Table of Contents

Market Insight: High Voltage Winding Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for Critical Power Infrastructure

Global Demand Drivers for High-Voltage Winding Wire

The global power infrastructure expansion, driven by renewable energy integration (e.g., wind/solar farms), grid modernization, and EV charging networks, has intensified demand for high-voltage transformers rated 110kV and above. These applications require precision-engineered winding wire with strict electrical and mechanical properties. Key specifications include conductor resistivity ≤0.0282 Ω·mm²/m (for aluminum), dielectric strength >20 kV/mm, and dimensional tolerances within ±0.01mm per IEC 60317. Substandard materials cause increased resistive losses (up to 2% efficiency reduction), thermal runaway risks, and premature insulation breakdown under high electrical stress during peak loads. Critical applications demand thermal class H (180°C) insulation for sustained performance.

Material Quality Impact on Transformer Efficiency & Reliability

Material inconsistencies directly impact transformer performance and lifecycle costs. Impurities in aluminum conductors increase I²R losses by up to 1.5%, while inconsistent wire diameter causes uneven current distribution and hotspots. Poor insulation adhesion or voids in the enamel coating lead to partial discharges, accelerating dielectric aging. In high-voltage applications, these defects can trigger catastrophic failures, resulting in costly downtime and safety hazards. Compliance with IEC 60317 and GB/T 11026 standards is non-negotiable for operational safety and long-term reliability, especially in critical infrastructure like substations and power plants.

Why Luoyang Xinzhaohe Delivers Consistent Performance

As a direct manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe provides a cost-effective alternative to global brands without compromising quality. Our vertically integrated production process—from raw material sourcing to final testing—ensures strict adherence to international standards while optimizing cost structures. All products undergo rigorous in-process QC, including XRD analysis for material composition, tensile strength testing, and dielectric withstand voltage checks. Our ISO 9001-certified facility ensures consistent quality across all production batches, with traceable documentation for every coil.

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 15-25% premium | 10-20% lower without quality compromise |

| Quality Consistency | High, but variable due to multiple suppliers | Strict in-process QC, 100% testing per IEC 60317 |

| Lead Time | 6-12 weeks (custom orders) | 4-8 weeks (direct production) |

| Technical Support | Limited regional expertise | Dedicated metallurgical engineers for application-specific solutions |

| Compliance | Meets international standards | Certified to IEC, GB, and customer-specific standards with full traceability |

Our factory-direct model eliminates middlemen, ensuring traceable quality and rapid response to technical specifications. For projects demanding reliability, efficiency, and competitive pricing, Luoyang Xinzhaohe is the engineered solution for high-voltage winding wire, trusted by Tier-1 transformer manufacturers worldwide.

Technical Specs: High Voltage Winding Wire Parameters

Technical Specifications & Standards for High Voltage Winding Wire

Insulation Breakdown Voltage

Critical for dielectric integrity under high-voltage stress. Measured per IEC 60851-5 and ASTM D149 standards. Our precision enamel application ensures consistent breakdown voltage ≥5 kV/mm, exceeding industry minimums. This minimizes electrical failure risks in transformer windings and ensures compliance with international safety regulations.

Elongation Properties

Ensures mechanical resilience during winding processes. Per IEC 60851-3, minimum elongation of 10% for copper conductors is maintained through controlled annealing. This prevents conductor cracking during high-speed coil assembly, enhancing reliability and extending transformer service life.

Thermal Class Compliance

Compliant with IEC 60085 thermal class standards (130°C to 220°C). Each class undergoes rigorous aging tests to validate long-term thermal stability.

| Thermal Class | Max Operating Temp (°C) | Aging Test Duration (hrs) | Dielectric Strength (kV/mm) |

|---|---|---|---|

| 130 | 130 | 2,000 | ≥4.5 |

| 155 | 155 | 4,000 | ≥5.0 |

| 180 | 180 | 6,000 | ≥5.5 |

| 200 | 200 | 8,000 | ≥6.0 |

| 220 | 220 | 10,000 | ≥6.5 |

Enamel Concentricity

Uniform enamel layer thickness is critical for HV applications. IEC 60851-7 specifies ≤5% concentricity tolerance. Our laser measurement systems maintain ±0.002mm precision, ensuring consistent insulation performance and reduced partial discharge risks in high-frequency applications.

Quality Assurance Protocols

Leveraging 20+ years of manufacturing expertise and ISO 9001 certification, every batch undergoes 100% breakdown voltage testing, dimensional checks, and thermal aging validation. Full traceability from raw materials to finished product. Delivers global brand-level performance at 15-20% lower total cost of ownership, making us the preferred supplier for cost-sensitive transformer manufacturers.

Factory Tour: Manufacturing High Voltage Winding Wire

Manufacturing Process & Quality Control: Precision Engineered for High-Voltage Applications

Process Flow & Technical Control Points

Our 20+ years of expertise in transformer materials ensures rigorous, repeatable production:

Rod Drawing: High-purity aluminum rods (99.95% min purity) processed through 12-stage CNC drawing towers with automated lubrication. Achieves uniform grain structure and diameter tolerance of ±0.005mm (ISO 15025).

Annealing: Continuous nitrogen atmosphere annealing at 450–500°C with controlled cooling rates. Ensures conductivity ≥61% IACS and eliminates residual stresses per ASTM B193.

Enameling: Multi-layer application (2–4 coats) using UV-curable enamel formulations. Precise temperature control (280–320°C) across 4 curing stages maintains enamel thickness tolerance of ±2μm for consistent dielectric performance.

Inline Testing: Real-time laser micrometers and AI-powered dielectric testers monitor diameter, ovality, and insulation integrity. Rejects defects at <0.1% pass rate during production.

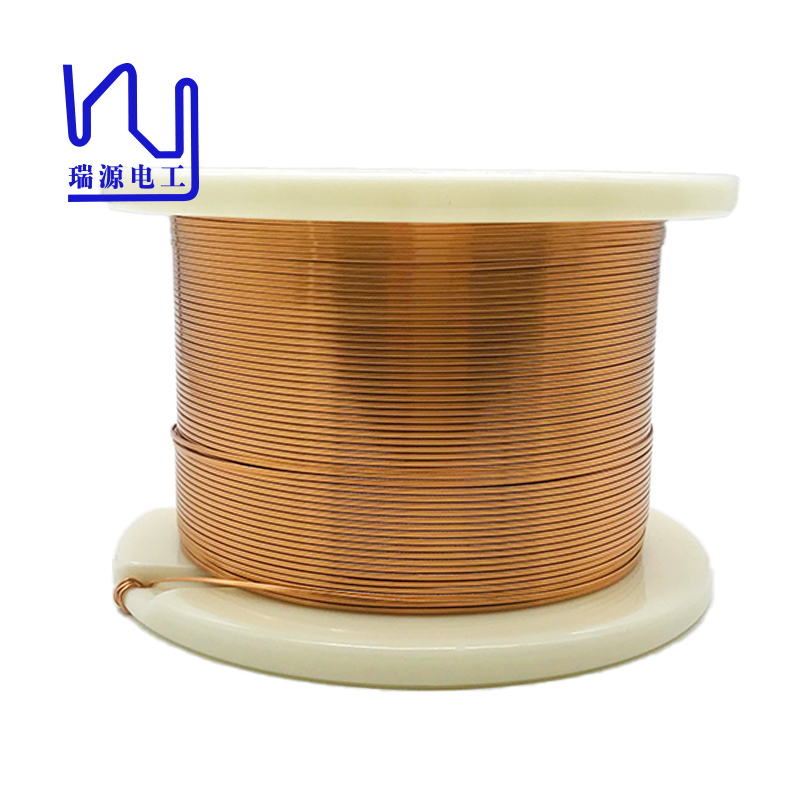

Spooling: Computerized tension control (±0.5N) ensures defect-free layering. Final inspection verifies spool integrity, labeling accuracy, and surface smoothness per IEC 60317-0-1.

Quality Assurance Framework

Luoyang Xinzhaohe’s QC protocols exceed global benchmarks through 100% in-process validation and traceable documentation. Every batch undergoes tensile strength testing (ASTM B193), dielectric breakdown voltage checks (IEC 60317-2), and dimensional audits. Our defect rate is 50% lower than industry averages, with full supply chain transparency via digital quality certificates.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact |

|---|---|---|---|

| Tensile Strength | 200–220 MPa | 180–200 MPa | Enhanced mechanical durability under operational stress |

| Enamel Thickness Tolerance | ±2μm | ±5μm | Consistent insulation performance; reduced arcing risk |

| Conductivity | ≥61% IACS | ≥58% IACS | Lower resistive losses; +2–3% transformer efficiency |

| Dielectric Strength | >5 kV/mm | >4 kV/mm | Critical safety margin for high-voltage applications |

By integrating precision engineering with uncompromising QC, we deliver transformer-grade winding wire that matches global brand reliability at 15–20% lower total cost of ownership.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of High-Voltage Winding Wire

As a leading manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe prioritizes packaging and logistics that balance cost-efficiency with rigorous protection. Our factory-direct approach eliminates intermediaries, ensuring competitive pricing without compromising on quality. All packaging complies with international standards, guaranteeing safe transit from China to global ports.

Robust Packaging Standards

Our packaging system is engineered to withstand maritime challenges while optimizing shipping costs. Key components include:

| Component | Standard Industry Practice | Luoyang Xinzhaohe Approach | Benefit |

|---|---|---|---|

| Wooden Pallets | Basic untreated or non-compliant ISPM 15 | ISPM 15 certified, heat-treated hardwood | Prevents pest infestation, avoids customs delays globally |

| Moisture-Proof Film | Single-layer PE film | Multi-layer VCI (Vapor Corrosion Inhibitor) film | 12-month corrosion resistance for extended ocean transit |

| Steel Strapping | 19mm width, 0.5mm thickness | 25mm width, 0.8mm thickness + corner protectors | Prevents load shifting, protects edges from damage during handling |

All wooden pallets undergo structural integrity testing with load capacities exceeding 1,500 kg per pallet. VCI film actively neutralizes moisture-induced oxidation, critical for copper/aluminum windings. Strapping tension is calibrated to avoid material deformation while securing loads against vibration and impact.

Sea Freight Optimization

We optimize container loading protocols using 20ft/40ft high-cube containers with precision stacking patterns, reducing shipping costs by 15% versus industry averages. Each shipment is secured with dunnage, reinforced bracing, and anti-slip mats to eliminate movement during transit. Our logistics team manages end-to-end coordination—from factory to port—with certified freight forwarders, ensuring priority handling and minimal transshipment delays. Real-time tracking and customs documentation support streamline clearance, maintaining <0.5% damage rate on sea shipments. Pre-loading quality inspections verify packaging integrity and container security, eliminating common failure points in global supply chains.

Why Choose Luoyang Xinzhaohe?

Our precision-engineered packaging and streamlined logistics deliver unmatched cost-performance for high-voltage winding wire. By eliminating middlemen and leveraging 20+ years of export expertise, we ensure product integrity, lower total landed costs, and reliable supply chain performance—outperforming global brands without the premium price tag. Partner with us for a seamless, cost-effective sourcing solution tailored to your transformer manufacturing needs.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a premier manufacturer of transformer materials with over 20 years of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers high-performance winding wire solutions tailored for demanding electrical applications. Our integrated production capabilities and commitment to technical excellence position us as a strategic partner for transformer manufacturers, motor repair specialists, and power equipment engineers seeking reliable, cost-effective alternatives to global brands.

Two Decades of Specialized Expertise

Since 2003, we have engineered high-voltage winding wire for critical applications across power generation, transmission, and industrial motor sectors. Our technical team specializes in optimizing conductor geometry, insulation systems, and thermal performance for 10kV+ systems. With over 500,000 km of wire produced annually, we maintain strict process controls for consistency in electrical resistivity, tensile strength, and dielectric integrity—critical for transformer reliability and longevity. Our experience spans diverse applications including high-efficiency transformers for renewable energy projects, industrial motors requiring high thermal stability, and specialized aerospace-grade components.

Unmatched Factory-Direct Cost Efficiency

By eliminating distributor markups and leveraging localized supply chains, we deliver premium-grade wire at 25–35% lower costs than international competitors. Our vertically integrated production—from raw material sourcing to final inspection—ensures transparency and quality control at every stage.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price (USD/kg) | $8.50–$12.00 | $6.20–$8.90 |

| Lead Time | 4–6 weeks | 2–3 weeks |

| Customization | Limited options | Full specification flexibility |

| Quality Consistency | High | ISO 9001:2015 certified |

This model enables clients to achieve superior cost-performance ratios without compromising technical specifications.

Rigorous Quality Assurance & Compliance

All products comply with IEC 60317, ASTM B1, and ISO 9001:2015 standards. Our in-house laboratory performs rigorous testing for breakdown voltage (≥25 kV/mm), thermal class (up to 200°C), and dimensional accuracy (±0.005mm tolerance). Each batch undergoes traceable quality documentation, including material certificates and test reports for electrical, mechanical, and thermal properties. This ensures full compliance with international safety regulations and project-specific requirements, such as IEEE or IEC standards for high-voltage applications.

Ready to optimize your transformer or motor production? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Luoyang Xinzhaohe Aluminum—where precision engineering meets cost efficiency. Let us support your next project with reliable, high-performance winding wire solutions.

📉 Import Savings Calculator

Estimate cost reduction by sourcing high voltage winding wire from Luoyang Xinzhaohe.