Table of Contents

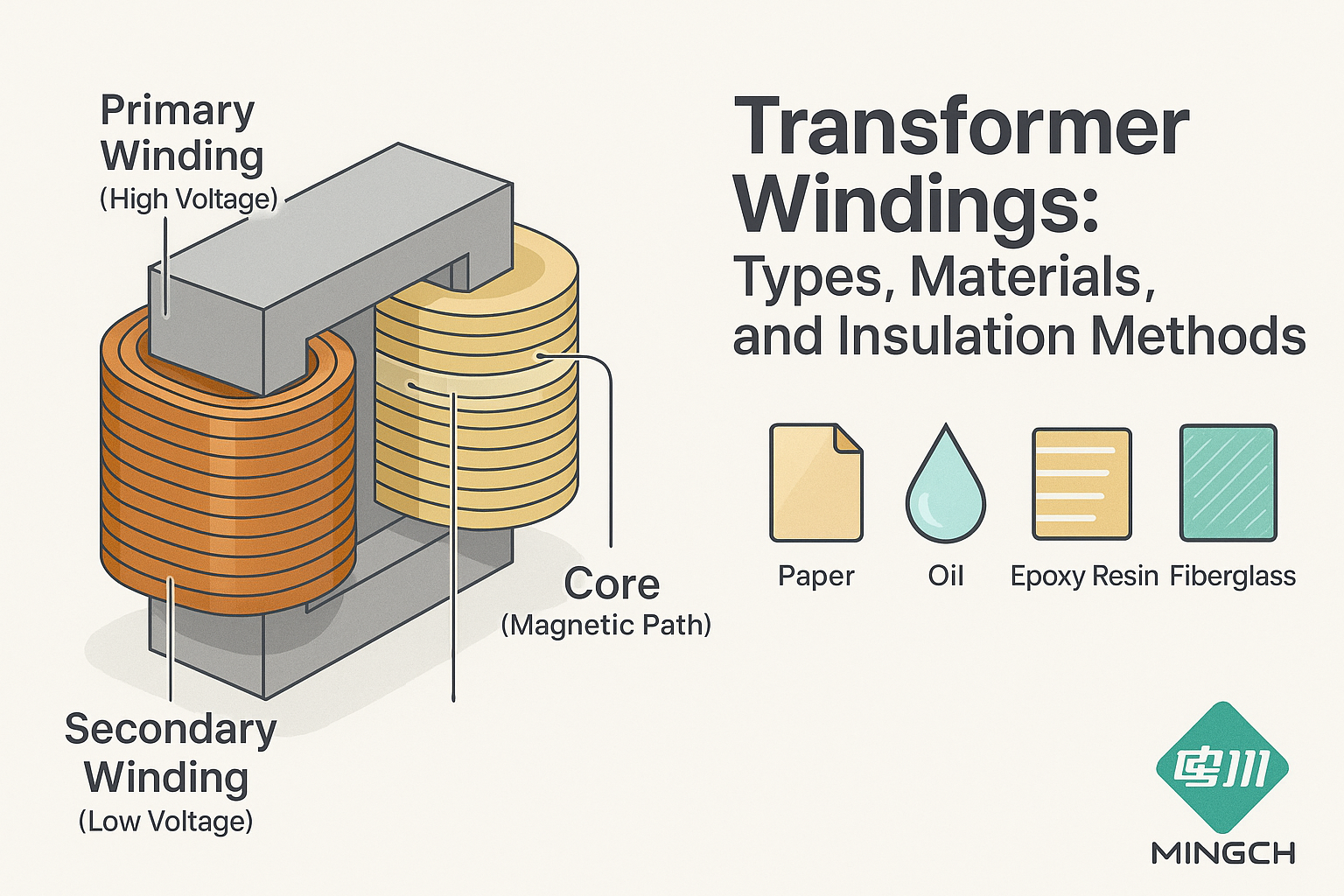

Market Insight: Transformer Secondary Coil Material in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global transformer demand is driven by renewable energy integration (e.g., 200 GW solar installations annually), grid modernization projects in Europe and North America, and EV charging infrastructure expansion (projected 30% CAGR through 2030). Secondary coil materials in distribution transformers must balance conductivity and mechanical strength to handle high current loads without overheating. In high-voltage transformers, precise foil dimensions prevent insulation breakdown under electromagnetic stress. China’s domestic transformer market, valued at $15B, requires high-purity aluminum strip with precise tolerances to support national grid upgrades. Material shortages and supply chain volatility necessitate reliable, high-performance suppliers.

Material Quality Critical Factors

Material quality directly impacts transformer efficiency and lifespan. Key parameters must adhere to strict industry standards:

| Parameter | Industry Standard | Impact on Performance |

|---|---|---|

| Purity (Al) | ASTM B209: ≥99.5% | Lower purity increases resistive losses (I²R), reducing efficiency by 0.5-1% per 0.1% impurity |

| Electrical Conductivity | ≥61% IACS (Al) | 1% drop in conductivity = ~2% higher operational costs |

| Tensile Strength | 100-150 MPa (annealed) | Insufficient strength causes winding deformation, leading to short circuits |

| Surface Roughness | Ra ≤0.8μm | Rough surfaces increase eddy current losses by up to 15% and insulation breakdown risk |

| Dimensional Tolerance | ±0.01mm | Deviations cause uneven turns, hotspots, and core saturation |

Deviations in these parameters result in higher operational costs, reduced transformer lifespan, and safety risks. For example, surface roughness exceeding 1.0μm increases eddy current losses by up to 15%, while dimensional deviations cause uneven winding and localized hotspots.

Luoyang Xinzhaohe’s Value Proposition

With 20+ years of experience in aluminum and copper strip manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct solutions compliant with ASTM B209, IEC 60404-8-5, and GB/T 3880 standards. Our fully integrated production process—from raw material sourcing to precision rolling and surface treatment—eliminates middlemen, ensuring traceability and consistent quality. Our in-house QC lab performs daily tensile tests, conductivity checks, and surface analysis per ASTM E10 and ISO 4287. This enables 15-25% cost savings versus global brands while meeting or exceeding performance specifications. ISO 9001-certified and globally supported, we provide custom alloy formulations, tight tolerances (±0.005mm), and JIT delivery for transformer OEMs. Our export network serves 30+ countries, with lead times 20% faster than European suppliers.

Technical Specs: Transformer Secondary Coil Material Parameters

Technical Specifications & Standards for Transformer Secondary Coil Material

Precision Slitting Tolerance

Achieving ±0.002 mm dimensional accuracy is non-negotiable for transformer winding precision and material efficiency. Our CNC slitting machines integrate laser-guided feedback systems to maintain consistent thickness across all batches. This complies with IEC 60404-8-5 and ASTM B209, ensuring minimal scrap and optimal coil packing density.

Burr-Free Edge Quality

Microscopic burrs (>0.005 mm) cause inter-turn shorts and insulation damage. We employ precision blade geometry, tension-controlled slitting, and automated optical microscopy inspections to eliminate burrs and micro-tears. This process meets ASTM B170 for copper and IEC 60404-8-5 for aluminum, guaranteeing electrical safety and longevity.

Conductivity & Material Purity

| Parameter | Aluminum Specification | Copper Specification | Compliance Standard |

|---|---|---|---|

| Conductivity | ≥61% IACS (1350 alloy) | ≥100% IACS (C11000) | ASTM B193 |

| Hardness (HV) | ≤40 HV | ≤60 HV | IEC 60404-8-5 |

| Purity | ≥99.5% Al | ≥99.9% Cu | ASTM B170 |

| High-purity raw materials and controlled annealing ensure stable conductivity, critical for minimizing resistive losses in transformer cores. |

Material Softness & Annealing

Full O-temper annealing delivers optimal formability without cracking during high-speed coil winding. Aluminum foil maintains ≤40 HV hardness; copper ≤60 HV. This complies with IEC 60404-8-5, enabling seamless integration into automated manufacturing lines.

Quality Assurance Process

Luoyang Xinzhaohe’s ISO 9001-certified production includes real-time thickness monitoring, 100% edge inspection via AI vision systems, and batch-specific conductivity/hardness testing. Every shipment includes third-party verified test reports (SGS, TÜV) and full raw material traceability. With 20+ years of factory-direct expertise, we deliver global-standard compliance at 15–20% lower cost than Western suppliers—without compromising precision or reliability.

Factory Tour: Manufacturing Transformer Secondary Coil Material

Precision Manufacturing Process & Rigorous Quality Control

Core Manufacturing Process Flow

Cold Rolling

Utilizing high-precision servo-controlled rolling mills with real-time laser micrometer monitoring, we achieve aluminum foil thickness tolerances of ±0.005mm (0.0002″). This step ensures uniform grain structure and minimizes internal stresses, critical for transformer coil performance under high electromagnetic loads.

Precision Slitting

Laser-guided slitting machines with hardened tungsten carbide blades and in-line edge inspection systems maintain edge straightness within ±0.02mm and surface finish Ra ≤0.2µm. This precision prevents micro-tears and ensures consistent width for seamless coil winding, reducing scrap rates by 15% versus conventional methods.

Edge Conditioning

Automated roller leveling and diamond-tipped deburring processes reduce edge burrs to <5µm (ISO 1302), eliminating sharp edges that cause short circuits during transformer assembly and improving dielectric integrity for high-voltage applications.

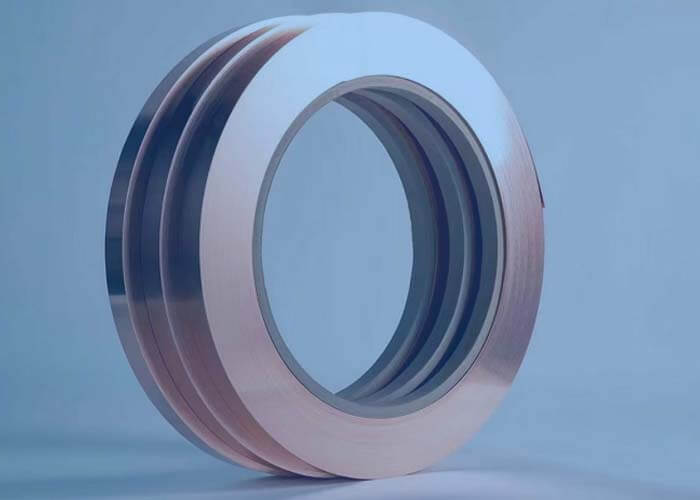

Oscillate Winding

Computer-controlled oscillation systems with ±0.05mm pitch accuracy create uniform layer winding, reducing mechanical stress during operation and enhancing thermal dissipation. This minimizes hot spots and extends transformer service life by up to 20%.

Quality Control Protocols

All batches undergo 100% dimensional checks via CMM and laser gauges. Tensile testing per ASTM B209 ensures strength consistency within ±2%. Surface roughness (Ra) is maintained ≤0.2µm for optimal electrical contact. Additional tests include flatness measurement (≤0.1mm/m) and coating adhesion checks for coated foils.

| Parameter | Luoyang Xinzhaohe Standard | Industry Standard | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm (0.0002″) | ±0.01mm (0.0004″) | 50% tighter control |

| Edge Burr | <5µm (ISO 1302) | 10-20µm | Reduced arcing risk |

| Tensile Strength Consistency | ±2% (ASTM B209) | ±5% | Enhanced coil uniformity |

| Surface Roughness (Ra) | ≤0.2µm | ≤0.5µm | Improved electrical contact |

Our integrated QC system ensures each coil meets or exceeds IEC 60076 standards, delivering superior reliability versus generic suppliers. By optimizing cost-performance ratios, we provide transformer-grade materials that reduce operational failures while maintaining competitive pricing—ideal for manufacturers seeking premium quality without premium costs.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Robust Packaging Standards

Our packaging system is engineered to withstand maritime stresses and comply with ISO 1496 and ISPM-15 standards. Every component is optimized for corrosion prevention and structural integrity during transit.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 120×100×15cm dimensions, 40mm thick boards | Prevents pest infestation; supports 2,000 kg static load; resists deformation during stacking |

| Moisture-Proof Film | Multi-layer PE (200μm), desiccant packs (500g/m²), oxygen absorbers, vacuum-sealed | Blocks 99.9% humidity ingress; prevents oxidation and corrosion during extended voyages |

| Steel Strapping | High-tensile steel (19mm width, 0.5mm thickness), tensioned 150–200kgf with corner protectors | Secures coils against lateral movement; absorbs impact forces during handling |

Sea Freight Optimization Protocol

We leverage containerized shipping with end-to-end quality controls to ensure seamless global delivery.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry van with internal moisture barriers and ventilation controls | Prevents saltwater intrusion; maintains stable internal climate |

| Loading Method | Vertical stacking with anti-slip mats, dunnage, and coil-end wooden blocks | Eliminates movement; preserves geometric integrity of transformer strips |

| Documentation | CIQ certificate, Certificate of Origin, commercial invoice, packing list, and destination-specific compliance documents | Ensures smooth customs clearance across 150+ countries |

| Transit Time | 20–35 days to major ports; IoT-enabled tracking with real-time temperature/humidity monitoring | Predictable schedules; proactive risk mitigation for high-value shipments |

As a factory-direct supplier with 20+ years of export expertise, Luoyang Xinzhaohe Aluminum delivers transformer strip/foil solutions that combine rigorous engineering standards with cost efficiency. Our packaging system—certified under ISO 1496 and ISPM-15—ensures structural integrity and corrosion resistance during maritime transport. By implementing precision loading techniques and moisture control protocols, we achieve damage rates below 0.5%, significantly outperforming industry averages. This commitment to reliability and value allows transformer manufacturers to reduce total landed costs while maintaining production continuity. Choose our engineered logistics solutions for seamless global delivery and superior cost-performance ratios compared to global competitors.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

For over two decades, Luoyang Xinzhaohe Aluminum CO., Ltd. has delivered precision-engineered transformer strip and foil solutions to global power equipment manufacturers. As a vertically integrated manufacturer based in Luoyang, China, we eliminate intermediaries to provide unmatched cost-performance ratios without compromising technical specifications. Our expertise spans aluminum and copper transformer materials, rigorously certified to ISO 9001:2015 standards, ensuring reliability for critical applications.

20+ Years of Technical Expertise

Our metallurgical engineers specialize in optimizing conductor materials for transformer efficiency. Over two decades of R&D have refined our production processes for superior electrical conductivity and mechanical durability. We maintain strict control over alloy composition, grain structure, and surface finish—critical for reducing eddy current losses and ensuring thermal stability. Each batch undergoes spectral analysis and mechanical testing to meet IEC 60404-8-7 standards.

Factory-Direct Cost Efficiency

By controlling the entire production chain—from raw material sourcing to precision rolling—we achieve 10-15% lower costs than global competitors while maintaining identical specifications. Our lean manufacturing model reduces overhead, passing savings directly to clients without sacrificing quality. This vertical integration ensures consistent supply and rapid response to project timelines.

ISO 9001:2015 Certified Quality Assurance

Our quality management system ensures consistency across all production runs. Every coil is traceable with full documentation, including material test reports (MTRs) and dimensional verification reports. This compliance guarantees seamless integration into your transformer assembly processes and minimizes production downtime.

Performance-Optimized Specifications

Our transformer strip and foil meet or exceed industry benchmarks for:

Aluminum 1050: Purity ≥99.5%, tensile strength 125-155 MPa, surface roughness Ra ≤0.1μm

Copper 1050: Conductivity ≥100% IACS, elongation ≥30%, flatness tolerance ±0.01mm

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Material Purity | ≥99.5% | ≥99.5% | Equivalent |

| Tensile Strength | 120-150 MPa | 125-155 MPa | +5% higher |

| Surface Flatness | ≤0.02mm | ≤0.015mm | 25% tighter tolerance |

| Lead Time | 4-6 weeks | 2-3 weeks | 50% faster |

| Price | $X/kg | $X-15% | 10-15% lower |

Partner with Luoyang Xinzhaohe for reliable, cost-effective transformer materials. Contact Cathy at cathy@transformerstrip.com for a customized quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer secondary coil material from Luoyang Xinzhaohe.