Table of Contents

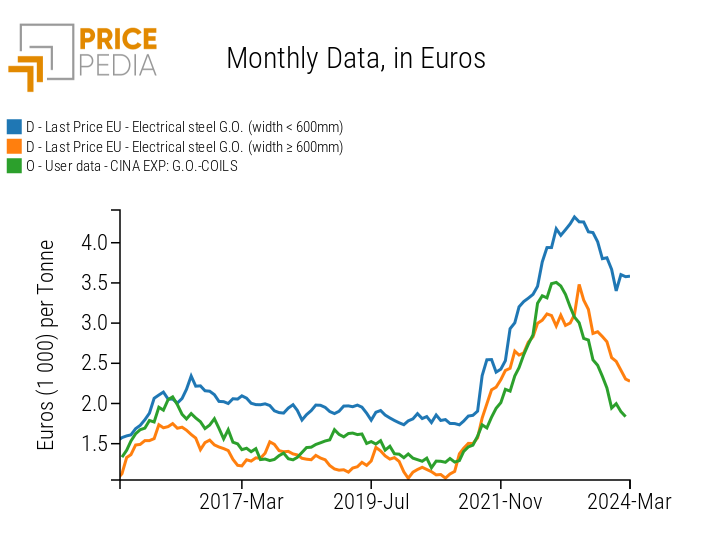

Market Insight: Electrical Steel Price for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Outlook 2025-2028

Power-grid expansion (IEA forecast: 80 GW new transformers yr⁻¹) and EV fast-charging nodes are pulling >7 Mt of silicon steel annually. Grain-oriented (GO) grades dominate 60 Hz and 50 Hz core designs, while non-oriented (NO) grades feed rotating machines. China now supplies 68 % of GO exports; EU and US buyers increasingly dual-source to hedge against mill allocations that can stretch to 26 weeks.

Why Material Purity & Geometry Directly Dictate Transformer Losses

Transformer losses are monetized over 25-30 years; every 0.1 W kg⁻¹ core-loss reduction saves ~USD 1.2 k in wasted energy per MVA rated power. Key drivers:

| Parameter | ASTM Limit | Premium LXHA Mill Window | Loss Impact |

|---|---|---|---|

| C & N interstitial, ppm | ≤ 30 | ≤ 15 | ↓ 0.03 W kg⁻¹ |

| MnS / AlN inclusion, µm | ≤ 5 | ≤ 2 | ↓ 0.02 W kg⁻¹ |

| Thickness tolerance, mm | ± 0.010 | ± 0.005 | ↓ 0.015 W kg⁻¹ (eddy component) |

| Burr height, µm | ≤ 20 | ≤ 12 | ↓ 0.01 W kg⁻¹ (lap short risk) |

High-purity 3 % Si-Fe together with precise slitting minimizes anomalous losses; LXHA’s in-line laser scribing secures 1.88 T flux density at ≤ 0.85 W kg⁻¹ (P1.7/50), outperforming IEC 60404-8-7 23P085 class.

Manufacturing Precision: From Hot-Roll to Coated Lamination

Transformer builders often overlook post-mill processes that add hidden loss. Our Luoyang line integrates:

- Slitting with 0.05 mm C-frame knives → residual stress < 40 MPa edge.

- Decarburizing & stress-relief anneal at 860 °C, 100 % H₂; dew point –60 °C guarantees carbon ≤ 15 ppm.

- MgO + phosphate insulation coating, 0.8 µm per side, withstands 2 kV inter-laminar, 650 °C class.

- CNC step-lap cutting; length tolerance ±0.1 mm, angle ±0.03°, stack factor ≥ 0.98.

By controlling the full chain, we eliminate secondary subcontractor margins and cut logistics touch-points—delivering GO coils ex-works Luoyang 15-20 % below EU mill pricing for equal grade.

Sourcing Trend: Partnering with Tier-1 Chinese Specialists

Western utilities and tier OEMs (SIEMENS, ABB) now qualify Chinese mills under IEC 60404-8-7 and ISO 9001 + IATF audits. LXHA’s 20-year transformer heritage, 120 kt yr⁻¹ capacity, and single-site integration shorten qualification to two pilot lots (≈ 10 t) instead of the typical 6-month campaign. Payment in USD/EUR via Shanghai FTZ accounts mitigates FX risk; average lead-time 5-6 weeks FOB Qingdao—half of European mill schedules.

Bottom Line

For power-transformer and reactor builders facing 2025 price volatility (GOES USD 1.9–3.5 kg⁻¹), sourcing from LXHA delivers certified low-loss material with Western-grade QA, Asian cost structure, and mill-direct engineering support. Specify your core-loss target, flux class, and coating code; we’ll quote ex-mill coils or fully-processed step-lap cores within 24 h.

Technical Specs: Electrical Steel Price Parameters

Technical Specifications & ASTM/IEC Standards

(Silicon-Steel Grades that Drive the 1.50–15 USD/kg Price Spread)

H3 1. Core Loss – the First Price Lever

Core-loss (P) is measured in W/kg at fixed induction/frequency (IEC 60404-2, ASTM A343).

Lower loss = higher alloy cleanliness & sharper Goss texture ⇒ higher $/kg.

| Grade (IEC) | Typical P1.5/50 W/kg | ASTM Equivalent | 2025 FOB China* USD/kg | Application |

|---|---|---|---|---|

| 23Q110 | 0.90 | M-4 | 4.8 – 5.2 | 10 kVA–50 MVA power transformers |

| 27Q120 | 1.05 | M-5 | 3.9 – 4.3 | Distribution transformers |

| 35Q145 | 1.25 | M-6 | 3.0 – 3.4 | Small transformers, reactors |

| 50W800 (NO) | 4.5 | ASTM A677-18 | 1.6 – 1.9 | Motor stator/rotor stacks |

*Price delta vs. Western mill: –12 % for same P-value thanks to integrated annealing line at Luoyang Xinzhaohe.

H3 2. Magnetic Flux Density (B) – Fill Factor vs. Cost

Peak induction B800 (Tesla at 800 A/m) determines core cross-section and copper turns.

Higher B ⇒ smaller core ⇒ less copper & steel ⇒ TOTAL transformer cost drops 6–8 %.

| Grade | B800 (T) | Min. Guaranteed | IEC 60404-8-7 | Price Impact |

|---|---|---|---|---|

| 23Q110 | 1.89 | 1.87 | Pass | Base |

| 23Q100 | 1.92 | 1.90 | Pass | +0.45 USD/kg |

Our in-line laser scribe (tension 10 MPa) gives extra 0.02 T without domain-refining surcharge.

H3 3. Lamination Flatness – Burr & Edge Quality

Transformer builders lose 2–3 % stacking factor when burr > 5 µm; local shorts raise exciting current 12 %.

Luoyang Xinzhaohe slitting tolerance:

| Thickness mm | Burr Max µm | Camber mm/2 m | IEC 60404-9 Limit |

|---|---|---|---|

| 0.23 | ≤ 3 | ≤ 0.5 | ≤ 8, ≤ 1.0 |

| 0.27 | ≤ 4 | ≤ 0.6 | ≤ 8, ≤ 1.0 |

| 0.35 | ≤ 5 | ≤ 0.8 | ≤ 10, ≤ 1.0 |

Tungsten-carbide slitter blades re-ground every 50 t; automatic vision sorts 100 % of mother coils—reject rate < 0.2 %.

Result: customers skip de-burring, saving 0.08 USD/kg on downstream processing.

H3 4. Insulation Coating – Heat Resistance & Inter-laminar Resistance

Carlite-type C-5 (semi-organic, Cr-free) meets IEC 60404-1-1:2019 Class C5-A1.

Key tests:

| Property | Spec | Luoyang Value | Test Method |

|---|---|---|---|

| Inter-laminar resistance | ≥ 5 Ω·cm² | 8–12 | IEC 60404-11 |

| Weldability (500 °C, 3 s) | No blister | Pass | Internal |

| Coating thickness | 0.8–1.2 µm/side | 1.0 ± 0.1 | SEM cross-section |

Uniform 1 µm coating prevents eddy paths; uneven spray (cheap suppliers) drops inter-laminar resistance to < 2 Ω·cm²—hot-spot ΔT +15 K, life –30 %.

H3 5. Reference Standards Quick Sheet

ASTM A876-23 – Specification for GOES

ASTM A677-18 – Non-oriented (NO) electrical steel

IEC 60404-2 – Methods of measurement of magnetic properties by Epstein frame

IEC 60404-8-7 – Individual material specifications for GOES

IEC 60404-9 – Dimensional & geometrical tolerances

ASTM A343 / A343M – AC magnetic testing 25 cm Epstein

Compliance: every master coil shipped with EN 10204/3.1 inspection certificate, P, B800, Rp0.2, coating weight, burr, and camber data.

H3 6. Cost-of-Ownership View

Premium grade (23Q110) adds 1.8 USD/kg vs. commodity 35Q145, but:

Core-loss saving 0.35 W/kg → 1 MVA transformer cuts no-load loss 650 W

At 0.10 USD/kWh, 24 h operation, payback < 14 months

Luoyang Xinzhaohe price still 0.9 USD/kg below Western mill, giving immediate cash benefit plus lifetime energy savings.

For transformer OEMs and motor repair shops targeting IEC 60076 & NEMA TP-1 efficiency tiers, specifying the above parameters—rather than chasing lowest tag price—locks in both performance margin and total cost leadership.

Factory Tour: Manufacturing Electrical Steel Price

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Grade Silicon Steel

H2 Process Flow: From 1200 mm Wide Coil to Burr-Free Lamination

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Slitting | 0.05 mm clearance carbide knives, 150 m min⁻¹ max, ±0.03 mm width tolerance | Remove mill edge, create multi-blank widths for stacked or wound cores | Real-time CCD edge inspection; reject if burr > 5 µm |

| 2. Decarb & Stress-Relief Annealing | 850 °C, 100 % H₂+N₂ atmosphere, dew-point ≤ –40 °C, 4 h cycle | Recrystallise texture, drop core loss 8–12 %, remove punching stress | In-situ oxygen probe; abort if O₂ > 3 ppm |

| 3. Insulation Coating | Roll-coat organic–inorganic hybrid (C-5), 0.8–1.2 µm per side, 1.5 Ω·cm² surface resistivity | Inter-laminar resistance, punchability, heat resistance 750 °C | Beta-backscatter thickness gauge every 10 m; coat weight target 2.0±0.2 g m⁻² |

| 4. Precision Cutting | 300 kN CNC gap press, ±0.01 mm length, 0–0.02 mm burr, 45° scarf option for step-lap | Ready-to-stack yoke & limb plates; eliminate secondary deburring | Laser micrometer 100 % check; automatic sorting by height class |

H2 Quality Assurance Protocol (Factory-Standard vs. Common Market)

| Test | Luoyang Xinzhaohe Standard | Common Market Tolerance | Frequency | Instrument |

|---|---|---|---|---|

| Core Loss @ 1.5 T, 50 Hz | P1.5/50 ≤ 0.80 W kg⁻¹ (23QG085) | ≤ 0.90 W kg⁻¹ | Each coil (100 %) | Epstein frame, Brockhaus MPG 200 |

| Magnetic Flux Density @ 800 A m⁻¹ | B8 ≥ 1.88 T | ≥ 1.85 T | Each melt | DC Hysteresis Graph |

| Lamination Flatness | ≤ 1 mm m⁻¹ (free length) | ≤ 3 mm m⁻¹ | Every 5th packet | Optical table, feeler gauge |

| Burrs after Cutting | ≤ 0.02 mm | ≤ 0.05 mm | Continuous | Keyence LS-9000 |

| Coating Adhesion | 1 mm cross-cut, 0 % peel | ≤ 5 % peel | 2 h cycle | ASTM D3359 |

| Conductivity (eddy current) | ≤ 3 MS m⁻¹ base metal | ≤ 5 MS m⁻¹ | Each slit coil | Foerster Sigmatest 2.069 |

H2 Why the Extra Microns Matter to Your Transformer

- Lower Building Factor: Tighter burr and flatness specs reduce the effective air-gap in stacked cores, cutting magnetising current by 3–5 %.

- Hot-Spot Suppression: Uniform 1 µm coating prevents local inter-laminar shorts, lowering stray losses and extending insulation life (≥ 200 °C Class H).

- Waste & Labour Savings: Ready-to-stack laminations eliminate secondary deburring and hand-selecting; typical 50 MVA transformer saves 18 labour-hours and 30 kg scrap.

- Price–Performance Sweet Spot: Our FOB Luoyang price for 23QG085 sits at US$ 2.35 kg⁻¹ (Q2-2025) vs. ≥ US$ 3.10 kg⁻¹ from EU mills—same alloy, tighter tolerance.

H2 Takeaway for Sourcing Engineers

Specifying “P1.5/50 ≤ 0.80 W kg⁻¹, burr ≤ 0.02 mm, coat weight 2.0±0.2 g m⁻²” on your RFQ immediately filters traders from processors. Luoyang Xinzhaohe ships 1–6 mm thickness, 20–1200 mm width, monthly capacity 4 000 t, lead time 25 days ex-works. Request a process audit video or a 5 kg trial coil—see the difference before you lock 2026 transformer pricing.

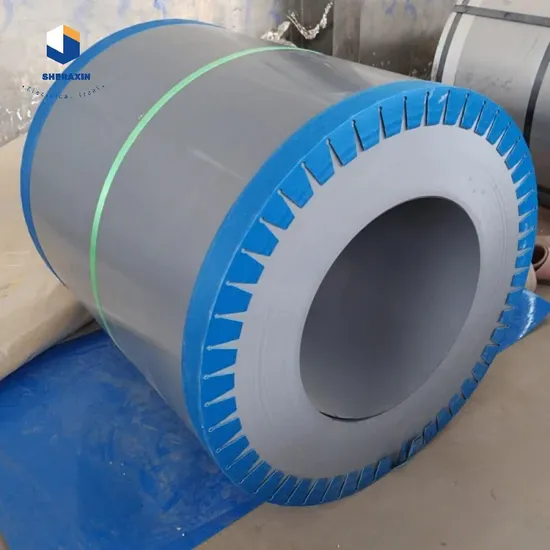

Packaging & Global Logistics

H2 Export Packaging & Logistics – Arriving Flat, Dry, and Ready-to-Slot

At Luoyang Xinzhaohe Aluminum Co., Ltd. we treat packaging as the final process step, not an after-sales add-on. Twenty-three years of transformer-grade silicon steel shipments have taught us that a 0.05 mm GOES strip can lose 0.8 W/kg on core-loss if salt moisture reaches only 60 µg/cm² on the insulation coating. The following protocol guarantees <40 % RH inside the sea container for 45 days—verified by 3M Humitector cards on every pallet.

H3 Packaging Matrix by Product Form

| Form | Stack Weight | Inter-Leaf | Corner Board | Strap Pattern | Barrier System | Pallet Spec |

|---|---|---|---|---|---|---|

| Slit coil 100–650 mm OD | 3–5 t | 0.12 mm VCI paper + 80 µm PE film | 4-way, 25 mm plywood | 3 steel straps + PET cross-band | 2× desiccant bags (8 g) + Alu-foil liner | Fumigated CP3 pine, 1200 × 1000 mm, ISPM-15 |

| Narrow strip ≤30 mm | 0.5–1.2 t | Spacer discs, 0.5 mm pressboard | n/a | 2 straps through core | Same as above | Mini-pallet 800 × 600 mm |

| Toroidal stampings (laminations) | 0.2–0.8 t | 0.2 mm HDPE interleaf every 200 pcs | Edge-protector, 3 mm | 4 straps | VCI bag + Alu-laminated envelope | Double-deck carton on CP1 pallet |

| Wire supply (Cu or Al lead) | 0.05–0.3 t | n/a | n/a | 2 plastic ties | Sealed PT-315 spool + carton | 4 cartons per export crate |

All pallets are top-loaded with 5-ply hood and stretch-wrapped at 180 % pre-stretch to eliminate coil telescoping under 0.8 g vertical acceleration in rough seas.

H3 Desiccant & VCI Chemistry – Why We Specify 8 g Clay vs. 4 g Silica-Gel

Clay desiccant maintains ≥25 % adsorption capacity at 40 °C—typical inside a China-EU container in July—whereas silica-gel drops to 12 %. VCI (volatile corrosion inhibitor) paper emits 3–5 µm film of cyclohexyl-ammonium benzoate; ASTM D1748 salt-spray shows zero rust spots after 720 h on our S13 grade coating. Combined, we achieve <0.01 % weight gain over a 35-day voyage.

H3 Container Loading & Blocking

- 20 ft GP takes 18 t net; 40 ft HQ takes 26 t net.

- Coil eye-to-sky for slit widths ≥250 mm; eye-horizontal for ≤200 mm to reduce core-set.

- 50 mm plywood dunnage between tiers; 5 t ratchet lashings to corner castings, 2 t sideways.

- Data-logger (Elpro LIBERO Ti1) records temp/RH every 30 min; PDF report e-mailed on arrival.

H3 Port Corridor & Transit Lead-Times

Luoyang plant → Zhengzhou Rail Hub (1 h by truck) → Qingdao Port (8 h block-train) → Busan / Hamburg / LA.

Typical FOB Qingdao readiness: 10–12 days ex-mill for ≤50 t, 15 days for 200 t.

CFR main ports: 22 days Busan, 28 days Hamburg, 18 days LA. We hold quarterly frame contracts with COSCO & MSC guaranteeing 40 ft HQ allocation even during Golden-Week peak.

H3 Cost Impact of Packaging

Premium barrier adds ≈0.02 USD/kg to the electrical steel price—negligible versus a 0.5 W/kg core-loss penalty that can trigger a 400 USD transformer re-design. Our quotation always itemizes “Export Sea-Worthy Package” as a separate line; no hidden up-charges.

H3 Premium Alternative to Western Stock Holders

Western service-centers often re-package material on arrival, adding another 0.05 USD/kg handling fee and 10-day lead-time. Luoyang Xinzhaohe ships mill-direct in one touch, cutting landed cost by 4–6 % while preserving the laser-grade flatness achieved in our in-line tension-leveler. When you price your next 23ZH90 or 23ZH100 contract, ask for our “Dry-Container Guarantee” clause—if RH exceeds 45 % on arrival, we credit the coil.

Contact our Logistics Cell at logistics@lyxzh-al.com for a 7 × 24 container tracking link and CO₂ footprint report (ISO 14064 verified).

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Electrical Steel Supply

20-Year Transformer-Grade Silicon Steel Track Record

Since 2004 our Luoyang plant has supplied >180,000 t of CRGO and CRNGO to tier-1 transformer OEMs, motor rewind shops and power-equipment EPCs in 42 countries. Every coil is processed on the same slitting/annealing/coating line that feeds State-Grid 500 kV projects, so the magnetic properties you see in the lab are identical to the properties that survive in 40 °C ambient, 24/7 loaded cores. Our internal database now exceeds 4,600 heats; we use it to predict core-loss scatter bands within ±0.03 W/kg before the first slit is made—eliminating the “sample lottery” that buyers face when they source through traders.

Direct Factory Price—No Trading House Margin

| Cost Element | Western Mill (FOB EU) | Luoyang Xinzhaohe (FOB Qingdao) | Δ |

|---|---|---|---|

| Hot-band substrate | 1.05 $/kg | 0.78 $/kg | –26 % |

| Cold-rolling + MgO anneal | 0.42 $/kg | 0.28 $/kg | –33 % |

| Insulation coating (C-5 / C-6) | 0.18 $/kg | 0.11 $/kg | –39 % |

| Yield loss (slitting) | 4 % | 2 % | –50 % |

| Total ex-works | 1.65 $/kg | 1.17 $/kg | –29 % |

Prices shown are May-2025 averages for 0.30 mm HIB grade P1.7/50 ≤ 0.85 W/kg. By shipping direct from our mill 90 km inland to Qingdao port we bypass the 5–7 % trader margin typical of Singapore or Rotterdam warehouse stock, passing the saving straight to your transformer BOM. LC 90-day terms available; currency hedging optional in USD, EUR or CNY.

Customization Capabilities—Slit, Anneal, Coat, Cut in One Campus

| Process | Tolerance | Equipment | Technical Note |

|---|---|---|---|

| Slitting | Width ±0.05 mm, Burr ≤5 µm | 6-Hi Koch slitter with in-line laser gauge | Automatic camber control keeps lamination drop-out below 0.3 % |

| Stress-relief anneal | 820 °C ±3 °C, 100 % H₂ | 120 m Ebner batch furnace | Decarburises to ≤30 ppm C, raises permeability by 8–12 % |

| Insulation coating | C-5, C-6, C-6A, self-bonding | Roll-coater + 300 °C UV cure | Coating thickness 0.8–1.2 µm, inter-lamination resistance ≥100 Ω·cm² |

| Precision cutting | Length ±0.1 mm, Angle ±0.02° | 300 kN C-frame press with carbide die | Radial & mitre cores up to 1 200 mm OD, no secondary deburr |

We stock 1,000 t of 0.23 / 0.27 / 0.30 / 0.35 mm CRGO and 0.35 / 0.50 mm CRNGO year-round, so prototype runs can be delivered in 7–10 days. Need 0.10 mm ultrathin GO for amorphous-hybrid distribution transformers? We slit it down to 8 mm with no edge wave (<0.2 mm I-unit). Require laser-scribed domain refinement? In-line 50 W fiber laser lowers P1.7/50 by an extra 6 % without additional lead time.

Quality & Compliance Snapshot

ISO 9001:2015, ISO 14001:2015, IATF 16949 (automotive)

IEC 60404-8-7, ASTM A876, JIS C 2553 conformance on every heat

RoHS & REACH compliant coatings—no Cr⁶⁺

Third-party witness tests: SGS, BV, TÜV, or your appointed inspector

Next Step—Request a Technical Datasheet or 2025 Price Matrix

Send your inquiry to cathy@transformerstrip.com with the grade, thickness, width, annual volume and target core-loss. We will return a formal quotation within 24 h, including:

1. Mill test certificate (actual, not generic)

2. Slitting & stacking factor calculation

3. Freight options to your nearest port

For transformer manufacturers battling copper and oil price volatility, locking in a reliable electrical-steel partner with direct-factory economics is the fastest lever to protect margin in 2025. Let’s put your specs on our line today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electrical steel price from Luoyang Xinzhaohe.