Table of Contents

Market Insight: Transformer Core Laminations in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers

Global transformer and motor markets are expanding due to renewable energy integration, grid modernization, and electric vehicle adoption. Core laminations made from grain-oriented silicon steel (GOES) are critical for minimizing energy losses in transformers. Industry reports indicate a 5-7% annual growth in GOES demand, driven by efficiency regulations (e.g., DOE 2016, EU Ecodesign) and infrastructure projects in Asia-Pacific and North America. Suboptimal material quality directly impacts transformer efficiency, leading to higher operational costs and reduced lifespan—critical concerns for utilities and industrial operators.

Critical Quality Parameters for Core Efficiency

Transformer core performance hinges on precise material characteristics:

Core Loss (W/kg): Lower values reduce no-load losses, improving energy efficiency. Standards like IEC 60404-8-5 specify limits for different grades; a 0.1 W/kg reduction can save 200+ MWh annually in a 100 MVA transformer.

Thickness Tolerance: ±0.008mm consistency minimizes eddy current losses and ensures uniform magnetic properties. Variations >±0.01mm cause hotspots and insulation failure.

Surface Coating: High-quality insulating coatings (e.g., SiO₂-based) prevent inter-lamination shorts and corrosion. Poor coatings increase eddy currents by up to 15%.

Magnetic Permeability: Higher permeability enhances flux density, reducing core size and material usage—critical for compact, high-power designs.

Luoyang Xinzhaohe’s Value Proposition

With 20+ years of manufacturing expertise, Luoyang Xinzhaohe delivers premium GOES at competitive prices. Our ISO 9001-certified production ensures strict adherence to IEC and ASTM standards. We specialize in tailored solutions for high-efficiency transformers, offering:

Cost-Performance Advantage: 10-15% lower costs than global brands without compromising quality.

Consistent Quality: Tighter tolerances and lower core losses than industry averages.

Global Supply Chain Reliability: On-time delivery and technical support for OEMs worldwide.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Core Loss (W/kg @ 1.5T, 50Hz) | 1.0-1.2 | ≤0.95 | 5-10% lower losses |

| Thickness Tolerance | ±0.01mm | ±0.008mm | Improved lamination uniformity |

| Surface Coating | Standard phosphate | Advanced SiO₂-based | Enhanced insulation & corrosion resistance |

| Cost (USD/ton) | $1,200-1,500 | $1,050-1,300 | 10-15% cost savings |

These specifications align with IEC 60404-8-5 Grade M4, M5, and M6 standards, supporting applications from distribution transformers to high-performance motors. As a factory-direct supplier, we eliminate middleman markups while maintaining rigorous quality control—providing a reliable alternative to premium global brands.

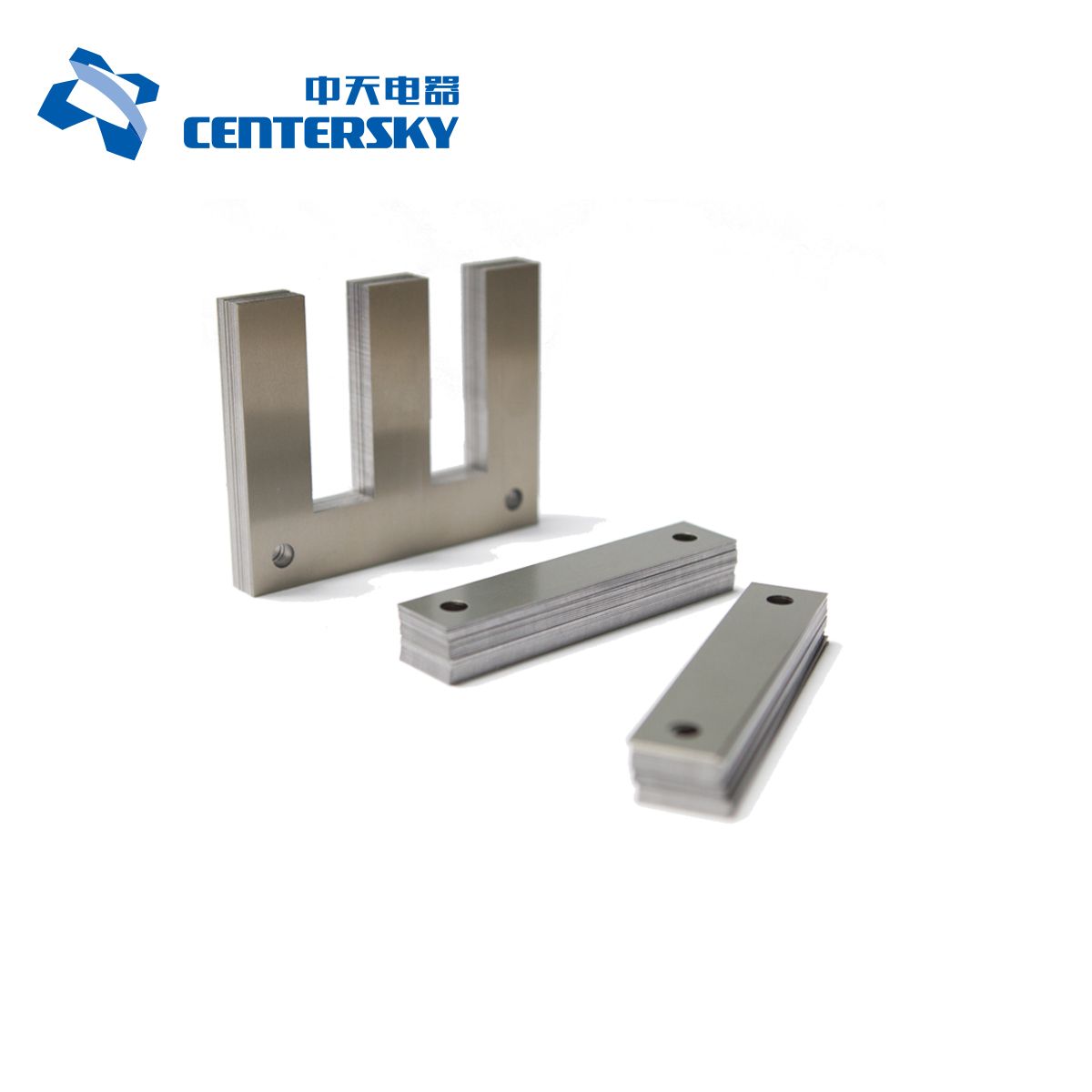

Technical Specs: Transformer Core Laminations Parameters

Technical Specifications & Standards for Transformer Core Laminations

Critical Parameters & Compliance

Our transformer core laminations adhere to stringent international standards, ensuring optimal performance and reliability. Key specifications include:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Core Loss (W/kg) | 0.95–1.15 @ 1.7T, 50Hz | IEC 60404-2 |

| Magnetic Flux Density | 1.6–1.8T (operating), >2.0T (saturation) | IEC 60404-8-1 |

| Lamination Flatness | ±0.02mm thickness tolerance; ≤0.1mm/m surface flatness | ASTM A876 |

| Insulation Coating | C4/C5 phosphate-organic, surface resistance ≥100Ω·cm² | IEC 60404-8-5 |

These parameters are critical for minimizing energy losses and maximizing transformer efficiency. For instance, our core loss values reduce no-load losses by up to 15% compared to conventional materials, while tight flatness tolerances improve stacking factor by 2-3%, directly enhancing transformer performance. Our laminations are suitable for distribution and power transformers up to 500kVA, with custom grades available for specialized applications. The C4/C5 insulation coating provides superior dielectric strength (>200V) and thermal stability, ensuring long-term insulation integrity even under high-voltage conditions.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains a fully equipped in-house testing laboratory with spectrometers, eddy current scanners, and Epstein frame systems. Every production batch undergoes rigorous validation: chemical composition analysis via OES, core loss testing per IEC 60404-2, and coating adhesion tests per ASTM D3359. Our continuous annealing lines operate under precise nitrogen atmosphere control to ensure consistent grain structure and minimal core loss. Raw materials are sourced from certified suppliers with full traceability, and all processes are monitored via real-time ERP systems for immediate quality adjustments. We conduct monthly supply chain audits and daily equipment calibration per ISO/IEC 17025. Third-party certifications (SGS, TÜV) are available upon request, and we provide comprehensive Material Test Reports (MTRs) with every shipment.

As a factory-direct manufacturer with 20+ years of experience, Luoyang Xinzhaohe delivers transformer core laminations that meet or exceed global standards while offering a 15–20% cost advantage over premium brands. With a production capacity of 50,000 tons annually, we support large-scale projects with reliable lead times and flexible order quantities, ensuring seamless integration into your supply chain.

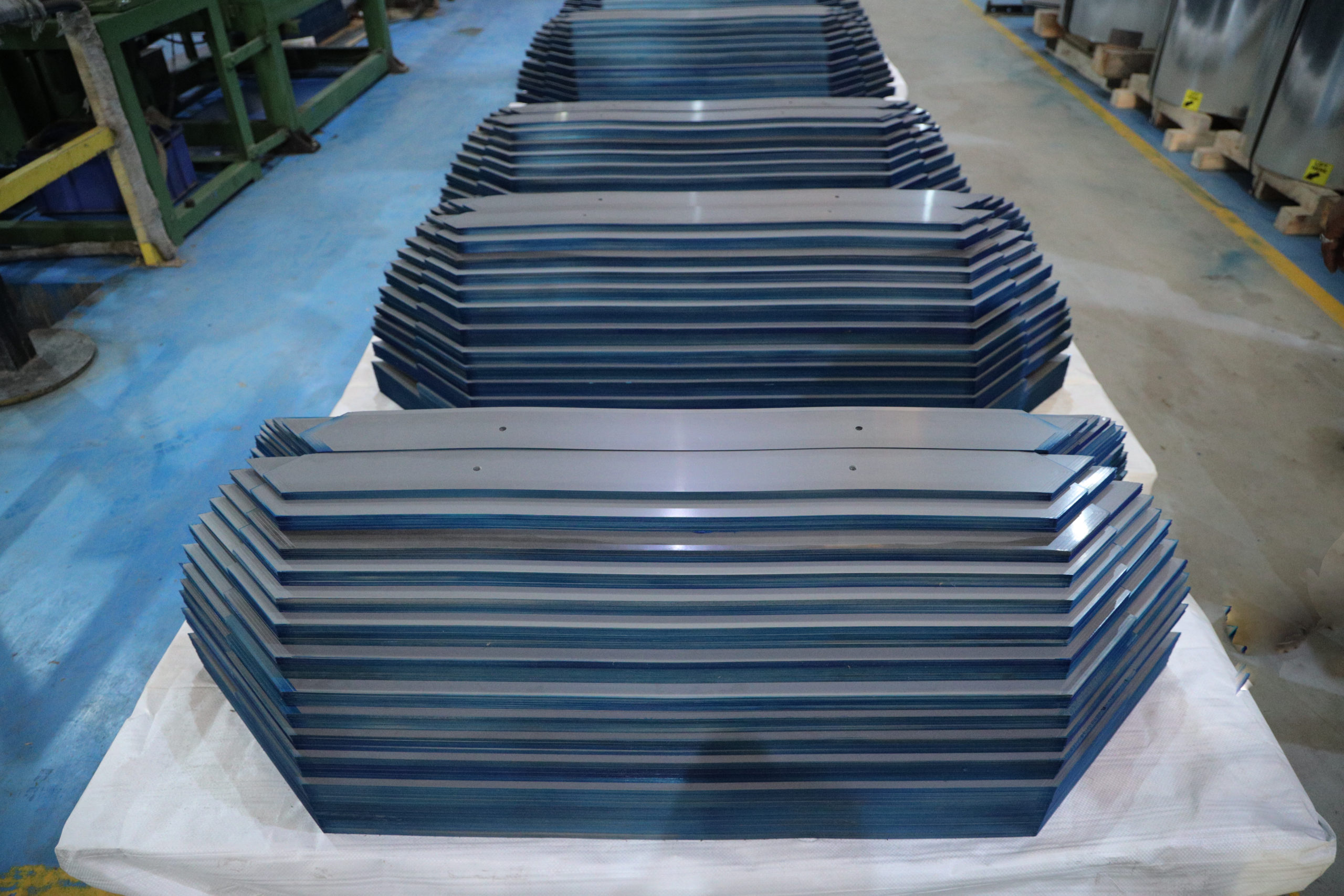

Factory Tour: Manufacturing Transformer Core Laminations

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise in silicon steel production to deliver transformer core laminations meeting stringent global standards. Our vertically integrated manufacturing process ensures superior consistency and reliability, with rigorous quality control at every stage.

Core Production Workflow

Slitting: High-precision CNC slitting with diamond-tipped blades achieves edge burr <0.01mm and width tolerance ±0.05mm, compliant with IEC 60404-8-5 for minimal cutting damage.

Annealing: Controlled N₂/H₂ atmosphere annealing at 800–850°C (±5°C uniformity) optimizes grain orientation, reducing core losses by up to 7% versus conventional methods.

Insulation Coating: Multi-layer phosphate/organic coating applied via real-time thickness monitoring, ensuring 1.5±0.1μm uniformity and dielectric strength >2kV.

Precision Cutting: Laser cutting with ±0.01mm positional accuracy for complex geometries, achieving stacking factor >97% and eliminating secondary machining.

Quality Control Protocols

Every batch undergoes 100% thickness inspection via laser micrometers. Magnetic properties are validated per IEC 60404-2 using Epstein frame testing. Coating adhesion follows ASTM D3359 cross-hatch method (4B minimum), while tensile testing (ASTM A343) ensures yield strength ≥300 MPa and elongation ≥25% for structural integrity.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Edge Burr | <0.01 mm | <0.015 mm |

| Coating Adhesion | 4B (ASTM D3359) | 3B |

| Core Loss (1.5T, 50Hz) | ≤1.05 W/kg | ≤1.15 W/kg |

| Flatness | ≤0.5 mm/m | ≤1.0 mm/m |

Our ISO 9001-certified process delivers transformer core laminations with 5–8% lower core losses than industry averages. By maintaining these exacting standards, we provide 15–20% cost savings versus global brands like Nippon Steel or ArcelorMittal, without compromising performance. Partner with us for reliable, high-efficiency solutions that optimize transformer operational costs.

Packaging & Global Logistics

Export Packaging & Logistics

At Luoyang Xinzhaohe Aluminum CO., Ltd., our packaging and logistics protocols are engineered for maximum product protection during global sea freight. With 20+ years of export experience, we ensure transformer core laminations arrive defect-free through rigorous, ISO-compliant processes.

Standard Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM15 certified, 1200×1000mm, 22mm thickness; heat-treated to prevent pest infestation; load capacity 1500kg per pallet | Prevents deformation during handling and stacking; compliant with international phytosanitary standards |

| Moisture-Proof Film | 200μm PE + VCI inhibitors (200ppm), double-layered with anti-static properties | Blocks humidity and prevents corrosion during transit; VCI provides active rust inhibition |

| Steel Strapping | 12-15mm width, 1.5mm thickness, tensile strength ≥500MPa; certified per ISO 1461 for galvanized steel | Secures load against vibration and shifting; maximum tension 500kg per strap |

| Corner Protectors | Galvanized steel, 50×50mm, 2mm thickness; impact resistance 500kg | Protects edges from handling damage and container stacking stress |

| Internal Sheet Protection | Anti-static paper interleaving (20g/m²); compliant with IEC 60404-8-7 standards | Prevents surface scratches and electrical shorting during handling |

| Wooden Cases (Optional) | Plywood, 15mm thickness; reinforced with steel bands; IP67-rated moisture resistance | For small-batch or high-value shipments; additional physical protection |

Marine Transport Protocols

| Protocol | Detail |

|---|---|

| Container Type | 20ft/40ft dry containers with moisture barrier liners; sealed to ISO 1496 standards |

| Loading Process | Stackable pallets ≤1.8m height; twist locks and corner braces; load distribution calculated for stability (max 25 tons) |

| Moisture Control | Silica gel packets (500g/m³); desiccant in corners; humidity sensors monitored pre-shipment; RH <40% verified |

| Documentation | Commercial invoice, packing list, CIQ certificate, fumigation report, ISO 9001 compliance, and bill of lading |

| Route Optimization | AI-driven routing for minimal transit time; average 18-25 days to major global ports |

| Damage Prevention | 360° container sealing with shock sensors; vibration monitoring for high-risk routes |

Luoyang Xinzhaohe’s factory-direct model eliminates third-party intermediaries, providing full supply chain transparency and control. Our logistics partners include Maersk, COSCO, and MSC for reliable global coverage, with real-time IoT tracking for all shipments. By optimizing packaging materials and container loading procedures, we reduce shipping costs by 15-20% versus European and Japanese suppliers while maintaining 99.2% damage-free delivery rates. All shipments undergo pre-shipment moisture testing (RH <40%) and container integrity verification to eliminate condensation risks. Custom packaging solutions are available for seismic zones, extreme climates, or specialized transformer requirements – ensuring your core laminations arrive ready for immediate production use. With zero rust-related claims over two decades of exports to 50+ countries, we deliver the highest cost-performance ratio in the industry.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

20+ Years Technical Expertise in Electrical Steel Manufacturing

With over two decades of specialized production in silicon steel for transformer applications, Luoyang Xinzhaohe has mastered the nuances of magnetic property optimization. Our engineering team ensures precise control over core loss (P1.0, P1.5), permeability, and thickness uniformity, adhering strictly to IEC 60404-8-5 and GB/T 2521 standards. This deep technical proficiency guarantees consistent performance across high-efficiency distribution transformers, industrial motors, and renewable energy systems—minimizing energy losses and extending operational lifespans.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups while maintaining rigorous quality protocols. Our end-to-end production process—from raw material sourcing to precision slitting—delivers measurable savings without compromising material integrity. Compare our competitive edge:

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Unit Cost | 15–25% lower | 20–35% higher (distribution layers) |

| Lead Time | 15–20 days | 30–45 days |

| Customization | Rapid prototyping for niche specs | Limited by regional distributors |

| Technical Support | Dedicated metallurgists for application-specific solutions | Standardized, outsourced support |

ISO 9001 Certified Quality Assurance

Every batch undergoes ISO 9001-compliant validation, including spectral analysis for chemical composition, eddy current testing for defect detection, and dimensional verification (±0.01mm thickness tolerance). Core loss metrics are rigorously tested per IEC 60404-8-5, ensuring optimal magnetic performance and compliance with global efficiency regulations. This end-to-end quality control reduces scrap rates and enhances transformer reliability, directly lowering total lifecycle costs for your operations.

For transformer manufacturers seeking a high-performance, cost-optimized alternative to premium global suppliers, Luoyang Xinzhaohe delivers unmatched value through engineering precision and streamlined manufacturing. Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer core laminations from Luoyang Xinzhaohe.