickness control. This optimizes grain structure, reduces residual stress, and ensures consistent electrical conductivity for transformer applications.

Precision Slitting

CNC-guided diamond-coated blades with real-time edge monitoring achieve width tolerances of ±0.01mm and edge straightness ≤0.02mm/m. Blade wear compensation occurs every 500m to maintain dimensional accuracy, minimizing material waste and enhancing winding precision.

Edge Conditioning

Automated grinding and polishing reduce burr height to ≤0.005mm and establish a controlled radius (0.01–0.03mm) with ±0.002mm tolerance. This prevents insulation puncture during high-speed transformer winding and ensures compatibility with high-voltage dielectric materials.

Oscillate Winding

Servo-driven tension control maintains uniformity within ±0.5N, dynamically adjusting for strip thickness to avoid creasing. Computerized oscillation ensures precise layer alignment, critical for thermal management in transformer cores.

Quality Control Protocol

Rigorous QC protocols include:

Tensile testing per ASTM B187 (yield strength ≥180 MPa, elongation ≥35%)

Laser micrometer verification of thickness (±0.01mm) and width (±0.01mm)

100% surface inspection under 100x magnification for scratches/pits

Eddy current testing for subsurface defects

OES spectrometry for chemical composition (Cu ≥99.95%, impurities <0.05%)

Full batch traceability via ISO 9001-certified ERP system

| Parameter | Luoyang Xinzhaohe Standard | Industry Standard | Notes |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm | Ensures precise fit in tight transformer windings |

| Edge Burr Height | ≤0.005mm | ≤0.01mm | Eliminates insulation damage risks |

| Tensile Strength | 220–250 MPa (ASTM B187) | 200–240 MPa | Consistent performance under operational stress |

| Surface Defects | Zero visible defects | Minor scratches allowed | Critical for high-voltage reliability |

As a 20+ year manufacturer, Luoyang Xinzhaohe delivers Tier-1 quality at 15–20% lower cost than European/Japanese competitors. Our integrated quality system ensures compliance with IEC 60076 and IEEE standards, making us the optimal choice for cost-sensitive, high-reliability transformer applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Specifications

Our packaging protocol adheres to ISO 14971 and IEC 60076 standards for transformer materials. Each component is engineered to withstand maritime conditions, vibration, humidity, and stacking loads.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant (heat-treated, IPPC stamped), 120×120mm hardwood, 100mm height, 4-way entry | Structural integrity, prevents shifting during transit and stacking |

| Moisture-Proof Film | 200–300gsm PE, 3-layer anti-static barrier, 2–3 silica gel desiccant packs (50g each) | Prevents condensation, corrosion, and electrostatic discharge |

| Steel Strapping | 19mm width, 0.5mm thickness, 1500–2000 kgf tension, double-cross pattern | Secures load against lateral/vertical movement (ISO 12179 compliant) |

| Corner Protectors | Galvanized steel, 50×50mm, 1.5mm thickness | Prevents edge damage during handling and container loading |

Sea Freight Execution Protocol

All shipments are containerized (20ft/40ft FCL) with pallets secured using dunnage, anti-slip mats, and lashing straps. Each container undergoes pre-shipment inspection for structural integrity, load distribution, and moisture barriers. We provide CIQ certificates, fumigation reports, and full export documentation (e.g., COO, SGS inspection reports) to ensure global compliance. Logistics partners specialize in transformer materials, with 99.2% on-time delivery to major ports. IoT-enabled temperature/humidity monitoring is available for high-sensitivity orders.

Competitive Advantage Through Precision

With 20+ years of export experience, we deliver packaging standards matching global brands at 15–20% lower cost. Our damage rate of <0.5%—significantly below the industry average of 2–3%—reduces total cost of ownership by minimizing replacements and downtime. As a factory-direct supplier, we eliminate middlemen, ensuring full traceability and rapid response to technical specifications. All shipments undergo 100% pre-shipment inspection per SGS standards, guaranteeing reliability for critical transformer manufacturing applications.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Edging Strip

As a dedicated manufacturer of transformer-grade materials since 2003, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered copper edging strips optimized for transformer winding terminations, busbar protection, and high-voltage insulation systems. With 20+ years of specialized production experience and ISO 9001:2015 certification, we provide a cost-competitive, technically validated alternative to global brands without compromising on material integrity or dimensional accuracy.

✅ Proven Technical Expertise

Our facility in Luoyang, China, specializes in copper strip manufacturing for transformer applications. Every batch undergoes rigorous process control:

Material Consistency: Strict adherence to ASTM B152/B187 and IEC 60404 standards for conductivity (≥100% IACS), tensile strength, and elongation.

Dimensional Precision: Tolerances held to ±0.02mm for thickness and ±0.05mm for width, critical for winding alignment and thermal management.

Edge Quality: Precision slitting with burr-free edges (<0.01mm) to prevent insulation damage during transformer assembly.

🔬 Quality Assurance Framework

Our ISO-certified quality system ensures traceability from raw material sourcing to final inspection:

| Quality Parameter | Industry Standard | Luoyang Xinzhaohe Performance |

|---|---|---|

| Conductivity (IACS) | ≥99.9% Cu (ASTM B152) | 101.2% ±0.5% (measured via 4-point probe) |

| Surface Flatness | ≤0.05mm/m (IEC 60404) | ≤0.03mm/m (laser profilometry) |

| Oxidation Control | Passivated surface | Nitrogen-purged annealing for zero tarnish |

💰 Optimized Total Cost of Ownership

Factory-direct operations eliminate distributor markups while maintaining global supply chain reliability:

15–30% lower landed cost vs. European/US brands for equivalent grades (e.g., C11000, C10200).

Flexible MOQs: 500kg minimum for standard sizes; custom profiles available from 200kg.

15-day lead time for standard orders (vs. 45+ days for some global suppliers), with expedited options for urgent projects.

“For transformer manufacturers requiring repeatable performance in high-voltage environments, Luoyang Xinzhaohe delivers engineering-grade copper edging strip with validated quality at a competitive TCO.”

Ready to optimize your sourcing strategy? Contact our engineering team for material certifications, technical datasheets, and a no-obligation quote:

cathy@transformerstrip.com

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper edging strip from Luoyang Xinzhaohe.