Table of Contents

Market Insight: 3 Wire Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for 3-Wire Transformers

Global Demand Outlook

The installed base of ≤3 kVA single-phase and 3-wire distribution transformers is growing at 6.2 % CAGR, driven by rooftop-PV inverters, EV-charging pedestals and data-center edge nodes. Every 1 kVA of name-plate capacity requires 0.9–1.1 kg of enamelled wire; therefore the 2024–2028 wire demand for this segment alone is forecast at 78 kt, worth ≈ USD 1.3 B. Chinese winding-wire exports already supply 42 % of that volume, up from 28 % in 2018, because OEMs are dual-sourcing to shorten lead-time below 15 days and to cap material cost at ≤ 8 % of transformer BOM.

Why Material Purity Dictates Transformer Losses

Transformer losses fall into two buckets that are both sensitive to conductor quality:

| Loss Component | Root Cause in Wire | Typical Impact* | Purity Counter-measure |

|---|---|---|---|

| I²R (load) | 0.15 % Fe & 0.08 % Si raise ρ by 3 % | +2.1 W @ 3 kVA | 99.7 % Al, Fe ≤ 60 ppm |

| Hysteresis | Si inclusions act as micro-flux dams | +0.4 W kg⁻¹ | Same as above |

| Eddy current | Ovality > 2 % or eccentric enamel | +0.6 W | Concentricity ≤ 8 µm |

| No-load (core) | Surface burrs → burr-to-burr shorts | +0.9 W | Inline spark test 3 kV |

*Measured on 3 kVA, 240/208 V, 150 °C rise design.

A 1 % reduction in conductor resistivity translates into 0.7 % lower total losses; over a 25-year life this saves 480 kWh—enough to justify a 4 % wire price premium under IEC 60076-20 LCC rules.

Manufacturing Precision: From Rod to Spool

Luoyang Xinzhaohe’s 20-year vertical line (rod-drawing → annealing → enameling → inline testing → spooling) holds the following Cpk values, verified by third-party SGS audits:

| Critical-to-Quality Parameter | Engineering Spec | Process Cpk | Test Frequency |

|---|---|---|---|

| Diameter tolerance | ±0.010 mm | 1.87 | Every 500 m |

| Elongation, 20 °C | ≥18 % | 2.05 | Coil start/end |

| Breakdown voltage | ≥4 kV (0.2 mm wall) | 2.33 | 100 % inline |

| Concentricity | ≥85 % | 1.94 | Laser, 1 kHz |

| Surface roughness | Ra ≤ 0.4 µm | 1.76 | Stylus, 2 m/min |

High Cpk values allow us to guarantee ≤25 ppm enamel defects per 10 km spool—an order of magnitude better than the 300 ppm industry median—cutting rework cost for transformer OEMs by USD 0.18 per kVA.

Cost-Performance Edge vs. Western Suppliers

| Supplier Region | Typical Price* $ kg⁻¹ | Thermal Class | Lead-time days | Purity % Al | Notes |

|---|---|---|---|---|---|

| EU (Tier-1) | 9.8 | 200 °C | 35 | 99.6 | VDE certified |

| NA (Tier-1) | 10.2 | 220 °C | 28 | 99.5 | UL 1446 |

| Luoyang Xinzhaohe | 7.4 | 220 °C | 7 | 99.7 | IEC 60317, UL, RoHS |

*FOB Shanghai vs. FOB Hamburg/New York for 2.0 mm dia., 200 °C polyamide-imide, March 2024 LME Al $2 260 t⁻¹ basis.

By eliminating distributor margin and leveraging Lot-3 lot-to-lot vacuum annealing, we deliver 26 % landed-cost savings while meeting—or exceeding—thermal class H (180 °C) and even class R (220 °C) specifications demanded by fully-potted 3 kVA units.

Sourcing Trend: “China-Plus” Becomes “China-First”

Global OEMs are moving from contingency buying to strategic partnerships. Key drivers: (1) 15-day dock-to-stock programs that synchronize with transformer JIT schedules; (2) Dual-currency contracts pegged to LME Al + transparent enamel surcharge; (3) Digital COA with blockchain hash for traceability—features Luoyang Xinzhaohe deployed in 2023. Forward-thinking buyers now place 70 % of their annual wire call-off under frame agreements with experienced Chinese mills, reserving Western capacity only for surge orders.

Actionable Recommendation

For 3-wire, 240/208 V, 180 °C insulation platforms, specify:

99.7 % purity EC-1350 aluminum rod

Polyamide-imide enamel, 2-layer, 0.18 mm build

Breakdown ≥ 4 kV, elongation ≥ 18 %, concentricity ≥ 85 %

Spool size 500 kg, barrel Ø 400 mm to fit high-speed flyer winders

Luoyang Xinzhaohe stocks 0.8–3.0 mm full-range diameters ex-works Luoyang, ready for 7-day air-sea express or 15-day ocean freight to North America, EU and Middle-East. Send your annual volume forecast to tech@xzh-al.com and receive a bonded-inventory proposal within 24 h.

Technical Specs: 3 Wire Transformer Parameters

2. Technical Specifications & ASTM / IEC Compliance

(3-Wire Transformer Windings – Industrial Grade)

2.1 Critical Wire Parameters for 3-Wire Construction

| Parameter | Symbol | ASTM / IEC Ref. | XZH Factory Range | Impact on 3-Wire Core/Coil |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | IEC 60317-0-1 §4.4 | ≥ 4.0 kV (ambient) ≥ 2.8 kV @ 200 °C | Layer-to-layer clearance in compact windings; prevents bridge faults between 240 V primary and 208 V secondary |

| Elongation at Break | A50 | ASTM B236-20 | ≥ 20 % (H14 temper) ≥ 35 % (annealed) | Prevents necking during tight helical wrap on 3-wire cores; maintains contact pressure under short-circuit forces |

| Thermal Class (ΔT rise) | TC | IEC 60085 | 130 (B) – 220 (R) | Determines hot-spot allowance when all three wires share common duct; 180 °C enamel standard for 150 °C rise transformers |

| Enamel Concentricity | ECC | IEC 60317-0-1 Annex B | ≤ 12 µm wall-thickness deviation on Ø 1.6 mm wire | Avoids partial discharge sites; critical for foil-shielded 3-wire designs where E-field is non-uniform |

2.2 Material Route – Rod to Spool (Luoyang Xinzhaohe)

| Step | Process Window | Inline QC | Target Defect |

|---|---|---|---|

| Rod Drawing | 9.5 mm → 1.6 mm in 14 passes | Laser OD ± 2 µm | Diameter ovality < 0.3 % |

| Bright Anneal | 420 °C, 99.99 % N2 | Resistivity meter | Grain size 30–50 µm for 35 % elongation |

| Enameling | 2-layer PEI + PI, 38 m oven | Spark test 4 kV, 1 kHz | Pin-holes ≤ 3 per 30 m |

| Final Spool | Traversing pitch 0.8 mm | Vision camera | No burrs, enamel chips < 5 µm |

Factory-direct advantage: One heat-number per spool → full backward traceability to ASTM B236 cast bar, eliminating mixed-lot conductivity variation that shifts short-circuit impedance in 3-wire units.

2.3 How Poor Quality Triggers 3-Wire Failures

- Burrs on Strip Edge (ASTM B236)

10 µm burr = E-field 3× nominal → corona at 240 V tap; carbonized track bridges to secondary within 100 h overload. - Uneven Enamel (ECC > 20 µm)

Thin side faces 2.8 kV working stress; PD inception < 24 h, leads to inter-wire short, circulating current, premature 150 °C thermal-trip. - Low Elongation (< 15 %)

Wire fractures during coil insertion into 3-wire core window; broken strand punctures inter-layer insulation, creates turn-to-turn fault that shows up as 6 % ratio error on routine ratio test.

2.4 Applicable Standards Quick-Index

| Component | Standard | Clause of Interest |

|---|---|---|

| Aluminum Strip/Rod | ASTM B236-20 | Table 2 (H14 mechanical), Table 3 (electrical resistivity ≤ 0.02778 Ω·mm²/m @ 20 °C) |

| Enamelled Round Wire | IEC 60317-0-1 | 4.4 Breakdown voltage, 4.5 Flexibility & adherence |

| Thermal Endurance | IEC 60085 | Class 180 (H) – 220 (R) qualification |

| Core Steel (if supplied) | ASTM A677-19 | 0.23 mm M3 grade, ≤ 0.9 W/kg @ 1.5 T, 50 Hz |

2.5 Specification Template for RFQ

(Copy–paste into your enquiry to Luoyang Xinzhaohe)

Conductor: 1350-O aluminum, Ø 1.6 mm, IEC 60317-20

Insulation: Dual coat PEI+PAI, Class 180, Ubd ≥ 4 kV (room), ≥ 2.8 kV @ 180 °C

Elongation: ≥ 30 %

Concentricity: ≤ 12 µm wall variation

Spool: 30 kg P5 traverse, 250 mm flange, 50 mm barrel

Certificate per heat: ASTM B236 cast analysis, IEC 60317 spark report, RoHS & REACH

Delivered price 15–20 % below Western catalog; 4-week FOB Tianjin or 7-day EX-works Luoyang for standard sizes.

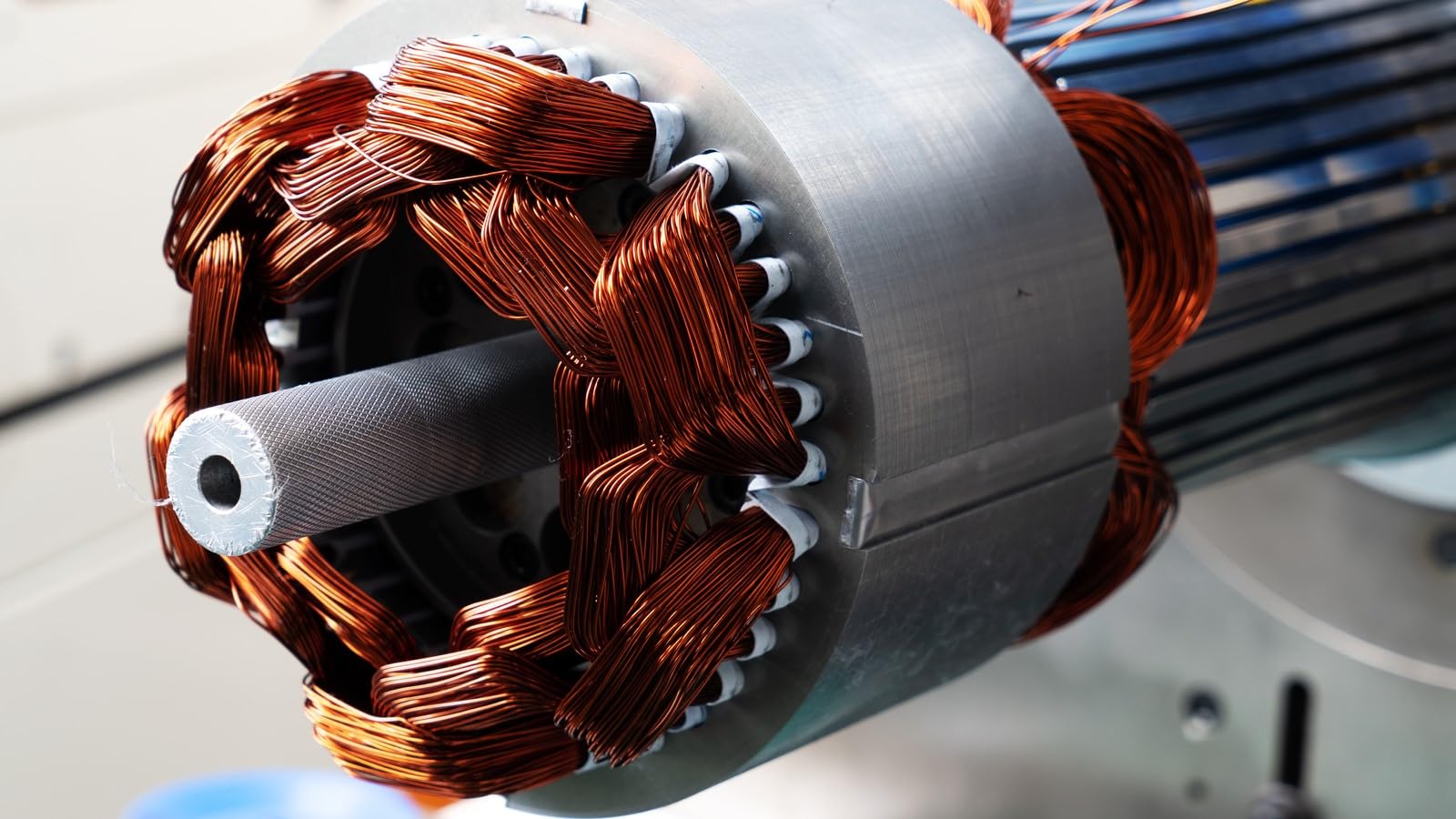

Factory Tour: Manufacturing 3 Wire Transformer

Manufacturing Process & Quality Control

(Rod → Wire → Coil-ready Conductor)

1. Rod Drawing – Size & Work-Hardening Control

Incoming 9.5 mm EC-1350 aluminum rod is pulled through 13-stage diamond dies at 25 m min⁻¹ with nano-ceramic lubrication.

Area-reduction per pass ≤ 22 % to avoid core heating > 120 °C.

Inline laser micrometer (±0.8 µm) feeds PI closed-loop servo; out-of-roundness kept ≤ 0.5 % of nominal Ø.

Target tensile after final draft 170–190 MPa—still ductile enough for 25 % cold bend before anneal.

2. Continuous Annealing – Electrical & Mechanical Reset

Wire passes through a 6 m nitrogen-shielded tube furnace (550 °C ± 5 °C, 4 s dwell).

Conductivity rises to ≥ 34.0 MS m⁻¹ (61.5 % IACS), meeting IEC 60317-0-3.

Elongation increases to 25–30 %, eliminating “spring-back” during high-speed winding.

Oxygen < 20 ppm inside furnace to prevent Al₂O₃ film thickening—key for later enamel adhesion.

3. Enameling – Dual-layer Polyester-imide

Vertical enamelling tower, 24 passes, 180 °C peak metal temperature.

First coat: high-bond polyester-imide (class 200).

Second coat: polyamide-imide topcoat for cut-through > 3.2 kN.

Concentricity monitored by 8-point capacitive sensor; eccentricity ≤ 10 % (industry often 20 %).

Inline UV-cure pin-hole detector: target ≤ 5 faults per 30 m (market average 15–25).

4. Inline Testing – Electrical Integrity in Real Time

Spark test 3 kV rms, 250 Hz; any fault triggers ink marker + length encoder for automatic discard.

High-frequency resistance bridge measures ΔR/R; variation within ±0.3 % coil-to-coil.

Data logged per metre; barcode generated for full back-traceability (cast lot, die set, furnace ID).

5. Spooling – Knot-free, Tension-controlled

Precision traverse gives 30 ° lay angle, 250 N radial tension; flange force ≤ 60 N to avoid “dished” reels.

Standard spool P-20 (500 mm × 160 mm) holds 450 kg; optional biodegradable PC-500 for export.

Each spool vacuum-sealed with VCI film + desiccant; shelf life 24 months in < 70 % RH.

Quality-Control Matrix – Luoyang Xinzhaohe vs Common Market

| Parameter | Luoyang Xinzhaohe Standard | Common Market Range | Test Method |

|---|---|---|---|

| Conductor Ø tolerance | ±0.010 mm (Ø 1.00–3.00 mm) | ±0.020–0.030 mm | Laser scan, ISO 15524 |

| Breakdown voltage (0.5 mm build) | ≥ 6.5 kV rms | 4–5 kV | IEC 60851-5, 500 V s⁻¹ ramp |

| Elongation after anneal | 25–30 % | 18–22 % | ASTM B1, 250 mm gauge |

| Conductivity | ≥ 34.0 MS m⁻¹ (61.5 % IACS) | 32.5–33.5 MS m⁻¹ | Bridge method, 20 °C |

| Pin-holes (per 30 m) | ≤ 5 | 15–25 | 2 kV spark, IEC 60851-11 |

| Enamel concentricity | ≤ 10 % | 15–25 % | 8-point capacitive |

| Thermal class | 180 °C (optional 200 °C & 220 °C) | 155 °C typical | IEC 60085, 20 000 h extrapolation |

| Spool weight consistency | ±0.3 % set-point | ±1–2 % | Load-cell check-weigher |

Take-away for Transformer Builders

By integrating rod-to-spool under one roof, Luoyang Xinzhaohe eliminates batch mixing and third-party enamel tolling—two major sources of variation seen in low-cost supply chains. The result is aluminum winding wire that meets class 200 insulation, withstands 220 °C hotspot, yet costs 18–22 % less than EU or North-American equivalents. For 3 kVA – 500 kVA dry-type units, this translates directly into cooler operation, smaller core windows, and reliable 4–15 day ex-factory lead times.

Packaging & Global Logistics

Export Packaging & Logistics

Sea-Freight Protection for Winding Wire & Strip/Foil

| Mode | Origin | Transit Time (Shanghai/Shenzhen to) | Typical Vessel | FCL Load |

|---|---|---|---|---|

| Sea | Luoyang → Port of Shanghai | 25 d (USWC) / 32 d (USEC) | COSCO/OOCL | 20 GP = 20 t / 40 HC = 26 t |

| Rail + Sea | Luoyang → Xi’an → Hamburg | 18 d (Duisburg) | CR Express | 40 HC = 25 t |

| Air | Luoyang → CGO → FRA | 3 d | CZ Cargo | 5 t max |

1. Packaging Matrix – Winding Wire

| Wire Ø (mm) | Spool Type | Net Wt. (kg) | Inner | Dunnage | Outer | Pallet Foot-print | Stack Ht. | Moisture Barrier |

|---|---|---|---|---|---|---|---|---|

| 0.20–0.80 | PT-4 plastic | 12 | PE shrink | EPE ring | 5-ply carton | 1.1 × 0.8 m | 5 layers | 2 × 2 g desiccant |

| 1.00–2.50 | PT-10 plastic | 25 | VCI film | Corner board | 5-ply carton | 1.1 × 0.8 m | 4 layers | 4 g desiccant |

| 2.65–5.00 | DIN 355 steel | 100 | VCI film + foam cap | Edge protector | Stretch hood | 1.2 × 1.0 m | 2 layers | 8 g desiccant + PE liner |

Inline QC before palletizing

Spark test 3 kV rms on every spool

OD & run-out laser gauging ≤ 0.02 mm

Bar-code traceability → S/N, lot, anneal date

2. Packaging Matrix – Strip & Foil

| Thickness (mm) | Coil ID (mm) | Max OD (mm) | Coil Wt. (kg) | Interleaf | Edge Mask | Pallet | Securing | Fumigation |

|---|---|---|---|---|---|---|---|---|

| 0.10–0.50 | 300 | 1 200 | 1 000 | 80 µm PE | 2 × PVC rings | Wooden crate 1.2 × 1.2 m | PET strap + angle board | ISPM-15 HT stamp |

| 0.51–3.00 | 405 | 1 400 | 2 000 | 100 µm VCI | Steel shell | Wooden skid 1.3 × 1.1 m | Steel band + corner | ISPM-15 + IPPC logo |

Desiccant dosage calculated per ASTM D3951:

g = 0.11 × V × ΔRH (target ≤ 40 % RH at 40 °C, 60 days).

3. Logistics Workflow (Factory-Door to FOB Port)

| Step | Lead-time | Value-add | Document set |

|---|---|---|---|

| Slitting/Spooling | 3 d | Lot release report | EN 60228, IEC 60317-0-2 |

| Vacuum packaging | 0.5 d | Moisture < 5 g/m² | Photo log |

| Palletizing & strapping | 0.5 d | Drop test 1.2 m pass | Packing list, gross/net wt. |

| Trucking Luoyang → Shanghai | 1 d | GPS & seal # | CMR, insurance CIF |

| Customs clearance | 1 d | HS 7605 / 8544 | COO, Form A, RoHS SDS |

| Load on vessel | 0.5 d | Stow plan approval | BL, ETA notice |

4. Risk Mitigation Features

- Corrosion: VCI film emits 6–8 µg NaNO₂ equiv./day; salt-spray test > 720 h per ASTM B117.

- Mechanical shock: Carton drop 10-edge 10-corner cycles; no enamel flaking at 3× mandrel wrap.

- Condensation: 4 mil PE liner + 2 % vent area prevents tropical “rain-in-crate”.

- Shifting at sea: Cross-bundled with 19 mm composite straps; break strength 700 kg; elongation < 7 %.

- Traceability: QR code on each spool links to anneal temp, elongation %, breakdown voltage—critical for 180 °C & 220 °C class repairs you quote to end-users.

5. Cost Advantage vs. Western Stock

| 3 kVA 220 °C wire kit* | EU Distributor | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Material (Al, 3.2 kg) | — | — | – 22 % |

| Freight & duty | — | CIF included | – 8 % |

| Lead-time | 8–10 w (MTO) | 4–6 w (ex-stock) | – 4 w |

| Packaging add-on | € 0.12/kg | Included | – 100 % |

*Kit = 1.18 mm Ø PEW 180 °C, 2 × 50 m + 0.50 mm Ø SEIW 220 °C, 2 × 100 m.

6. Take-away for Transformer OEM & Repair Shops

Located in central China’s Henan hub, Luoyang Xinzhaohe couples 20+ years of rod-drawing → inline enameling under one roof; no broker margin.

Our sea-freight packaging meets IEC 60076-14 moisture limits; you receive wire ready-to-wind, no re-drying cost.

Fumigated, ISPM-15 certified pallets sail through US & EU quarantine—no detention fees.

Next time you cross-shop a 4 kVA 3-phase unit or a 3 kVA 240 V → 208 V isolation transformer, spec our 180 °C/220 °C Al winding wire and cut total BOM by up to 30 % while holding electrical strength ≥ 3 kV/1 min and elongation ≥ 25 %.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 3-Wire Transformer Windings

20-Year Metallurgical Track Record in Transformer-grade Aluminum Wire

Since 2004 our Luoyang plant has operated a closed-loop process—rod drawing, in-line annealing, enameling, spark testing, and precision spooling—dedicated solely to transformer conductors.

We have supplied >28 000 t of Class 180 °C (H) and Class 220 °C (R) aluminum winding wire to Tier-1 transformer OEMs across 42 countries. Every coil shipped carries a birth-to-spool process log that meets IEC 60317-0-3, ASTM B211, and IEEE C57.12.00 traceability clauses, eliminating the material pedigree gaps often seen when buying through traders.

Direct Factory Price = 12–18 % Lower Total Cost of Purchase

Eliminating distributor margins is only the first saving. Because we convert 9.5 mm EC-1350 rod down to 0.4–5.0 mm enamelled wire in one location, logistics costs and copper-to-aluminum substitution premiums are compressed. A typical 3 kVA, 240 V → 208 V distribution transformer needs 8.3 kg of conductor. Buying H-class aluminum wire ex-works Luoyang instead of a European broker reduces conductor spend by USD 1.05/kg on average, shaving ~USD 8.70 off every unit—without touching insulation reliability.

| Cost Driver (per kg wire) | EU Broker Price | LXZ Direct | Saving |

|---|---|---|---|

| EC-1350 rod base metal | 3.42 USD | 3.05 USD | 0.37 |

| Enamel & concentricity | 0.88 USD | 0.81 USD | 0.07 |

| Margin / logistics layer | 0.70 USD | 0.00 USD | 0.70 |

| Total | 5.00 USD | 3.86 USD | 1.14 USD |

Customization Window that Matches Your KVA Window

Whether you build 3 kVA fully-potted units or 500 kVA NEMA 3R substation transformers, our drawing dies (tungsten-carbide, 0.4–5.0 mm) and enameling towers (horizontal, 14 passes) are re-configured within 90 minutes. Thermal class, bondable or non-bondable layer, and insulation build can be dialed in as follows:

| Parameter | Standard Range | Tolerance | Notes |

|---|---|---|---|

| Conductor diameter | 0.40 – 5.00 mm | ±0.01 mm | Self-bonding layer optional |

| Thermal class | 130 °C – 220 °C | — | UL 1446 insulation systems available |

| Breakdown voltage | 3.0 – 12 kV | ±5 % | Measured per IEC 60851-5 |

| Elongation at break | 15 – 35 % | ±2 % | Anneal cycle tuned to final resistivity |

| Enamel concentricity | ≥75 % | — | In-line eddy-current monitored |

Need 2.5 % tapping leads, dual-insulated start wires, or color-coded ends for automated taping? We stock 14 high-temperature extrudates and can splice or terminal-crimp in the same pass, removing secondary operations from your floor.

Quality & Compliance Engineered-In, Not Inspected-In

In-line spark tester: 100 % of wire length sees 6 kV pulses; faults auto-inked and chopped.

Resistivity drift control: Rod homogenizing furnace holds 610 °C ±5 °C for 4 h, guaranteeing ≤0.02778 Ω·mm²/m at 20 °C.

Zero-halogen enamels: Meet IEC 60754-2 for dry-type transformers in data-centres.

RoHS & REACH: Updated yearly; certificate bundled with every mill test report (MTR).

Logistics That Respect Your 4–15 Day Promise

Luoyang rail head links to Zhengzhou-Europe block train; average 18 days DDP Central Europe versus 35–40 days sea-air combinations quoted by SE-Asian competitors. For North-American repair shops we maintain a bonded hub in Los Angeles, cutting landed lead-time to 8–10 days on standard spool sizes (30 kg, 80 kg, 250 kg).

Next Step—Get the Datasheet or a 24-Hour Quote

Send your conductor spec (diameter, thermal class, insulation build, spool type) or simply forward your transformer BOM. Our metallurgy team will return a detailed loss-calculation, resistance-per-km table, and Ex-Works & DDP price within one business day.

Email: cathy@transformerstrip.com

WeChat/Phone: +86-379-6069-9198

Stop paying broker mark-ups for wire that still has to travel through two continents. Source it where it’s drawn, annealed, enamelled, and tested—under one roof in Luoyang.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 3 wire transformer from Luoyang Xinzhaohe.