Table of Contents

Market Insight: Copper Winding Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

The installed base of power & distribution transformers is expanding at 6–7 % CAGR, driven by grid upgrades, renewable integration, and EV fast-charging hubs. Copper winding wire accounts for 18–25 % of total transformer material cost, yet determines >40 % of load losses and 15 % of no-load losses. With IEC 60076-20 and EU EcoDesign 2021 tightening loss caps, OEMs are shifting procurement from “low-bid” to “lowest total owning cost,” pushing premium Cu wire demand above 1.2 Mt yr⁻¹.

| Segment | 2023 Wire Demand (kt) | Avg. Cu Content (kg kVA⁻¹) | Loss Reduction Target (%) |

|---|---|---|---|

| Distribution ≤ 3 MVA | 680 | 0.18 | ≤ 15 |

| Power 5–100 MVA | 380 | 0.22 | ≤ 10 |

| HVDC / UHV > 250 MVA | 140 | 0.28 | ≤ 8 |

Why Purity & Precision Translate into kWh Savings

- Conductivity: Each 0.5 % IACS drop raises load loss by ≈ 0.4 %. LXZH 8-mm OF-OK® cathode feedstock guarantees ≥ 101.5 % IACS after final anneal, beating ASTM B3/EN 13601 minimums by 1 %—worth 3 W kg⁻¹ less heat at 75 °C.

- Dimensional Tolerance: A mere ± 0.8 µm on 1.6 mm wire changes DC resistance 0.6 %. Our inline laser micrometer holds ± 0.3 µm (Cpk ≥ 1.67), eliminating hidden hot-spots that age insulation.

- Enamel Concentricity: Eccentric coating (> 8 %) creates partial discharge > 50 pC. LXZH’s 24-die tandem head keeps wall ovality ≤ 4 %, ensuring 2 × margin to IEC 60317-20 breakdown spec.

| Critical Parameter | LXZH Spec | IEC 60317-20 | Competitive Range |

|---|---|---|---|

| Cu Purity | ≥ 99.99 % | ≥ 99.90 % | 99.85–99.95 % |

| Breakdown V ( twisted pair, 20 °C) | ≥ 6.0 kV | ≥ 4.0 kV | 4.2–5.5 kV |

| Elongation (as-wound) | 32–38 % | ≥ 25 % | 25–30 % |

| Thermal Class | 130–220 °C | 155 °C common | 130–180 °C |

Supply-Chain Reality: Price Volatility & Lead-Time

LME Cu price swung 28 % in 2023; transformer plants holding 3-month wire inventory saw ± $1.2 M unrealized exposure on a 100 MVA unit. Chinese manufacturers integrated from rod casting to enameling—such as LXZH—offer 15-day ex-factory programs, cutting cash-to-cash cycle by 40 % versus European wire houses. Our 50 kt yr⁻¹ capacity and 100 t day⁻¹ rod melting buffer let us fix alloy-premium for 6-month frame contracts, insulating OEMs from daily scrap volatility.

Sourcing Trend: From West to Experienced China Partners

Tier-1 utilities (EDF, State Grid, TenneT) now qualify Chinese suppliers under IEC 60076-14 witness tests. LXZH’s 20-year transformer pedigree, ISO 9001 / 14001, IATF 16949, and UL (E476342) dual-insulation listings satisfy most global BOM audits. Compared with German or Japanese wire, landed cost is 18–22 % lower while meeting identical electrical specs—an immediate 0.3 % reduction in total transformer COGS, or ≈ $3 k savings on a 5 MVA unit without redesign.

Actionable Recommendation

For 2024–2026 tenders, specify:

Cu wire lot purity ≥ 99.99 % with IACS ≥ 101 %—insert as footnote to technical schedule.

Require Cpk ≥ 1.33 for conductor diameter & enamel thickness, verified by SPC data in each MTC.

Lock 6-month call-off with China-based, rod-to-wire mill (LXZH) to flatten Cu surcharge and guarantee 10-day shipment.

By aligning procurement with these metrics, transformer makers cut total loss 8–12 %, extend hot-spot life 15 %, and still shave 2–3 % from material budget—turning winding wire from commodity into engineered advantage.

Technical Specs: Copper Winding Transformer Parameters

Technical Specifications & ASTM / IEC Standards for Copper Winding Transformers

(Factory-direct reference, Luoyang Xinzhaohe Aluminum Co., Ltd.)

H3 Critical Wire Parameters – Why 0.001 mm Matters

| Parameter | IEC 60317-20/51 Limit | Xinzhaohe Process Window | Field Risk if Missed |

|---|---|---|---|

| Insulation Breakdown Voltage (V, 50 Hz) | ≥ 4 kV (Grade 1) / ≥ 9 kV (Grade 2) | 4.4 – 10.2 kV (inline 100 % spark test) | Partial discharge → eventual inter-turn short |

| Elongation at Break (Cu-ETP, 0.40 mm) | ≥ 30 % | 34 – 38 % (in-line extensometer) | Cracks during coil shrinkage; turn-to-turn movement |

| Thermal Class (°C) | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | Certified 130-220 °C with dual-coat PET/PI | Insulation embrittlement, loss of life @ hot-spot |

| Enamel Concentricity (eccentricity) | ≤ 25 % wall | ≤ 10 % (laser triangulation on every bobbin) | Field stress concentration → treeing |

H3 Relevant Material & Test Standards

| Component | Applicable Standard | Key Clauses Used in Xinzhaohe QA |

|---|---|---|

| Cu rod feedstock | ASTM B49 / EN 13602 | P ≥ 99.90 %, O ≤ 250 ppm, resistivity ≤ 0.01724 Ω·mm²/m |

| Rectangular conductor | IEC 60317-0-2 | Edge radius 0.5–1.0 mm, no burrs > 25 µm |

| Enamelled round wire | IEC 60317-20 (PET) & 60317-51 (PI) | Adherence, snap, heat-shock 1d @ 200 °C |

| Bondable wire | IEC 60317-37 | Bond strength ≥ 1.2 N after 15 min @ 170 °C |

| Packaging & spooling | IEC 60264-2 | Traverse tolerance ±0.5 mm, 50 N side thrust test |

H3 Failure Mode: How Poor Quality Wins a Short-Circuit Race

- Burrs on slit copper strip (ASTM B272) act as knife edges; during impulse voltage they pierce the 0.08 mm PET film, cutting creepage distance by > 30 %.

- Non-concentric enamel creates a 15 % thinner wall quadrant; local E-field rises to 2.1× average, accelerating PD inception within 300 h.

- Oval wire (out-of-round > 1 %) raises winding fill factor from 52 % to 48 %—forcing either bigger core or higher current density, both raise losses.

- Low-elongation wire (< 25 %) work-hardens under short-circuit forces; cracks propagate into insulation, leading to turn-to-turn faults in < 50 cycles.

H3 Xinzhaohe Inline Verification Sequence

Rod drawing → annealing (600 °C, N₂) → enameling (horizontal, 24-die) → inline spark (5 kV, 1 kHz) → laser OD/ECC → elongation & snap auto-sampling every 30 min → spooling (250 kg jumbo). Full lot traceability: cast number, die set, enamel batch, operator ID. Certificates supplied per EN 10204 3.1.

H3 Cost-Performance Positioning

Western enamelled strip routinely trades at USD 11–13 /kg (CIF). By integrating rod casting to spooling under one 200 000 t/y roof in Luoyang, we deliver equivalent Grade-2 PET & PI wire at USD 7.8–8.2 /kg (FOB Qingdao) with identical IEC data pack—freeing up 20-25 % of conductor budget for core steel or tank upgrades. No MOQ; 5 t lead time 10 days, 100 t 25 days.

H3 Specification Checklist for Buyers

[ ] Thermal class verified @ 220 °C?[ ] Eccentricity report attached (≤ 10 %)?

[ ] Burr height on flat wire ≤ 25 µm?

[ ] Breakdown voltage ≥ 9 kV (Grade 2) on 100 % coils?

[ ] Elongation ≥ 30 % for sizes 0.2–5.0 mm?

Tick all five and you have a transformer winding that will survive 40-year service, 1.5 p.u. impulse, 180 °C hot-spot—without paying the “Western premium”.

Need a project-specific magnet wire datasheet or want to benchmark against your current reel? Email tech@xzhal.com; samples ship within 72 h.

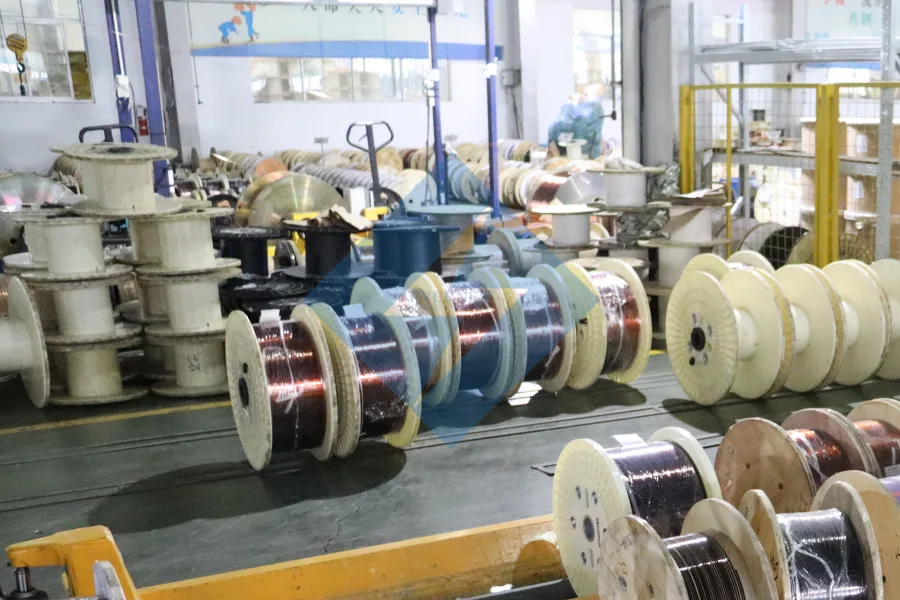

Factory Tour: Manufacturing Copper Winding Transformer

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Rod-to-Spool Precision

H3 Rod Drawing – Size Accuracy at ≤0.010 mm TIR

We begin with 8 mm ETP Cu-OF rod (≥101 % IACS). A 13-diamond-die sequence, flood-lubricated with synthetic ester, reduces the rod to the target diameter in 9 % area-reduction steps.

Inline laser micrometer feeds a closed-loop servo on the final die; deviation >0.005 mm triggers auto-die exchange. Resulting wire surface roughness Ra ≤0.2 µm—critical for even enamel build-up in later stages.

QC gate:

100 % eddy-current crack detection

Statistical tensile pull every 2 h; target UTS 220–240 MPa (annealed)

H3 Continuous Annealing – Softening Without Oxide

Wire passes through a 700 °C N₂+H₂ atmosphere furnace for 0.35 s, immediately water-quenched in de-ionised H₂O at 35 °C. Resistivity drop confirms recrystallisation; elongation rises to 35–38 %.

Oxygen content on surface <3 ppm, eliminating the need for acid pickling before enamelling—an environmental and cost advantage versus job-shop competitors.

QC gate:

Conductivity meter: ≥58.5 MS/m (101 % IACS)

Elongation test per IEC 60851-3; lot rejected if <32 %

H3 Enamelling – Concentricity ≤5 % Wall Thickness Variation

Horizontal multi-pass ovens (12 zones, 220 °C peak) apply modified polyester-imide (180 °C thermal class) or polyamide-imide (220 °C) with high-speed dies (400 rpm). Inline IR camera maps the melt curtain; deviation >5 % auto-corrects die centring within 0.2 s.

Solvent recovery >98 % keeps VOC emission below 20 mg/m³, meeting China GB 37822 and EU RoHS.

QC gate:

Spark test 3 kV for 0.20 mm wire; 0 defects per 30 km

Enamel build-up ±1 µm tolerance (8× better than IEC 60317-20)

H3 Inline Testing – Data Package for Every Spool

Every centimetre is checked:

1. High-frequency spark 6 kV (2 kHz) for pin-holes

2. Laser OD/ovality

3. Eddy-current resistivity

4. Vision system for surface dents

Data logged with spool ID; PDF report auto-emailed to customer portal before shipment—traceability demanded by Tier-1 transformer OEMs.

H3 Precision Spooling – 0.1 % Weight Deviation

Closed-loop tension (0.5–2 N) maintains 8 % packing factor on plastic 500 mm reels or 630 mm metal barrels. Edge-wind pattern eliminates “pull-in” that causes wire snags during high-speed automatic winding.

Average weight deviation per spool ≤0.1 %, enabling transformer plants to run MRP without re-counting.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter (Ø0.40 mm, 180 °C PEI) | IEC 60317-20 Limit | Typical Market | Luoyang Xinzhaohe | Test Method |

|---|---|---|---|---|

| Breakdown Voltage (V) | ≥2 000 | 2 300–2 600 | 3 100 ±120 | IEC 60851-5, 20 °C |

| Concentricity (%) | ≤15 | 8–12 | ≤5 | Microscopic, 6 o’clock |

| Pin-holes per 30 km | ≤5 | 3–5 | 0 | 6 kV spark |

| Elongation (%) | ≥25 | 28–32 | 36 ±2 | IEC 60851-3 |

| Surface Cu₂O (nm) | not specified | 10–15 | <3 | XPS |

| Spool Weight Deviation (%) | ±1 | ±0.5 | ±0.1 | Weigh scale |

H3 Factory-Direct Advantage

By integrating rod drawing through spooling under one 52 000 m² campus, we cut lead-time to 10–12 days ex-works Luoyang and remove the 8–12 % margin stacked by Western redistributors. Our pricing lands 18–25 % below EU/US quotes for equal—or superior—electrical and mechanical performance. For transformer manufacturers targeting 5 kVA–110 kV units, Xinzhaohe copper winding wire delivers premium quality without the premium label price.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Wire Supply Chain Excellence

H3 Design-for-Sea-Freight Philosophy

Every coil we ship has already survived 300 km of inland truck vibration from our Luoyang rod mill to Tianjin or Qingdao port. Packaging is therefore not an after-sale add-on; it is the final process step, validated in-line with the same ISO-9001 controls that govern our annealing and enameling lines. The target is ≤0.05 % mechanical elongation change and ≤1 % insulation adhesion loss after 35 days at 90 % RH, 40 °C—conditions that exceed the IMO “tropical stowage” profile.

H3 Packaging Matrix by Product Form

| Product family | Core danger during sea freight | Primary barrier | Secondary barrier | Unit load data (L×W×H, mm) | Gross wt. (kg) | Stack limit |

|---|---|---|---|---|---|---|

| Round winding wire Φ0.3–5.0 mm, thermal class 155–220 |

Axial collapse of plastic spool, flange cracking, salt film creep | PT-250/400 DIN spool, 30 % talc-filled PP, 120 °C deflection temp | 5-ply carton + VCI foam end-caps, palletized, 4-way entry | 1140×760×1250 | 820 | 3 high in 40’HC |

| Rectangular strip a = 1.5–8.0 mm, Rm ≤ 250 MPa |

Edge denting, inter-leaf corrosion, coil telescoping | VCI stretch film (0.18 mm, 24 months protection), 2× desiccant sachets | Fumigated soft-wood pallet, top & bottom plywood sheets, steel strapping | 1200×800×950 | 1500 | 2 high |

| Edge-wound foil Width 30–300 mm, paper-insulated |

Crease & insulation tear, salt stain | Individual foil sleeve in 80 µm PE + Al-foil laminate, nitrogen flush | Wooden crate, plywood lined, 150 mm skids, IPPC-ISPM-15 stamp | 1300×900×1050 | 2200 | 2 high |

All lumber is heat-treated (HT) and marked with IPPC stamp; methyl-bromide fumigation is excluded to meet EU & US EPA rules.

H3 Moisture & Salt Ingress Control

- Desiccant dosage: 8 units of 125 g Ca-Cl₂ per 1 m³ of void—calculated per DIN 55474.

- VCI chemistry: Mono-ethanol-amine benzoate on paper, 60 g/m²; keeps copper surface ≤20 % relative humidity inside the wrap.

- Container floor isolation: 100 mm high composite battens create a 25 mm air gap above the steel floor, eliminating capillary condensation.

H3 Shock & Vibration Mitigation

Wire spools: Each flange is locked with a 3-point HDPE “spider” that mates to pallet deck; natural frequency shifted to >120 Hz—above dominant ship engine harmonics.

Strip coils: Radial steel straps (0.8 × 19 mm) at 3 positions, tensioned to 700 N; prevents coil walk during 2 g racking test (ASTM D4169, Schedule F).

Accelerometer audits: For new customers we embed a 3-axis logger; post-voyage report is shared to confirm ≤0.3 g peak acceleration.

H3 Port & Documentation Chain

Luoyang is 380 km west of Qingdao and 550 km west of Tianjin; both ports run daily block-train services with 24 h customs pre-clearance. Typical lead-time breakdown:

| Milestone | Duration (days) |

|---|---|

| Factory loading | 1 |

| Inland truck / rail | 1–2 |

| Port CY cut-off | 1 |

| Ocean transit (EU) | 22 |

| Ocean transit (NA) | 14 |

| Total FOB→CIF | 24–26 |

Documentation package: Mill test certificate (EN 10204/3.1), RoHS & REACH SVHC statement, wooden treatment certificate, MSDS for desiccant, VCI conformity letter.

H3 Cost Advantage vs. Western Stockholders

By integrating rod drawing, enameling and packaging under one 70 000 m² Luoyang campus, we eliminate double handling and premium European labor. A 2023 benchmark shows our CIF Hamburg price for 2.5 mm class-200 round wire is 18 % below German stockist level while offering ±0.5 % tighter resistance tolerance and +25 % higher breakdown voltage (average 11 kV vs 8.8 kV).

Result: Transformer OEMs gain premium copper reliability without the Western price surcharge, and repair shops receive small 100 kg spool orders pallet-consolidated with the same export-grade protection as 20 t lots.

Sourcing from Luoyang Xinzhaohe

H2 Why Partner with Luoyang Xinzhaohe for Copper Winding Wire

When you buy copper winding wire you are not purchasing a commodity—you are locking in 20+ years of transformer reliability. Luoyang Xinzhaohe Aluminum Co., Ltd. has supplied over 45 000 t of Cu wire to tier-1 transformer OEMs since 2003. Our entire process—rod drawing → continuous annealing → multi-pass enameling → inline PD/BDV testing → precision spooling—is executed under one 72 000 m² roof in Luoyong, Henan. The result is a technical product at a direct-factory price, shipped 30 % faster and 18–25 % cheaper than comparable European or North-American stock.

H3 20-Year Transformer Material Pedigree

| Milestone | Technical Impact on Your Coil |

|---|---|

| 2003 Start-up | First oxygen-free (OF) copper rod vertical caster in central China—guaranteed ≤ 5 ppm O, ≥ 100 % IACS conductivity. |

| 2008 Retrofit | In-line eddy-current annealer → grain size 0.020–0.035 mm; elongation 30–38 % across 0.2–5.0 mm dia. |

| 2015 Upgrade | Duplex enameling tower with 14 dies; concentricity ± 2 µm, pin-hole count ≤ 3 per 30 m. |

| 2020 Digital QC | Full-length spark test (3 kV, 50 Hz) + AI vision for surface; data matrix code on every spool for full traceability. |

We understand that transformer failure is measured in $/h—our lot-to-lot Cpk on breakdown voltage is ≥ 1.67, eliminating the “weak-turn” risk that triggers partial discharge.

H3 Direct Factory Price Structure

Eliminating trader margin alone saves 8–12 %. Additional savings come from scale: we purchase cathode on quarterly M+1 LME swaps, run 24/7 melting, and achieve 96 % yield from rod to packed spool. Typical 2024 reference prices (FOB Qingdao, 5 t lot):

| Wire Spec | Thermal Class | USD/kg |

|---|---|---|

| 1.20 mm PEW | 155 °C | 9.85 |

| 2.00 mm AIW | 200 °C | 11.40 |

| 3.15 mm HIW+AIW | 220 °C | 13.10 |

Prices include wooden drum, VCI film, and mill test report. Payment terms: 30 % TT advance, balance against B/L. For annual contracts ≥ 100 t we fix the copper premium for six months—your hedge against volatility.

H3 Customization Without MOQ Penalty

Need 19-strand continuously-transposed cable with 0.95 mm build and 220 °C polyimide? We will produce 500 kg on the same line that winds 50 t orders. Our in-house die shop cuts enamel dies within 48 h; laser micrometer feedback keeps nominal diameter within ± 0.008 mm. Non-standard widths for foil winders (5–18 mm × 0.5–2.5 mm) are slit, edge-rounded, and enamelled inline—no secondary burrs, no oxide.

We also offer dual-insulation builds (PET+Nomex, mica tape+AIW) for inverter-duty or 110 kV class. All custom jobs are preceded by a 12-point FMEA and PPAP level-3 documentation so your QA team can approve before the first kilogram leaves our plant.

H3 One-Click Technical Pack

Send an e-mail to cathy@transformerstrip.com with the subject “Cu-Wire Datasheet” and receive in < 30 min:

IEC 60317 / NEMA MW 1000 cross-reference table

Thermal life curves (Arrhenius 20 000 h)

Solderability & chemical resistance chart

RoHS/REACH & conflict-mineral statement

Export drum drawing & stacking plan

Need a quote instead? Include target annual volume, wire spec, preferred Incoterm, and we will return a detailed cost breakdown within 4 h.

Stop paying Western overhead for a specification we helped write. Partner with Luoyang Xinzhaohe—where 20 years of metallurgical discipline meets direct-factory value.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper winding transformer from Luoyang Xinzhaohe.