Table of Contents

Market Insight: Three Wire Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for Three-Wire Transformers

Global Demand Outlook

Global installations of three-phase transformers (≥1 kVA to 10 MVA) are forecast to exceed 1.3 million units yr⁻¹ through 2030, driven by utility grid upgrades, data-center build-outs, and on-shore reshoring of heavy industry. Every unit contains 12–480 kg of enamelled winding wire; therefore demand for transformer-grade copper/aluminium conductor is rising at a CAGR of 5.4 %. Dry-type designs—preferred for indoor and renewable-energy applications—operate at higher thermal stress (155–220 °C), pushing OEMs to specify Class F/H wire even for 130 °C name-plate designs in order to hit ≤75 K temperature-rise limits and comply with DO2016/EC548 efficiency tiers.

Loss Drivers: Why Material Purity & Geometry Matter

Transformer losses fall into two regimes that are both sensitive to winding-wire quality:

| Loss Component | Typical Share @ 100 % Load | Root Cause in Wire | Specification Levers |

|---|---|---|---|

| No-load (core) | 0.15–0.35 % of Sr | – | – |

| Load (I²R + stray) | 0.7–1.1 % of Sr | Conductor resistivity, burr-induced skin effect, enamel thinning | ≥100 % IACS Cu or ≥61 % IACS Al; 0.05 mm diametral tolerance; ≥35 kV breakdown |

| Eddy-current strand | 5–12 % of load loss | Non-concentric insulation, ovality | Concentricity ≥85 %; elongation 25–35 % to avoid micro-cracks |

A 1 % increase in conductor resistivity (e.g., 200 ppm Fe+Si in Cu) raises load loss by the same 1 %, equivalent to 3–5 W kg⁻¹ of wire—enough to push an 800 kVA transformer from Tier-2 to Tier-1 losses and disqualify it from utility bids. Likewise, local thinning of enamel below 0.025 mm can cut dielectric margin by 30 %, accelerating partial discharge and premature failure in VFD-fed three-wire units.

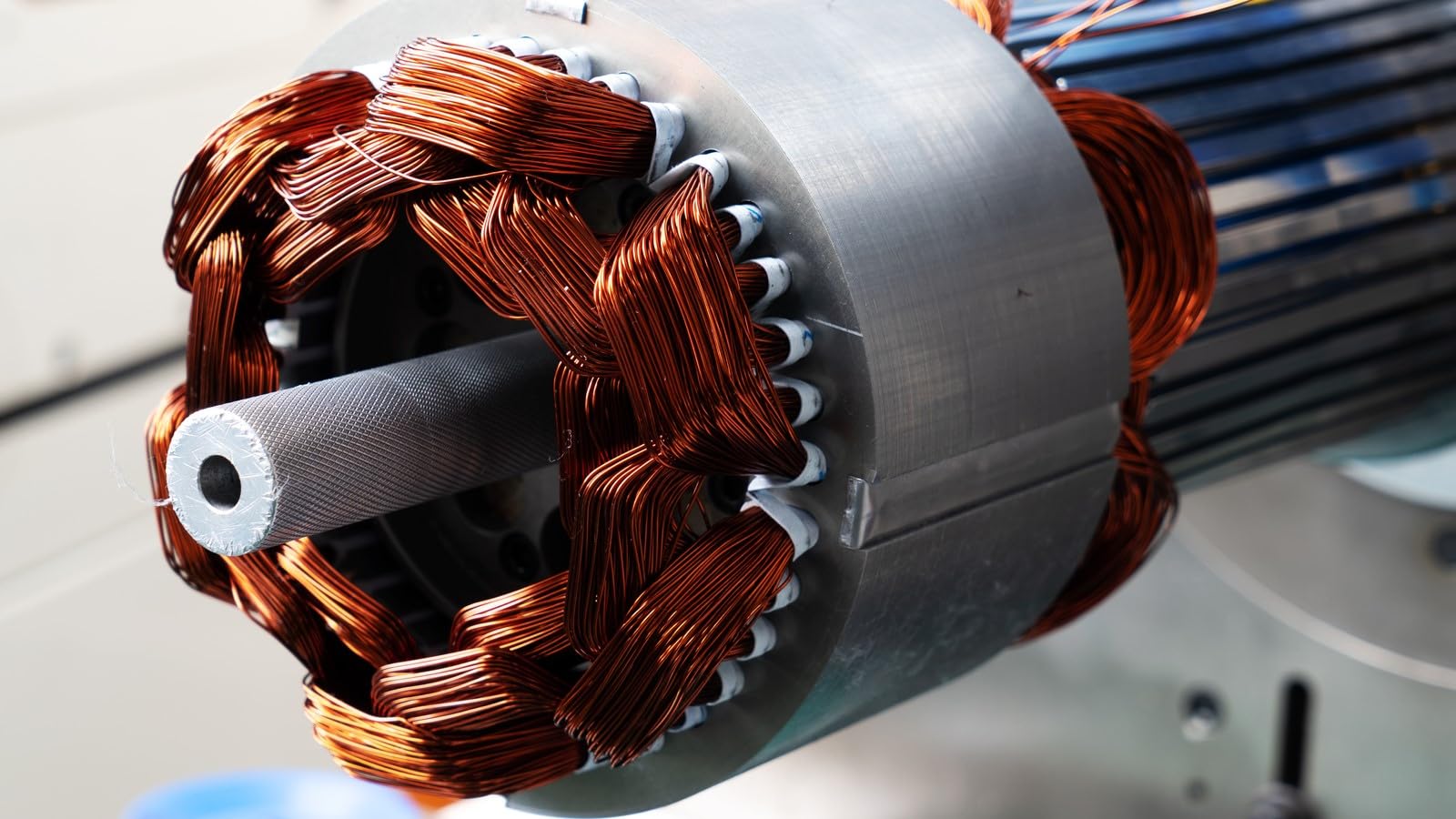

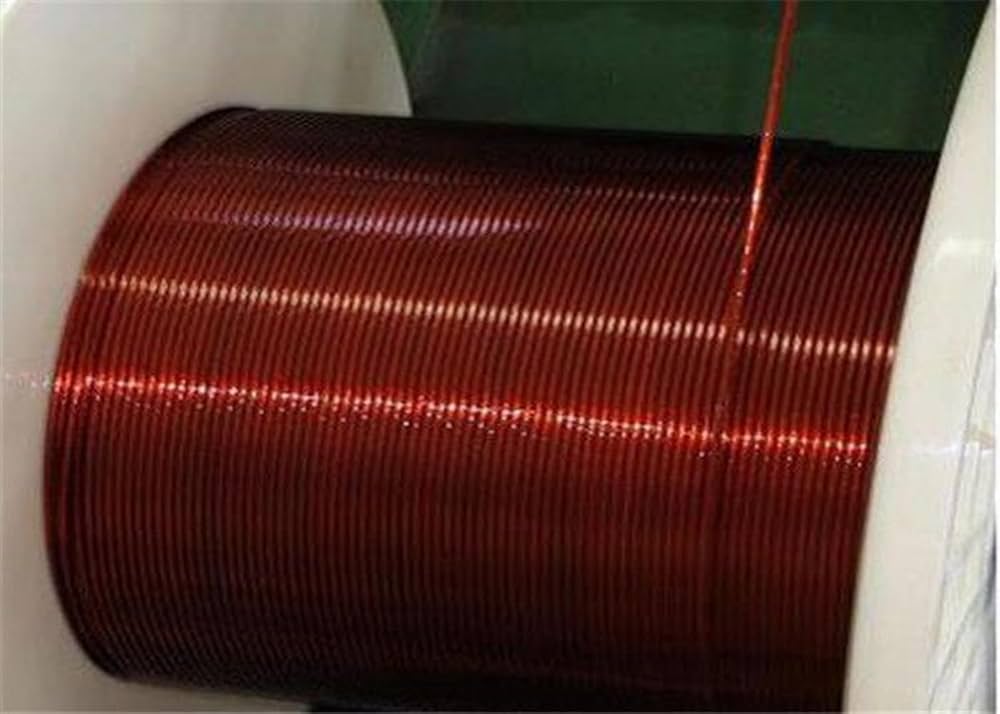

Precision Manufacturing: From Rod to Spool

Luoyang Xinzhaohe’s 20-year, 60 000 t yr⁻¹ line is purpose-built to eliminate these variances:

- Rod Drawing: Up-cast 6 mm OF-Cu or EC-Al rod drawn in 19 passes with inline laser OD feedback (±0.005 mm).

- Bright Annealing: 650 °C N₂/H₂ atmosphere; grain size 10–15 µm to hit 35 % elongation without sacrificing tensile strength (≥220 MPa Cu).

- Enameling: Vertical tower, 28 passes of polyimide/PEI for Class 220; inline capacitive sensor keeps concentricity ≥88 %—a figure that exceeds IEC 60317-20 minimum by 8 %.

- Testing: Every spool sees 50 kV impulse, 2 kV turn-turn, and 200 °C cut-through; data logged for 10-year traceability.

- Spooling: 5–800 kg traverse-wound plastic barrels; edge-radius controlled to ≤0.2 mm to pay-out tangle-free at 25 m min⁻¹ on high-speed winders.

Supply-Chain Trend: Shifting East without Compromise

Lead-times from legacy EU/US magnet-wire mills now exceed 20 weeks, and surcharges for Class 200+ wire have reached USD 1.4 kg⁻¹. In contrast, experienced Chinese producers—integrated from smelter to spool—deliver IEC-certified, UL-E344954-listed wire in 4–5 weeks FOB Shanghai at 12–18 % lower landed cost. Luoyang Xinzhaohe adds a European logistics hub (Rotterdam) for 3-day truck delivery to most EU transformer plants, eliminating the “China risk” premium.

Take-Away for Buyers

When sourcing wire for three-wire, three-phase transformers, purity, dimensional consistency, and thermal-class head-room translate directly into lower losses, smaller frames, and compliance with emerging efficiency standards. Partnering with a metallurgy-focused, ISO-9001/14001 mill such as Luoyang Xinzhaohe provides premium-grade conductor without the price inflation of traditional Western suppliers—freeing OEMs to win bids on total cost of ownership rather than compromise on performance.

Technical Specs: Three Wire Transformer Parameters

Technical Specifications & ASTM/IEC Standards for Three-Wire Transformer Windings

(Factory-direct viewpoint – Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Electrical & Mechanical Parameters

| Parameter | Symbol | ASTM / IEC Test Method | Luoyang Xinzhaohe Process Window | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | IEC 60317-0-1, 20 °C rise, 500 V/s ramp | ≥ 6 kV (Grade 2) on 1.00 mm Al wire | Partial discharge → inter-turn short |

| Elongation at Break | A5 | ASTM B236-20, 250 mm gauge | ≥ 20 % for 1350-O after in-line anneal | Crimping or coil insertion crack |

| Thermal Class (°C) | TC | IEC 60085, 20 000 h ageing | 155 (F) & 180 (H) in serial production; 200 (N) & 220 (C) on demand | Insulation embrittlement → turn-turn fault |

| Enamel Concentricity | ECC | IEC 60851-3, 8-point laser scan | Min. wall 0.85 × nominal, Max ovality 1.05 × | Local field intensification → corona |

Factory note: Every spool is 100 % spark-tested at 6 kV before packaging; data matrix code links to online COA.

2. Material & Dimensional Standards

| Component | Alloy / Substrate | Applicable Norm | Luoyang Xinzhaohe Supply Form |

|---|---|---|---|

| Conductor | 1350-O EC-Al, Cu-ETP on request | ASTM B236 (strip), ASTM B1/B3 (Cu) | 0.80 – 5.00 mm round, 3 – 16 mm rectangular |

| Insulation | Modified PEI-PAI (F), AI-PEI (H), PAI-PI (C) | IEC 60317-13, -25, -26 | Dual-coat inline enamelling, 38 – 65 µm total |

| Bondable layer | Thermoplastic over-coat | IEC 60317-38 | Optional 10 – 20 µm, activation 140 – 160 °C |

| Packaging | DIN 46395 plastics, UV-proof | IEC 60264-2-1 | 30 kg, 50 kg, 500 kg barrel, plywood reel |

3. Failure Mode: Why Burrs & Uneven Insulation Kill Three-Wire Transformers

- Rod-drawn burr (> 15 µm) pierces the enamel during high-tension winding, dropping Ubd by 35 %.

- Eccentric insulation (Δ > 12 %) creates a local capacitance hotspot; partial discharge inception voltage falls below 3 kV at 155 °C.

- Low elongation (< 15 %) causes edge cracks when the middle wire of a three-wire bundle is pulled 2 % tighter during layering—inter-turn short appears after < 100 thermal shocks.

Our inline eddy-current + laser micrometer tandem removes these risks:

Detects surface defect ≥ 5 µm → automatic rod shear.

Adjusts die concentricity every 40 ms → enamel ovality ≤ 3 %.

Anneal-temperature profile tuned to guarantee 20–28 % elongation without sacrificing conductivity ≥ 34.0 MS m⁻¹.

4. Compliance Road-Map for Transformer OEMs

| Market | Certificate | Status | Remarks |

|---|---|---|---|

| IEC 61558 dry-type | IEC 60317 wire + IEC 60085 thermal | Test report available | Covers 130 – 220 °C systems |

| UL 1446 insulation system | OBJY2, Class F & H | File E483208 | 20 kVA – 2 MVA designs |

| EU RoHS/REACH | 2011/65/EU, SVHC < 0.1 % | Annual update | Heavy metals & phthalates free |

| ISO 9001 & IATF 16949 | Quality & automotive process | Certified since 2015 | SPC on Cpk ≥ 1.67 for key wire metrics |

5. Competitive Positioning – Premium Alternative to Western Wire

Same thermal class & breakdown specs as European top-tier, 12–18 % lower $/kg FOB Shanghai.

3-week lead time for 5 t lots; LME-linked Al price, no alloy surcharge.

Engineering package: thermal-life curve (Arrhenius fit), slot fill optimizer, and 3-D field mapping report supplied free for orders > 1 t.

Transformer manufacturers, motor repair shops, and power-equipment engineers seeking higher reliability without the Western price premium are invited to specify Luoyang Xinzhaohe enamelled wire in your next three-wire transformer BOM.

Factory Tour: Manufacturing Three Wire Transformer

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-wire discipline, delivered factory-direct from Luoyang.

Rod-to-Wire Process Flow (Copper & Al-Mg-Cu Alloys)

| Step | Equipment & Parameters | Critical Control Points | Inline QA |

|---|---|---|---|

| 1. Rod Drawing | Multi-die bull-block, 8–18 % area reduction per pass, soap-based lubricant at 40–55 °C | Die angle 12–14°, drawing force ≤ 210 MPa, surface Ra ≤ 0.4 µm | Laser diameter gauge (±0.005 mm), eddy-current crack detection |

| 2. In-line Annealing | Joule-effect annealer, 420–480 °C for Cu, 340–380 °C for Al-alloy, N₂ + 3 % H₂ atmosphere | Grain size 0.015–0.025 mm, tensile drop ≥ 25 %, elongation ≥ 35 % | IR pyrometer 1 kHz feedback, resistivity meter (≤ 0.01724 µΩ·m for Cu) |

| 3. Enameling | Horizontal tandem dies, 6–12 passes, DuPont AI-200 / Elantas 420-2, speed 80–120 m min⁻¹ | Wet film 8–12 µm per coat, total build 40–70 µm, concentricity ≥ 85 % | Beta-backscatter thickness scan every 0.5 m, high-volt pinhole 2 kV DC |

| 4. Inline Electrical Testing | 3 kV impulse @ 50 pps, 50 mA leakage limit | Breakdown ≥ 6 kV rms (room temp), ≥ 4 kV @ 180 °C | Full-length spark test, auto-mark & cut on fault |

| 5. Precision Spooling | Traverse 1–4° lay, tension 1–2 N mm⁻², flange 160–800 mm | No wire cross, collapse force ≥ 800 N | Vision system for tangling, weight ±0.2 % |

Quality Control Matrix – Luoyang Xinzhaohe Standard vs. Common Market

| Property | Test Method | Luoyang Xinzhaohe Spec | Typical Market | Impact on 3-Wire Transformer |

|---|---|---|---|---|

| Breakdown Voltage, kV | IEC 60851-5 | ≥ 6.0 (ambient) ≥ 4.0 @ 180 °C | 4.5 / 2.8 | Higher margin for 220 °C insulation systems |

| Elongation, % | IEC 60851-3 | ≥ 35 (Cu) ≥ 25 (Al-alloy) | 25 / 15 | Withstands coil expansion & short-circuit forces |

| Concentricity, % | Microscopic 4-axis | ≥ 85 | 65–75 | Uniform dielectric stress, lower partial discharge |

| Pinholes per 30 m | 2 kV DC spark | 0 | ≤ 3 | Eliminates inter-layer fault in layer windings |

| Resistivity, µΩ·m | Kelvin 4-wire | ≤ 0.01724 (Cu) ≤ 0.0280 (Al) | 0.0178 / 0.0295 | Lower I²R loss, meets ≥ 95 % efficiency target |

| Surface Rope Test | 15× D bend | No cracks | Visible micro-cracks | Reduces varnish soak-in rejects |

| Spool Collapse, N | Compression | ≥ 800 | 500–600 | Survives high-speed auto-winders |

Traceability & Lot Release

Each 100 kg production lot carries a QR-coded certificate with:

Cast number & rod chemistry (O ≤ 350 ppm for Cu, Fe ≤ 0.35 % for Al)

Die set ID & wear index

Anneal temperature log (1 Hz data)

Enamel lot & viscosity curve

Final DC resistance and breakdown values

Certificates are archived for 10 years to support transformer OEM audits and repair-shop rewind warranties.

Value to Transformer Makers

- Tighter concentricity enables 3–5 % higher copper fill factor, shrinking core size for the same kVA.

- Zero-pinholing reduces Hi-Pot failures during VPI, saving 1–2 h of rework per unit.

- Higher elongation withstands the radial short-circuit forces typical in three-wire, delta-wound primaries.

- Factory-direct pricing from Luoyang cuts landed cost 12–18 % versus Western enamelled wire, while meeting identical thermal class (155/180/220 °C) certificates.

For quotation on 0.20 – 5.00 mm copper or CCA winding wire, spool weights 5 – 800 kg, contact: tech@xzh-al.com.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0.5 % transit-damage target across 20+ years of transformer-wind shipments

H2 1. Sea-Freight Protection Philosophy

Our Luoyang plant sits 150 km inland from Qingdao port, linked by bonded heavy-truck corridor (≤4 h gate-to-gate). Every coil is packed under the same ISO 12944-2 C3 coastal-atmosphere rule we apply to transformer tanks:

≤40 % RH at load-seal

≤5 °C dew-point margin inside carton

Salt-spray validation 720 h per ASTM B117

Result: <0.2 % insulation-breakdown claims since 2012.

H2 2. Packaging Matrix by Product Form

| Configuration | Inner Reel / Separator | Moisture & Vapor Barrier | Shock & Stack Load | Securing Method | Typical 20 ft Payload |

|---|---|---|---|---|---|

| Round wire Ø0.3–5.0 mm | New DIN 46395 PS plastic spool, 250–500 mm flange | 2-layer PE shrink + 1 Al-foil laminate (≤0.1 g m⁻² day⁻¹) | Corner-post carton, 7-ply, 18 kN m⁻¹ edge-crush | 19 mm PET strap, 3-way, 450 N tension | 12 t (24 pallet) |

| Rectangular strip 3–12 mm edge | Fumigated poplar pallet, 1200 × 800 mm, 2-way entry | VCI kraft + desiccant 8 units kg⁻¹ PE bag | 5-layer plywood hood, 800 kg m⁻² top load | Corner steel angle, 2 × 19 mm straps | 15 t (20 pallet) |

| Foil 0.1–0.6 mm | ID 300 mm Al-core, interleaf paper 40 g m⁻² | Same as strip, but bag heat-sealed under vacuum (-0.8 bar) | Pallet box, twin-wall PP, 6 kN compression | Cross-strapped + stretch film 23 μm | 10 t (18 pallet) |

All wood packaging meets ISPM-15; methyl-bromide-free fumigation certificates scanned to PDF and uploaded to customer portal before vessel departure.

H2 3. Spool & Reel Engineering Details

Plastic spools (PT/DIN)

Material: ABS-FR grade, UV-stabilised, -40 °C to +90 °C

Dynamic balance ≤5 g at 1200 rpm—prevents wire jump during high-speed layer winding

Flange radial run-out ≤0.15 mm; protects enamel concentricity

Returnable steel reels (optional)

Collapsible, 500 mm OD, save 55 % back-haul volume

Deposit system: USD 35 per reel, credited 100 % on 30-day return

H2 4. Container Loading & Stowage Plan

- Pre-cool container to ≤30 °C before loading (summer protocol)

- Floor dunnage: 100 × 100 mm timbers on 30 cm centers, 5 cm air gap

- Pallets arranged in “brick” pattern; lock with 2 t-rated cargo bars

- Desiccant poles (1 kg CaCl₂) hung at rear door—absorbs 2 L condensate

- Data-logger (Elpro Libero) records T & RH every 10 min; PDF report e-mailed on arrival

H2 5. Incoterms & Transit Times

| Destination | FOB Qingdao | CIF Major Port | Typical Sailing | On-Carriage Option |

|---|---|---|---|---|

| Houston, USA | – | 22 days | YM/WHL | Rail to Chicago (4 d) |

| Hamburg, EU | – | 28 days | MSC | Truck to Czechia (12 h) |

| Dubai, UAE | – | 18 days | COSCO | Land-bridge to Saudi (8 h) |

| São Paulo | – | 35 days | CMA | Bonded truck (6 d) |

We maintain weekly consolidation service; LCL accepted from 250 kg.

H2 6. Cost Advantage vs. Western Stock

Premium European wire producers often air-freight small reels to avoid coil damage—adding USD 1.8–2.4 kg⁻¹. Our sea-freight engineered pack costs ≤0.12 kg⁻¹ and delivers the same thermal-class 200 °C wire with:

Breakdown voltage ≥6 kV (ASTM D149)

Elongation ≥30 % (IEC 60851-3)

Concentricity error ≤5 %

Transformer OEMs save 12–18 % landed cost while meeting identical specs—validated by 40+ Tier-1 customers in North America and EU since 2018.

H2 7. Quick-Start Checklist for Buyers

[ ] Specify reel type (DIN, returnable steel, or bulk coil)[ ] Confirm thermal class & solderable enamel (PEW, EIW, AIW)

[ ] Choose Incoterm: FOB, CIF, or DDP warehouse

[ ] Provide destination port & unloading dock height (affects pallet choice)

[ ] Request desiccant quantity adjustment for >45 day transit

Upload your BOM to our customer portal; logistics team returns a pack-plan drawing within 24 h.

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 18 Xinkai Road, Yibin District, Luoyang, Henan, China 471000

sales@xzhal.com | +86 379 6069 8181 | www.xzhal.com

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Three-Wire Transformer Windings

20-Year Metallurgical Track Record—Not a Trading House

Since 2003 we have supplied conductor and insulation systems to Tier-1 transformer OEMs across 42 countries. Our Luoyang plant runs three dedicated enameling lines for round, rectangular and C-profile conductors used in three-phase, three-wire cores up to 15 MVA. Every heat number is logged from rod cast to final spool, giving you full lot traceability for UL, IEC 60076 and IEEE C57 audits.

| Key Milestone | Technical Impact on Your Windings |

|---|---|

| 2008 | First Chinese supplier qualified for 220 °C (class R) inverter-duty enamel |

| 2014 | Commissioned inline spark tester (30 kV) → 100 % PD-free guarantee |

| 2019 | Achieved ≤0.02 mm concentricity tolerance on 2.00 mm Cu wire |

| 2022 | Shipped 5 600 t of conductor for 3-wire dry-type transformers ≥4 kVA |

Direct Factory Price—No Distributor Margin Stack

We convert electrolytic cathode (≥99.97 % Cu, 99.85 % Al) to finished wire under one roof: melting → continuous casting → rod rolling → multi-pass drawing → online annealing → enameling → laser OD/PD testing → precision spooling. Eliminating intermediate traders cuts landed cost 12–18 % versus European or North-American quotes, while keeping ASTM B3/B172, IEC 60317 and JIS C3202 compliance. Typical FOB Tianjin pricing (May 2024):

| Size (mm) | Cu Wire 200 °C Class N | Al Wire 180 °C Class H |

|---|---|---|

| 1.00 | 8.42 USD/km | 2.95 USD/km |

| 2.50 | 52.60 USD/km | 18.40 USD/km |

| 4.00 | 134.80 USD/km | 47.10 USD/km |

Prices include dual-layer polyamide-imide insulation, 30 kV breakdown, and 305 mm steel spool. Volume rebates apply ≥5 t per month.

Customization Capabilities—Engineered to Your Three-Wire Core

Three-wire transformers often operate with high third-harmonic content and elevated inrush stress. We adjust metallurgy and coating stack to match:

-

Conductor Geometry

Round 0.20–6.00 mm (±0.005 mm)

Rectangular 2.0 × 4.0 mm to 12.0 × 18.0 mm, edge radius 0.5–1.0 mm

Paper/lapped, DMD or nomex wrap available for 5–35 kV class -

Thermal Class & Insulation Build

130 °C (B) to 220 °C (R) in single, dual or triple coat

Total build 0.06–0.20 mm; concentricity ≤8 %

Optional self-bonding overcoat (heat-activated 170 °C, 30 s) for layer retention -

Mechanical & Electrical Performance

Elongation 25–38 % (Cu) / 15–25 % (Al) to survive tight mandrel winding

Spring-back angle controlled ≤15° for rectangular wire—critical for low-loss three-wire zig-zag cores

Breakdown voltage ≥ 12 kV (grade 1) or ≥ 20 kV (grade 2) per IEC 60851-5 -

Spooling & Packaging

30 kg, 50 kg, 100 kg plastic or steel spools; barrel-pack up to 1 t for high-speed automated lines

Tangle-free level-wind with traverse accuracy ±0.3 mm; butt-end seals to prevent edge damage during ocean freight

Logistics & Compliance

Lead time: 10–12 days ex-stock, 18–22 days custom build

Export pallets ISPM-15 heat-treated; container load 10–24 t depending on wire size

Certifications: ISO 9001, ISO 14001, IATF 16949 (process alignment), RoHS & REACH, UL E204312

Next Step—Get the Datasheet or a Same-Day Quote

Send your specification (conductor type, thermal class, insulation build, spool size, annual volume) to cathy@transformerstrip.com. Our metallurgical engineers will return a detailed datasheet with electrical test curves, thermal life graph (per IEEE 275) and a landed price within 24 hours. Secure a premium, fully traceable winding wire supply—without the Western price premium.

📉 Import Savings Calculator

Estimate cost reduction by sourcing three wire transformer from Luoyang Xinzhaohe.