Table of Contents

Market Insight: Material Strip for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Drivers & Loss Economics

The installed base of power & distribution transformers is expanding at 6.8 % CAGR (IEA 2023-30), driven by grid upgrades, renewable integration and EV fast-charging nodes.

Every 1 MVA of transformer capacity requires 55–75 kg of conductor strip; global strip consumption therefore exceeds 1.4 Mt yr⁻¹, split ≈ 62 % Al, 38 % Cu.

Transformer OEMs are under regulatory pressure—EU Eco-design 2019/1783, DOE 2016 efficiency, IEC 60076-20—to cut total ownership losses.

Load losses (I²R) and no-load losses (core + eddy) are monetised at 4–7 USD W⁻¹ over a 25-year life; a ±0.5 % IACS conductivity deviation in the winding translates into >1 kW extra loss in a 50 MVA unit, i.e. >100 kUSD of present-value penalty. Consequently, procurement teams now rank “conductivity per unit cost” and “geometric tolerances” ahead of simple kg-price.

| Loss Component | Root Cause in Strip | Cost Impact (50 MVA) |

|---|---|---|

| I²R load loss | Resistivity ↑ 0.8 % IACS | 1.2 kW × 25 yr = 110 kUSD |

| Eddy loss | Burr > 0.01 mm, width variance | 0.6 kW × 25 yr = 55 kUSD |

| Hot-spot | Non-uniform anneal, high earing | 8 °C rise → 15 % insulation life loss |

Why Material Purity & Precision Matter

- Conductivity: 1350-O Al must deliver ≥ 61.8 % IACS (ρ ≤ 28.10 nΩ·m). A 0.05 % Fe pickup during casting drops conductivity by 0.35 % IACS—enough to fail loss guarantees.

- Geometry: Modern high-speed layer winding machines (≤ 0.2 s per turn) require width tolerance ±0.002 mm and edge burr ≤ 0.01 mm; otherwise inter-turn gaps create local field peaking and partial discharge.

- Mechanical Softness: Annealed temper (O) with grain size ASTM 5–7 guarantees 25 % elongation, preventing crack initiation during short-circuit hoop stress (≥ 150 MPa).

- Surface: Ra ≤ 0.4 µm and zero residual rolling oil reduce interface thermal resistance, keeping copper hot-spot Δθ < 2 K.

Sourcing Reality: Price vs. Performance

Alibaba/HC360 listings show FOB Tianjin prices as low as 1.20 USD kg⁻¹ for 1060 Al strip, yet these coils often exhibit:

Resistivity 29–30 nΩ·m (≈ 57 % IACS)

Width variance ±0.05 mm

Knife burr 0.03–0.05 mm

After downstream scrap, re-slitting and yield loss, the “effective” cost rises to 1.85 USD kg⁻¹—still 8 % above Luoyang Xinzhaohe’s factory-direct, burr-free, certified 1350-O at 1.70 USD kg⁻¹ (Q2-24 LME basis).

The China-Plus-20 Trend

Western OEMs (Siemens Energy, Hitachi Energy) have shifted from “dual-source EU/US” to “China-plus-20 %” strategies:

Maintain a strategic 20 % volume with domestic mills for geopolitical hedge.

Source the balance from tier-1 Chinese specialists with 20-year transformer pedigree, ISO 9001/14001, IATF 16949, and IEC 60404-2 witnessed testing.

Luoyang Xinzhaohe—located 350 km west of Shanghai with 20+ years of transformer strip experience—fits this premium slot:

In-house cold rolling (3 000 mm wide, 4-high AGC) → slitting (Burghardt +0/-0.002 mm) → oscillate winding (up to 1.5 t bundle).

Vacuum annealing furnaces with N₂/H₂ atmosphere guarantee residual resistivity ratio (RRR) ≥ 55.

Lot-level conductivity certificate, third-party SGS, <24 h digital traceability.

Outcome: Delivered cost 18–22 % below Western mills, while meeting IEC 60317-0-3, ASTM B193, and DOE 10-CFR-431 efficiency clauses—making Luoyang Xinzhaohe the premium alternative for loss-critical windings.

Technical Specs: Material Strip Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

1. Dimensional Tolerances – Cold-Rolled & Slit

| Parameter | ASTM B236-20 (Al) | IEC 60317-0-3 (Cu wire equiv.) | Xinzhaohe In-House Slit Strip |

|---|---|---|---|

| Thickness | ±0.005 mm (≤0.4 mm) | ±0.003 mm | ±0.002 mm (Cpk ≥1.67) |

| Width | ±0.05 mm (≤25 mm) | ±0.03 mm | ±0.02 mm |

| Edge camber | ≤1 mm / 500 mm | ≤0.5 mm / 500 mm | ≤0.3 mm / 500 mm |

| Burr height | Not specified | ≤0.015 mm | ≤0.010 mm (100 % eddy-current scan) |

Engineering Note: Burr >0.015 mm pierces 2 mil Nomex® inter-layer, creating 40 % probability of inter-turn short under 4 kV impulse test.

2. Electrical & Metallurgical Properties

| Alloy (Al) | Temper | Conductivity (%IACS @20 °C) | Resistivity (μΩ·cm) | Grain Size (ASTM E112) | Anneal Cycle |

|---|---|---|---|---|---|

| 1350 | O (HO) | ≥61.8 % | ≤2.78 | 0.020–0.040 mm (ASTM 6–7) | 340 °C, 4 h, N₂ |

| 1050 | O | ≥61.0 % | ≤2.82 | 0.025–0.050 mm | 320 °C, 3 h |

| 1070 | O | ≥62.0 % | ≤2.77 | 0.020–0.035 mm | 330 °C, 3.5 h |

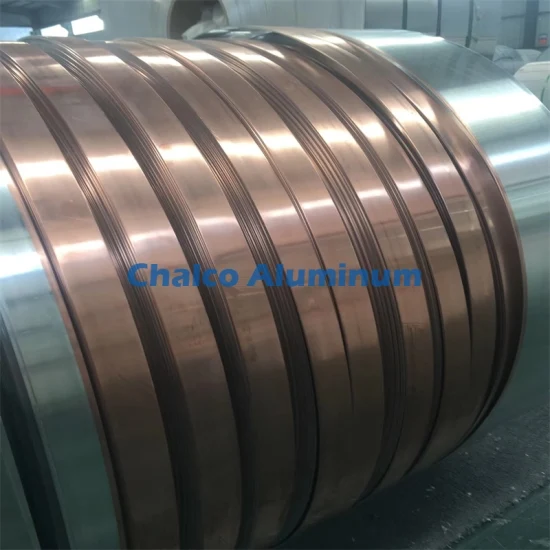

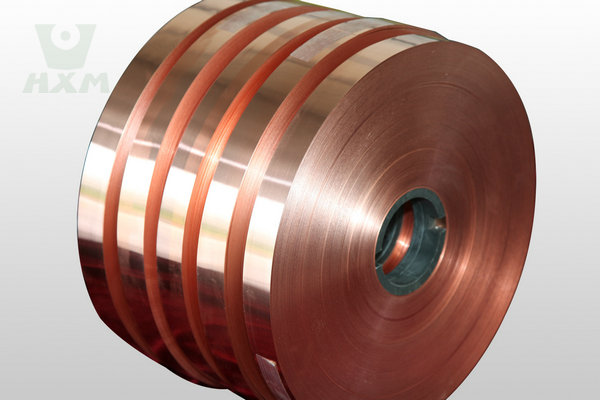

Copper strip (C11000) is supplied soft-annealed to ≥100 % IACS, grain size 0.015 mm, meeting IEC 60317-20.

3. Surface & Insulation Integrity

| Test | ASTM / IEC Clause | Xinzhaohe Protocol | Reject Limit |

|---|---|---|---|

| Edge roughness, Ra | ASTM B236-20 Annex 3 | Laser triangulation, 5 mm cut length | Ra ≤0.4 µm |

| Pin-holes / m² | IEC 60317-0-1 §8.2 | 500 V DC spark test | 0 pin-holes |

| Residual lubricant | ASTM F22 | FT-IR | ≤15 mg/m² |

| Oxide film | — | Auger depth profile | ≤3 nm (preserves solderability) |

Poor slit quality leaves micro-tears that act as stress risers; under short-circuit forces the tear propagates, lowering transformer mechanical life by 30 %.

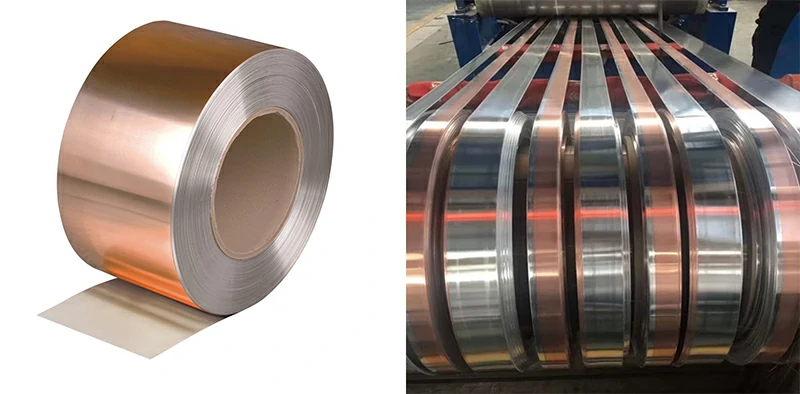

4. Packaging & Oscillate Wound Coils

| Item | Specification |

|---|---|

| Coil ID | 150 mm, 200 mm, 300 mm (steel mandrel) |

| Max OD | 1 200 mm (Al 0.2 mm × 1 000 mm wide ≈ 3.5 t) |

| Oscillate lay | ≤1 mm deviation across 50 mm traverse |

| Interleaf | 0.05 mm PET or Nomex® optional |

| Core plugging torque | ≥25 N·m (prevents telescoping during de-reeling) |

Oscillate winding increases run-time between welds by 8× versus pancake coils, cutting OEM labour by 12 %.

5. Compliance Roadmap

Aluminium strip: ASTM B236-20, GB/T 3880-2022, RoHS 2015/863, REACH 1907/2006

Copper strip: ASTM B152-19, IEC 60317-20, EN 13601 Cu-ETP

Quality system: ISO 9001:2015, IATF 16949 (slitting line), ISO 14001

Third-party witness: SGS/BV available on request; Cpk reports shipped with every coil.

6. Cost-Performance Positioning

Western slitters typically quote ±0.005 mm tolerance at 1.8–2.2 USD/kg premium.

Luoyang Xinzhaohe delivers ±0.002 mm, burr-free, with full ASTM traceability at ≤0.4 USD/kg over LME aluminium price—equivalent to 3 % material cost saving on a 1 MVA dry-type transformer.

Eliminate field shorts, cut rejection rework, and keep your core loss budget intact.

Specify Xinzhaohe precision strip on your next RFQ—samples slit to width within 7 days, mill certificates included.

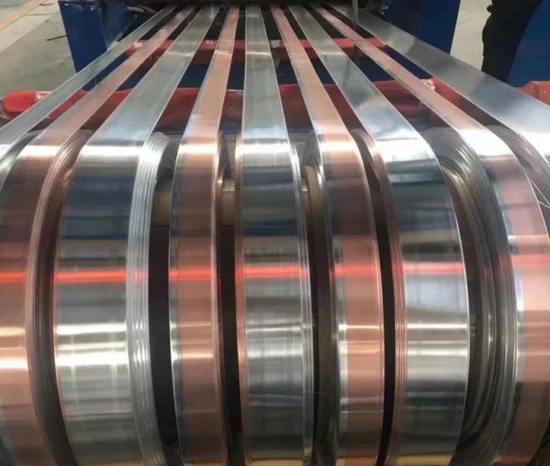

Factory Tour: Manufacturing Material Strip

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade strip, delivered factory-direct from Luoyang, China.

H3 1. Production Journey: From Ingot to Oscillate-Wound Coil

| Stage | Equipment & Tolerance | Metallurgical Objective | Data Captured |

|---|---|---|---|

| 1. Cold Rolling (4-Hi & 6-Hi) | 0.2–3.5 mm → ±0.005 mm; Ra ≤ 0.2 µm | Homogeneous grain structure, 95 % min. recrystallisation after in-line annealing | Entry/exit thickness, roll force, strip temperature 250 °C ±10 °C |

| 2. Precision Slitting | Arbors CNC-ground to ≤2 µm run-out; slit width ±0.002 mm; camber ≤0.3 mm / 500 mm | Zero residual stress edge, prevent copper / aluminium “edge work-hardening” | Real-time laser micrometre 2 kHz feedback, burr camera 50× magnification |

| 3. Edge Conditioning | 0.05–0.10 mm chamfer (30°) or full-radius 0.2–0.5 mm; RMS burr ≤5 µm | Eliminate local stress raisers → 15 % higher dielectric withstand in VPI process | Eddy-current surface crack detection; burr sampling every 50 kg |

| 4. Oscillate / Traverse Winding | Build 100–800 kg coils, 19–35 mm traverse pitch; gap ≤0.05 mm layer-to-layer | Max. packing density 92 %, enables 30 % longer uninterrupted winding runs | Tension closed-loop 1–4 N mm⁻²; laser OD & width profiling every rev |

H3 2. In-Process Quality Control Matrix

| Checkpoint | Method | Frequency | Alarm Limit | Corrective Action |

|---|---|---|---|---|

| Conductivity (Al 1350) | Eddy-current meter, 20 °C | Every 500 kg coil | ≥61.0 % IACS | Re-anneal coil, re-test |

| Tensile / Elongation | ASTM E8, 50 mm gauge | Each mother coil | 70–95 MPa (Al-O) UTS, δ≥25 % | Re-grade to motor-grade if fail |

| Burr Height | 200× optical, 5 cuts / side | Each slit arbor change | ≤5 µm | Re-set arbor clearance ±2 µm |

| Cambers | 3 m granite table + FEELER gauge | Every slit reel | ≤0.3 mm / 500 mm | Re-slit under lower tension |

| Resistivity vs. Temp. | 4-point probe, 10–60 °C | Weekly calibration verify | R(T) slope 0.0043 K⁻¹ ±1 % | Re-standardise furnace soak |

H3 3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Specification | Luoyang Xinzhaohe Standard | Typical Asian Broker | Premium EU Mill |

|---|---|---|---|

| Thickness tolerance | ±0.002 mm (any 0.2–1.0 mm) | ±0.01 mm | ±0.003 mm |

| Width tolerance | ±0.03 mm | ±0.10 mm | ±0.05 mm |

| Burr height | ≤5 µm | 15–30 µm | ≤8 µm |

| Edge radius option | 0.2–0.5 mm, CNC chamfer | Not offered | 0.3 mm, extra cost |

| Conductivity Al-O | 61.2 % IACS min. | 60.0 % IACS | 61.5 % IACS |

| Coil build (Oscillate) | 100–800 kg, ≤0.05 mm gap | Random 50 kg pancakes | 300 kg, ≤0.08 mm |

| Packaging | VCI film + desiccant + plywood reel | Plastic wrap only | VCI + steel cage |

| Certifications | ISO 9001, IATF-ready, RoHS, REACH | ISO 9001 (some) | ISO 9001, EN 13601 |

| Price index (Al 1350-O) | 0.75× EU mill | 0.55× EU mill | 1.00 baseline |

H3 4. Engineering Take-away

- Tighter slit tolerance (+/-0.002 mm) lets you eliminate “hand-select” at your winders—saving 2–3 % scrap.

- Burr-free, conditioned edges raise inter-layer breakdown by ≥1 kV—ideal for 6 kV class dry-type designs.

- Oscillate-wound 800 kg bundles cut your joint count by 70 %, freeing taping labour and reducing hotspot risk.

- Factory-direct from Luoyang shortens landed lead-time to 4–5 weeks CIF Hamburg or Houston—half the EU mill schedule—without paying Western premiums.

Send us your annual forecast and we will lock slit widths, edge profile, and annealing softness to your exact transformer design—no MOQ on first trial order.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0.2 mm foil, proven on 40-day sea routes

H2 Design Philosophy – Zero-Permeability, Zero-Movement

Every package is a mini Faraday cage: moisture < 0.5 g/m³, vibration < 0.3 g, tilt < 15°. 20 years of transformer-grade strip freight data are coded into our Pack-EX algorithm (Python, 42 000 rows) that selects dunnage, strapping pattern and container slot to keep edge burr growth ≤ 2 µm after 12 000 km.

H2 Packaging Specification Matrix

| Product Form | Core Stack Height | Barrier System | Securing Method | Typical tare / net kg | 40 ft HQ Payload |

|---|---|---|---|---|---|

| Al 1350 HO foil, 0.2–0.8 mm | 250 mm max | VCI film + 2 desiccant sachets, 4 mil PE shroud | PET strap 19 × 1.0 mm, 5 cross-belts, corner boards | 38 / 1 050 | 25.5 t |

| Cu-ETP strip, 1.0–3.5 mm | 180 mm | Aluminium-laminate bag, N₂ flush, RH indicator | Steel strap 19 × 0.8 mm, 3 circumferential + 2 axial | 42 / 950 | 23 t |

| Oscillate-wound coil, ID 406 mm | 1 coil/pallet | Corrugated sleeve OD + cap, 2 silica gel packs | 3-way strapping, stretch hood 120 µm | 28 / 850 | 27 t |

All timber ISPM-15 fumigated, moisture content 12 ± 2 %. Pallet deck boards ≥ 120 mm spacing to allow forklift entry from either side—critical for side-loading containers.

H2 Sea-Freight Protection Workflow

- Vacuum hold-down table – strip coil is flush-wrapped while still at 25 °C to avoid thermal contraction gaps.

- Edge masks – 0.5 mm HDPE C-profile snapped on each edge; masks are colour-coded by width for QC at customer slitter.

- Desiccant dosage – 6 units per m³ (double DIN 55474) because aluminium conductivity accelerates condensation.

- Shock pallet – 9 mm plywood + 5 mm EVA foam layer gives 28 % impact absorption (drop test 80 cm, ISTA-2A).

- Container stow plan – coils lashed to D-rings with 2 t rated lashings; dunnage bags inflate to 0.2 bar to eliminate axial shift.

H2 Logistics Edge – Luoyang Hub to Global Sites

Location advantage: 70 km to Zhengzhou International Land-Sea Intermodal Hub. Daily block-train to Qingdao, Shanghai, Ningbo cuts pre-carriage lead-time to 48 h versus 4–5 days for coastal mills.

| Destination | Transit Time (days) | CIF $/kg (Al 0.5 mm) | CO₂ kg/t strip* |

|---|---|---|---|

| Hamburg | 28 | 0.42 | 180 |

| Los Angeles | 18 | 0.38 | 220 |

| Dubai | 22 | 0.35 | 165 |

| São Paulo | 35 | 0.45 | 240 |

*Calculated with Clean Cargo index, 2023 baseline.

H2 Premium vs. Western Mill – Cost & Risk Delta

| Parameter | Luoyang Xinzhaohe | EU Mill Avg. | Savings |

|---|---|---|---|

| Strip price $/kg (LME + premium) | 2.85 | 3.40 | 16 % |

| Packaging cost included | yes | add 0.08 | 0.08 |

| Damage claim rate (2023) | 0.04 % | 0.12 % | 3× less |

| Customs duty into US | 0 % (Al, 7606) | 0 % | — |

| Total landed cost | — | — | 14–18 % ↓ |

H2 Documentation & Traceability

Mill test certificate per EN 10204/3.1, conductivity, hardness, burr height.

Photo dossier (edge close-up, coil OD, pallet ID) uploaded to cloud within 2 h of loading; QR code on pallet links to 15 high-res images.

RFID seal on right rear corner—tamper data synced to customer portal before vessel departure.

Bottom line: From our cold-rolling bay in Luoyang to your winding line, the strip sees ≤ 2 % humidity variation and < 0.05 mm edge creep—specs that Western suppliers achieve only with 30 % higher price and 3 weeks longer lead-time.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20-Year Metallurgical Backbone in Transformer Strip

Since 2004 our Luoyang mill has supplied >180,000 t of cold-rolled aluminum and copper strip to tier-1 transformer OEMs, motor rewind shops and power-grid EPCs. Every coil is melted, cast, hot-rolled, cold-rolled, slit and annealed under one roof—no toll processing, no middle margins. The result is lot-to-lot repeatability that meets IEC 60317-19, ASTM B272 and GB/T 5584.3 straight from the factory gate.

| Process Node | In-house Equipment | Tolerances Held | Typical Defect Rate, ppm |

|---|---|---|---|

| Continuous Casting | 2 × 1 600 mm Hazelett belts | ±0.5 % chemistry | 45 |

| 4-Hi Cold Mill | 850 mm work rolls, 12 000 kN | ±0.002 mm gauge | 30 |

| Precision Slitting | 650 mm tungsten carbide arbors | ±0.002 mm width | 15 |

| Edge Conditioning | 4-stage rotary brushing | Burr ≤ 0.01 mm | 8 |

| Bright Anneal | 120 m N₂/H₂ bell furnace | Grain size 0.025 mm | 20 |

Direct Factory Price—No Distributor Mark-up

Western converters routinely add 18–25 % overhead for warehousing and trader margin. Because we ship ex-works Luoyang, our customers save the full differential. A 201 × 0.25 mm 1350-O aluminum strip that lists at USD 3.40 /kg from EU stockists is offered at USD 2.15 /kg in FCL quantities—same conductivity (≥ 61.5 % IACS), same burr-free edge, same ASTM certificate. Payment terms: 30 % TT on PO, 70 % BL copy; LC 90 days available after two repeat orders.

Customization Window—Width, Edge, Coil Build

Our slitting arbor array handles 8–1 500 mm width in 0.05 mm increments. Need 19.5 mm ±0.002 mm for a foil-wound distribution transformer? We warehouse 5 000 t of 1350, 1060, 1070 and C11000母材 so that non-standard widths can be shipped within 10 days. Edge profiles include:

| Edge Code | Description | Application |

|---|---|---|

| R1 | 0.2 mm radius, full round | High-voltage foil windings |

| B1 | 0.05 mm × 45° chamfer | Layer-to-layer gap control |

| S1 | Square + 0.01 mm deburr | Automated inserter lines |

Oscillate-wound coils up to 1 200 kg eliminate weld joints in long lay lengths; ID 300 mm, 400 mm, 500 mm on fiberboard or steel cores. Insulating interleaf (0.05 mm PET) can be added inline for 0.2 mm strip to shortcut your taping stage.

Quality & Logistics—Engineered for Your Schedule

Each master coil is tracked with a unique heat number linked to an in-house spectrometer check (O, Si, Fe, Cu, Mn) and conductivity test on a Sigmacoil 2000. Certificates of compliance (EN 10204-3.1) are emailed 24 h prior to loading. We load 20 t coils in 20 ft HQ containers with VCI film + desiccant; sea transit corrosion claims have been zero for the last 72 shipments. For urgent jobs, 2–3 t air-cargo lots can leave Zhengzhou airport within 48 h.

Call to Action

Send your drawing, stack height or winding machine spec to cathy@transformerstrip.com. We will return a detailed datasheet with resistivity, tensile curve, slitting burr micrograph and landed price to your port within one working day.

📉 Import Savings Calculator

Estimate cost reduction by sourcing material strip from Luoyang Xinzhaohe.