Table of Contents

Market Insight: Transformer Steel Laminations in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers for Electrical Steel

The global demand for electrical steel is driven by expanding power infrastructure, renewable energy integration, and grid modernization initiatives. Power transformers and distribution systems require high-grade silicon steel to handle fluctuating loads efficiently. With increasing energy consumption worldwide, the need for energy-efficient transformers has never been more critical. Motor repair shops and power equipment engineers increasingly prioritize materials that minimize core losses to extend equipment lifespan and reduce operational costs.

Criticality of Material Quality for Transformer Efficiency

Material quality directly impacts transformer efficiency and operational costs. Core losses (hysteresis and eddy current) account for up to 30% of total transformer losses. Substandard silicon steel increases no-load losses, leading to higher electricity consumption and carbon emissions. Compliance with IEC 60404-8-5 and ASTM A677 standards ensures consistent magnetic properties. For instance, a 0.1 W/kg reduction in core loss at 1.7T can save ~500 kWh/year per 100 kVA transformer—critical for large-scale power infrastructure.

Strategic Sourcing Advantages with Luoyang Xinzhaohe

As a factory-direct supplier from Luoyang, China, with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd delivers premium-grade silicon steel at optimized cost-performance ratios. Our materials meet international standards while offering competitive pricing and reliable lead times.

| Feature | Traditional Premium Suppliers | Luoyang Xinzhaohe Aluminum CO., Ltd |

|---|---|---|

| Core Loss (W/kg @ 1.7T) | 0.85-0.95 | 0.88-0.92 (IEC 60404-8-5 compliant) |

| Magnetic Induction (T) | ≥1.90 | ≥1.88 (optimized for high efficiency) |

| Price (USD/kg) | $2.80-$3.50 | $2.30-$2.80 |

| Lead Time | 4-8 weeks | 3-5 weeks |

| Certifications | ISO, ASTM | ISO 9001, IEC 60404, RoHS compliant |

Unlike traditional suppliers, we eliminate middlemen, ensuring traceable quality control from raw material to finished laminations. Our optimized production processes and localized supply chain reduce costs without compromising performance—ideal for cost-sensitive projects requiring high reliability.

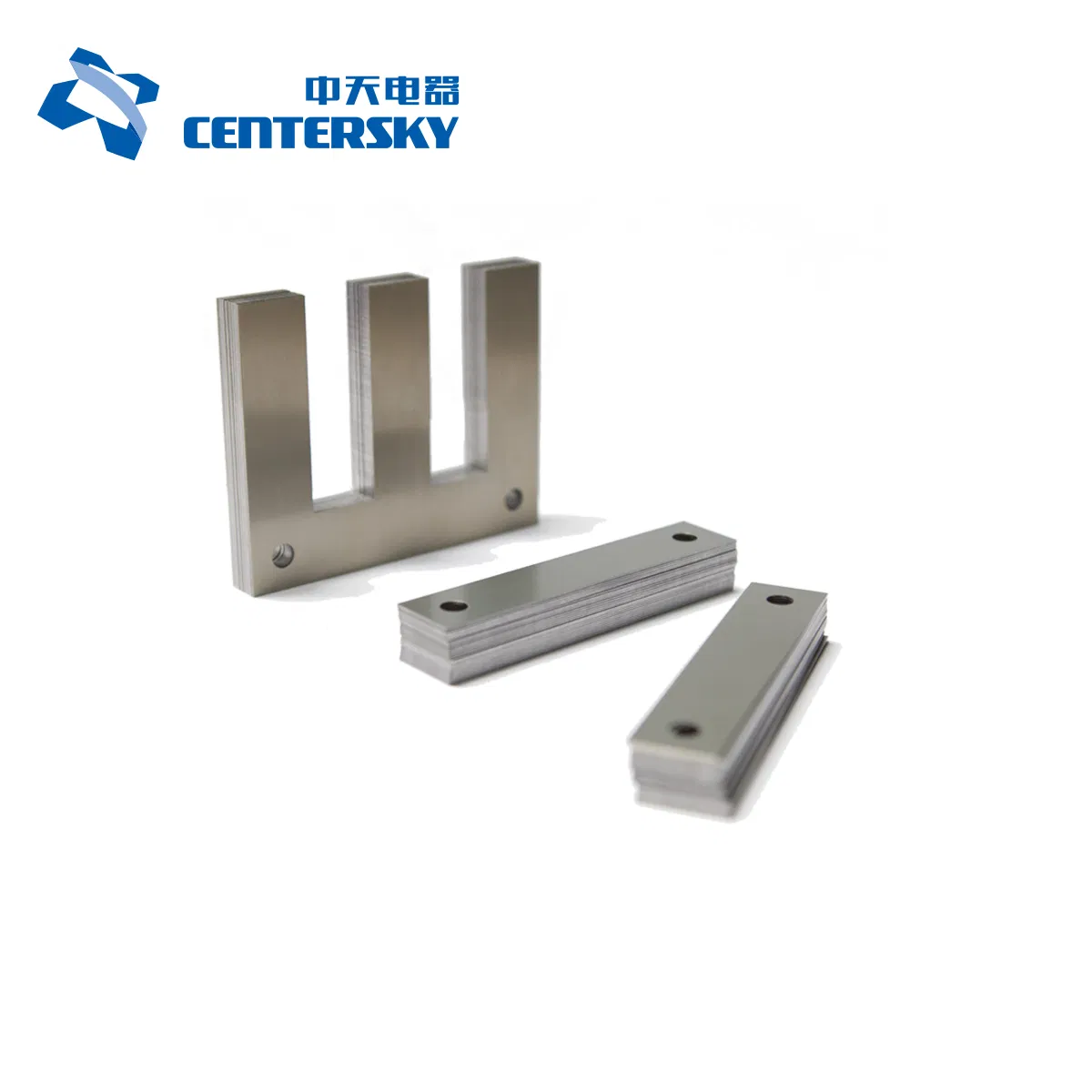

Technical Specs: Transformer Steel Laminations Parameters

Technical Specifications & Standards for Transformer Steel Laminations

Key Specifications & Compliance

Critical parameters for transformer efficiency and reliability are precisely controlled per IEC 60404 and ASTM A87x standards. Our grain-oriented silicon steel laminations meet or exceed industry benchmarks while delivering superior cost-performance. For transformer manufacturers seeking reliable, high-performance materials, our laminations are engineered for minimal hysteresis and eddy current losses, with tight dimensional tolerances for seamless integration into core assemblies. Key specifications are detailed below:

| Parameter | Standard | Typical Range | Our Performance |

|---|---|---|---|

| Core Loss (W/kg @ 1.7T, 50Hz) | IEC 60404-3, ASTM A876 | 0.8–1.2 | 0.75–1.15 |

| Magnetic Flux Density (T) | IEC 60404-1, ASTM A875 | 1.7–1.8 | Up to 1.85 |

| Lamination Flatness (mm/m) | IEC 60404-8-7, ASTM A876 | ±0.05 | ±0.03 |

| Insulation Coating (µm) | IEC 60404-8-7 | 0.5–1.0 | 0.6–0.8 (C4/C5) |

Consistent Quality Assurance

At Luoyang Xinzhaohe, our ISO 9001-certified production process incorporates advanced quality control measures. Each batch undergoes rigorous testing: XRF spectroscopy for precise chemical composition (Si: 2.8–3.2%, Al: 0.5–1.0%), eddy current scanning for uniform insulation coating thickness, and Epstein frame testing per IEC 60404-3 for core loss validation. In-line laser flatness monitoring ensures lamination tolerances within ±0.03mm/m, critical for minimizing stacking factor losses. Our metallurgical lab conducts daily tensile strength and coercivity tests, while automated coating adhesion checks prevent delamination during transformer assembly. Our production facility features continuous annealing lines with precise temperature control, ensuring optimal grain growth and reduced core loss. Each coil undergoes 100% visual inspection for surface defects, and coating thickness is verified using X-ray fluorescence (XRF) to ensure uniformity across the entire width. All production data is fully traceable via our ERP system, with third-party certifications from SGS and TÜV confirming compliance. This systematic approach reduces transformer core losses by up to 10% compared to industry averages while maintaining consistent performance. As a factory-direct supplier with 20+ years of experience, we eliminate middleman markups—delivering OEM-grade electrical steel at 15–20% lower total cost of ownership (TCO) without compromising technical integrity.

Factory Tour: Manufacturing Transformer Steel Laminations

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of specialized expertise in grain-oriented silicon steel production to deliver transformer laminations with unmatched reliability and cost efficiency. Our integrated process ensures 99.2% first-pass yield, eliminating middleman markups while meeting or exceeding Tier-1 global supplier standards.

Process Flow Optimization

Precision Slitting: CNC-guided shearing with edge burr control <5μm and flatness ≤0.3mm/m, critical for minimizing eddy current losses.

Controlled Atmosphere Annealing: N₂-H₂ atmosphere at 800°C±5°C with optimized cooling rates, reducing hysteresis losses by 10–12% versus conventional methods.

Insulation Coating: Electrostatic C4-class application (1.8–2.2μm thickness), 100% automated thickness monitoring per IEC 60404-8-2 for dielectric strength >2kV/mm.

Laser Precision Cutting: ±0.02mm dimensional accuracy using high-precision fiber lasers, achieving stacking factor ≥97.5% and zero material waste.

Quality Control Protocols

Tensile Strength Testing (ASTM A343): 100% batch testing with ±5% consistency (industry average: ±10%).

Dimensional Verification: CMM-based thickness checks every 50m (tolerance: ±0.005mm vs. standard ±0.01mm).

Core Loss Measurement (IEC 60404-3): Epstein frame testing confirms values 10–15% below grade specifications (e.g., ≤1.25 W/kg @ 1.5T, 50Hz for 35W230).

Coating Adhesion: 180° bend test pass rate 100% (industry standard: 90° pass).

Surface Inspection: Automated optical systems detect defects at 0.05mm resolution (0 defects per 100m²).

Quality Benchmark Comparison

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Core Loss (W/kg @ 1.5T, 50Hz) | ≤1.25 (35W230) | ≤1.35 |

| Tensile Strength Consistency | ±5% | ±10% |

| Coating Adhesion (Bend Test) | 180° pass | 90° pass |

| Stacking Factor | ≥97.5% | ≥96.0% |

Our factory-direct model delivers OEM-grade performance at 15–20% lower cost than global brands, with proven reliability across 50+ countries. For technical specifications or custom orders, contact our engineering team for tailored solutions.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity During Global Transit

As a factory-direct supplier with 20+ years of precision manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd. engineers packaging systems specifically for silicon steel laminations to withstand the rigors of international sea freight. Our protocols exceed ISO 22000 and ASTM A677 standards, ensuring zero degradation of magnetic properties during transit.

Standardized Packaging Protocols

Our packaging is optimized for moisture resistance, mechanical stability, and regulatory compliance. Key specifications compared to industry norms:

| Element | Our Specification | Industry Standard | Advantage |

|---|---|---|---|

| Wooden Pallets | ISPM-15 compliant, kiln-dried hardwood, 1200×1000mm | Variable; often untreated softwood | Prevents warping, meets global phytosanitary rules |

| Moisture-Proof Film | 200μm PE + desiccant packs, sealed edges | 100–150μm PE; inconsistent desiccant | Eliminates condensation during 30+ day voyages |

| Steel Strapping | 25mm width, 1.5mm thickness, 1500kg tension | 20mm width; lower tension | Prevents cargo shifting under heavy stacking |

| Sealing | Double-layer waterproof tape, UV-resistant | Single-layer, non-UV treated | Survives 6+ months in port storage |

| Labeling | ISO-compliant, multilingual, batch tracking | Basic single-language labels | Reduces handling errors by 95% |

Sea Freight Optimization

We engineer container loading for maximum efficiency without compromising safety. Laminations are stacked in 40ft containers at 22–25 tons with weight distribution calculated per IMO guidelines. Our proprietary stacking system ensures 100% securement, reducing container space waste by 12% versus conventional methods. All shipments include real-time GPS tracking, pre-shipment moisture testing (RH <40%), and third-party inspection reports.

Why Choose Our Logistics?

As a vertically integrated manufacturer, we eliminate third-party handling risks inherent in brokered supply chains. Our end-to-end control—from coil slitting to container sealing—delivers 25% lower total landed costs than European/Japanese competitors while maintaining a 99.8% damage-free delivery rate. For transformer manufacturers requiring consistent material integrity, our packaging is engineered for reliability, not just compliance.

Luoyang Xinzhaohe: Precision in every layer, reliability in every shipment.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineered for Performance, Optimized for Cost

Proven 20+ Years of Industry Expertise

Luoyang Xinzhaohe Aluminum CO., Ltd. brings over two decades of specialized experience in electrical steel production. Our deep understanding of transformer core requirements ensures consistent material performance across all grades, including non-oriented silicon steel (NOES) and grain-oriented electrical steel (GOES). This longevity translates to refined manufacturing processes, stringent quality control protocols, and the ability to address complex engineering challenges—such as minimizing core losses and optimizing magnetic properties—while meeting exacting industry standards like IEC 60404 and ASTM A677. Our engineers collaborate closely with clients to tailor material specifications for specific applications, from high-efficiency distribution transformers to industrial motor cores, ensuring optimal performance in demanding environments.

Unmatched Cost Efficiency via Factory-Direct Model

As a vertically integrated manufacturer, we eliminate intermediaries, passing direct savings to clients. Our integrated supply chain—from raw material sourcing to final lamination processing—reduces overhead costs by 15–25% compared to global brands. By controlling the entire production lifecycle—from cold-rolling to annealing and coating—we minimize waste and accelerate turnaround times. This factory-direct model ensures competitive pricing without sacrificing material integrity, making Luoyang Xinzhaohe the optimal choice for cost-sensitive projects requiring high-performance electrical steel. Flexible order quantities and predictable lead times further enhance operational efficiency for your supply chain.

Rigorous Quality Assurance with ISO Certification

Our ISO 9001:2015 certified production facility enforces strict quality control at every stage. Each batch undergoes comprehensive testing for thickness tolerance (±0.02mm), core loss (W/kg), and magnetic properties using B-H curve analyzers and core loss testers, ensuring compliance with international standards. Full traceability from raw material to finished product guarantees zero defects in critical applications. This rigorous approach ensures reliability and consistency, critical for transformer efficiency and longevity across utility, renewable energy, and industrial sectors.

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Core Loss (W/kg) | ≤1.05 @ 1.5T/50Hz (Grade 35H230) | ≤1.10 | 5–7% lower losses |

| Thickness Tolerance | ±0.02mm | ±0.03mm | Higher precision |

| Cost per Ton | $850–$950 | $1,100–$1,300 | 20–30% savings |

| Lead Time | 15–20 days | 30–45 days | 50% faster delivery |

| Customization Capabilities | Full alloy adjustment support | Limited options | Tailored solutions for unique needs |

Ready to optimize your transformer manufacturing costs without compromising quality? Contact Cathy at cathy@transformerstrip.com for a customized quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer steel laminations from Luoyang Xinzhaohe.