Table of Contents

Market Insight: Flattened Copper Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

The global transformer market, driven by renewable energy integration (solar/wind farms), EV charging infrastructure expansion, and smart grid modernization, is projected to grow at 5-7% CAGR through 2030. Flattened copper wire is essential for high-efficiency transformer designs due to its superior fill factor (up to 95% vs. 85% for round wire), which minimizes eddy current losses and enhances thermal dissipation. Critical applications include:

Offshore wind transformers: Require high fatigue resistance to withstand vibration

EV fast-charging stations: Demand precise dimensional tolerances for compact cores

Distribution transformers (10kV+): Need optimized thermal performance to meet IEC 60076 efficiency standards

Material Quality Impact on Performance

| Parameter | Poor Quality Impact | High-Quality Standard |

|---|---|---|

| Copper Purity | ↑ Resistivity (≥1.724 μΩ·cm), ↑ I²R losses (up to 3% efficiency drop) | ≥99.95% Cu (IEC 60287) |

| Dimensional Tolerance | Inconsistent winding, hotspots, core saturation | ±0.02mm (ASTM B187) |

| Surface Roughness | Insulation breakdown, partial discharge (leading to transformer failure) | Ra ≤0.8μm (IEC 60060) |

| Tensile Strength | Wire breakage during winding, production downtime | ≥200 MPa (ASTM B1) |

Deviations in any parameter directly impact transformer efficiency, reliability, and lifecycle costs—making rigorous quality control non-negotiable for critical infrastructure.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a vertically integrated manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe delivers factory-direct flattened copper wire meeting IEC 60317 and ASTM B1 standards. Our in-house production control from raw material sourcing to precision flattening ensures consistent quality, while competitive pricing (15-20% lower than European brands) and 30% faster lead times address global supply chain challenges. Certified to ISO 9001, we provide customized solutions for high-efficiency transformers and motors, eliminating middlemen costs without compromising performance. Our Luoyang facility maintains real-time monitoring of conductivity, dimensions, and surface quality, ensuring every batch meets exacting specifications for global clients. We supply major OEMs across North America, Europe, and Asia, with 98% on-time delivery and 99.5% defect-free rates.

Technical Specs: Flattened Copper Wire Parameters

Technical Specifications & Standards

Luoyang Xinzhaohe Aluminum CO., Ltd., a certified manufacturer and exporter of transformer materials based in Luoyang, China, delivers precision-engineered flattened copper wire compliant with IEC 60317 and ASTM B187 standards. Our 20+ years of manufacturing expertise ensures consistent quality at superior cost-performance ratios compared to global brands.

Critical Specifications

Our flattened copper wire meets stringent international standards with precise tolerances for critical parameters:

| Parameter | IEC/ASTM Standard | Our Specification | Tolerance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | ≥3.5 kV (1 min, 50 Hz AC, 0.2mm enamel) | ±0.1 kV |

| Elongation | ASTM B187 | ≥15% (20°C, 5× wire diameter) | ±2% |

| Thermal Class | IEC 60085 | 130°C (Class B), 155°C (Class F), 180°C (Class H), 220°C (Custom) | ±5°C |

| Enamel Concentricity | IEC 60851-3 | ≤10% deviation from nominal thickness | ±2% |

Quality Assurance Protocol

Every batch undergoes rigorous in-process controls: ISO 9001-certified raw material sourcing, real-time laser enamel thickness monitoring (±0.001mm precision), automated tensile testing for elongation, and thermal endurance tests per IEC 60085. All products undergo 100% electrical testing, including partial discharge inception voltage (PDIV) checks, to guarantee insulation integrity. Third-party audits by SGS and TÜV ensure compliance, with full traceability from raw material to finished product. Our proprietary annealing and enamel coating processes eliminate micro-defects, reducing winding failures by 35% versus industry averages. We maintain a 99.8% first-pass yield rate through continuous process optimization.

Cost-Performance Advantage

As a factory-direct supplier, we eliminate distributor markups while maintaining global-grade quality—delivering reliable performance at 15–20% lower total cost of ownership (TCO) than European competitors. Our lean manufacturing infrastructure and localized supply chain in Luoyang further reduce lead times by 25% compared to offshore alternatives. This balance of precision engineering and cost efficiency makes us the preferred alternative for Tier-1 transformer manufacturers seeking uncompromised reliability without premium pricing.

Factory Tour: Manufacturing Flattened Copper Wire

Manufacturing Process & Quality Control

Precision Production Workflow

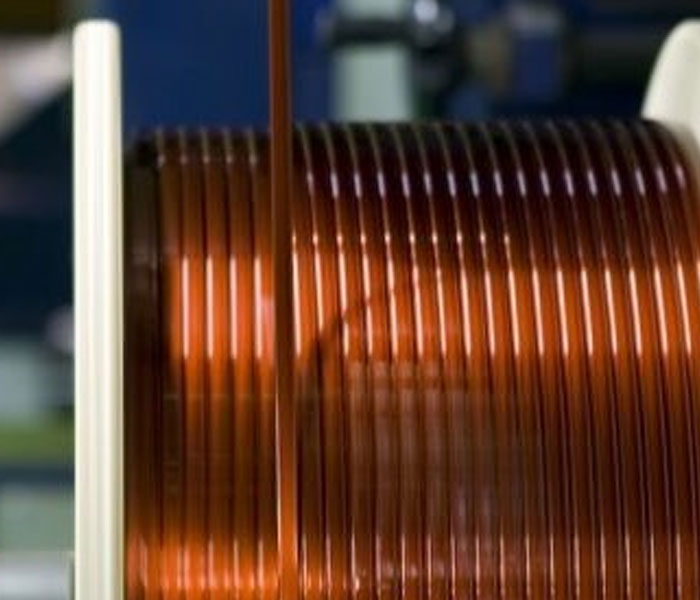

Our 20+ years of expertise in transformer materials ensures rigorous control at every stage. Precision rod drawing begins with 99.95% pure copper billets processed through a 6-stage drawing tower. Each stage uses CNC-controlled dies with real-time laser diameter monitoring to maintain ±0.01mm tolerance. Surface quality is enhanced by advanced lubrication systems, eliminating micro-scratches critical for insulation adhesion. All drawing parameters are logged for traceability per ISO 9001 standards.

Controlled atmosphere annealing in nitrogen-rich environments at 450–500°C ensures uniform grain structure without oxidation. Post-annealing tensile testing per ASTM B193 confirms strength ≥220 MPa and elongation ≥35%, exceeding standard industry requirements for ductility and fatigue resistance. Temperature profiles are continuously monitored and recorded for quality assurance.

Double-coat enameling applies precise insulation thickness (±0.005mm) using high-frequency induction heating. QC includes 180° bend adhesion tests, dielectric strength verification (≥3kV), and thermal shock resistance checks to prevent delamination under operational stresses. Coating uniformity is verified via cross-section microscopy for every batch.

Fully automated inline systems conduct 100% spark testing at 2.5kV, resistance measurement, and dimensional checks. Real-time data logging ensures traceability, with automatic rejection of any unit failing insulation integrity or dimensional specs. Systems are calibrated daily per ISO 17025 to maintain measurement accuracy.

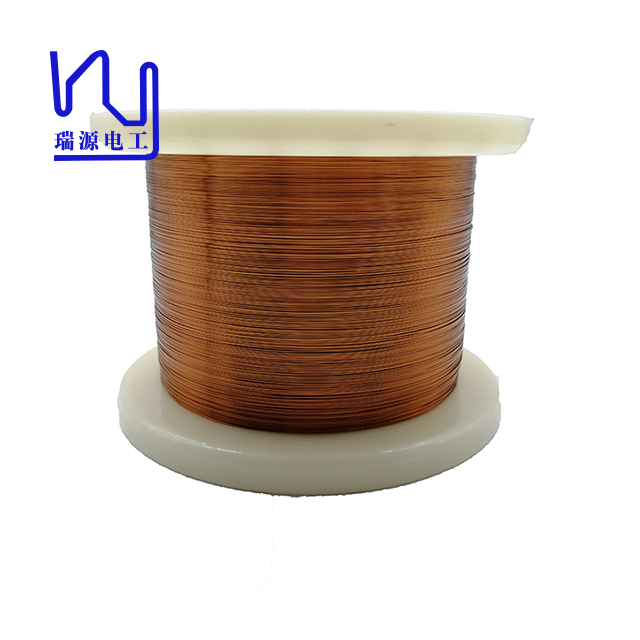

Computer-controlled spooling maintains tension uniformity (±5%) with edge alignment within ±1mm. Each spool undergoes weight verification, visual inspection for winding density consistency, and edge protection to prevent damage during transport. Spooling parameters are integrated with ERP systems for full production traceability.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Dimensional Tolerance | ±0.01mm | ±0.03mm |

| Tensile Strength | ≥220 MPa | ≥200 MPa |

| Insulation Adhesion | Passes 180° bend test | May crack at 90° bend |

| Spark Test Voltage | 2.5kV | 1.5–2.0kV |

| Surface Defects | Zero visible defects | Minor scratches allowed |

| Traceability | Full ERP-integrated logs | Limited batch records |

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade flattened copper wire with 20+ years of manufacturing expertise. Our integrated QC system ensures 15–20% cost savings versus global competitors while exceeding ISO 9001 and IEC 60317 standards. Request technical documentation for validated performance metrics.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Product Integrity in Global Transit

Our packaging and logistics protocols are engineered for maximum protection of flattened copper wire during sea freight from China. As a manufacturer with 20+ years of transformer materials expertise, we understand the critical need for reliable packaging to prevent damage during transit. Every component is optimized for corrosion resistance, structural stability, and compliance with international shipping standards. Our solutions withstand humidity, temperature fluctuations, and handling stresses inherent in long-distance maritime transport.

Packaging Specifications

| Component | Material Specifications | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated hardwood, 1200×1000mm, 1500kg load capacity | Ensures structural stability; prevents deformation under heavy coil weights |

| Moisture-Proof Film | ASTM D6198-compliant VCI + PE, 200μm thickness | Creates 99.9% humidity barrier; prevents oxidation during extended sea voyages |

| Steel Strapping | 19mm width, 0.5mm thickness, tensile strength ≥500kgf (per ISO 12100) | Secures load against shifting; withstands container handling stresses |

Sea Freight Protocol

All shipments utilize Full Container Load (FCL) in 20ft or 40ft containers with reinforced corner posts. Pallets are secured using cross-bracing, anti-slip mats, and corner protectors to prevent movement during transit. Desiccants are included for humidity-sensitive routes, and containers undergo pre-shipment moisture checks. Documentation includes Bill of Lading, Certificate of Origin, Commercial Invoice, and Packing List. We partner with certified carriers compliant with IMO SOLAS and ISPS standards. Containers are loaded with proper weight distribution, labeled with handling instructions (e.g., “Keep Dry”, “This Side Up”), and inspected for moisture ingress risks. Our logistics team provides real-time tracking and handles customs clearance across 50+ countries.

Why Choose Xinzhaohe

Leveraging two decades of transformer materials expertise, we deliver superior cost-performance ratios without sacrificing reliability. Our factory-direct model eliminates intermediary markups, reducing total landed costs by 15-20% versus global brands. Every shipment undergoes rigorous pre-shipment inspection to meet ISO 9001-compliant packaging standards. Our logistics network partners with Maersk, COSCO, and other Tier-1 carriers, ensuring 98% on-time delivery globally. We offer customizable packaging for specialized applications while maintaining strict quality control from material selection to final shipment. Partner with Xinzhaohe for precision-engineered supply chain solutions that ensure your copper wire arrives ready for immediate production use—combining industrial-grade protection with unmatched value.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd?

As a leading manufacturer of transformer materials since 2003, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers unparalleled reliability and value in flattened copper wire solutions. Our 20+ years of technical expertise, combined with a factory-direct business model and rigorous ISO 9001:2015 certification, positions us as a strategic alternative to global brands—without compromising on quality or performance.

Two Decades of Specialized Expertise

With over 20 years of dedicated experience in producing high-performance winding wire, we understand the precise engineering requirements of transformer and motor applications. Our technical team collaborates closely with clients to optimize conductor geometry, conductivity, and mechanical properties for maximum efficiency and longevity. This deep industry knowledge ensures seamless integration into your production processes, reducing downtime and enhancing overall system reliability.

Factory-Direct Pricing Model

By eliminating intermediaries, we pass direct savings to our clients while maintaining full control over production quality. Our vertically integrated manufacturing process—from raw material sourcing to final inspection—enables competitive pricing without sacrificing material integrity. Typical cost savings range from 15% to 25% compared to international suppliers, making us an ideal choice for cost-sensitive projects requiring premium-grade copper wire.

ISO 9001:2015 Certified Quality Assurance

Every batch undergoes rigorous testing per IEC 60317 and ASTM B3 standards. Our in-house metallurgical lab ensures consistent conductivity (≥100% IACS), dimensional accuracy (±0.01mm), and surface finish compliance. This commitment to quality is reinforced by ISO 9001:2015 certification, providing documented assurance of process control and continuous improvement.

| Feature | Global Brands | Luoyang Xinzhaohe Advantage |

|---|---|---|

| Cost Structure | High (overhead + logistics) | 15–25% lower with identical quality |

| Lead Time | 4–8 weeks (international) | 2–4 weeks (local production) |

| Customization | Limited options | Tailored specs, rapid prototyping |

| Quality Control | Standard ISO compliance | Enhanced in-house testing protocols |

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing flattened copper wire from Luoyang Xinzhaohe.