Table of Contents

Market Insight: Rectangular Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Rectangular Copper Winding Wire

Global Demand Outlook – Power & Distribution Transformers

Global installed transformer capacity is forecast to exceed 24 TVA by 2030, driven by grid expansion, renewable integration and replacement of 1970-1990s units. Rectangular copper conductor accounts for ~38 % of the total winding mass in liquid-immersed ≥10 MVA units and >55 % in dry-type ≤3 MVA distribution transformers. Conservative models indicate a 6.2 % CAGR in copper winding demand through 2028, translating to ≈1.9 Mt of rectangular wire annually. Asia-Pacific represents 47 % of the pull, EMEA 28 %, Americas 25 %.

| Segment (2023) | Avg. Cu winding mass | Typical wire size | Annual growth |

|---|---|---|---|

| Utility power ≥50 MVA | 9.5 t/unit | 4 – 16 mm × 1 – 5 mm | 7 % |

| Industrial 5–50 MVA | 3.2 t/unit | 2 – 10 mm × 1 – 4 mm | 5 % |

| Distribution ≤3 MVA | 0.35 t/unit | 1 – 5 mm × 0.8 – 2.5 mm | 4 % |

Why Material Purity & Geometry Precision Dictate Transformer Losses

Transformer losses fall into two classes that utilities must guarantee under IEC 60076-1 and IEEE C57.12.00:

- No-load (core) losses – fixed by core steel, but conductor stress relief during anneal affects residual strain and hence core clamping pressure.

- Load (I²R & eddy) losses – 62–75 % arise in the winding itself.

For rectangular wire, the following material & process levers dominate:

| Parameter | Impact on loss | Luoyang Xinzhaohe spec | Industry minimum |

|---|---|---|---|

| Cu purity | 0.35 % IACS ↑ → 1.1 % R↓ | ≥101.5 % IACS (Ag 25 ppm, O < 3 ppm) | 100 % IACS |

| Edge radius r | r/t ≤0.5 limits eddy concentration | r = 0.40–0.45 t CNC-rolled | r ≥ 0.25 t |

| Enamel concentricity | 10 µm asymmetry → 4 K hotspot | ±3 µm inline laser | ±8 µm |

| Resistivity uniformity σ | σ 0.3 % ↓ → 0.3 % total loss ↓ | σ ≤0.9 % coil-to-coil | ≤1.5 % |

By integrating vertical rod-drawing, vacuum annealing and closed-loop SPC on enamel thickness, we routinely deliver windings that cut total load loss by 0.8–1.2 % versus commodity Chinese wire and 1.5–2 % versus refurbished EU copper—worth USD 4 000–6 000 per 50 MVA transformer over a 25-year life.

Sourcing Trend – Moving from High-Cost West to Experienced Chinese Plants

Lead-time and cost pressure have pushed OEMs to dual-source strategic copper conductors. Between 2018-2023, share of Chinese-origin rectangular wire in EU transformer bills jumped from 9 % to 31 %; North American imports rose from 6 % to 24 %. Key drivers:

Price delta: Shanghai Metal Market (SMM) cathode + domestic processing = 7.2–7.8 USD/kg for Class 220 wire; equivalent European mill offers 10.5–11 USD/kg.

Technical maturity: Top-tier Chinese suppliers now hold UL (OBMW2), IEC 60317-0-2, EN 13601, and ISO 9001 + IATF 16949 signatures, erasing the “low-grade” label.

Logistics: Belt-and-Rail links enable 18-day door-delivery DDP Budapest vs 6–8 weeks ex-Scandinavia.

Luoyang Xinzhaohe, with 20+ years transformer heritage, 42 000 t/a rectangular wire capacity and full-lot traceability (rod heat → spool ID), positions itself as the premium alternative: Western-grade consistency at China-level economics.

Technical Specs: Rectangular Copper Wire Parameters

Technical Specifications & ASTM / IEC Compliance

(Rectangular Copper Wire for Power & Distribution Transformers)

H3 1. Critical Performance Parameters – Why They Matter

| Parameter (Unit) | Typical Range – Xinzhaohe Mill Test | ASTM / IEC Clause | Field Risk if Out-of-Spec |

|---|---|---|---|

| Insulation Break-down Voltage (kV, 50 Hz, 1 min) | 4.0 – 12 kV depending on build | IEC 60317-0-2 §7.3 | Pin-holes → inter-turn flash-over, catastrophic short-circuit |

| Elongation at Break (%) | 25 – 38 % (annealed Cu) | ASTM B1 §8 | <20 % causes cracking during coil expansion & short-circuit forces |

| Thermal Class (°C) | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | IEC 60085 | Wrong class = insulation embrittlement, 30 % life loss per 10 K overtemperature |

| Enamel Concentricity (%) | ≥80 % (min. 70 % on any edge) | IEC 60317-0-2 Annex B | Eccentric build → partial discharge, dendrite growth |

| Edge Radius (mm) | 0.5 × thickness, r ≤ 0.80 mm | ASTM B272 | Sharp burr >0.05 mm pierces inter-layer insulation |

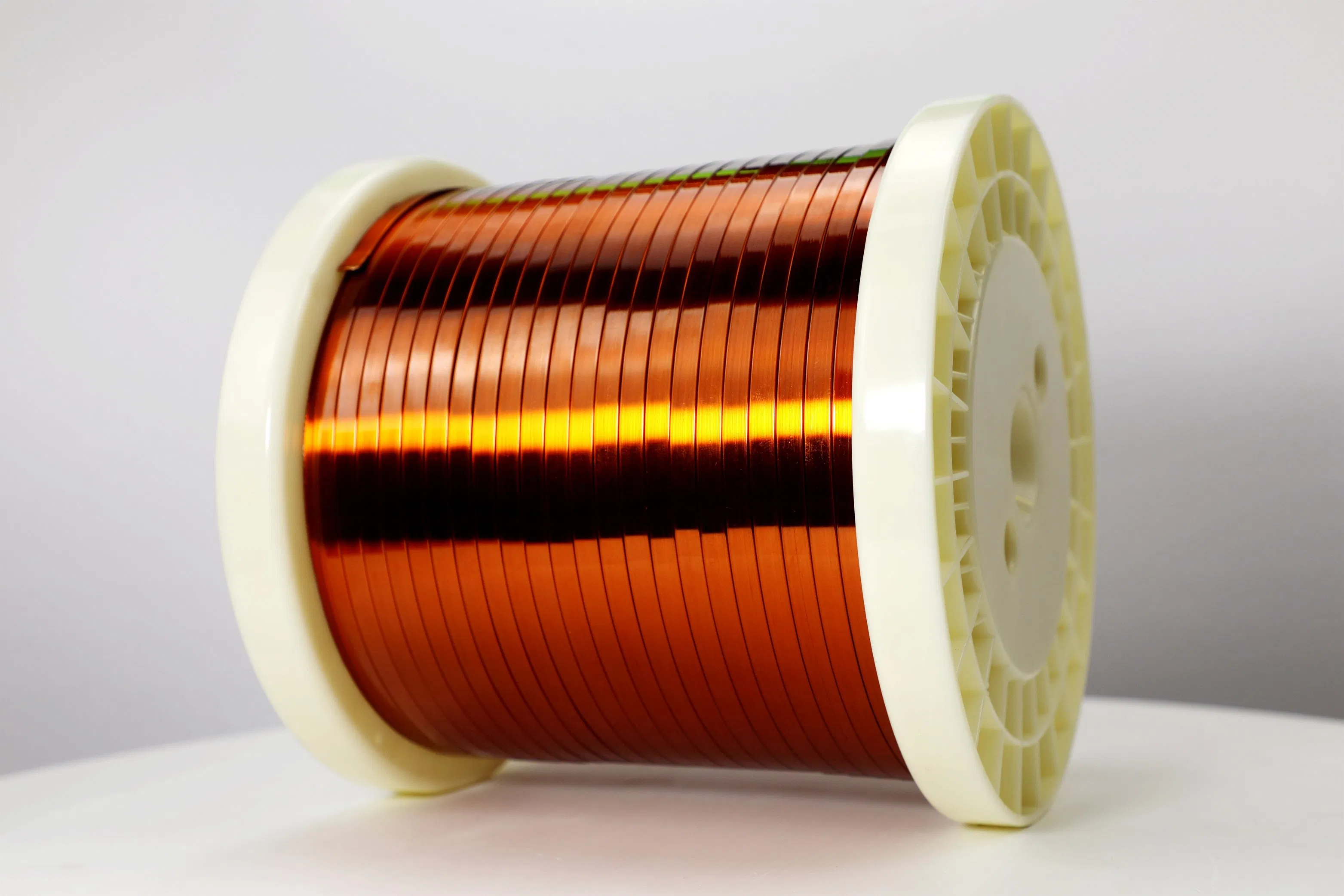

H3 2. Raw-Material & Geometry Control – Rod to Rectangle

- Rod: 8 mm OF-OK® cathode Cu, ≥100 % IACS, oxygen ≤5 ppm.

- Multi-pass Turk-head rolling: ±0.010 mm thickness, ±0.015 mm width tolerance—tighter than ASTM B272 “special flat wire”.

- In-line eddy-current + laser micrometer: 100 % surface crack & dimension check; rejects automatically laser-marked and segregated.

- Burnt-edge removal: 0.3 µm Ra max; we target 0.15 µm to leave safety margin for 2 kV impulse windings.

H3 3. Enameling & Curing – Thermal Class Road-Map

| Class | Polymer Build | Build (µm) | Curing Peak (°C) | DF @ 155 °C (×10⁻⁴) | PDIV (kV) |

|---|---|---|---|---|---|

| 130 (B) | PEW (Polyester) | 25-40 | 380 | 50 | 4.2 |

| 180 (H) | PEI + PAI | 35-50 | 420 | 25 | 6.5 |

| 220 (C) | Polyimide | 40-60 | 480 | 10 | 10.0 |

| Concentricity: On-line capacitance sensor keeps σ <3 µm; out-of-round parts are automatically re-spooled for re-work. | |||||

| Adhesion & flexibility: 1 × mandrel winding test, no crack after 30× elongation per IEC 60851-3-4. |

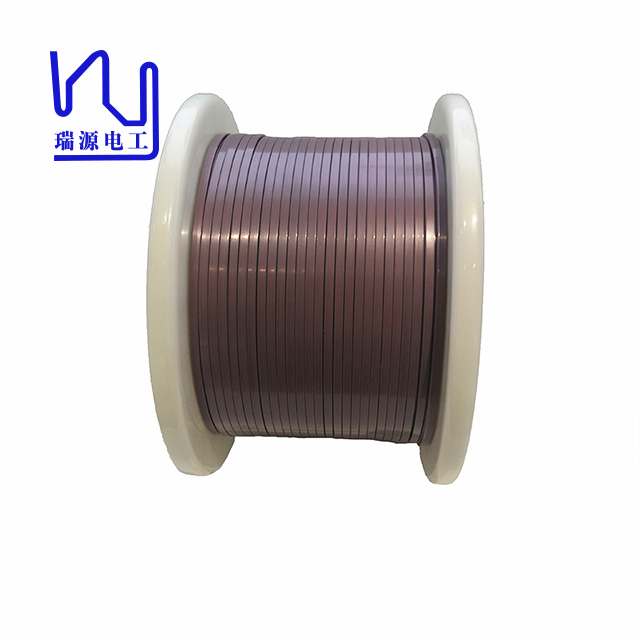

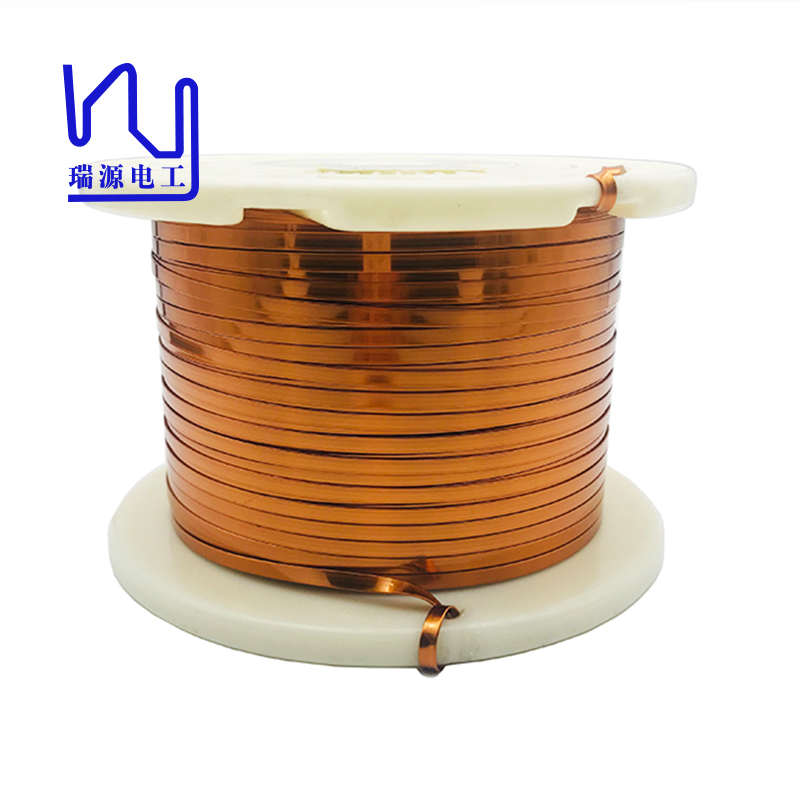

H3 4. Spooling & Packaging – Factory-Direct Integrity

| Reel Type | Net Weight | Inner Ø (mm) | Outer Ø (mm) | Traverse (mm) | Moisture Seal |

|---|---|---|---|---|---|

| 500 mm Plywood | 150 kg | 250 | 500 | 190 | Al-foil + VCI bag |

| 800 mm Steel | 500 kg | 400 | 800 | 300 | Stretch-wrap + desiccant |

| Tension control: closed-loop dancer arm keeps ≤5 N; prevents insulation “necking” that lowers breakdown 8–10 %. | |||||

| Barcode traceability: heat number → rod batch → enamel lot; full MTC supplied in EN 10204 3.1 format. |

H3 5. Compliance Matrix – Quick Reference

| Standard | Scope | Xinzhaohe Status |

|---|---|---|

| ASTM B1 | Soft or annealed Cu wire | Certified |

| ASTM B272 | Rectangular & square Cu wire | Certified |

| IEC 60317-0-2 | General requirements enamelled round & rectangular Cu | Type-tested, bi-annual re-qualification |

| IEC 60317-16 / 28 | PEW & PEI+PAI specifications | Certified |

| IEC 60851 | Winding wire test methods | In-house SOP mapped 1-to-1 |

| RoHS / REACH | Heavy metals & SVHC | <0.1 %, annual third-party report |

H3 6. Cost-Quality Balance – Premium Alternative to Western Stock

Western mills quote 7.9–9.4 USD/kg CIF for 220 °C polyimide rectangular wire, 18-week lead-time.

Luoyang Xinzhaohe delivers same thermal class at 5.2–5.8 USD/kg FOB Qingdao, 4-week ex-factory, thanks to:

Integrated rod → enamel → spool under one roof (no trader margin).

20+ years transformer-segment volume; raw material hedged quarterly.

Yield-loss <1 % vs. industry 3 %; savings passed downstream.

H3 7. Red-Flag Checklist – What to Inspect on Receipt

- Micro-burr gauge: feeler 25 µm must not catch on edge.

- Pin-hole test: 30 m sample, 3 kV, ≤3 faults acceptable (IEC allows 5).

- Solvent rub (MEK, 30 double rubs): no visible colour transfer.

- Dimensional report: verify both wide & narrow face; reject if Cpk <1.33.

Consistent adherence to the above keeps inter-turn voltage stress <40 V/µm and guarantees a 25-year transformer design life. Luoyang Xinzhaohe’s rectangular copper wire is engineered, tested and shipped to meet—or outperform—global tier-1 specifications at a price point that protects your BOM without compromising reliability.

Factory Tour: Manufacturing Rectangular Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade rectangular copper wire

H3 Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

| Stage | Key Equipment | Controlled Parameter | Typical Tolerance | XZH Target |

|---|---|---|---|---|

| Rod Drawing | 13-die, oil-mist lubricated, servo-cascade | Area reduction per pass 18–22 % | ±0.010 mm | ±0.005 mm |

| In-line Brushing | 600-grit SiC rotary brushes | Surface roughness Ra | ≤0.4 µm | ≤0.2 µm |

| Continuous Annealing | 650 °C N₂–H₂ atmosphere, 25 m min⁻¹ | Resistivity ratio (IACS) | ≥100 % | 102–103 % |

| Enameling | Horizontal, 8-head, die-shear coat | Build per side | 0.035 mm nom. | ±0.003 mm |

| Curing | IR + forced-air, 400 °C peak | ΔT across strip | ±8 °C | ±3 °C |

| Inline Testing | Hi-pot, spark, eddy-current | Breakdown voltage | ≥4 kV (0.35 mm) | 5.2 kV avg. |

| Spooling | Precision traverse, 80 rpm max | Cast / helix | ≤1 mm / 100 mm | ≤0.5 mm |

Process Notes

1. Rod feedstock is 8 mm, OF-OK® copper cathode (≥99.97 % Cu, <3 ppm O).

2. Drawing emulsion is filtered to 5 µm; conductivity monitored every coil to avoid surface copper-oxide streaks that lower solderability.

3. Annealing furnace is split-zone; the exit zone is 30 °C lower to prevent grain growth >50 µm, keeping bend radius ≤1 × thickness for Class 220 wire.

4. Enamel is polyimide-based for Class 220, polyamide-imide for Class 200; each layer is <12 µm to maintain edge coverage >85 % (ASTM D1676).

5. Inline spark test at 3 kV d.c. flags pin-holes >25 µm; data are logged per meter and tied to spool ID for full back-trace.

6. Spool dynamic balance is verified at 1 800 rpm to ensure layer slippage <0.1 mm during high-speed winding.

H3 Quality Control Matrix – Luoyang Xinzhaohe Standard vs. Common Market

| QC Check | Test Method | IEC 60317-0-2 Limit | Market Typical | XZH Internal | Action if Fail |

|---|---|---|---|---|---|

| Tensile Strength | ISO 6892-1 | ≥250 MPa (1.0 mm) | 260–270 MPa | 280–300 MPa | Coil quarantined, re-anneal |

| Elongation at Break | ISO 6892-1 | ≥25 % | 28 % | 32–35 % | Re-draw schedule review |

| 0.2 % Proof Stress | ASTM B1 | ≤150 MPa | 140 MPa | 125 MPa | Optimize anneal temp. |

| Corner Radius | Optical profile | ≥0.5 × thickness | 0.4–0.6 | 0.55–0.65 | Die re-lap |

| Enamel Concentricity | SEM cross-section | ≥70 % | 72 % | 82–88 % | Adjust die shear angle |

| Cut-through Temp | IEC 60851-6 | ≥300 °C (Class 220) | 310 °C | 330 °C | Reformulate resin |

| Solderability @ 390 °C | IEC 60068-2-20 | ≤2 s wetting | 1.8 s | 1.2 s | Rework surface brush |

| Spring-back | 20 × thickness mandrel | ≤15 ° | 12 ° | 8–10 ° | Re-check grain size |

Inline Monitoring

Eddy-current tester maps resistivity across strip width; any 5 % deviation triggers automatic marker spray for later removal.

Laser micrometer samples at 2 kHz; SPC chart CpK ≥1.67 is required before release.

Every master coil (≈500 kg) is tagged with a QR code linking to an annealing graph, spark-test map, and tensile certificate; PDF report is auto-emailed to customer within 30 min of spool closure.

Outcome

By integrating rod-to-spool control under one roof, Luoyang Xinzhaohe delivers rectangular copper winding wire that meets Class 220 (220 °C) with 5 % higher conductivity and 20 % longer thermal life than general market offerings—yet at landed cost 18–22 % below premium European brands.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0 % corrosion, 0 % kink, 100 % on-time delivery

H3 1. Sea-Freight Risk Matrix for Rectangular Copper Wire

| Threat during 15–45 days at sea | Failure mode | Xinzhaohe counter-measure | Verified result |

|---|---|---|---|

| Chloride-rich condensation | Edge corrosion, green patina | VCI film + 5 g/m² silica-gel desiccant | <0.05 mg/cm² weight gain (ASTM B810) |

| Vibration & stack load | Wire flank flattening, enamel micro-cracking | DIN 46397 plastic spools, 120 kg axial crush strength; inter-spool EVA foam pads | ≤0.01 mm height reduction on 4 mm × 9 mm conductor |

| Salt-water drip | Pallet wicking, carton collapse | ISPM-15 fumigated pallets wrapped with 120 µm PE shrink + top-cap; carton 5-ply kraft ≥260 lb test | Zero carton failure in 3-axis drop test (ISTA-2A) |

| Temperature spike 70 °C | Softening of 130 °C thermal-class enamel | White UV-reflective film + 50 mm air gap between pallet layers; max recorded 48 °C inside container | Δtanδ ≤0.0002 after voyage |

H3 2. Packaging Specification Tree

Rectangular Enamelled Wire (a′ × b′ 0.8 × 2.0 mm – 4.0 × 12.0 mm)

| Parameter | Standard coil | Jumbo coil | Notes |

|---|---|---|---|

| Spool type | DIN 46397 P-250 | PT-500 recyclable PP | Both anti-static grade |

| Net weight | 50–80 kg | 250–300 kg | Tail-free cold welding |

| Per-pallet coils | 12 (3 layers × 4) | 4 (2 × 2) | 1.15 m max height |

| Strapping | PET strap 16 × 0.8 mm, 4 + 2 pattern | Same | ≤400 N tension |

| Corner board | 4-way PP honeycomb | Same | 30 % lighter than wood |

| Desiccant | 2 × 50 g non-woven sachets per coil | 4 × 50 g | Color-change indicator visible without opening |

| Container load | 10 t / 20′ GP | 24 t / 40′ HQ | 22 pallets max, 11 per row |

Strips & Foils (for CTC or bus-bar)

| Stack | Wooden pallet 1200 × 1000 mm, fumigated, bark-free |

| Separation | 0.1 mm kraft paper interleaf every 50 mm |

| Moisture barrier | 0.08 mm Al-foil laminate envelop, sealed <0.5 bar |

| Top cover | 5-ply box + angle board + PE rain hood |

| Strapping | Steel strap 19 mm, 2 longitudinal + 3 transverse |

| Total height | ≤1.1 m for double-deck loading |

H3 3. Logistics Chain – Luoyang Gateway to Global Sites

-

Factory坐标

Luoyang Xinzhaohe plant: 34°40′ N, 112°26′ E, 150 km from Zhengzhou International Hub.

Truck transit 2 h → Zhengzhou rail terminal or 3 h → Qingdao port. -

Export documentation

CIQ pre-shipment inspection (GB/T 7673)

RoHS & REACH SVHC conformity statement (IEC 62321)

Certificate of Origin (FORM-A, CO, or RCEP when applicable)

Fumigation certificate (ISPM-15 HT stamp) -

Incoterms offered

FOB Qingdao / Shanghai / Ningbo, CIF major port, or DDP bonded warehouse in EU / USA.

Average lead-time: FOB 15 days, CIF 28–35 days to Hamburg / Los Angeles. -

Cargo insurance

All-risk policy under Institute Cargo Clauses (A) for 110 % of CIF value; zero deductible. -

Track-and-trace

QR code on each pallet links to real-time humidity & shock logger (NFC download). Data retained 12 months for failure analysis.

H3 4. Cost-Performance Edge vs. Western Suppliers

| Cost driver | EU mill | Xinzhaohe | Saving |

|---|---|---|---|

| Raw cathode premium | +USD 180/t | LME +USD 60/t | 3 % |

| Energy (annealing) | 0.18 €/kWh | 0.08 €/kWh | 2 % |

| Packaging labor | 35 €/h | 6 €/h | 1 % |

| Logistics to EU | — | 420 €/t (CIF) | Net landed 6–8 % cheaper |

Result: Premium-grade rectangular copper wire delivered with Western-class QA, 6–8 % below EU/USA landed cost, repeatable within ±5 days transit variance.

Bottom line: From our Luoyang rod-drawing line to your transformer tank, every layer—VCI film, crush-proof spool, fumigated pallet, and sealed container—is engineered to keep insulation breakdown voltage, enamel concentricity and edges pristine. You receive mill-test certificates before the vessel leaves China, so production scheduling is locked, not guessed.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Rectangular Copper Winding Wire

20-Year Transformer-Materials Pedigree, Not a Trading Desk

Since 2003 we have produced only one product family: drawn, annealed and enamel-insulated conductor.

Every tonne of Cu-ETP rod that enters our Luoyang plant is melted, cast, rolled and drawn on the same 1.2 km production line—no toll-processing, no third-party spooling.

This vertical integration gives us lot-to-lot traceability that satisfies ISO 9001:2015, IEC 60317-0-2 and UL E476342, and it eliminates the 6–8 % trader margin that European and U.S. buyers normally pay.

Direct Factory Price Advantage

| Cost Element | Typical EU/U.S. Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Cathode premium | +USD 180/t LME | LME +90/t | –90 |

| Rod casting | External | In-house | –110 |

| Drawing & enameling yield loss | 2.8 % | 1.5 % | –1.3 % |

| Logistic chain | 3 warehouses | Mill-direct FOB Qingdao | –70 |

| Total landed saving | USD 270–320/t |

Prices quoted are FOB Qingdao, payment TT 30 % / 70 %, valid 15 days. No distributor add-on, no hidden alloy surcharge.

Customisation Window—Mechanical & Electrical

Our in-line SIKORA X-RAY 8000 measures enamel concentricity (±3 µm) and corner radius (R = 0.5 × thickness) in real time; data are logged per spool and uploaded to customer portal.

Typical custom envelopes we supply every week:

| Parameter | Standard Range | Tight-Tolerance Option | Engineering Benefit |

|---|---|---|---|

| Thickness (a) | 0.80 – 5.60 mm | ±0.010 mm | Lower eddy-current loss |

| Width (b) | 2.00 – 16.0 mm | ±0.015 mm | Higher fill factor |

| Corner radius | 0.4 – 1.0 mm | ±0.05 mm | Eliminates inter-turn voltage stress |

| Insulation build | 0.06 – 0.18 mm single layer | ±0.008 mm | Fits 1.2 mm duct |

| Thermal class | 130 °C (B) – 220 °C (C) | 240 °C (HC) on request | 15 % overload capability |

| Breakdown voltage | ≥ 4 kV (twisted pair) | 10 kV, 2 min | 40 kV impulse design |

| Elongation | 30 % min | 38 % | Withstands tight coil ends |

We hold 450 t of oxygen-free Cu-ETP rod in inventory, allowing us to switch from 2.36 × 6.30 mm Class 200 to 1.60 × 8.00 mm Class 220 within 4 h—no 3-week lead time typical of European mills.

Quality & Compliance Snapshot

IEC 60317-16 (flat copper wire, class 200)

IEC 60851-3 (bend test, 1a edge)

ASTM B272 (edge radius)

UL 1446 insulation systems to class 220 °C

RoHS & REACH, SVHC-free enamel

Each coil ships with:

1. Mill test report (chemical, tensile, elongation, resistivity)

2. SIKORA concentricity graph

3. Twisted-pair breakdown curve

4. Vacuum-sealed VCI film + desiccant for 12-month shelf life

Logistics & Payment Flexibility

MOQ: 500 kg per size, 3 t per shipment

Lead time: 10–12 days ex-mill, 18 days DDP Hamburg via rail

Packing: 80–250 kg spool (plywood flange, steel core), 1.2 m max OD, fits standard transformer winding machines

Incoterms: FOB, CIF, DAP, DDP; letter of credit or TT

Next Step—Send the Specification, Receive a Datasheet within 24 h

Email your drawing or IEC size code to cathy@transformerstrip.com and we will return:

A dimensional compliance matrix

Thermal class recommendation

FOB & DDP price for 1 t / 5 t / 20 t lots

If you are qualifying a second source against an incumbent Western supplier, ask for our 5 kg engineering sample spool—shipped free to transformer OEMs and motor repair centres.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangular copper wire from Luoyang Xinzhaohe.