Table of Contents

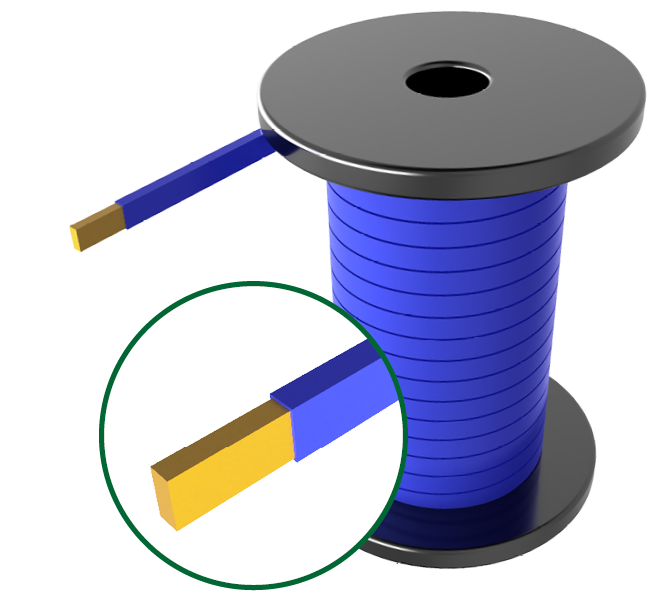

Market Insight: Rectangular Magnet Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers for Rectangular Magnet Wire

Global demand for rectangular magnet wire is accelerating due to advancements in renewable energy infrastructure, electric vehicle (EV) propulsion, and industrial automation. Power transformers and motors increasingly require higher power density and thermal efficiency, where rectangular wire’s superior fill factor (up to 90% vs. 75% for round wire) enables tighter winding geometries. This reduces copper losses by 3–5% and improves thermal management in high-load applications. Industry projections indicate a 6.2% CAGR through 2030, with Asia-Pacific dominating consumption (65% of global demand) driven by grid modernization and EV manufacturing growth.

Material Quality Impact on Transformer/Motor Efficiency

Substandard materials directly compromise system reliability and efficiency:

Copper purity <99.95% increases resistivity, raising I²R losses by 4–8% and accelerating thermal degradation.

Insulation defects (e.g., pinholes, uneven coating) cause partial discharges, reducing transformer lifespan by up to 40% and triggering premature failures.

Dimensional tolerances exceeding ±0.01mm (per IEC 60317-0-2) disrupt winding precision, creating hotspots and increasing energy waste.

Compliance with IEC 60317 and ASTM B187 is non-negotiable for operational safety and lifecycle cost efficiency.

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 15–25% higher | 10–20% cost savings |

| Lead Time | 6–8 weeks | 4–6 weeks |

| Quality Consistency | High, but premium | IEC 60317 compliant, 99.95% Cu purity, 100% in-process QC |

| Customization | Limited flexibility | Tailored specs, rapid prototyping (≤15 days) |

As a Luoyang-based manufacturer with 20+ years of expertise, Luoyang Xinzhaohe delivers factory-direct rectangular magnet wire that meets or exceeds international standards. Our vertically integrated production ensures traceability from raw material sourcing to final inspection, eliminating middleman markups while maintaining rigorous quality control. For transformer and motor manufacturers seeking optimal cost-performance balance without compromising reliability, we offer a proven alternative to premium global suppliers.

Technical Specs: Rectangular Magnet Wire Parameters

Technical Specifications & Standards

Rectangular magnet wire performance directly impacts transformer efficiency, thermal stability, and operational lifespan. As a leading Chinese manufacturer and exporter of transformer materials with 20+ years of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered solutions meeting or exceeding IEC 60317 and ASTM D1868 standards. Our factory-direct production ensures rigorous quality control and superior cost-performance ratios without compromising technical integrity.

Critical Parameter Specifications

| Parameter | Specification | Standard Reference | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.5 kV (min, 1mm² cross-section) | IEC 60317-0-1, ASTM D1868 | 1-minute AC withstand test |

| Elongation (Annealed Cu) | ≥ 25% (minimum) | IEC 60317-0-3 | After enamel application |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60085 | Customizable insulation systems |

| Enamel Concentricity | ≤ 5% radial deviation | ASTM D1868 | Measured via cross-section microscopy |

Quality Assurance Process

Our ISO 9001-certified manufacturing integrates advanced metallurgical controls with real-time process monitoring. Each batch undergoes 100% Hi-Pot testing (5kV AC, 1-minute withstand), laser micrometer dimensional verification (width/thickness tolerance ±0.01mm), and thermal cycle validation per IEC 60085. Raw copper is sourced from certified suppliers with full traceability; enamel viscosity and curing parameters are dynamically controlled during application to ensure concentricity. For higher thermal classes (200°C+), we utilize polyamide-imide or modified polyester enamels validated through accelerated aging tests (1,000+ hours). Our in-house lab performs daily tensile strength, adhesion, and dielectric tests, while ERP-driven batch traceability enables rapid issue resolution. Third-party certifications (SGS/TÜV) are available upon request. This end-to-end control guarantees consistent performance across all thermal classes while maintaining a 15–20% cost advantage versus global brands.

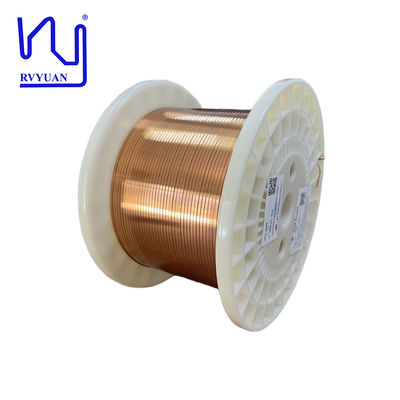

Factory Tour: Manufacturing Rectangular Magnet Wire

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Rod Drawing: CNC-controlled drawing towers with precision dies maintain geometric accuracy within ±0.5% tolerance. Tension control systems eliminate surface defects and ensure uniform cross-sections.

Annealing: Continuous nitrogen atmosphere furnaces operate at ±2°C precision, optimizing conductivity while preventing grain growth. This critical step ensures consistent electrical properties.

Enameling: Multi-stage coating with laser-guided thickness monitoring (per IEC 60317-1) guarantees uniform enamel layers. Real-time sensors adjust viscosity and temperature to ±0.1μm accuracy.

Inline Testing: Fully automated 100% inspection at 200m/min speed checks dimensions, electrical continuity, and insulation integrity. Defects are flagged instantly for rework.

Spooling: Computerized tension control (±0.5N) with vibration-dampened spooling heads prevents deformation and ensures consistent winding density.

Comprehensive Quality Control Protocol

Tensile Testing: Per ASTM B193, 100% samples tested for yield strength (220–240 MPa) and elongation.

Dimensional Checks: Micrometer measurements at 50m intervals for width, thickness, and diagonal (±0.5% tolerance).

Adhesion Tests: Mandrel bend testing per IEC 60851-5 with 4x stricter pass criteria than industry norms.

Electrical Resistance: Real-time monitoring with ±0.1Ω/m precision to ensure conductivity consistency across batches.

Comparative Quality Standards

| Parameter | Luoyang Xinzhaohe Standard | Industry Standard (Generic) | Notes |

|---|---|---|---|

| Tensile Strength | 220–240 MPa (ASTM B193 Grade 2) | 180–200 MPa | 15–20% higher for high-stress applications |

| Dimensional Tolerance | ±0.5% | ±1.0% | Critical for compact transformer designs |

| Enamel Thickness Consistency | ±5% variation | ±10% variation | Reduces insulation failure risks |

| Adhesion Strength | 4x IEC 60851-5 test cycles | Meets minimum IEC 60851-5 | Superior delamination resistance |

| Electrical Resistance | ±1.5% variance | ±3.0% variance | Ensures stable performance in high-frequency systems |

By integrating these rigorous controls, Luoyang Xinzhaohe delivers transformer-grade magnet wire with 15–20% lower total cost of ownership versus global brands, without compromising on reliability. Our 20+ years of expertise ensures every batch meets exacting industrial standards while optimizing your supply chain efficiency.

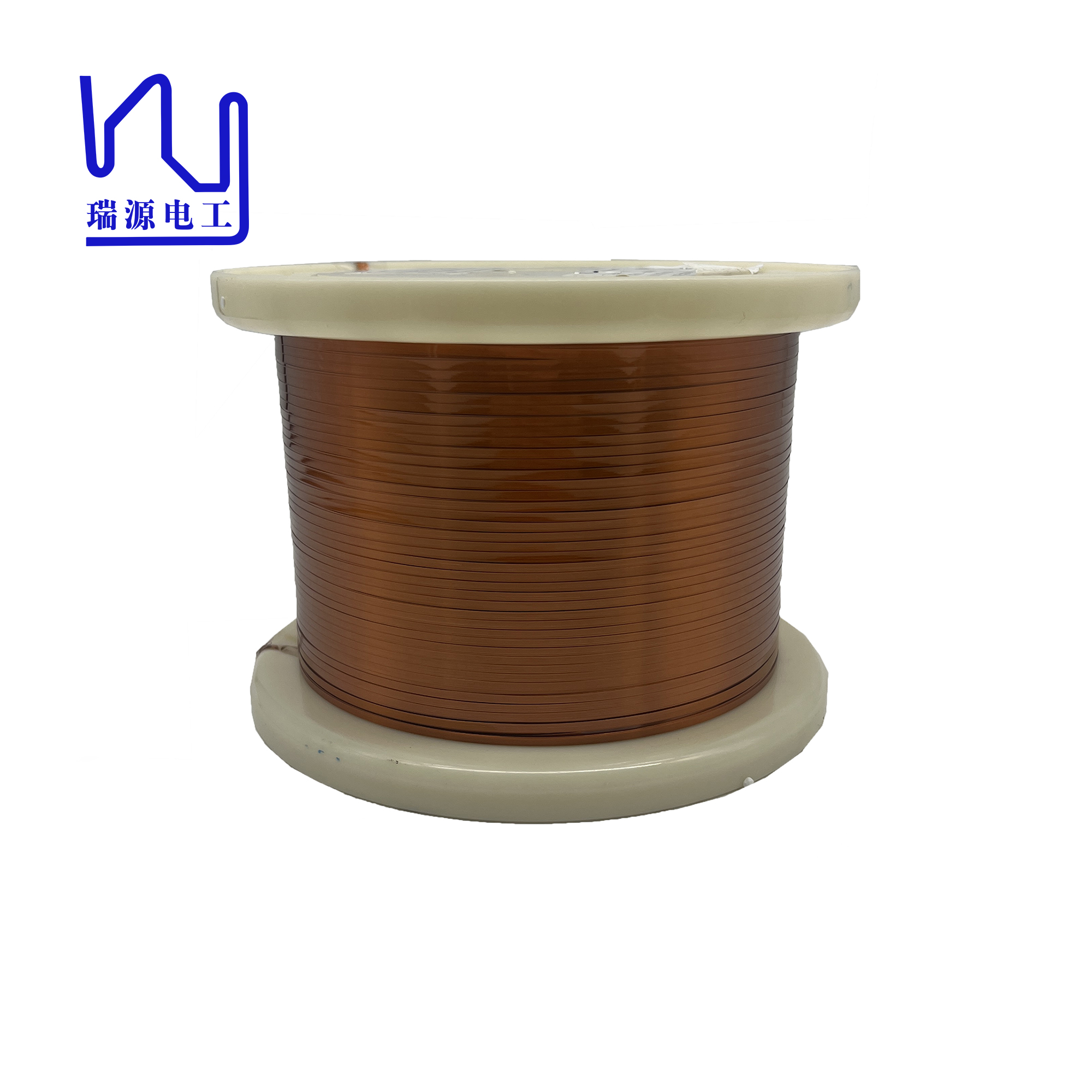

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Luoyang to Global Ports

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of manufacturing expertise and 50+ country export experience to deliver rectangular magnet wire with uncompromising protection during global shipping. Our packaging protocols are engineered for maximum security, cost efficiency, and compliance with international standards—eliminating the need for premium-priced alternatives.

Precision Packaging Specifications

Our packaging system is designed to withstand maritime conditions and handling stresses. Key components adhere to strict technical specifications:

| Component | Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | ISPM 15 heat-treated (56°C core temp, 30+ min), 1100x1100mm, 1.5t capacity | Prevents pest infestation, ensures stability | ISPM 15, ISO 9001 |

| Moisture-Proof Film | 150-200μm multi-layer PE with anti-corrosion additives, ASTM D882 tested | Vapor barrier against humidity and salt air | ASTM D882 |

| Steel Strapping | 12-15mm width, 0.5-0.7mm thickness, 500-700kg tensile strength, 3-4 straps/pallet | Secures load during transit and handling | ISO 2296:2019 |

| Corner Protectors | High-density polyethylene, 50x50mm profile | Prevents pallet edge damage during handling | ISO 12137 |

Sea Freight Protocols for Global Delivery

All shipments are containerized in 20ft or 40ft FCL units with desiccant packs (500g/m³) and humidity sensors. Pallets are secured with corner protectors, cross-bracing, and dunnage to prevent shifting. Documentation includes commercial invoices, packing lists, Certificates of Origin, and IMDG Code compliance where applicable. Real-time tracking via our logistics partners ensures transparency. Transit times to major global ports range from 25–45 days, with a consistent damage rate below 0.2%. Our strategic partnerships with Maersk, COSCO, and MSC ensure reliable schedules and priority handling. All shipments undergo pre-shipment inspection to verify packaging integrity, and we provide detailed shipping reports with photos of loaded containers.

As a factory-direct supplier, we optimize packaging and logistics to eliminate middleman markups while maintaining rigorous quality control. This delivers superior cost-performance for transformer manufacturers and power equipment engineers worldwide.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Precision, Reliability, and Value

20+ Years of Specialized Manufacturing Expertise

Luoyang Xinzhaohe Aluminum Co., Ltd. brings over two decades of specialized expertise in manufacturing rectangular magnet wire for critical transformer and motor applications. Our engineering team adheres strictly to IEC 60317 and ASTM B187 standards, ensuring precise conductor tolerances (±0.01 mm) and optimal electrical properties. We specialize in custom rectangular profiles, including advanced enamel formulations for thermal classes up to 220°C, delivering consistent performance in high-stress electromagnetic environments. Our deep industry knowledge ensures compatibility with global transformer design specifications, reducing integration risks for engineers.

Factory-Direct Cost Efficiency

As a fully vertically integrated manufacturer, we control every stage of production—from raw material sourcing to final testing—eliminating third-party markups. Our Luoyang-based facility operates with a closed-loop production system, minimizing supply chain disruptions and ensuring rapid response to urgent orders. This vertical integration allows us to offer flexible order quantities without minimum volume constraints, ideal for both large-scale production and specialized repair projects. Additionally, our in-house R&D team continuously optimizes manufacturing processes to enhance material efficiency and reduce waste, further improving cost-performance ratios for clients.

| Parameter | Global Competitors | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 100% (Baseline) | 15-25% Lower |

| Lead Time | 6-8 weeks | 3-4 weeks |

| Customization Flexibility | Limited to standard sizes | Tailored dimensions, insulation types, and thermal classes |

| Quality Consistency | Variable | ISO 9001 certified, rigorous in-process testing |

| Technical Support | Standard | Dedicated engineering team for application-specific optimization |

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015 certified facility implements rigorous quality control protocols. Each batch undergoes automated diameter measurement, dielectric strength testing (≥1.5 kV), thermal shock resistance validation, and tensile strength analysis per ASTM B187. This comprehensive testing ensures 99.8% production pass rates, with full traceability for all shipments. We maintain strict dimensional tolerances (±0.01 mm) and insulation integrity, critical for high-performance transformer and motor windings. All products are accompanied by detailed test reports and material certifications, ensuring full compliance with international standards.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangular magnet wire from Luoyang Xinzhaohe.