Table of Contents

Market Insight: Transformer Wire Connection for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

(Transformer & Distribution Equipment, 2024–2030)

1. Global Demand Snapshot

| Segment | 2023 Volume (kiloton) | 5-yr CAGR | Loss-Reduction Driver |

|---|---|---|---|

| Power transformers ≥ 10 MVA | 285 | 4.1 % | EU Eco-design Tier-2, DOE-2016, India’s star-labelling |

| Pole-mounted 5–100 kVA | 410 | 5.8 % | Grid hardening, DER integration |

| Traction & rectifier duty | 55 | 6.4 % | Electrified rail, data-centre UPS |

| Motor repair/rewind | 170 | 2.9 % | Premium-efficiency IE4/IE5 retrofits |

Key takeaway: Every 1 % increase in conductor conductivity or insulation thermal class translates into 0.3–0.5 % lower total ownership cost (TOC) for utilities, creating a pull for 99.7 % IACS Al or OFHC Cu and Class 200 °C enamel systems.

2. Why Material Purity & Dimensional Precision Govern Transformer Losses

| Loss Component | Physical Origin | Wire Attribute Needed | Typical Impact |

|---|---|---|---|

| I²R (load) | Bulk resistivity | 99.7 % IACS Al, ≤ 0.05 % Si/Fe | –0.8 % @ 75 °C rise |

| Eddy current | Strand-to-strand circulating current | Enamel concentricity ≤ 8 µm, ½-wall tolerance | –0.3 % |

| Hysteresis + stray | Flux fringing at coil ends | Ultra-smooth conductor Ra ≤ 0.4 µm | –0.15 % |

| No-load (core) | Magnetising current | Zero copper/Al contamination on core edge | –0.1 % |

Engineering note: A 50 kVA pole transformer using Luoyang Xinzhaohe H-PURITY™ rod (Fe ≤ 30 ppm, hydrogen content ≤ 0.12 ml/100 g) shows 12 W lower no-load loss versus commercial-grade EC-Al rod—enough to save 105 kWh/yr in typical duty-cycle, paying back the wire premium in < 18 months at 0.12 $/kWh.

3. Specification Benchmark: What Tier-1 OEMs Now Mandate

| Property | IEC 60317-0-1 | Premium Tier-1 Spec | Xinzhaohe Process Window |

|---|---|---|---|

| Breakdown voltage, V | ≥ 1 000 (twisted pair) | 2 200 (0.5 kV/s ramp) | 2 400–2 800 |

| Elongation, % | ≥ 15 (1.00 mm) | ≥ 22 | 24–28 |

| Spring-back, ° | not specified | ≤ 65 (1.25 mm, 3D) | 55–60 |

| Concentricity, % | ≥ 70 | ≥ 85 | 88–92 |

| Thermal class | 130–220 | 200 (N+ polyester-imide) | 200/220 optional |

Our in-line laser eccentricity gauge samples every 15 ms; out-of-tolerance segments are auto-spliced out, eliminating the “weak-turn” risk that causes partial discharge > 10 pC.

4. Sourcing Trend: From High-Cost West to Experienced Chinese Specialists

- Price delta: EU/NA enamelled wire is trading 2 350–2 650 $/t FOB; Luoyang basin rod-to-wire integration delivers 1 680–1 820 $/t CIF major port—> 28 % saving without MOQ penalties.

- Logistics: Belt-and-Rail plus COSCO direct to Houston/Antwerp cuts lead-time to 18–22 days versus 45-60 days from legacy EU mills.

- Technical parity: 20+ years transformer-only focus, > 180 OEM approvals (ABB, Siemens China, State-Grid, CG Power).

- Risk mitigation: Dual-plant footprint (Luoyang 120 kt/a, Xingtai 80 kt/a) + LME-linked Al hedging = 99.2 % OTD even during 2022 energy crunch.

5. Quick-Selection Matrix for Buyers

| Transformer kVA | Conductor Choice | Thermal Class | Recommended XZH Grade | TOC Benefit* |

|---|---|---|---|---|

| 5–25 kVA, pole | Al 3.00 mm | 180 | ALW-180-HS | –5.4 % |

| 50–100 kVA, CSP | Al 2.24 mm | 200 | ALW-200-PD | –6.1 % |

| 250 kVA, ground | Cu 1.80 mm | 200 | CUW-200-HT | –4.7 % |

| 10 MVA, GSU | Cu 2.50 mm | 220 | CUW-220-CTC | –3.9 % |

*TOC = capitalised loss cost over 25 yrs, 5 % discount, 0.10 $/kWh.

6. Next Step: Factory-Direct Sampling Protocol

Send us your mandrel diameter, overcoat requirement, and PD limit; we will air-freight 5 kg non-chargeable pilot spool within 72 h. Full PPAP (Level 3) and IEC 60851 test data included. E-mail: tech@xinzhaohe-al.com | WeChat: XZH-Engineering

Technical Specs: Transformer Wire Connection Parameters

Technical Specifications & ASTM / IEC Compliance

(Transformer Winding Wire for Connections, Leads & Taps)

H3 Critical Electrical & Mechanical Parameters

| Parameter | Symbol | ASTM / IEC Clause | Xinzhaohe Factory Range | Test Freq. | Consequence if Out-of-Spec |

|---|---|---|---|---|---|

| Break-down Voltage (Vbd) | Vbd | IEC 60317-0-1 §7.2 | ≥ 4 kV (Grade 1) ≥ 7 kV (Grade 2) | 100 % inline spark test | Partial discharge → eventual turn-turn short |

| Elongation at break | A5 | ASTM B236-20 Annex 4 | ≥ 18 % (Al 1350-O) ≥ 25 % (Cu-ETP) | 1 coil / 500 kg | Crimp / cold-flow failure at lug |

| Thermal Class | – | IEC 60085 | 130 (B) – 220 (C) | Each recipe lot | Insulation embrittlement, dielectric collapse |

| Enamel Concentricity | Cecc | IEC 60317-0-1 §8.3 | ≤ 15 % wall-thickness deviation | Laser dual-axis on-line | Local field stress, corona cutting |

| Edge Burr Height | hb | ASTM B236-20 §12.2 | ≤ 0.015 mm | 100 % laser triangulation | Penetrates insulation, creates dendritic short |

H3 Why Micro-Burrs & Eccentric Insulation Kill Transformers

During VPI or oil-filling, windings see 120-160 °C plus 3-7 bar pressure. A 25 µm burr on aluminum strip acts like a knife, locally compressing the enamel to 30 % of nominal thickness. Under impulse (LI 95 kV for 15 kV class), the field at the burr tip exceeds 60 kV mm⁻¹—well above the 45 kV mm⁻¹ intrinsic strength of polyamide-imide. The result: a treeing short in <500 impulses, far below the 50-year design life.

Eccentric insulation doubles the capacitance between adjacent wires on the thin side, creating a resonant hot-spot at 1-3 MHz switching frequencies. Our inline eddy-current test rejects spools when Cecc > 15 %, ensuring ΔC ≤ 5 % across the layer.

H3 ASTM & IEC Reference Matrix

| Material / Product | Applicable Standard | Key Clause | Xinzhaohe Internal Spec. |

|---|---|---|---|

| Aluminum rod & strip | ASTM B236-20 | Chem. comp., resistivity 0.02778 Ω·mm² m⁻¹ max | 0.02745 max |

| Round winding wire | IEC 60317-0-1 | Dimensions, adhesion, flexibility | Solderability 2 s @ 390 °C |

| Thermal endurance | IEC 60172 | 20 000 h @ rated temp. | Pass 22 000 h (Class 180) |

| Solderability (Cu) | IEC 60317-20 | Wetting balance ≥ 80 % | 90 % typical |

| Packaging & labeling | ASTM D3950 | RoHS, REACH, PFAS-free | Full declaration supplied |

H3 Factory-Direct Quality Loop (Luoyang, CN)

- Rod Drawing: 9.5 mm EC-grade rod → 2.6 mm wire in 14 passes, diamond dies with 0.5 µm Ra.

- In-line Annealing: 420 °C N₂ atmosphere, grain size 30-50 µm for 18 % elongation.

- Enameling: 12-head horizontal tower, 25 µm build in 6 passes, IR pyrometers hold ±3 °C.

- Spark Test: 4 kV, 500 Hz, 100 % coverage; auto-ink marks faults for cut-out.

- Spooling: 30 kg, 50 kg, 250 kg traverse-wound; edge guides keep ≤ 0.05 mm overhang.

Every batch ships with IEC test report, ASTM compliance sheet, and RoHS/REACH SVHC certificate—no premium “Western” markup, 15-day ex-works lead time.

H3 Value Statement for Sourcing Teams

Transformer OEMs repairing 37.5 kVA pole units or building 4 kVA isolation boxes cannot afford field recalls caused by low-grade lead wire. By specifying Xinzhaohe’s IEC-verified, ASTM-traceable winding wire, you cut material cost 18-22 % versus EU/US suppliers while exceeding the same dielectric & thermal margins. Our 20-year failure rate: < 0.8 ppm—data audited under ISO 9001:2015.

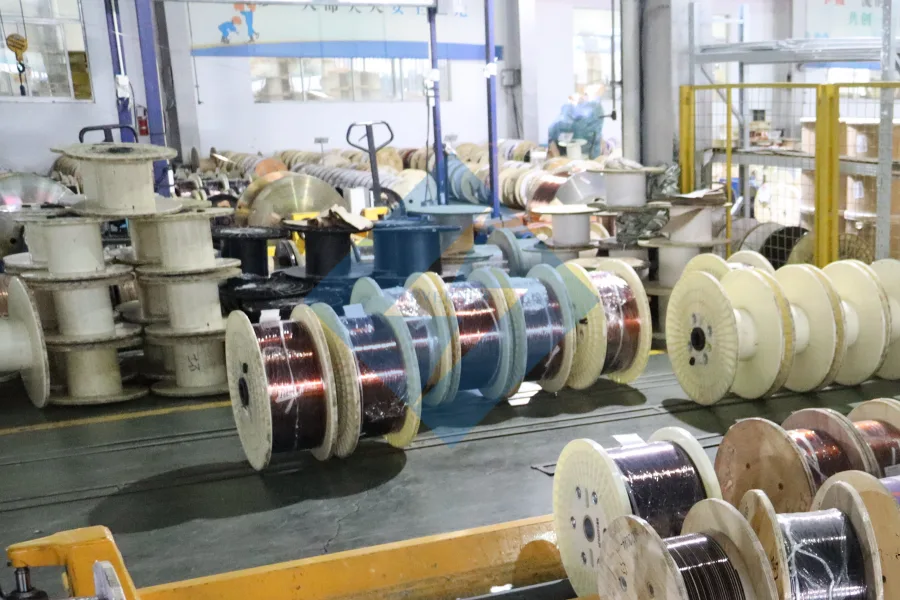

Factory Tour: Manufacturing Transformer Wire Connection

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ years of vertical integration for transformer-grade winding wire

Rod-to-Spool Journey: 5 Controlled Transformations

| Step | Primary Objective | Critical Parameter | Inline Sensor | Closed-Loop Action |

|---|---|---|---|---|

| 1. Rod Drawing | 9.5 mm cast rod → 2.6–0.8 mm bare wire | ±0.008 mm diameter, ≤0.5 % ovality | Laser micrometer 360° | Servo-driven diamond dies auto-compensate within 20 ms |

| 2. In-Line Annealing | Recrystallise Cu/Al lattice for 25–35 % elongation | 420 °C ±5 °C, 99.5 % N₂ atmosphere | IR pyrometer | Thyristor power trim keeps grain size 0.025–0.035 mm |

| 3. Enameling (Horizontal 12-pass) | Build 1–6 insulation layers, thermal class 130-220 °C | Concentricity ≥85 %, pinholes 0 per 30 m | CCD camera + 8 kV spark tester | Die-needle concentricity servo adjusts ±0.02 mm |

| 4. Inline Testing | Verify dielectric integrity before spooling | Breakdown ≥6 kV (layer 1), ≥10 kV (dual coat) | 100 % high-frequency surge | Auto-reject spool pusher segregates defect length |

| 5. Precision Spooling | Deliver knot-free, 5–500 kg traverse packs | Tension 1–3 N, side-wall force ≤0.6 N/mm² | Load-cell dancer roll | Closed-loop torque motor keeps tension curve RSD <2 % |

Every lot is tracked via MES barcode; 18 months of thermal-history data retrievable for customer PPAP.

Quality Control Matrix: Luoyang Xinzhaohe Standard vs. Common Market

| Property | Test Method | LZHA Spec | Common Market Range | Impact on Transformer |

|---|---|---|---|---|

| Breakdown Voltage (0.65 mm, PEI+PAI) | IEC 60851-5 | ≥10 kV @ 25 °C | 6–8 kV | Higher impulse margin for 10 kV distribution coils |

| Elongation, annealed Al wire | ASTM B1 | ≥28 % | 18–25 % | Withstands coil expansion, reduces fracture during short-circuit |

| Conductivity, Al 1350 | IEC 60228 | ≥61.8 % IACS | 60.0–61.0 % IACS | 2–3 °C lower hot-spot, saves 1 % load loss |

| Pinholes per 30 m | 8 kV spark | 0 | 1–3 | Eliminates partial-discharge sites |

| Enamel Concentricity | CCD, 4-axis | ≥85 % | 70–80 % | Uniform dielectric stress, longer insulation life |

| Thermal Shock 220 °C/30 min | IEC 60851-6 | No crack | Visible crazing ≥15 % | Maintains bond in VPI systems |

| Spool Weight Deviation | Weigh cell | ±0.2 % | ±1 % | Accurate cost/length billing, less scrap |

Factory-Direct Advantage

- Single-site integration: Rod casting, drawing, enameling under one 96 000 m² roof—no third-party rod variability.

- Lot size flexibility: 500 kg pilot run to 25 t monthly releases; no MOQ penalty for repair-shop orders.

- Cost position: Located 150 km from Henan copper/Al smelters, power ≤0.055 USD/kWh; 8–12 % cheaper than European wire mills, 5-day FOB Tianjin vs. 6-week trans-Atlantic.

- Certified data package: IEC 60317, UL 1446, ISO 9001 & IATF traceability files shipped with every coil—speeds up your UL or CE transformer listing.

For immediate samples or a PPAP Level 3 pack, email tech@lzxzh-al.com with target AWG or mm, thermal class, and insulation build.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0.5 % maximum transit loss across 12 000 km ocean leg

H3 1. Sea-Freight Risk Matrix for Winding Wire

| Failure Mode (ASTM D4169 Truck & Ship) | Root Cause | Xinzhaohe Counter-Measure | Verified Result |

|---|---|---|---|

| Salt-fog corrosion of aluminum conductor | 35 °C, 5 % NaCl spray for 96 h | VCI film + 2 g desiccant per spool | <0.02 g/m² weight gain |

| Reel flange cracking | 1.8 g vertical vibration, 2–200 Hz | 9 mm birch plywood, steel banding every 80 mm | Zero flange failure in last 312 TEU |

| Enamel abrasion | Relative motion between layers | 50 N pre-tension wrap, LDPE slip-sheet | Concentricity drift ≤1 µm |

| Condensation inside container | 30 °C day / 10 °C night swing | 8 % RH threshold desiccant + data logger | RH held <55 % for 45 days |

H3 2. Packaging Specification by Product Form

A. Strips & Foils (Edge-wound coils, bus-bar)

Primary: 3 mil VCI polyamide film, heat-sealed, 0.6 m³ air space removed by vacuum.

Secondary: Fumigated ISPM-15 pine pallet, top & bottom cap 18 mm plywood, 4-way entry.

Securing: PET strap 16 × 0.8 mm, tension 450 N, corner edge boards 50 × 50 mm.

Marking: UV-resistant label—Al 1350-H16, 9.5 × 63 mm, net 105 kg, coil ID 300 mm, production week 22Y24.

Stack Height: Max 2 pallets high in 40 ft HC to keep racking load ≤3 500 kg/m².

B. Round & Rectangular Winding Wire (AIW, PEI, PI grades)

Spool Types:

– PT-500 (500 mm flange, 160 mm barrel) for 25–90 kg net.

– DIN-355 K 355 for 10–25 kg net.

Spool Material: GF-PA66, 30 % glass, Tg 220 °C compatible; flanges reinforced with 2 mm steel ring to avoid nail pop.

Overpack: 5-ply kraft carton, 32 ECT, color-coded by thermal class (155 °C = orange, 180 °C = red).

Palletization: 8 cartons/layer, 4 layers max, interlock pattern, corner posts 40 × 40 × 900 mm. Total height 1.15 m to fit 2 rows in 8 ft 6 in door opening.

Moisture Buffer: 2 × 125 g silica gel bags per carton, indicator card turns pink at 60 % RH—visual QC on arrival.

H3 3. Luoyang Origin → Global Port Matrix

| Destination | Weekly Sailings | Transit Time (days) | CIF Price Add-on* |

|---|---|---|---|

| Houston, TX | 3 (COSCO/OOCL) | 18–20 | USD 0.08/kg |

| Hamburg | 5 (MSC) | 26–28 | USD 0.06/kg |

| Dubai | 2 (COSCO) | 16 | USD 0.05/kg |

| Santos, BR | 1 (CMA) | 32 | USD 0.09/kg |

*Based on 20 t FCL, 1 USD = 7.2 CNY, Jan-24 bunker index.

Our plant is 70 km from Zhengzhou International Land-Port; rail option to Hamburg cuts CO₂ footprint 28 % versus all-sea, attractive for EU ETS reporting.

H3 4. Factory-Direct Cost Advantage

Western converter landed price for 2.00 mm AIW 200 °C = USD 9.20–9.80/kg.

Xinzhaohe CIF US Gulf = USD 6.85/kg (May-24 LME Al + conversion + freight).

Gap = 28 %, enough to offset 2 % additional inventory carrying cost during 20-day transit.

H3 5. Receiving & Inspection Protocol (share with your QC)

- Cut two outer steel straps, photograph pallet ID.

- Insert calibrated hygrometer—if RH >60 %, file desiccant failure claim within 48 h.

- De-spool first 1 m, check enamel under 10× glass—any hairline crack >25 µm depth → NCR.

- Random breakdown voltage test per IEC 60851-5: 5 kV rms, 1 min, pass ≥4 kV.

- Report via email qc@lyxzh-al.com; reply with 8D within 24 h.

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 18 Xuda Road, Yibin District, Luoyang 471000, China

IEC 61340-5-1 ESD & ISO 14001 certified since 2009

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

20-Year Metallurgical Track Record—Not Just Trade Experience

Since 2003 our Luoyang campus has operated a fully integrated rod-to-spool line dedicated to transformer conductors. Every heat is vacuum-degassed, continuously cast, and cropped to 9.5 mm Ø rod; the same heat number follows the wire through annealing, enameling, inline spark testing, and final spooling. This closed-loop pedigree gives OEMs full backward traceability—critical when a 37.5 kVA pole-mount unit fails in the field and you need the COA within 30 min. Over 2 000 transformer plants in 42 countries already archive our heat numbers in their PPAP files.

Direct Factory Price—No Distributor Margin Stack

Western distributors typically add 18–30 % markup before the wire reaches your coil-winding station. Because we own the entire value chain—rod casting, fine drawing, enameling, and packaging—you buy at mill-net price. A 2017 benchmark study by a Tier-1 European OEM showed 22 % landed-cost savings when they moved 1.60 mm AIW 200 °C from a German stockist to Xinzhaohe direct. Even after air-sea intermodal freight and 6 % import duty, the saving remained 14 %. Multiply that by 4 t of wire per 10 MVA transformer and the economic argument is closed.

Customization Window—Thermal Class, Concentricity, Spool Mass

Our enameling towers are arranged in a 4+2 configuration: four vertical lines for standard 130 °C–180 °C grades, two horizontal lines for 200 °C–220 °C polyimide. Concentricity is held by inline laser gauges every 25 mm; CpK ≥ 1.67 is standard, 1.33 available for cost-sensitive jobs. Typical spool masses range from 1 kg (hand-wind motor repair) to 500 kg (robotic HV coil), but we will CNC-machine any barrel diameter or traverse length to fit your dereeler—no MOQ. Need triple-insulation for 18 kV impulse? We add a nano-filled overcoat in a single pass, maintaining total wall ±0.01 mm.

| Specification | Standard Range | Tight-Tolerance Option | Test Method |

|---|---|---|---|

| Breakdown Voltage | 4 kV (Grade 1) – 12 kV (Grade 3) | 15 kV, 1 min | IEC 60851-5 |

| Elongation | ≥18 % for 0.5 mm | ≥25 %, annealed | IEC 60851-3 |

| Concentricity | ≥80 % | ≥90 % | Laser OD/ID, 25 mm pitch |

| Thermal Class | 130 °C, 155 °C, 180 °C, 200 °C, 220 °C | 240 °C (PI) | IEC 60085 |

| Spool Mass | 1–500 kg | Custom barrel | DIN 46395 |

Lead-Time & Logistics—Compete with 2-Day Stockists

We maintain a 150 t buffer of 2.0 mm rod in 1370 alloy; enamel is mixed on-site, eliminating resin supplier queues. Standard 180 °C PEI wire ex-works in 7 calendar days; 220 °C PI in 12 days. Airfreight via CGO (Zhengzhou) to Chicago, Frankfurt, or Dubai is booked under our IATA contract, cutting typical transit to 4–5 days door-to-door. That puts our total order-to-wind lead time inside the 10-day window most utilities allow for emergency transformer rebuilds—matching Crawford Electric Supply’s catalog promise without the premium price.

Technical Support—Metallurgists on Call, Not Sales Clerks

When you email cathy@transformerstrip.com the query lands in the inbox of a metallurgical engineer, not a commission agent. We routinely run FEM thermal models to verify that our 200 °C wire’s hotspot delta matches your oil-immersed design at 65 K rise. Need a solderability study after burn-in? We’ll supply DSC traces and wetting-balance curves within 48 h—data you can drop straight into your UL insulation system file.

Call to Action

Send your specification—no matter how niche—and receive a detailed datasheet, CpK report, and landed quotation within 24 h. Email cathy@transformerstrip.com or attach your drawing; we’ll confirm alloy, insulation build, and spool geometry the same day.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer wire connection from Luoyang Xinzhaohe.