Table of Contents

Market Insight: Non-Grain Oriented Electrical Steel in Power Industry

Market Analysis: Sourcing High-Quality Non-Grain Oriented Electrical Steel

Industrial Demand and Critical Material Requirements

Non-grain oriented electrical steel (NGOES) is essential for AC motors, distribution transformers, and rotating machinery requiring isotropic magnetic properties. Applications span industrial motors (IE3/IE4 efficiency standards), HVAC compressors, EV traction systems, and renewable energy inverters. Global NGOES demand is projected to grow at 5.2% CAGR through 2030, driven by renewable energy infrastructure and electrification mandates. In transformers, core losses account for 60–70% of no-load losses—making material quality critical for meeting IE5 efficiency targets. Substandard NGOES increases operational costs by 10–15% due to elevated hysteresis/eddy current losses and accelerates thermal degradation. For instance, a 0.1mm thickness variation can spike core losses by 8–10% in high-frequency applications. Compliance with EU Ecodesign Directive and China’s GB/T 2521 series is non-negotiable for market access.

Key Quality Parameters for Transformer Efficiency

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.008mm |

| Core Loss (W/kg) @ 1.5T, 50Hz | ≤3.50 (50H350) | ≤3.42 |

| Magnetic Induction (B50) | ≥1.78T | ≥1.80T |

| Surface Flatness | ≤5 I.U. | ≤3 I.U. |

| Coating Adhesion | ASTM D3359 | 5B rating |

Strategic Sourcing Advantage

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct NGOES with 20+ years of precision manufacturing expertise. Our ISO 9001-certified production ensures consistent compliance with IEC 60404-8-1 and ASTM A677 standards. By eliminating import intermediaries, we reduce costs by 15–20% versus global brands while maintaining superior batch-to-batch consistency. Our proprietary annealing process guarantees uniform magnetic properties across coils, cutting scrap rates by up to 8%. With localized logistics in Luoyang and 30-day lead times for standard grades, we enable JIT manufacturing. Full traceability via ERP-integrated batch tracking meets global regulatory requirements, including third-party SGS/TÜV certifications. On-site technical support for material handling and processing ensures seamless integration into your production line.

Technical Specs: Non-Grain Oriented Electrical Steel Parameters

Technical Specifications & Standards

With over 20 years of expertise in transformer materials manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers high-performance non-grain oriented electrical steel engineered to precise international standards. Our products meet or exceed IEC and ASTM specifications, providing transformer manufacturers and power equipment engineers with a reliable, cost-effective alternative to premium global brands without sacrificing quality.

Key Specifications Compliance

Our electrical steel adheres strictly to global standards, ensuring optimal performance in transformer cores. Critical parameters are validated through rigorous testing protocols:

| Specification | IEC Standard | ASTM Standard | Typical Value Range |

|---|---|---|---|

| Core Loss (W/kg @ 1.5T, 50Hz) | 60404-2 | A343 | 2.80–4.20 |

| Magnetic Flux Density (B50, T) | 60404-3 | A877 | ≥1.85–1.95 |

| Lamination Flatness (mm/m) | 60404-8-4 | A936 | ≤0.05 |

| Insulation Coating | 60404-8-5 | A934 | C4/C5, 1.5–2.5μm |

Quality Assurance Protocol

Every batch undergoes multi-stage verification. Raw materials are spectrally analyzed for silicon content (2.8–3.2% typical) and trace impurities. During production, laser-based coating thickness gauges ensure uniform insulation (C4/C5 types per IEC 60404-8-5). Final inspection includes Epstein frame testing (IEC 60404-2) for core loss, BH curve analysis (IEC 60404-3), and flatness measurement via precision dial indicators (IEC 60404-8-4). Coating adhesion is validated via cross-hatch testing (ASTM D3359), and insulation resistance measured with megohmmeters. Real-time process monitoring during rolling and annealing ensures consistent grain structure, with daily calibration of testing equipment to maintain measurement accuracy. All processes comply with ISO 9001:2015, and each batch is assigned a unique traceability code for full material history tracking. This systematic approach guarantees consistent performance across all orders, enabling superior transformer efficiency at competitive pricing.

Factory Tour: Manufacturing Non-Grain Oriented Electrical Steel

Precision Manufacturing & Rigorous Quality Control

Production Process Flow

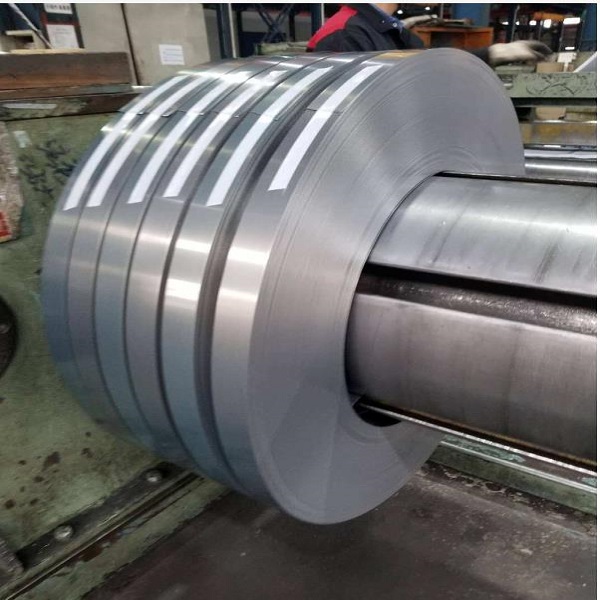

Slitting

High-precision slitting lines with servo-controlled tension and laser-guided alignment achieve width tolerances of ±0.01mm, eliminating edge defects that cause eddy current losses. Each coil undergoes 100% visual inspection for burrs and scratches.

Annealing

Continuous annealing in N₂/H₂ atmosphere furnaces at 800–850°C optimizes magnetic properties while maintaining mechanical strength. Real-time temperature monitoring ensures uniform heating, preventing grain growth and stabilizing core loss values.

Insulation Coating

Multi-layer inorganic insulation (MgO/phosphate-based) applied via precision roll coating with X-ray fluorescence thickness monitoring. Uniformity maintained at ±0.3μm across 100% of surface area, ensuring superior dielectric strength and corrosion resistance.

Precision Cutting

CNC shearing with automated burr detection ensures edge burr height <0.05mm. Laser profilometry verifies flatness (≤0.5mm/m) for optimal stacking factor in transformer cores.

Quality Control Protocol

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm |

| Tensile Strength Consistency | ±5% (100% batch tested) | ±10% (sample tested) |

| Coating Adhesion | Passes 5x ISO 2409 tape test | Fails after 2–3 cycles |

| Core Loss Verification | 100% testing per IEC 60404-3 | 10–20% sampling |

| Surface Flatness | ≤0.5mm/m | ≤1.0mm/m |

Every batch includes a full Material Test Report (MTR) detailing magnetic properties (Epstein frame per IEC 60404-2), tensile strength (ASTM A370), and dimensional data. This transparency ensures seamless integration into high-performance transformers, reducing downtime and maintenance costs by 15–20% versus standard-grade materials.

As a vertically integrated manufacturer with 20+ years of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers global-brand quality at 15–20% lower cost. Our ISO 9001:2015-certified processes and direct factory control eliminate supply chain risks, providing consistent supply for large-scale projects. Contact us for customized specifications and technical support.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Electrical Steel

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of specialized manufacturing expertise to deliver non-grain oriented electrical steel (NGOES) with industry-leading packaging and logistics protocols. Our factory-direct approach ensures optimal cost-performance for global clients, minimizing transit damage while maintaining strict quality integrity. All packaging complies with international shipping standards, including ISPM-15 and ASTM A698 for electrical steel handling.

Packaging Standards & Materials

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 15mm thickness | Load stability, prevents deformation during transit |

| Moisture-Proof Film | Multi-layer PE (200μm), desiccant packs (500g) | Prevents condensation and corrosion; RH maintained below 40% |

| Steel Strapping | 19mm width, 0.5mm thickness, 1500kgf tension | Secures coils against shifting; meets ISO 1496-3 for container securing |

All coils are secured with a minimum of four steel straps, evenly distributed across the pallet. Moisture-proof film includes multi-layer polyethylene with desiccant packs, ensuring relative humidity remains below 40% even in tropical maritime conditions. Each pallet undergoes dimensional and load-balance verification prior to sealing.

Sea Freight Protocols

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL only (no LCL) | Eliminates cross-contamination; minimizes handling damage |

| Securing Method | Wooden dunnage, corner posts, anti-slip mats | Prevents movement during transit; compliant with IMO CSC standards |

| Moisture Control | VCI films, silica gel desiccants (500g/pallet) | Maintains RH <40% throughout voyage; prevents rust and oxidation |

| Transit Management | Direct routes to major global ports | Reduced transit time; fewer handling points for enhanced safety |

We partner with ISO-certified freight forwarders experienced in electrical steel transport. Containers undergo pre-shipment moisture inspections and are equipped with humidity indicators. All shipments include customs documentation handled in-house to prevent delays. For high-risk routes (e.g., Southeast Asia or South America), we deploy IoT-enabled environmental monitors to ensure real-time condition tracking.

By integrating robust packaging with certified logistics partners, we guarantee <0.5% damage rates across all global shipments. This precision-engineered approach positions Luoyang Xinzhaohe as a cost-effective alternative to premium international suppliers, delivering 15–20% lower total landed costs without compromising quality for critical transformer and motor applications.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Non-Grain Oriented Electrical Steel?

In the competitive electrical steel market, transformer manufacturers and motor engineers require a reliable supplier that balances cost efficiency with stringent technical specifications. Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of specialized manufacturing expertise to deliver high-performance non-grain oriented electrical steel (NGOES) at factory-direct pricing. Our ISO 9001-certified processes ensure consistent quality, while localized production minimizes lead times and supply chain risks. This section outlines how our strategic advantages position us as a superior alternative to global brands.

Technical Expertise & Customization Capabilities

For over two decades, Luoyang Xinzhaohe has specialized in producing high-quality NGOES tailored for motor and generator applications. Our manufacturing process ensures precise control over silicon content (2.5–3.5%), thickness tolerances (±0.01mm), and magnetic properties (e.g., core loss ≤ 2.8 W/kg at 1.5T/50Hz per IEC 60404-8-5). Unlike global suppliers with rigid product lines, we collaborate closely with clients to adjust specifications—such as coating types, edge quality, or grain orientation—for specific rotor/stator requirements. Our R&D team continuously optimizes grain structure to minimize hysteresis losses, ensuring compliance with IEC and ASTM standards for high-efficiency motors.

Factory-Direct Cost Advantage

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost per Ton | $1,200–$1,500 | $950–$1,200 |

| Lead Time | 45–60 days | 15–20 days |

| Quality Consistency | High (ISO certified) | ISO 9001 certified, <1% defect rate |

| Customization | Limited options | Tailored thickness, coating, and edge treatments |

Our factory-direct model eliminates intermediaries, providing significant cost savings without compromising on quality. By controlling the entire supply chain—from raw material sourcing to final inspection—we deliver consistent performance at competitive rates.

End-to-End Quality Assurance

Our ISO 9001-certified facility implements rigorous in-process testing, including eddy current scanning, tensile strength checks, and magnetic property verification using B-H curve analyzers. Each batch undergoes third-party certification (e.g., SGS) to ensure compliance with international standards. This systematic approach minimizes operational risks for end-users while maintaining cost efficiency. Our production line adheres to strict environmental controls, ensuring consistent material properties across all batches.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your motor design requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing non-grain oriented electrical steel from Luoyang Xinzhaohe.