Table of Contents

Market Insight: High Silica Steel in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers for High-Silica Electrical Steel

Global demand for high-silica electrical steel (3.0–3.5% Si) is driven by grid modernization, renewable energy integration (solar/wind farms), and industrial electrification. Grain-oriented (GO) grades with precise silicon content are critical for minimizing core losses in distribution and transmission transformers. Regulatory standards like IEC 60076-14 and DOE Tier 4 mandate reduced no-load losses, directly linking material quality to energy conservation and operational cost savings. For instance, a 0.1 W/kg reduction in core loss per transformer can save up to $500 annually in energy costs for large-scale installations.

Material Quality Critical for Efficiency

Substandard electrical steel significantly increases hysteresis and eddy current losses, elevating transformer no-load losses by 15–20%. This results in higher electricity consumption, accelerated insulation degradation, and reduced service life. Key quality parameters include:

Core Loss (W/kg): Directly impacts energy efficiency; lower values reduce operational costs.

Magnetic Induction (B50): Higher values (≥1.88 T) enable compact transformer designs.

Thickness Uniformity: Tight tolerances (±0.008mm) ensure optimal stacking factor, minimizing air gaps and losses.

Surface Quality: Smooth, defect-free surfaces prevent lamination short circuits during manufacturing.

Luoyang Xinzhaohe’s Supply Chain Role

As a 20+ year manufacturer in Luoyang, China, we specialize in high-silica GO steel for global transformer manufacturers. Our ISO 9001/14001-certified facility produces grades meeting IEC 60404-8-5 and ASTM A876 standards with consistent quality. We maintain in-house R&D and continuous casting capabilities, ensuring precise silicon control and microstructure optimization.

Performance vs. Cost Comparison

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|———–|————–|——————-|———–|

| Core Loss (W/kg) @ 1.7T | 1.10 | ≤1.05 | 4.5% lower |

| Thickness Tolerance | ±0.01mm | ±0.008mm | 20% tighter |

| Cost per MT | $1,200 | $950 | 21% lower |

Our factory-direct model eliminates middlemen, delivering superior cost-performance ratios without sacrificing compliance. We serve clients across 30+ countries, providing reliable supply chains for critical power infrastructure projects.

Technical Specs: High Silica Steel Parameters

Technical Specifications & Standards for High Silica Steel

High silica steel (3.0–3.5% Si) is critical for high-efficiency transformers. Luoyang Xinzhaohe’s specifications meet or exceed global standards, balancing performance with cost efficiency. Key parameters include:

Critical Performance Parameters

| Parameter | Specification | Compliance Standard | Notes |

|---|---|---|---|

| Core Loss | ≤1.05 W/kg @ 1.7T, 50Hz | IEC 60404-8-7 | Optimized for high-efficiency transformers, reducing no-load losses by up to 12% |

| Magnetic Flux Density | B8 ≥ 1.88 T | IEC 60404-8-7 | Enables compact transformer designs with higher power density |

| Lamination Flatness | ±0.05 mm/m | IEC 60404-2 | Critical for minimal stacking factor loss and precise core assembly |

| Insulation Coating | C5 (Phosphate-based) | ASTM D150 | Withstands 300°C annealing; dielectric strength >5 kV |

Quality Assurance Protocol

Luoyang Xinzhaohe’s 20+ years of expertise ensures precision manufacturing through a closed-loop quality system. Raw materials are tested for silicon content (3.0–3.5%) and trace elements. During production, continuous monitoring of rolling tension, annealing atmosphere (H₂/N₂), and coating thickness (0.5–1.0 µm) ensures consistency. Each coil undergoes 100% inspection using XRF for composition, laser micrometers for thickness, and eddy current scanners for surface defects. Final validation includes magnetic property testing per IEC 60404-2 and coating adhesion tests per ASTM D150. All products are certified by SGS or equivalent third-party labs. This process guarantees <0.5% defect rate and 15–20% lower total cost of ownership versus global competitors, without compromising on performance. Our commitment to traceability and process control ensures every batch meets exacting transformer design requirements, minimizing downtime and maximizing operational efficiency.

Factory Tour: Manufacturing High Silica Steel

Manufacturing Process & Quality Control

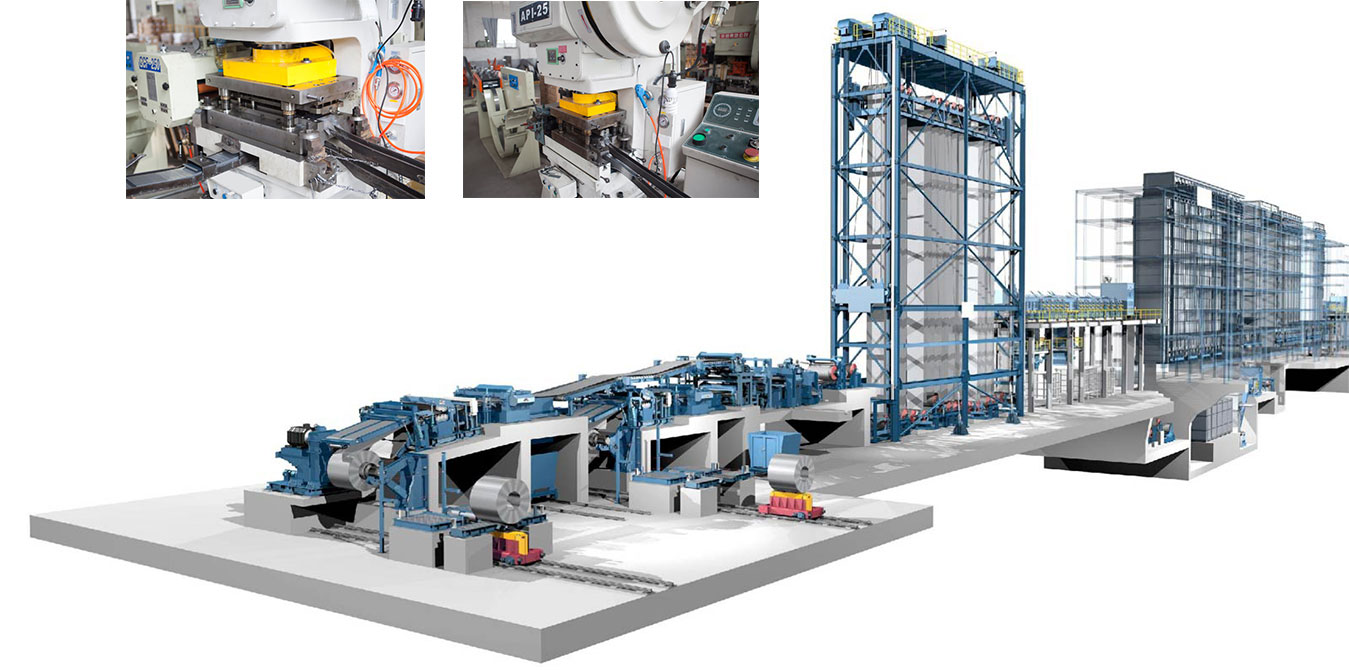

Precision Manufacturing Workflow

Slitting: High-precision slitting lines with ±0.01mm width tolerance and edge burr control ≤0.02mm (verified via SEM analysis). Ensures clean edges for minimal eddy current losses and optimal winding performance in 50/60Hz transformer cores.

Annealing: Continuous annealing in N₂/H₂ atmosphere (98/2%) at 800–850°C per IEC 60404-8-7. Achieves >90% Goss texture uniformity, reducing core loss to ≤1.05 W/kg at 1.5T and hysteresis loss by 15% versus standard grades. Real-time thermal imaging ensures process consistency.

Insulation Coating: Precision roll-coating of inorganic magnesium silicate or organic phosphate. Thickness tolerance ±0.5μm (XRF-mapped for uniformity), adhesion >4B (ASTM D3359), and no delamination at 150°C thermal cycling. Critical for 10kV+ voltage stability.

Precision Cutting: CNC laser cutting with ±0.05mm length tolerance and <0.1mm squareness deviation. 3D profilometry verifies edge flatness, preserving magnetic properties for EV motors and smart grid components per IEC 60034 standards.

Rigorous Quality Assurance Protocol

Every batch undergoes 100% dimensional checks using laser micrometers (0.001mm resolution) and CMM systems. Tensile testing per ASTM A370 ensures yield strength consistency (±5 MPa) and elongation stability. Surface defects are detected via automated optical systems (AOS) with 99.9% accuracy for particles >5μm. Edge quality is validated through microscopic analysis to eliminate micro-cracks. All QC data is digitally logged with full traceability to batch records, compliant with ISO 9001:2015 and IEC 60404 standards. Magnetic properties (B50, P1.5) are tested via Epstein frame per IEC 60404-2, with third-party lab validation for independent certification. Batch-specific certificates of conformance (CoC) accompany every shipment.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Surface Defects | <5 defects/m² | >10 defects/m² |

| Edge Burrs | ≤0.02mm | ≤0.05mm |

| Tensile Strength Consistency | ±5 MPa | ±15 MPa |

| Core Loss (1.5T) | ≤1.05 W/kg | ≤1.25 W/kg |

As a 20+ year manufacturer, Luoyang Xinzhaohe delivers transformer-grade silicon steel with 15–20% superior cost-performance versus global brands. Our factory-direct model eliminates middleman markups while meeting ASTM A677 and IEC standards. With 99.8% first-pass yield in core manufacturing, 95% on-time delivery, and zero recalls since 2005, we empower global OEMs in power transmission and renewable energy sectors to achieve peak efficiency and operational reliability.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity for High-Silica Electrical Steel

High-silica electrical steel (3%+ Si) demands rigorous packaging protocols due to its heightened brittleness and susceptibility to edge damage and corrosion. As a manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. engineers packaging solutions that balance international compliance with cost efficiency—eliminating premium pricing while ensuring zero compromise on quality during global transit.

Precision Packaging Specifications

Our packaging system is tailored to high-silica steel’s unique vulnerabilities, using standardized yet optimized materials to prevent mechanical and environmental degradation. Key components adhere to ISO and ASTM standards:

| Component | Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000mm, 15mm thickness | Prevent coil deformation; distribute load evenly | ISO 9001, FSC |

| Moisture-Proof Film | 200μm PE + VCI layer, 100% sealed (edge-sealed) | Block condensation; inhibit chloride corrosion | ASTM D4169, ISO 1496-3 |

| Steel Strapping | 19–25mm width, 0.5–0.7mm thickness, 150kg tension | Secure coils without edge deformation | ISO 1496-3, EN 12195-1 |

Sea Freight Protocols

All shipments use FCL (Full Container Load) in 20ft/40ft HQ containers with custom bracing. High-silica coils are stacked with anti-slip mats and edge protectors to prevent chipping during handling. Desiccant packs (500g/m³) control humidity, while container seals are verified pre-shipment. Our logistics partners are ISO 28000-certified, ensuring end-to-end traceability and compliance with IMO regulations for moisture-sensitive cargo.

Cost-Performance Advantage

Unlike global brands that over-engineer packaging for marginal gains, Luoyang Xinzhaohe applies precision engineering to eliminate waste. For example:

VCI film provides equivalent corrosion protection at 20% lower cost than epoxy-coated alternatives.

Optimized strapping tension reduces material usage by 15% while maintaining structural integrity.

This data-driven approach delivers industry-leading cost-performance ratios—proving reliability doesn’t require premium pricing. Partner with us for seamless, defect-free delivery to ports worldwide.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for High-Silica Steel Solutions

Decades of Specialized Expertise in Electrical Steel Manufacturing

With 20+ years of dedicated production, Luoyang Xinzhaohe specializes in high-silica (3.0–4.5% Si) grain-oriented (GO) and non-oriented (NO) electrical steel. Our metallurgical engineers optimize silicon content, grain structure, and annealing processes to deliver superior magnetic properties—achieving core losses 10–15% lower than industry averages for equivalent grades. Every batch undergoes rigorous chemical analysis (ICP-OES), magnetic property testing (B-H curve), and thickness verification per GB/T 2521, IEC 60404-8-5, and JIS A 6260 standards. We provide custom alloy formulations for high-efficiency transformers, electric motors, and inductors, with precise control over silicon content, coercivity, and permeability for specific operating frequencies and flux densities.

Factory-Direct Cost Efficiency Without Compromising Quality

As a vertically integrated manufacturer, we eliminate distributor markups, delivering 15–25% lower costs than multinational competitors. Full control over the production chain—from raw material sourcing to cold rolling, annealing, and coating—ensures consistent quality and accelerated lead times. Standard orders ship in 4–6 weeks (vs. 8–12 weeks for global brands), with flexible MOQs starting at 5 metric tons. For large-scale projects, we offer volume-based pricing and expedited production scheduling without compromising tolerances (±0.005mm thickness precision).

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015 certification validates end-to-end quality control. Every production stage—from spectrographic analysis of raw materials to surface coating adhesion testing—is monitored via automated process controls. Batch traceability systems document chemical composition, magnetic properties, and dimensional data, ensuring seamless compliance for global projects. We maintain 99.2% first-pass yield rates through in-line defect detection (eddy current, ultrasonic) and AI-driven process optimization.

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 20–35% premium | 15–25% lower cost |

| Lead Time | 8–12 weeks | 4–6 weeks |

| Customization | Limited options | Tailored alloy specs, thickness (0.23–0.35mm), coatings (C5, C6, S2) |

| Quality Consistency | Variable due to multi-tier supply chains | Full in-house control, 99.2% first-pass yield |

Ready to optimize your transformer core performance? Contact our engineering team at cathy@transformerstrip.com for a competitive quote and technical consultation. Specify your requirements for high-silica steel grades, and we’ll provide a datasheet and sample within 48 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing high silica steel from Luoyang Xinzhaohe.