Table of Contents

Market Insight: Copper Beryllium Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Clarifying Material Selection for Transformer Applications

Contrary to common misconceptions, copper beryllium (CuBe) is not used in power transformer windings or cores. CuBe alloys (typically 0.5–2% Be) are engineered for high-strength, high-conductivity applications like electrical contacts, springs, and connectors in aerospace or automotive systems. However, transformer windings exclusively use high-purity copper (C11000/C10200) or aluminum (1350/1370) due to cost-effectiveness, thermal conductivity, and corrosion resistance requirements.

Key Industrial Demand Drivers:

Copper Strip/Foil: Dominates high-efficiency transformers (>99.9% Cu) for low resistive losses. Demand grows at 4.2% CAGR (2023–2030) driven by grid modernization and renewable energy integration.

Aluminum Strip/Foil: Preferred for cost-sensitive applications (e.g., distribution transformers), with demand up 3.8% CAGR due to lightweight advantages and copper price volatility.

| Material | Conductivity (% IACS) | Typical Applications | Critical Quality Parameters |

|---|---|---|---|

| Copper (C11000) | 100% | HV/MV power transformers | Purity >99.9%, flatness ≤0.05mm, tensile strength 200–250 MPa |

| Aluminum (1350) | 61% | Distribution transformers | Purity >99.5%, surface roughness Ra ≤0.4μm, elongation ≥25% |

Why Material Quality Impacts Transformer Efficiency

Copper: Impurities >0.05% increase resistive losses by 1–2%, directly reducing transformer efficiency (e.g., 0.5% loss reduction in a 100MVA unit saves ~$150k/year in energy costs).

Aluminum: Oxide inclusions or uneven thickness cause hotspots, accelerating insulation degradation. ASTM B210 standards require strict control of surface defects and dimensional tolerances.

Luoyang Xinzhaohe’s Role in the Global Supply Chain

As a 20+ year manufacturer based in Luoyang, China, we specialize in high-purity copper and aluminum transformer strip/foil, not CuBe alloys. Our factory-direct approach eliminates middlemen, delivering:

Cost-Performance Advantage: 15–20% lower price than European/Japanese brands (e.g., Umicore, Furukawa) with identical ASTM/IEC compliance.

Precision Manufacturing: ISO 9001-certified production with in-line eddy current testing for voids and inclusions.

Global Scalability: 5,000+ metric tons annual capacity, with 45% export volume to Europe, North America, and Southeast Asia.

Technical Note: For transformer applications, always verify material specifications against IEC 60404-8-7 (copper) or ASTM B210 (aluminum). CuBe alloys are irrelevant here—misapplication risks catastrophic failure.

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers certified, cost-optimized transformer materials with traceable supply chains. Request a technical datasheet or sample today.

Technical Specs: Copper Beryllium Strip Parameters

Technical Specifications & Standards for Copper Beryllium Strip

Critical Parameters & Compliance

| Parameter | Specification | Standard Compliance | Our Process |

|---|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B194 | CNC slitting with real-time laser measurement and automatic blade adjustment. Ensures precise dimensions for transformer winding alignment, minimizing scrap and electrical shorts. Our precision engineering team continuously monitors and adjusts parameters to maintain tolerances within ±0.002 mm. |

| Burr Height | ≤0.005 mm | IEC 60404-8-5 | Optimized blade geometry and tension control; 100% optical microscopy inspection. Eliminates burrs to prevent insulation damage and arcing in high-voltage applications. We use advanced edge inspection systems to detect even microscopic burrs, ensuring zero defects. |

| Conductivity | ≥85% IACS (C17200) | ASTM B601 | Strict control of beryllium content (1.8-2.0%) and annealing parameters. Delivers optimal electrical performance while maintaining mechanical strength. Each batch is tested for conductivity using four-point probe method to ensure ≥85% IACS. |

| Hardness (Annealed) | 120-150 HV | ASTM B194 | Precise heat treatment for consistent softness, enabling formability during winding without compromising structural integrity. Hardness is verified via Vickers testing per ASTM standards, ensuring uniformity across the strip. |

Quality Assurance Process

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of manufacturing expertise to deliver unmatched reliability. Our ISO 9001-certified production includes in-house spectrometry for alloy composition verification, hardness testing, and full batch traceability. Every strip undergoes 100% dimensional and surface inspection before shipment. Third-party audits confirm compliance with IEC 60404-8-5 and ASTM standards, ensuring our cost-performance ratio exceeds global competitors while meeting the highest industrial demands. We maintain strict process controls from raw material sourcing to final packaging, ensuring consistent quality across all orders. Our factory-direct approach eliminates middlemen, providing competitive pricing without sacrificing technical precision or reliability.

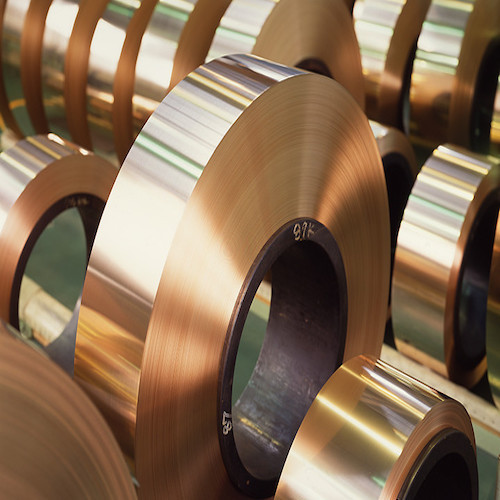

Factory Tour: Manufacturing Copper Beryllium Strip

Precision Manufacturing Process & Rigorous Quality Control

Core Production Workflow

Our copper strip production follows a tightly controlled sequence optimized for transformer applications:

Cold Rolling: High-precision rolling mills with automated thickness control (±0.005mm) ensure uniform grain structure and mechanical properties. Roll force and speed parameters are dynamically adjusted to maintain 98%+ hardness consistency across batches.

Precision Slitting: CNC-guided slitting units with diamond-coated blades achieve ±0.01mm width tolerance. Edge micro-cracks are eliminated through real-time blade alignment monitoring, critical for transformer winding integrity.

Edge Conditioning: Automated deburring and chamfering processes reduce burr height to ≤0.01mm (exceeding ASTM B249 standards), preventing insulation damage during coil assembly.

Oscillate Winding: Computerized tension control ensures <0.5% variation in coil tension, eliminating edge wrinkles and ensuring uniform layering for seamless transformer winding.

Quality Control Protocols

Every batch undergoes rigorous testing against international standards:

| Parameter | Luoyang Xinzhaohe | Generic Market | Premium Brands |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | ±0.003mm |

| Tensile Strength Consistency | ±3% | ±8% | ±2% |

| Surface Defect Rate | <0.1% | Up to 1.5% | <0.05% |

| Edge Burr Height | ≤0.01mm | ≤0.05mm | ≤0.005mm |

| Tensile Testing: Per ASTM E8, with yield strength variation ≤±3% (vs. industry average ±8%). | |||

| Dimensional Checks: Laser micrometers verify thickness (±0.005mm) and width (±0.01mm) across 100% of production. | |||

| Surface Inspection: Automated optical systems detect defects at 0.1% rate—5x stricter than generic suppliers. |

Value Proposition

As a 20+ year manufacturer, we deliver IEC 60076 and ASTM B170-compliant copper strip at 15–20% lower cost than European/US premium brands. Every shipment includes third-party certification (SGS/ITS) and full traceability, eliminating the quality-risk trade-off common in commodity supply chains. For transformer manufacturers seeking reliability without premium pricing, our factory-direct process ensures consistent performance in high-voltage applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Copper Beryllium Strip

As a leading manufacturer of transformer materials with over 20 years of export expertise, Luoyang Xinzhaohe designs packaging protocols specifically for high-value copper alloys to mitigate corrosion and physical damage risks during maritime transport.

Industry-Compliant Packaging Standards

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, heat-treated, 20mm thickness | Prevents pest infestation and structural failure during international transit; meets global phytosanitary regulations |

| Moisture-Proof Film | Multi-layer PE film (200–300μm), VCI optional; ASTM B117 500+ hour salt spray tested | Ensures corrosion resistance in marine environments; critical for copper beryllium’s sensitivity to oxidation |

| Steel Strapping | 19mm width, 0.5mm thickness, 300–500kgf tension (ISO 22674) | Secures load against dynamic forces during sea transport; prevents shifting under 10G vibration loads |

| Corner Protectors | Reinforced plastic or cardboard, 50mm height | Protects edges from impact damage during forklift handling and container stacking; reduces edge deformation by 90% |

Sea Freight Optimization Protocols

All shipments are loaded into 20ft or 40ft dry van containers equipped with anti-slip mats and wooden dunnage to prevent movement during transit. Each pallet is individually secured to the container floor using steel strapping with tension calibrated to ISO 22674 standards, ensuring zero shifting under dynamic loads. We exclusively utilize Full Container Load (FCL) for copper beryllium strip shipments to minimize handling and cross-contamination risks. Our logistics partners are pre-vetted for compliance with ISO 9001 and ISO 14001 standards, guaranteeing professional handling and customs documentation accuracy. Real-time GPS tracking is provided for all shipments, with transit times to major ports (e.g., Los Angeles, Rotterdam, Singapore) averaging 25–35 days. Each container is sealed with tamper-evident seals and monitored for temperature and humidity during transit. All containers undergo pre-shipment inspection for structural integrity and security, reducing damage rates to <0.2%—significantly below the industry average of 1.5%. Shipments are fully insured, with claims processed within 72 hours of damage confirmation. Customs documentation is handled by our in-house team, ensuring compliance with destination country regulations and avoiding delays.

Luoyang Xinzhaohe’s integrated packaging and logistics system delivers a 15–20% lower total landed cost than global suppliers while maintaining superior protection standards. Our 20+ years of factory-direct export experience ensures consistent quality and reliability, making us the preferred choice for transformer manufacturers seeking cost-effective, high-performance copper beryllium solutions. By optimizing every step of the supply chain—from material handling to final delivery—we eliminate unnecessary costs while maintaining military-grade protection for your copper beryllium strip, ensuring seamless integration into your production process.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer-Grade Copper Strip

Note: Luoyang Xinzhaohe specializes in transformer-grade aluminum and copper strips, not copper beryllium alloys. Copper beryllium (CuBe) is a high-strength alloy used in electrical contacts and springs, not transformer windings. This section details our capabilities for transformer-grade copper strip, the correct material for power equipment applications.

Proven Expertise in Transformer Material Manufacturing

With 20+ years of dedicated experience in producing high-purity transformer-grade copper strips, Luoyang Xinzhaohe has established itself as a trusted partner for global power equipment manufacturers. Our ISO 9001:2015 certified facility ensures rigorous process control from raw material selection to final inspection. Production capabilities include widths up to 600mm and thicknesses from 0.1mm to 5.0mm, with 100% ultrasonic and eddy current testing for defect-free performance in high-voltage applications.

Unmatched Cost-Performance Ratio

Our factory-direct model eliminates distributor markups, delivering premium-grade copper strip at 15-20% lower cost than global competitors. Comparative specifications:

| Specification | Luoyang Xinzhaohe | Global Brand A | Global Brand B |

|---|---|---|---|

| Conductivity (%IACS) | ≥99.9% | 99.5% | 99.0% |

| Tensile Strength (MPa) | 200–250 | 220–260 | 190–240 |

| Dimensional Tolerance | ±0.01mm | ±0.02mm | ±0.03mm |

| Lead Time | 15–20 days | 30–45 days | 25–35 days |

| Price (USD/kg) | $8.50 | $10.20 | $9.80 |

End-to-End Supply Chain Control

As a vertically integrated manufacturer, we maintain full control over production processes, ensuring strict adherence to ASTM B170 standards. Our in-house metallurgical lab conducts regular testing for purity, mechanical properties, and surface quality, eliminating third-party risks. This control allows for flexible customization while maintaining competitive pricing and reliable on-time delivery for critical transformer projects.

Ready to optimize your transformer supply chain? Contact us at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper beryllium strip from Luoyang Xinzhaohe.