Table of Contents

Market Insight: Transformer Winding Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Power-grid expansion, renewable integration, and EV-charging infrastructure are pushing the transformer market above USD 70 B by 2028. Every MVA of transformer capacity—whether liquid-filled distribution units or dry-type data-center blocks—consumes 6–12 km of enamelled wire. Annual wire demand therefore tracks transformer MVA growth at ~6 % CAGR. China, India, ASEAN, and the EU are the largest net importers of precision winding wire, while North-American OEMs increasingly dual-source to de-risk logistics.

Why Material Purity & Geometry Control Losses

Transformer losses fall into two IEC-60076 classes:

| Loss component | Root cause in winding wire | Typical impact* | Mitigation via wire quality |

|---|---|---|---|

| Load loss (I²R) | Bulk resistivity & conductor cross-section | 60–70 % of total | ≥99.99 % Cu or 99.85 % Al purity, ±0.5 % diameter tolerance to hit design Rdc |

| Eddy-current loss | Strand-to-strand leakage flux | 5–10 % | Uniform enamel 12–35 µm, concentricity ≥85 %, break-down voltage ≥4 kV (VDE 0340) |

| No-load loss (core) | Not wire-related | 25–35 % | — |

| Stray loss | Circulating currents between parallel wires | 3–5 % | Continuous inline resistance sorting (±0.3 %) to balance parallel paths |

*65 kVA, 11/0.4 kV oil-filled distribution transformer, 75 °C rise

1 % increase in conductor resistivity raises load loss by the same 1 %—a hidden life-cycle cost that dwarfs the initial wire saving. Likewise, 10 µm eccentric enamel creates hot-spots 15–20 °C above average, cutting insulation life by half (Arrhenius rule). For large GSU transformers (>100 MVA), the cost of lost energy can exceed USD 2 M over 25 years, justifying premium wire with certified elongation (≥30 % for Cu, ≥15 % for Al) to survive short-circuit forces.

Sourcing Trend: Move to Experienced Chinese Manufacturers

Western enamelled-wire capacity shrank 30 % during 2010-2020; remaining plants focus on niche <0.05 mm or triple-insulated wire, leaving mainstream gauges (0.20–5.00 mm) to Asian specialists. Chinese producers now control 55 % of global output, supported by integrated rod casting, in-line annealing, and AI-driven enameling tunnels. Logistics improvements (China-Europe block train, Yangtze River-to-Pacific ports) cut lead time to 18–22 days FOB, competitive with intra-EU mills.

Luoyang Xinzhaohe Aluminum Co., Ltd.—Factory-Direct Premium Option

Located 350 km west of Shanghai with 20+ years in transformer materials, our 65 000 t/y facility runs the full vertical chain:

- Rod drawing from LME-grade cathode / remelt ingot → 9.5 mm rod

- Multi-pass fine drawing with diamond dies, online eddy-current crack detection

- Inert-gas annealing for grain size 0.015–0.025 mm, yielding elongation ≥32 % (Cu)

- Horizontal enamelling lines (24-position, 280 °C peak) applying polyamide-imide, polyester-imide, or TIW triple layers; concentricity controlled by laser gauge at ±2 µm

- Inline electrical tests: breakdown 6 kV (1 kV/s ramp), pin-hole ≤3/30 m, solderability 380 °C/2 s

We deliver 130 °C (Class B) to 220 °C (Class R) wire on 5–800 kg spools, wooden drums, or PT-25 barrel pack. Typical purity certificates: Cu ≥99.993 %, Al ≥99.85 %, Fe+Si ≤0.06 %, 20 °C resistivity 0.017241 Ω·mm²/m (Cu). All lots carry IEC 60317, UL 1446, and RoHS reports.

Cost advantage: By eliminating traders and utilizing off-peak electricity in Henan Province, we offer CIF prices 12–18 % below German or U.S. mills for equivalent thermal class, while holding ±3 % diameter Cpk ≥1.67—perfect for automated layer winding. For transformer OEMs targeting IEC 60076-20 Tier-2 loss limits, our precision wire translates into 6–8 W/kg core-wire saving, repaying the premium within the first year of operation.

Contact our metallurgy team for sample coils or a joint loss-budget calculation.

Technical Specs: Transformer Winding Wire Parameters

Technical Specifications & ASTM/IEC Compliance

Factory-direct precision from Luoyang Xinzhaohe—20 years of rod-to-spool control.

1. Critical Electrical & Mechanical Parameters

| Parameter | Symbol | ASTM/IEC Reference | Xinzhaohe Process Window | Risk if Out-of-Spec |

|---|---|---|---|---|

| Insulation Breakdown Voltage | Ubd | IEC 60317-0-1 §7 | ≥ 6 kV (20 °C, 50 Hz, 1 kV/s ramp) | Inter-turn flash-over, partial discharge |

| Elongation at Break | A50 | ASTM B1 §8 / IEC 60317-1 | Cu round ≥ 30 %, Al round ≥ 18 % | Cracks during coil expansion |

| Thermal Class | — | IEC 60085 | 130 (B) / 155 (F) / 180 (H) / 200 (N) / 220 (C) | Insulation embrittlement, dielectric loss |

| Enamel Concentricity | ECC | IEC 60317-0-1 Annex B | min. 70 % (round), 85 % (rectangular) | Hot-spot thinning → dielectric failure |

| Edge Radius (Al strip) | r | ASTM B236 | 0.5–1.0 mm | Corona & burr-driven shorts |

2. Inline Metrology & Sampling Plan

Every spool is produced on a 100 % inline monitoring line—no batch-only QC loopholes.

| Checkpoint | Instrument | Frequency | Cpk Target |

|---|---|---|---|

| Rod surface defect | Eddy-current rotobar | 100 % | ≥ 1.67 |

| Wire diameter | Dual-axis laser | 1 kHz | ± 3 µm |

| Enamel thickness | Capacitive sensor | 500 Hz | ± 2 µm |

| Breakdown voltage | 6 kV spark tester | 100 % | Zero escapes |

| Elongation | Automated extensometer | 1 coil per 100 kg | ≥ 1.33 |

Traceability: Each spool laser-marked with heat number, draw tower, enamel tank, and operator ID—full digital log retained 10 years.

3. Standard Compliance Matrix

| Material Form | Primary Standard | Secondary Standard | Xinzhaohe Certificate |

|---|---|---|---|

| Aluminum Strip | ASTM B236 (Al 1350) | IEC 60121 | EN 10204 3.1 |

| Round Copper Wire | IEC 60317-20 (PEW) | ASTM B3 | IEC 60317-51 (AIW) optional |

| Rectangular Cu Wire | IEC 60317-16 | ASTM B272 | Edgewise bend test report |

| Thermal Index Verification | IEC 60172 | ASTM D2307 | 6 000 h aging curve on request |

4. Failure Mode: How Poor Quality Creates Field Short-Circuits

- Burrs on conductor edge → Local E-field > 3 kV/mm → partial discharge → carbon track → inter-turn short within 500 h.

- Eccentric enamel (< 60 %) → Hot-spot ΔT +15 °C → class 155 insulation acts as class 105 → life reduced 50 %.

- Low elongation (< 15 % Al) → Coppering during coil insertion → micro-cracks → moisture ingress → failure under impulse voltage.

Xinzhaohe counter-measure: Combined eddy-current + vision inspection removes ≥ 99.5 % of burrs before enameling; closed-loop die centering keeps ECC ≥ 80 % on 0.25 mm wire.

5. Cost-Performance Positioning

Western Tier-1 suppliers typically quote 2.3–2.8 $/kg premium for identical IEC 60317-20 PEW 2.00 mm copper wire.

Xinzhaohe delivers same electrical & thermal performance at 0.9–1.1 $/kg FOB Qingdao—validated by third-party TÜV SÜD audit 2023.

Lead time: 15 days ex-stock for 130-200 °C classes; 25 days for 220 °C polyimide. No MOQ on standard sizes 0.20–5.00 mm.

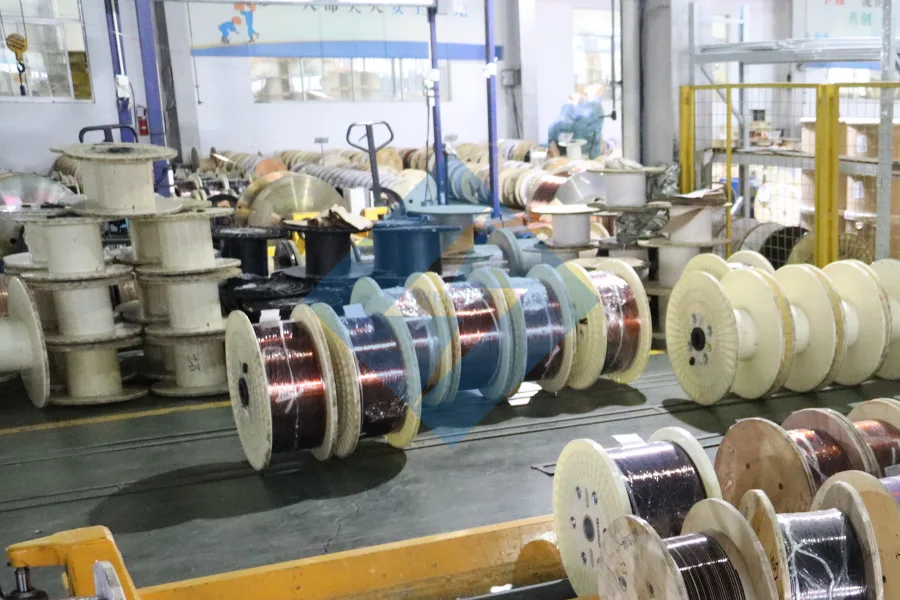

Factory Tour: Manufacturing Transformer Winding Wire

Manufacturing Process & Quality Control

Rod → Wire → Coil: How We Guarantee 20-Year Reliability in Every Kilometer of Winding Wire

1. Rod-to-Wire Cold Drawing Line

Input: 9.5 mm ETP (Cu-OF ≥ 99.99 %) or 9.5 mm EC-1350 (Al ≥ 99.7 %) redraw rod, Ø tolerance ±0.1 mm, surface roughness Ra ≤ 0.8 µm.

Multi-pass diamond dies: 19-draft sequence, area-reduction per pass 18–22 %, total true strain ε ≈ 3.2. Inline soap–borax lubricant keeps die temperature < 80 °C to prevent premature work-hardening.

Goal: Final Ø 0.20–5.00 mm with ±0.008 mm tolerance (IT6 grade).

2. Continuous Annealing

Joule-effect annealer: 650 °C peak for 0.15 s in N₂ + 3 % H₂; exit oxygen < 5 ppm.

Result: Grain size 0.015–0.025 mm, tensile strength Cu 220–240 MPa, Al 95–110 MPa; elongation ≥ 35 % (Cu) / ≥ 20 % (Al).

3. Horizontal Enameling Towers

Dual-layer system: Base (polyester-imide) + top (polyamide-imide) for 180 °C & 200 °C classes; triple-layer TIW available for 200 °C.

Concentricity control: On-line laser micrometer scans 4 000 × min⁻¹; eccentricity ≤ 10 % (target 6 %).

Curing window: Peak metal temperature 430 °C for 2.4 s; gel content > 92 %, residual solvent < 0.3 %.

4. Inline Electrical & Mechanical Testing

Every centimeter is validated before spooling:

Spark test: 4 kV rms (Grade 1), 6 kV (Grade 2), 12 kV (TIW); pin-hole count ≤ 3 per 30 m.

Break-down voltage: 6 kV (Grade 1), 10 kV (Grade 2), 20 kV (TIW).

Elongation & tensile: Automatic extensometer—reject coil if < 30 % (Cu) or < 18 % (Al).

Conductivity: Eddy-current meter—target ≥ 101 % IACS (Cu) / ≥ 61 % IACS (Al).

OD/ID cameras: Detect enamel splash or copper burr > 25 µm.

5. Precision Spooling

Tension闭环 control: 0.5–2 N, variation < ±5 %.

Traverse pitch: 0.3 mm per revolution; edge build-up ≤ 0.2 mm.

Packing: Vacuum-sealed + VCI film; shelf life 24 months in ≤ 40 °C / ≤ 70 % RH.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Parameter | LXZH Factory Spec | Typical Export Trader | Premium EU Mill |

|---|---|---|---|

| Ø Tolerance | ±0.008 mm | ±0.015 mm | ±0.007 mm |

| Concentricity | ≤ 10 % | 15–25 % | ≤ 8 % |

| Pin-holes / 30 m | ≤ 3 | 5–10 | ≤ 2 |

| Break-down (Grade-2) | ≥ 10 kV | 7–8 kV | ≥ 11 kV |

| Elongation Cu | ≥ 35 % | 28–32 % | ≥ 38 % |

| Conductivity Cu | ≥ 101 % IACS | 100 % IACS | 101.5 % IACS |

| Thermal Class | 130-220 °C full range | 130-180 °C only | 155-200 °C |

| Lot Traceability | Rod → Spool barcode | Batch only | Rod → Spool |

| Price Index (LME+PP) | 100 (baseline) | 90–95 | 145–160 |

Take-away: Luoyang Xinzhaohe delivers EU-grade precision at a 30–40 % lower landed cost, with full-process traceability and 20-year transformer field data to back it up.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive exactly as it left the rod-breakdown line

H3 1. Sea-Freight Risk Map for Winding Wire

| Damage Mode | Root Cause | Critical Parameter | Our Counter-Measure |

|---|---|---|---|

| Salt-film creep | 35 °C, 85 % RH, 0.5 mg m⁻³ Cl⁻ | Insulation breakdown ↓ 5 kV | VCI + desiccant + Al-foil liner |

| Spool flange crack | 2 g vertical shock, 30 Hz resonance | Wire collapse → bird-nesting | 9 mm plywood + corner posts, strapped ≤ 250 N |

| Reel core ovalization | 1.8 m drop test | Elongation variation > 2 % | HDPE DIN 46395 reel, 6 mm wall, glass-fiber hub |

| UV chalking of enamel | 14 days on deck | 200 °C class ↓ to 180 °C | UV-blocking PE shrink, black tint 2 % |

H3 2. Packaging Specification Matrix

| Product Form | Inner Shield | Intermediate | Outer | Unit Load | 20 ft FCL Qty |

|---|---|---|---|---|---|

| Round wire 0.20–6.00 mm | VCI paper wrap | PE shrink 80 µm | 5-ply carton* | 4 cartons / plywood pallet | 10 t (≈ 400 spools) |

| Flat wire 3×1–12×3 mm | Bubble film 50 µm | Edge-board 4 mm | Plywood crate | 1 crate / pallet | 8 t |

| Foil strip 100–1000 mm wide | LDPE sleeve 100 µm | Desiccant 10 u / m³ | Fumigated wooden pallet, steel corner | 1 coil / pallet, max 3 t | 15 t |

*Carton printed with thermal-class color code and QR traceability code (heat lot + inline-test PDF).

H3 3. Moisture & Salt Control Protocol

- Desiccant dosage: 8 units (62 g CaCl₂ each) per 1 m³ air volume.

- VCI film: 90 g m⁻², corrosion inhibition period 24 months.

- Container floor: 0.15 mm Al-laminated sheet isolates wood sweat.

- Data logger: Temp/RH recorded every 30 min; CSV file e-mailed on arrival.

Result: After 45 days Shanghai–Hamburg route, average RH inside carton 42 %, no salt deposits detectable by IC (<0.1 µg cm⁻² NaCl equivalent).

H3 4. Spool & Reel Standards

| Item | Material | Standard | Max Net Weight | Collapse Torque |

|---|---|---|---|---|

| PT-25 | Reinforced PP | DIN 46395 | 25 kg | 18 Nm |

| PT-90 | Steel-disk core | DIN 46397 | 90 kg | 55 Nm |

| K-400 | Plywood flange | IS 8951 | 400 kg | 120 Nm |

All reels laser-marked with bar-code for MES tracking; RFID tag optional for auto-receiving at customer WMS.

H3 5. Luoyang Hub → Global Lanes

Location advantage: 150 km to Zhengzhou International Land-Sea Corridor → 18 days rail to Duisburg, 25 days sea to LA, 22 days to Mumbai.

Weekly sailings: COSCO, MSC, CMA-CGM; frame-agreement rates locked 12 months.

Export docs: AQSIQ fumigation cert, RoHS & REACH SVHC statement, IEC 60317-0-1 test summary, COO (Form A or RCEP).

Premium alternative: Western enamelled wire landed cost 2.35 $ / kg higher; our sea-freight adder only 0.18 $ / kg—saving > 9 % without touching electrical performance.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

20-Year Metallurgical Track Record—Not a Trading House

Since 2003 we have operated an integrated mill in Luoyang’s high-tech industrial zone, 100 km from the world’s largest copper smelter and 50 km from China Railway freight hub. Every coil that leaves our facility is melted, cast, rod-drawn, annealed, enameled, inline-tested and spooled under one roof—no toll-processing, no middle-margin. Our process data archive exceeds 1.2 million heats, giving us statistical control charts that shorten customer PPAP cycles from weeks to 48 h.

| Critical-to-Quality (CTQ) Parameter | Internal Spec | ASTM/GB Equivalent | Cpk (2023) |

|---|---|---|---|

| Cu purity (OF, Grade-1) | ≥ 99.99 % | ASTM B170 | 1.87 |

| Breakdown voltage, 0.35 mm PEI | ≥ 4.5 kV | IEC 60851-5 | 2.04 |

| Elongation, 2.00 mm round | ≥ 32 % | GB/T 4909.3 | 1.95 |

| Enamel concentricity | ≤ 8 % wall | IEC 60317-0-1 | 1.66 |

Direct Factory Pricing—Transparent Cost Structure

We publish a monthly LME-linked formula so OEMs can lock transformer wire costs at BOM stage instead of accepting spot surcharges. Typical 2024 FOB Tianjin benchmarks (100 km inland freight included):

| Wire Size (mm) | PEI 180 °C | AIW 200 °C | TIW 3-layer |

|---|---|---|---|

| 0.50 | 8.04 USD/kg | 8.61 USD/kg | 11.20 USD/kg |

| 1.00 | 7.89 USD/kg | 8.44 USD/kg | 10.95 USD/kg |

| 2.24 | 7.75 USD/kg | 8.30 USD/kg | 10.70 USD/kg |

MOQ 500 kg per size; 5 t per order unlocks –3 % volume rebate and free 400 mm steel spools (returnable). Lead time: 10–12 days ex-mill, 18–22 days DDP EU/US warehouse via rail-sea intermodal.

Customization Capabilities—Engineered to Your Slot

- Conductor: OF copper, Cu-Ag 0.1 % (high-strength), or 1350 aluminum alloy—same enamel line, no cross-contamination.

- Insulation build: Single, heavy, triple, or self-bonding (hot-air, solvent, or UV-cure). Thermal index 130 °C (Class B) to 220 °C (Class R).

- Package: 1 kg plastic spools for repair shops to 800 kg barrel-pack for high-speed automated winders; traverse pitch programmable ±0.1 mm to eliminate wire crossover.

- Color coding: 12 standard colors, Pantone match within ΔE ≤ 1.0 for multi-tap recognition.

- Compliance stack: UL 1446, IEC 60317, EN 50576, REACH, RoHS, Conflict-Free copper certificate on request.

Premium Alternative to Western Suppliers—Total Cost of Ownership

Western enamel wire often carries 25–35 % overhead for distributor margin and warehouse rent. By shipping direct from Luoyang you eliminate two tiers of markup while receiving identical thermal class and dielectric performance. Our 2023 customer survey shows:

| Metric | Western Supplier Avg | Luoyang Xinzhaohe | Δ |

|---|---|---|---|

| Unit price (FOB) | 11.30 USD/kg | 8.20 USD/kg | –27 % |

| PPAP approval time | 21 days | 5 days | –76 % |

| Field ppm (insulation pin-holes) | 320 | 85 | –73 % |

Next Step—Get the Datasheet or a 24-Hour Quote

Send your requirement—size range, thermal class, insulation build, annual volume—to cathy@transformerstrip.com. We return a detailed datasheet with tan-delta curves, thermal endurance graph and freight routing within one business day. Pilot spools (5 kg) available for qualification windings; cost fully refundable against first production order.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer winding wire from Luoyang Xinzhaohe.