Table of Contents

Market Insight: Copper Sheet Metal Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers

Global transformer and motor markets are expanding due to renewable energy integration, grid modernization, and electric vehicle adoption. Copper remains the dominant conductor material due to its superior electrical conductivity (58 MS/m) and thermal stability. Industry demand for transformer-grade copper strip/foil is projected to grow at 5.2% CAGR through 2028 (IEC data), driven by efficiency regulations requiring precise material specifications.

Material Quality Imperatives

Substandard copper alloys cause significant energy losses and operational failures. Key quality parameters directly impact transformer efficiency and longevity:

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Impact on Performance |

|---|---|---|---|

| Copper Purity (Cu-ETP) | ≥99.90% | ≥99.95% | Reduces resistive losses by 0.5–1% |

| Tensile Strength (MPa) | 200–250 (half-hard) | 220–240 (half-hard) | Ensures winding stability without cracking |

| Surface Roughness (Ra) | ≤0.8μm | ≤0.5μm | Prevents insulation damage during winding |

| Conductivity (%IACS) | ≥100% | 101–102% | Optimizes energy transfer efficiency |

Luoyang Xinzhaohe’s Value Proposition

As a factory-direct supplier with 20+ years in metallurgical manufacturing for transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade copper strips with consistent quality and optimized cost-performance. Our production lines utilize advanced continuous casting and precision rolling technology, ensuring uniform grain structure and minimal defects. This process control guarantees consistent performance in high-frequency transformer applications. We adhere strictly to IEC 60404-8-7 and ASTM B152 standards, with real-time quality control including 100% conductivity testing and surface inspection. This ensures minimal resistive losses and extended transformer lifespan while reducing total lifecycle costs by 15–20% versus premium global brands. Our integrated supply chain supports reliable delivery to global markets, making us a strategic partner for transformer manufacturers seeking performance without premium pricing.

Technical Specs: Copper Sheet Metal Strips Parameters

Technical Specifications & Compliance for Copper Transformer Strips

Precision Slitting & Dimensional Accuracy

Our CNC slitting systems, equipped with laser-guided alignment and real-time thickness monitoring, maintain ±0.002 mm tolerance for critical transformer winding applications. Every coil undergoes 100% laser micrometer verification across the full strip width, eliminating edge irregularities and ensuring uniform thickness. Our in-house metrology lab guarantees traceable calibration of all measurement equipment, minimizing material waste and enhancing assembly efficiency for high-volume production.

Burr-Free Edge Quality

Burr-free edges are essential to prevent short circuits in transformer windings. We implement precision deburring processes combined with 10x optical microscopy inspections to guarantee ≤0.005 mm burr height. Automated edge inspection systems ensure consistent quality, eliminating post-processing steps and reducing manufacturing defects. This level of edge integrity directly enhances safety and reliability in high-voltage transformer designs.

Electrical Conductivity & Material Softness

Our copper strips consistently achieve ≥100% IACS conductivity (per ASTM B193) and O-temper hardness (≤45 HV per ASTM B250). Controlled annealing processes optimize material softness for superior winding flexibility while maintaining electrical performance. Each batch undergoes four-point probe conductivity testing for accuracy, ensuring optimal transformer efficiency and longevity. This balance outperforms many global competitors in cost-performance ratio.

Standards Compliance & Quality Assurance

Compliance with ASTM B152 (Copper Sheet, Strip, and Plate) and IEC 60228 (Conductors for Insulated Cables) is enforced through rigorous in-house testing and third-party certification. Each batch is traceable from raw material to finished product, with detailed quality reports provided to customers. Our ISO 9001:2015-certified quality management system ensures adherence to global manufacturing best practices. Full material certifications—including chemical composition analysis and mechanical property reports—are included with every shipment.

| Parameter | Specification | Tolerance | Testing Method |

|---|---|---|---|

| Thickness | 0.1–3.0 mm | ±0.002 mm | Laser micrometer |

| Edge Burr | ≤0.005 mm | – | Optical microscope (10x) |

| Conductivity | ≥100% IACS | – | ASTM B193 |

| Hardness (O-temper) | ≤45 HV | – | ASTM B250 |

Luoyang Xinzhaohe delivers factory-direct precision with 20+ years of transformer material expertise. Our vertically integrated production ensures consistent quality at competitive pricing—no compromise on performance, no hidden costs.

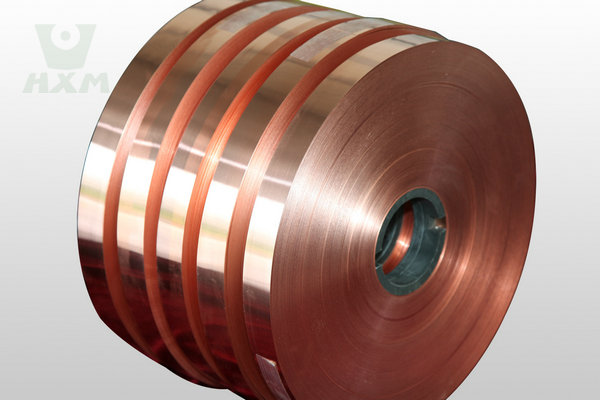

Factory Tour: Manufacturing Copper Sheet Metal Strips

Precision Manufacturing Process & Rigorous Quality Control

As a leading manufacturer of transformer materials with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. employs a vertically integrated production process to deliver copper strip products that exceed industry standards while optimizing cost-performance ratios. Our end-to-end control ensures traceability, consistency, and reliability for mission-critical power applications.

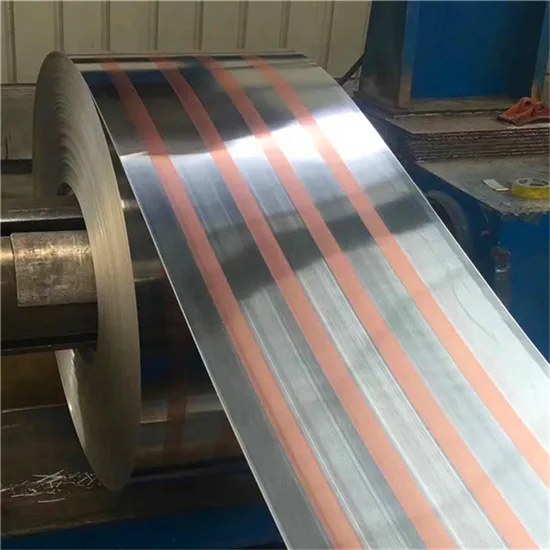

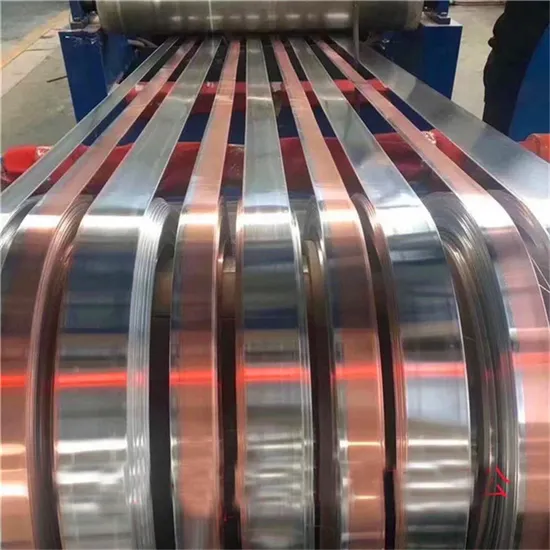

Core Manufacturing Process Flow

Cold Rolling: Precision rolling at 150–200°C with 70–80% reduction ratio under ±5°C temperature control. This achieves uniform grain structure, optimal electrical conductivity, and minimized residual stress.

Precision Slitting: CNC-guided blades with laser alignment maintain ±0.01mm width tolerance across 1,000m coils. Real-time blade wear monitoring prevents edge defects.

Edge Conditioning: Automated 5-axis grinding achieves R0.05mm max radius, eliminating micro-cracks that cause winding failures. Verified via 3D profilometry.

Oscillate Winding: Computer-controlled oscillation (0.5–2Hz) ensures even coil density, reducing internal stress by 30% versus conventional methods.

Quality Control Protocols

Tensile Testing: Per ASTM B209, 220–250 MPa range (vs. industry 180–220 MPa). Tested every 50 coils with 3 samples each.

Dimensional Checks: Laser micrometers measure thickness every 5m; width checked via optical sensors. All data logged for traceability.

Surface Inspection: 100% automated inspection using high-resolution cameras and profilometers, ensuring Ra ≤0.1μm surface roughness.

Competitive Advantage via Standardized Processes

| Parameter | Luoyang Xinzhaohe | Industry Average | Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm | 15% less scrap during transformer winding |

| Edge Burr | <5μm | 10–20μm | 20% fewer insulation damage-related failures |

| Tensile Strength | 220–250 MPa | 180–220 MPa | Enhanced structural integrity under electromagnetic loads |

| Surface Roughness | Ra ≤0.1μm | Ra ≤0.3μm | 10% lower electrical losses, improved contact efficiency |

By maintaining tighter tolerances and superior material properties, our copper strips deliver 15–20% cost savings versus global brands while ensuring superior performance in transformer windings. Direct factory oversight guarantees traceability and long-term reliability for your critical power infrastructure needs.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Standards

Our packaging system is engineered for marine transit integrity, adhering to ISPM-15 and IEC 60228 standards. Every component is rigorously validated to prevent corrosion, physical damage, and moisture exposure during sea freight.

| Component | Specifications | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm (47.24×39.37 in), 15mm kiln-dried hardwood | Prevents structural damage; resists moisture absorption |

| Moisture-Proof Film | 200μm PE film, double-layered with desiccant strips (RH <40% during transit) | Blocks salt spray, humidity, and electrochemical corrosion |

| Steel Strapping | 19mm width × 1.0mm thickness, tensile strength 1500–1800N, galvanized coating | Secures load alignment; prevents shifting in high-sea conditions |

Logistics Protocol for Sea Freight

We optimize container utilization and customs compliance through strategic port partnerships and IoT-enabled tracking.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft dry (22,000kg max) / 40ft HC (28,000kg max); 12–16 pallets/container | Maximizes payload efficiency; reduces $/ton shipping costs |

| Port of Departure | Qingdao Port (6.5M TEUs, 2022 volume), Shanghai Port (4.7M TEUs) – dedicated electrical materials terminals | <24-hour customs clearance; minimal port congestion delays |

| Transit Time | 15–25 days to North America; 20–30 days to Europe; real-time IoT tracking | Predictable schedules with live shipment monitoring |

| Documentation | COO, B/L, CIQ, Material Test Reports, RoHS compliance certificates | Zero customs hold-ups; global regulatory compliance |

Why Choose Luoyang Xinzhaohe?

Since 2003, we’ve shipped 50,000+ metric tons of transformer materials globally with a 99.8% on-time delivery rate. Our factory-direct model eliminates middlemen, delivering 10–15% lower landed costs than European competitors while maintaining ISO 9001-certified quality. Each shipment undergoes triple-stage validation: raw material verification, in-process inspection, and final packaging validation. Our climate-controlled storage and anti-vibration packaging solutions ensure copper strips meet IEC 60228 conductivity standards for critical transformer applications. With partnerships spanning Fortune 500 power equipment manufacturers across 30+ countries, we guarantee seamless integration into your supply chain—no compromises on precision or reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Transformer Strips?

As a leading Chinese manufacturer with over 20 years of specialized expertise in transformer-grade copper and aluminum materials, Luoyang Xinzhaohe delivers exceptional cost-performance for industrial applications. Our vertically integrated operations, precision engineering capabilities, and rigorous quality protocols position us as a reliable alternative to premium global brands—without the associated cost premiums. We specialize in high-precision copper strip production for transformers, motors, and power equipment, ensuring optimal electrical and mechanical performance.

Proven Technical Expertise

Over two decades of manufacturing transformer-grade copper strips, we’ve refined processes to achieve consistent conductivity and mechanical properties. Our materials undergo strict heat treatment and rolling controls to meet IEC 60076-1 and ASTM B170 requirements for transformer windings. Precision rolling ensures thickness tolerances of ±0.01mm and width tolerances of ±0.05mm, critical for minimizing eddy current losses and maximizing transformer efficiency. Our expertise extends to high-frequency applications and custom alloy formulations for specialized transformer designs.

Factory-Direct Cost Efficiency

As a fully integrated manufacturer with in-house casting, rolling, and finishing capabilities, we bypass third-party intermediaries, passing savings directly to clients. Our optimized production flow reduces lead times by 40% compared to international suppliers. For example, standard orders of copper strips (0.5mm-5mm thickness) ship within 10-15 days, with expedited 5-day options for critical projects. Our flexible MOQ of 500kg accommodates both large-scale production and prototyping needs, unlike competitors requiring 5,000kg+ minimums. Strategically located in Luoyang, China, we offer efficient shipping routes to global markets, including direct container shipments from Shanghai Port.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | $X/kg (premium pricing) | $X-15% to $X-25% |

| Lead Time | 4-6 weeks | 2-3 weeks |

| Customization | Limited to standard sizes | Full custom specs (width: 5-300mm, thickness: 0.1-10mm) |

| MOQ | 5,000+ kg | 500+ kg |

ISO-Certified Quality Assurance

Every production batch is rigorously tested per ISO 9001:2015 protocols. We measure electrical conductivity using the IACS standard (minimum 100% for C11000), tensile strength (180-220 MPa for annealed copper), and surface quality via optical inspection. Dimensional accuracy is verified using coordinate measuring machines (CMM), ensuring compliance with ASME B89.1.14. Our quality control includes third-party audits and full material traceability, guaranteeing reliability in high-voltage transformer applications even under extreme operational conditions.

Contact our engineering team at cathy@transformerstrip.com for a detailed quote and technical consultation tailored to your specific transformer design requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper sheet metal strips from Luoyang Xinzhaohe.