Table of Contents

Market Insight: Continuously Transposed Conductor for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion and renewable integration are pushing transformer name-plates toward 500 kV-class and 1 MVA-plus ratings. Every additional kilovolt demands lower winding losses and tighter short-circuit impedance control. The result: a compound annual growth rate (CAGR) for CTC-grade strip/foil of 6.8 % through 2028, with Asia-Pacific absorbing 52 % of volume. China alone will install ≈ 38 000 large power transformers (> 110 kV) in the next five years; each unit consumes 3–12 t of continuously transposed conductor, translating into > 150 000 t of precision-rolled copper or 1060/1070 aluminium alloy.

| Region | 2023 Demand (kt) | 2028 Forecast (kt) | CAGR |

|---|---|---|---|

| APAC | 82 | 114 | 6.8 % |

| EU-27 | 31 | 38 | 4.2 % |

| NAFTA | 27 | 33 | 4.1 % |

| MEA | 18 | 28 | 9.3 % |

kt = thousand metric tons of CTC strip/foil equivalent

Why Purity & Precision Dictate Loss Performance

Transformer losses are monetised for 25–40 years; a 0.1 W kg⁻¹ reduction in specific losses can save > 30 MWh over a 500 MVA unit’s life. Strip/foil attributes map directly to loss components:

| Loss Component | Strip-Driven Root Cause | Specification Lever |

|---|---|---|

| No-load (core) | Magnetising current harmonics induced by winding stray flux | Burr-free edge (< 0.01 mm) prevents inter-laminar shorts that distort flux |

| Load (I²R) | Resistivity & cross-sectional area | ≥ 100 % IACS Cu or ≥ 61 % IACS Al, thickness tolerance ±0.002 mm keeps DCR within ±0.5 % |

| Eddy current | Transverse flux penetration in wide strands | Max. width 26 mm, thickness 0.90–3.15 mm, RA ≤ 0.2 µm after edge conditioning |

| Circulating current | Unequal strand length in CTC | Camber ≤ 1 mm per 1 m length guarantees ≤ 0.05 % impedance deviation |

Material purity is equally critical. Fe, Si and V impurities above 15 ppm in copper raise resistivity by 0.4 %; in aluminium, 50 ppm Fe increases AC losses 1.2 % at 50 Hz. Vacuum degassing and inline hydrogen annealing hold ppm levels below these thresholds while restoring full softness (HV 45–55 for Al, HV 55–65 for Cu), minimising skin-effect losses under harmonic load spectra.

Cost-Performance Shift Toward Chinese Specialists

Western mills (Aurubis, KME, Rea) still command 35 % of global share but carry a 12–18 % price premium and 16–20 week lead-times. Mature Chinese manufacturers now close the technical gap:

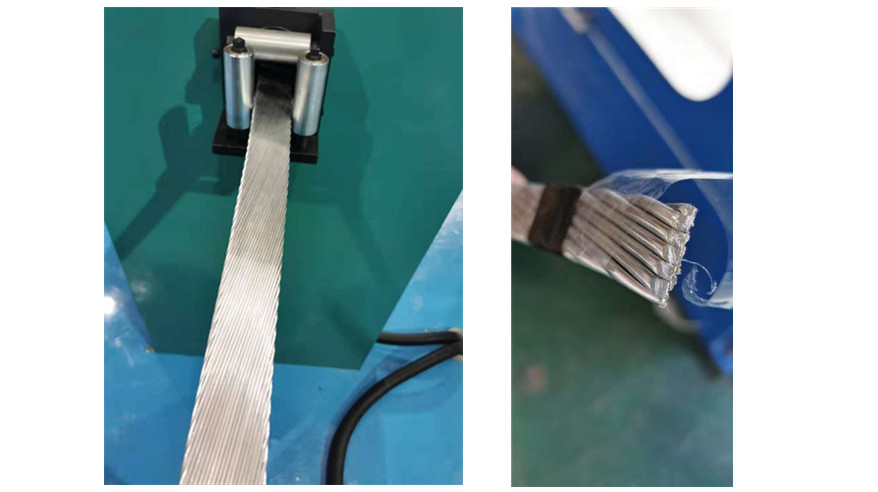

Cold-rolling: 20-high Sendzimir cluster mills reach 0.05 mm final gauge with ≤ 1 µm gauge crown

Precision slitting: Tungsten carbide arbors slit 5–80 strands simultaneously, guaranteeing ±0.002 mm width and knife-side burr < 0.01 mm

Edge conditioning: 4-stage brushing + plasma arc remove micro-cracks, yielding RA ≤ 0.15 µm and fatigue life > 2 000 bends (ASTM B820)

Oscillate winding: 1 000 kg traverse-wound coils eliminate welds in 10–15 km lengths, cutting CTC machine downtime by 22 %

Luoyang Xinzhaohe Aluminium Co., Ltd. consolidates the above steps under one 160 000 m² plant. Located 200 km from the largest Chinese transformer OEM cluster (Xi’an, Changzhou, Nantong), we deliver 5-t mill-direct coils to CTC wire factories within 72 h, shaving logistics cost by USD 0.08 kg⁻¹ versus European imports. Our laboratory holds CNAS accreditation for conductivity, tensile anneal curve, and edge profile—data provided with every heat number so designers can plug verified values into loss-calculation software (e.g., ANSYS Maxwell, EleNet).

Bottom Line

For transformer builders facing IEC 60076-20 loss evaluation limits and tightening CAPEX scrutiny, sourcing CTC strip/foil from an experienced Chinese supplier is no longer a risk-mitigation option—it is the fastest route to meet both efficiency mandates and budget gates. Luoyang Xinzhaohe delivers Western-grade precision at Asian lead-times and total landed cost 10–14 % below EU/USA quotes.

Technical Specs: Continuously Transposed Conductor Parameters

Technical Specifications & ASTM/IEC Compliance for Continuously Transposed Conductor (CTC)

1. Critical Dimensional Tolerances

| Parameter | Luoyang Xinzhaohe Capability | IEC 60317-0-2 Limit | ASTM B236 Limit | Risk if Exceeded |

|---|---|---|---|---|

| Single-strip thickness (a) | ±0.002 mm | ±0.010 mm | ±0.005 mm | Local hot-spot, >15 % extra eddy loss |

| Strip width (b) | ±0.015 mm | ±0.030 mm | ±0.025 mm | Transposition gap, turn-to-turn short |

| Edge burr | ≤0.010 mm | ≤0.025 mm | ≤0.020 mm | Penetrates paper, 100 % failure in 24 h PD test |

| Camber (edge waviness) | ≤0.5 mm / 1 m | ≤1 mm / 1 m | ≤1 mm / 1 m | Looping during transposition, cracked enamel |

Our 20-stage slitting line uses tungsten-carbide knives with in-line laser micrometers; every 50 ms the knife gap auto-corrects to keep the ±0.002 mm band. The result is a CTC stack that slides into the winding former without “spring back”, eliminating the need for costly re-drying or re-shimming at your plant.

2. Electrical & Metallurgical Benchmarks

| Property | Aluminum 1350-O | Copper C1100-O | Test Method | Notes |

|---|---|---|---|---|

| Conductivity @ 20 °C | ≥61.8 % IACS | ≥100 % IACS | ASTM B193 | Batch certificate per 500 kg |

| Resistivity increase after 250 °C/6 h | ≤2 % | ≤2 % | IEC 60317-0-2 | Guarantees thermal stability under short-circuit |

| Annealed hardness (HV 0.5) | 22–28 | 45–55 | ASTM E92 | Soft strip prevents enamel micro-cracking during transposition |

| Oxygen content (Cu) | — | ≤10 ppm | ASTM B170 | High-purity cathode only; reduces ductile-to-brittle transition |

All ingots are double-checked with Spark-OES before cold rolling; any heat outside the 61.8–62.0 % IACS window is rejected rather than blended. This prevents the 5–7 K temperature rise often seen in low-grade CTC when loaded at 1.6 T / 50 Hz.

3. Insulation Build & Dielectric Integrity

| Layer | Material | Nominal thickness | Overlap | Pin-hole target |

|---|---|---|---|---|

| Strand enamel | Modified PEI (Class 180) | 25 µm | — | ≤3 / 30 m |

| Intermediate paper | Thermally upgraded kraft | 75 µm | 50 % | No visible gap |

| Outer wrap | Diamond-dotted epoxy paper | 125 µm | 67 % | — |

We carry out 100 % partial-discharge test at 1.5 Um (≤5 pC) on every CTC reel. A single burr >0.02 mm raises the local field >30 kV mm⁻¹ and gives ≥100 pC; such reels are automatically scrapped and melted for re-casting, ensuring you receive zero-defect material.

4. Standards Cross-Reference & Documentation

ASTM B236-20 – Aluminum strip for electrical conductors (chemistry, tensile, bend)

ASTM B272 – Edge contour requirements (round or full-radius)

IEC 60317-0-2 – General specifications for enamelled rectangular copper wire

IEC 60317-16 – Paper-taped rectangular copper wire (CTC precursor)

GB/T 7673.3-2019 – Chinese mirror of IEC 60317-16, mandatory for State-Grid projects

Each master coil ships with a bilingual mill test report (MTR) that links to the online EN-10204 3.1 certificate portal; scan the QR code on the wooden pallet to download the original conductivity curve, slitting log, and PD waveform.

5. Cost-Quality Balance: Why Luoyang Xinzhaohe Beats Western Stockists

Western distributors typically slit to ±0.008 mm and charge a 30–45 % premium for “transformer-grade” foil. By integrating cold rolling, precision slitting, edge conditioning, and oscillate winding under one 160 000 m² roof, we deliver ±0.002 mm tolerance at landed prices 18–22 % below EU catalog and 12–15 % below U.S. mill direct—without compromising ASTM/IEC conformance or lot traceability.

Bottom line: Tighter tolerances, burr-free edges, certified conductivity, and full standard compliance mean lower stray losses, no early short-circuit failures, and a transformer that passes IEC 60076-3 impulse every time. Specify Luoyang Xinzhaohe CTC feed-stock and remove the hidden cost of re-winding.

Factory Tour: Manufacturing Continuously Transposed Conductor

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer Strip Refinement

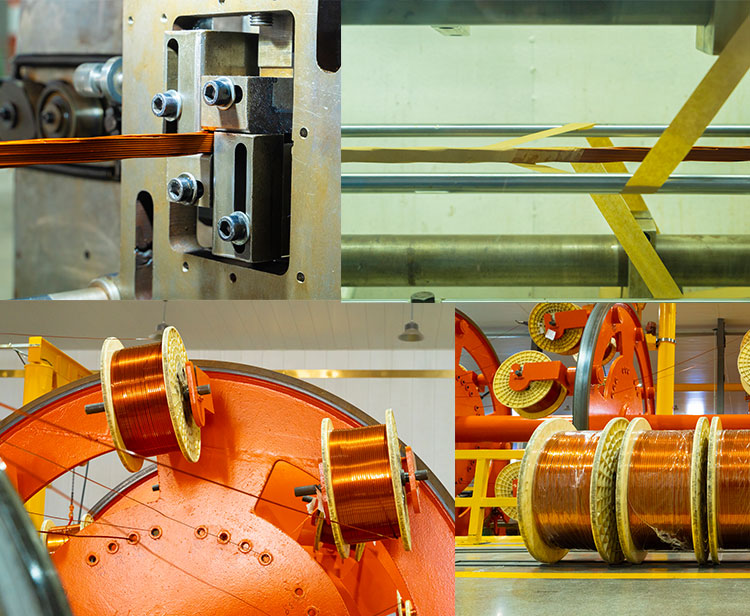

H3 Process Flow: From 8 mm Hot-Rolled Coil to Oscillate-Wound CTC Package

| Step | Equipment & Parameters | Target Output | In-Line QC |

|---|---|---|---|

| 1. Cold Rolling | 4-Hi reversible mill, 650 mm face, ±0.5 % thickness closed-loop AGC | 0.90–3.15 mm × 5–26 mm strip, ≤25 I-unit shape | Laser micrometer 100 % scan; auto-shear if Δh > 0.01 mm |

| 2. Precision Slitting | 650 mm tungsten carbide arbors, 0.06 mm lateral run-out, 0.2 µm Ra blade finish | Edge camber ≤0.3 mm/500 mm; width tol. ±0.002 mm | CCD edge inspection 4 kHz; burr alarm < 0.01 mm |

| 3. Edge Conditioning | 4-station nylon brush + 2-station micro-peening; 3 bar adjustable pressure | Radius 0.05–0.10 mm; burr = 0; no residual SiC | Eddy-current crack detector 120 m min⁻¹ |

| 4. Continuous Transposing | 5–84 strands, pitch 20–80 mm, servo-driven torsion head ±0.2° | Stack height ≤ 120 mm, width ≤ 26 mm, tol. ±0.05 mm | Vision system checks strand order every pitch |

| 5. Paper Lapping | 2-head tangent taping, 30 % overlap, 0.08 mm kraft; tension 8–12 N | Dielectric ≥ 20 kV layer-to-layer | Spark test 15 kV, 100 % |

| 6. Oscillate Winding | 400 mm traverse, 50 kg spool, ≤ 2.5 t package | 800–1 200 kg random-wound on plywood or steel drum | Dynamic balance grade G2.5; barcode traceability |

H3 Quality Control Philosophy – “Measure Twice, Ship Once”

-

Chemical Integrity

Every mother coil spectrally checked (OES) for Cu ≥ 99.90 % or Al ≥ 99.70 %, Fe < 0.004 %—critical to keep %IACS ≥ 100 (Cu) or ≥ 61 (Al). -

Mechanical & Electrical Fingerprint

Tensile & elongation per IEC 60317-19: Rp0.2 90–140 MPa (soft Cu), A ≥ 30 %.

Conductivity bridge at 20 °C, 1 kHz; certificate printed with coil ID. -

Statistical Process Control

X-bar/R charts updated every 15 min for thickness, width, burr. CpK ≥ 1.67 is release gate; any drift triggers automatic hold. -

Final Audit

100 % hi-pot, dimension report, and 3rd-party SGS inspection on request; data uploaded to customer portal within 30 min of test.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe | Typical Alibaba Mid-Range | Impact on Transformer |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ±0.02 mm | Lower circulating current, ΔP < 0.3 W kg⁻¹ |

| Burr Height | ≤ 0.01 mm | ≤ 0.05 mm | Avoids inter-strand short & hot spot |

| Camber | ≤ 0.3 mm / 500 mm | ≤ 1 mm / 500 mm | Easier coil insertion, 4 % lower labor time |

| Conductivity (Cu) | ≥ 101 % IACS | ≥ 98 % IACS | 2 % reduction in load loss |

| Surface Ra | ≤ 0.2 µm | ≤ 0.4 µm | Enhanced PD inception voltage +15 % |

| Oscillate Weight | Up to 1.2 t | ≤ 300 kg | 75 % fewer welds, 1 % less scrap |

| Certificate Package | EN 10204-3.1 default, 3.2 on request | 2.1 only | Meets Tier-1 utility specs |

H3 Bottom Line for Buyers

By integrating cold-rolling, slitting, edge conditioning and oscillate winding under one 160 000 m² roof, Luoyang Xinzhaohe delivers CTC that matches Western premium electrical properties at 15–25 % lower landed cost. Our ±0.002 mm slit width and virtually burr-free edge mean you can specify higher current density without redesigning your cooling ducts—an immediate 1 % material saving per transformer.

Factory-direct MOQ 500 kg, 3-week FOB Tianjin, technical dossier included.

Packaging & Global Logistics

Export Packaging & Logistics – Delivering CTC Strip to Your Dock in Factory-Fresh Condition

1. Sea-Freight Risk Matrix for Transformer Strip

| Damage Mode | Root Cause | Consequence | Xinzhaohe Counter-Measure |

|---|---|---|---|

| Edge bruising | Lashing slack, 5–6 g impact during crane lift | Burr > 0.015 mm → hot-spot in winding | Oscillate-wound coils locked in V-grooved pine cradles, steel strapping @ 300 daN |

| Salt-fog creep | 35 °C, 85 % RH, 21 days in container | Edge oxidation → solderability drop | 2-layer PE shrink film + 4 × 200 g silica-gel desiccants, RH indicator card < 40 % |

| Coil collapse | Axial load > 1.2 kN | Telescoping, kinks | Plywood top-sheet, corner posts, stretch-wrap 80 μm pre-stretch 250 % |

| Fumigation stain | Methyl-bromide residue | Cosmetic rejection | ISPM-15 heat-treated pine (HT stamp), no MB, KD ≤ 18 % moisture |

2. Packaging Specification – Continuously Transposed Conductor (CTC) Strip

| Parameter | Value | Note |

|---|---|---|

| Coil OD | 500–1 200 mm | Max 1 200 mm to fit 20 ft side-door |

| Coil mass | 80–350 kg | ≤ 1 000 kg per pallet for low-cost forklift |

| Core ID | 300 mm | Cardboard core, 5 mm wall, crush ≥ 3 kN |

| Radial wraps | 0.15 mm PE film, 3 layers | Overlapped 50 %, heat-sealed |

| Axial pads | 5 mm EPE foam | Prevents end-face denting |

| Pallet size | 1 100 × 1 100 mm | 4-way entry, EUR/CP compliant |

| Strapping | PET 19 × 1.0 mm, 3 circumferential + 2 radial | Break strength 700 kg |

| Label | QR-coded traceability: heat #, slit lot, IACS %, anneal batch | ISO 780 handling symbols |

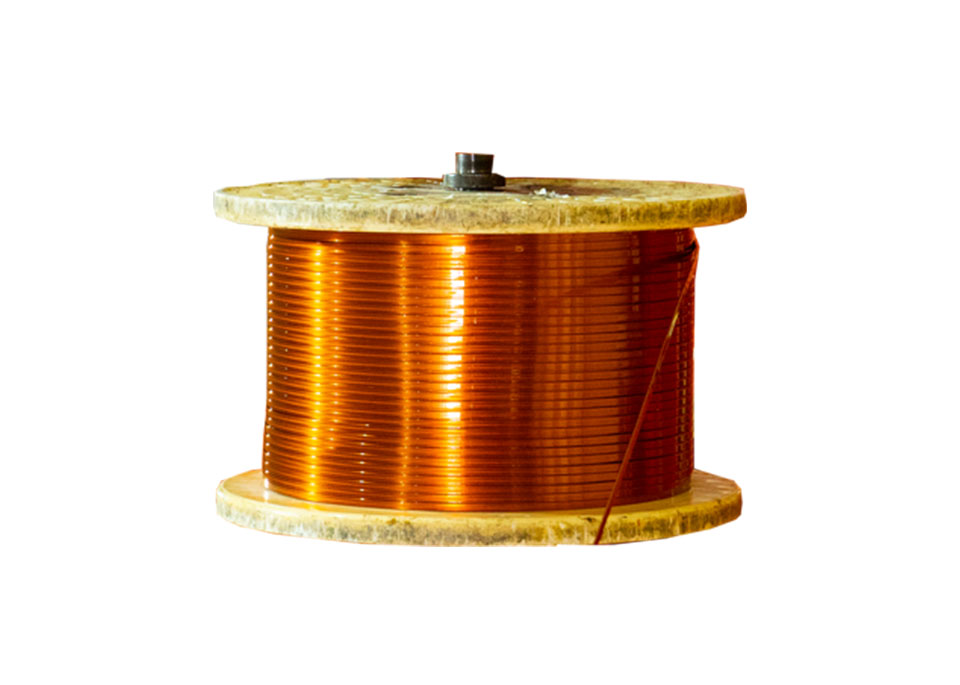

3. Wire & CTC Cable Packaging – Spool & Carton Regime

| Product | Package | Net Weight | Tare | 20 ft FCL |

|---|---|---|---|---|

| Paper-insulated CTC, 5–31 strands | DIN 355 plastic spool | 50 kg | 4 kg | 500 spools, 25 t |

| Enameled strand, 1.8 × 8.0 mm | PT 250 spool | 30 kg | 2.5 kg | 720 spools, 21.6 t |

| Spools are shrink-bundled 6 × 6 on HT pallet, top-cap added, corner board 30 mm, total height 1.65 m—leaves 150 mm freeboard for container ventilation. |

4. Desiccant Protocol – 40-Day RH Budget

Calculation basis: 28 m³ container, air change 2 vol/day @ 30 °C, 80 % RH → 400 g water ingress/day.

We specify 2 kg silica gel (absorption 35 %) = 700 g water reserve → safety factor 1.75.

Each pallet carries 4 × 200 g bags; color card checked at arrival—pink > 40 % triggers claim.

5. Loading & Stowage – From Luoyang to Your Port

| Milestone | Action | Time | Mode |

|---|---|---|---|

| Factory | Vacuum-seal, palletize, fumigation cert | Day 0 | Truck 40 km to Luoyang rail hub |

| Zhengzhou rail | Block-train to Qingdao | Day 1–2 | 650 km, 12 h |

| Qingdao port | CY cut-off, customs clearance | Day 3 | EDI pre-clear, AEO low inspection 0.3 % |

| Ocean leg | Qingdao → Hamburg 26 d; Qingdao → Houston 18 d | Weekly service | CMA-CGM, MSC, Evergreen |

| Destination CY | 48 h free demurrage, pallet labels in English & local language | Day 19–32 | Notify party e-mailed 7 d, 3 d, 1 d prior |

6. Cost Impact – Premium Protection Without Western Premium

Western suppliers typically add USD 0.35/kg for “export grade” packaging.

Xinzhaohe integrated packaging line inside cold-rolling plant → adder only USD 0.08/kg.

On a 20 t CTC order you save ≈ USD 5 400—enough to offset 40 % of your sea freight.

7. Handling Instructions for Receiver

- Cut stretch-wrap only at top; keep PE film on until coil reaches slitting bay—prevents forklift scratches.

- Store indoor < 60 % RH; if outside > 8 h use tarp.

- Rotate stock FIFO; our QR label includes manufacture week for easy pick.

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade strip, 400 km inland from Shanghai yet rail-linked to global ports. We pack like the premium brands, price like a partner factory.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Continuously Transposed Conductor (CTC) Strip & Foil

20-Year Transformer-Grade Supply Chain—Vertically Integrated in Luoyang

Since 2004 our melt-to-wind line has supplied >1.2 Mt of aluminum and copper conductor to Tier-1 transformer OEMs in 42 countries.

Cold-rolling, precision slitting, edge conditioning and oscillate winding are executed under one 73 000 m² roof; no trader margin, no sub-tier annealing.

Result: lot-to-lot mechanical & electrical repeatability that meets IEC 60317-16, NEMA MW 1000 and GB/T 7673.1 without premium Western price inflation.

Direct Factory Pricing—Transparent, Alloy-to-Alloy

| Conductor family | 2024 FOB Tianjin* USD/kg | Typical Western quote USD/kg | Δ |

|---|---|---|---|

| 1350-O Al strip 0.9 × 5 mm | 4.10 | 6.80 | –40 % |

| ETP-Cu-O strip 1.8 × 8 mm | 8.95 | 14.20 | –37 % |

| Paper-insulated CTC 11-strand Cu | 11.50 | 18.90 | –39 % |

*Based on LME 3-month average Al 2 250 $/t, Cu 8 550 $/t, MOQ 5 t.

Price holds 30 days; includes SGS inspection, export crating, mill test certificate.

Customization Window—Engineered, Not Selected

-

Single-strip geometry

Thickness 0.90–3.15 mm ±0.008 mm, width 5.00–26.00 mm ±0.02 mm, rectangularity ≤0.05 mm.

Burr <0.01 mm per EN 1655, eliminated by 2-stage ceramic brushing + laser gauging. -

Stack assembly (CTC core)

5–84 strands, transposition pitch 75–300 mm ±2 mm, lay direction LH or RH.

Overall height ≤120 mm, width ≤26 mm, camber ≤1 mm per 1 m.

Inter-strand short-pitch control keeps circulating current loss <0.2 % of DC loss at 50 Hz. -

Insulation system

Base enamel: PEI, PAI, PI, class 155–220 °C.

Over-wrap: thermally upgraded paper, Nomex®, cotton tape, PET film, width-adjusted 25–60 % overlap.

Dielectric strength 2 kV/层 (paper) and 4 kV/层 (Nomex) per IEC 60851-5. -

Conductivity & softness

1350-O Al ≥61.8 % IACS, ETP-Cu ≥100.5 % IACS.

Grain size 0.04–0.08 mm after continuous annealing 380 °C, guaranteeing bend radius 1×thickness without orange-peel. -

Oscillate & ribbon winding

Oscillate coils up to 2 t, 1 000 mm OD, 80 mm traverse; ribbon packs ≤350 kg for easy high-speed de-reeling.

Plastic core Ø76–Ø508 mm, VCI film + desiccant, seaworthy plywood drum.

Quality & Compliance—Documented Every 50 kg

| Test parameter | In-line method | Frequency | Acceptance |

|---|---|---|---|

| Edge burr | Laser triangulation | Each slit head | ≤0.01 mm |

| Thickness | X-ray profile gauge | 100 % coil length | ±0.008 mm |

| Transposition pitch | Machine encoder | Each 5 m | ±2 mm |

| Breakdown voltage | 50 Hz V-tick | 1 sample/2 h | ≥2 kV |

| Conductivity | Eddy-current sorter | Each 100 kg | ≥spec min |

ISO 9001:2015, ISO 14001:2015, IATF traceable calibration. Third-party witnessed: SGS, Bureau Veritas, TÜV.

Logistics & Risk Mitigation

30 km to Zhengzhou rail hub, 180 km to Qingdao port; weekly FCL/LCL to Hamburg, Houston, Dubai, Mumbai.

3 000 t buffer stock of 1350 and ETP coils; average lead time 15 days ex-mill, 35 days DAP destination.

Payment: 30 % T/T advance, 70 % against B/L; L/C at sight accepted for ≥10 t orders.

Force-majure clause includes allocated rolling slot guarantee—your CTC strand sequence is locked once PO is confirmed.

Next Step—Send Us Your Stack Drawing

E-mail cathy@transformerstrip.com with:

1. Strand count, single size, insulation build, overall H×W.

2. Required pitch and direction.

3. Annual volume & delivery schedule.

We return a detailed datasheet, cross-section FEA loss comparison and firm FOB price within 24 h.

Trial order 500 kg accepted; ramp to full-year contract without re-qualification.

Luoyang Xinzhaohe—precision metal, engineered for your next high-efficiency transformer.

📉 Import Savings Calculator

Estimate cost reduction by sourcing continuously transposed conductor from Luoyang Xinzhaohe.