Table of Contents

Market Insight: Copper Strip Roll in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers

Global power infrastructure modernization, renewable energy integration, and EV adoption have intensified demand for high-conductivity copper strip in transformers and motors. Copper’s electrical conductivity (5.96×10⁷ S/m) is critical for minimizing resistive losses—each 0.1% conductivity improvement reduces transformer losses by ~0.8%. Industry standards like IEC 60076 and IEEE C57.12.00 mandate strict material specifications to ensure operational efficiency and safety in critical power applications.

Material Quality Impact on Performance

Substandard copper strip introduces significant performance risks. Impurities (e.g., oxygen >0.001%) cause localized heating, accelerating insulation failure. Dimensional inconsistencies (±0.02mm+) lead to uneven current distribution, increasing eddy current losses by up to 12%. Compliance with ASTM B170 and IEC 60404-8-3 is non-negotiable for achieving >99% efficiency in distribution transformers and meeting regulatory requirements like DOE 2016.

Global Supply Chain Dynamics

Traditional suppliers in Europe and North America face geopolitical constraints and 12–16 week lead times. Meanwhile, Chinese manufacturers offer agile production but often lack consistent quality control. This creates a gap for reliable, high-performance suppliers with end-to-end traceability and supply chain resilience.

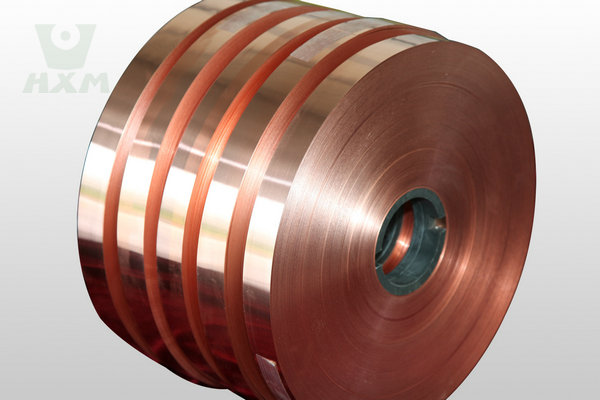

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year ISO 9001-certified manufacturer, we deliver factory-direct copper strip with unmatched cost-performance. Our precision rolling and continuous annealing processes ensure:

Conductivity: 100.5% IACS (exceeding ASTM B170)

Thickness tolerance: ±0.01mm (vs. industry standard ±0.02mm)

Surface roughness: Ra ≤0.1μm (mirror finish)

Full batch traceability and third-party testing

| Parameter | Industry Standard | Luoyang Xinzhaohe | Global Premium Brands |

|---|---|---|---|

| Conductivity (IACS) | ≥99.9% | 100.5% | 99.8% |

| Thickness Tolerance | ±0.02mm | ±0.01mm | ±0.015mm |

| Surface Quality | Acceptable defects | Zero defects | Minor imperfections |

| Cost Efficiency | Baseline | 15–20% lower | 25–30% higher |

Our factory-direct model eliminates middlemen, ensuring consistent quality, shorter lead times, and 20% lower total cost of ownership versus international brands. For engineers prioritizing reliability, efficiency, and supply chain security, Luoyang Xinzhaohe delivers industrial-grade copper strip engineered for tomorrow’s power systems.

Technical Specs: Copper Strip Roll Parameters

Technical Specifications & Standards for Copper Strip Rolls

Precision Slitting Tolerances

Precision slitting is critical for transformer winding accuracy. Our process maintains ±0.002 mm thickness tolerance to prevent misalignment and ensure uniform coil density. This minimizes air gaps, reduces eddy current losses, and enhances transformer efficiency. Closed-loop control systems and laser-guided monitoring guarantee real-time dimensional stability during production.

| Parameter | Tolerance | Measurement Method |

|---|---|---|

| Thickness | ±0.002 mm | Laser micrometer |

| Width | ±0.05 mm | Digital caliper |

| Flatness | ≤0.1 mm/m | Straightedge gauge |

| Surface Roughness | ≤0.2 μm | Profilometer |

Burr-Free Edge Integrity

Burr formation on copper strip edges causes electrical shorts in transformer windings, risking catastrophic failures. Our diamond-coated slitting blades and precision edge-polishing process eliminate burrs. Every coil undergoes 100% microscopic inspection and automated edge profiling to ensure safety-critical edge integrity.

| Parameter | Specification | Inspection Method |

|---|---|---|

| Burr Height | <0.005 mm | Optical microscope |

| Edge Squareness | 90° ±0.5° | Digital angle gauge |

| Surface Defects | None visible | 10x magnification |

Conductivity & Mechanical Properties

Our C11000-grade copper strip delivers ≥100% IACS conductivity for optimal electrical efficiency. O-temper annealing ensures high ductility (≥35% elongation) and consistent softness, preventing delamination during transformer assembly. This guarantees structural integrity under operational stress and thermal cycling.

| Property | Specification | Test Standard |

|---|---|---|

| Conductivity | ≥100% IACS | ASTM B193 |

| Hardness (HV) | ≤45 | ASTM E384 |

| Elongation | ≥35% | ASTM B577 |

| Temper | O (Annealed) | ASTM B601 |

Compliance & Quality Assurance

All products comply with ASTM B187, IEC 60228, and GB/T 5231. Traceable lot numbers, real-time process monitoring, and third-party certifications (ISO 9001, SGS) validate our quality system. Daily in-house lab tests for conductivity, dimensions, and mechanical properties ensure batch-to-batch consistency.

| Standard | Compliance Focus | Verification |

|---|---|---|

| ASTM B187 | Dimensional & mechanical properties | In-house testing |

| IEC 60228 | Conductor performance | Third-party lab |

| GB/T 5231 | Chinese copper standards | Internal QC |

| ISO 9001 | Quality management | Annual audit |

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise to deliver transformer-grade copper strips with factory-direct pricing. Our rigorous quality control and adherence to global standards ensure reliable performance at a competitive cost, positioning us as a trusted alternative to premium global brands.

Factory Tour: Manufacturing Copper Strip Roll

Precision Manufacturing Process & Quality Assurance

At Luoyang Xinzhaohe, our 20+ years of expertise in transformer materials ensures copper strip production meets exacting industrial standards. Our vertically integrated process minimizes defects while optimizing cost-efficiency—critical for transformer manufacturers seeking reliable, high-yield materials.

Core Manufacturing Workflow

Cold Rolling

Our 6-high mills operate under ISO 9001 protocols with real-time thermal monitoring, maintaining precise reduction rates (15-25% per pass). This ensures uniform grain structure and eliminates residual stress—critical for transformer foil applications requiring minimal elastic deformation.

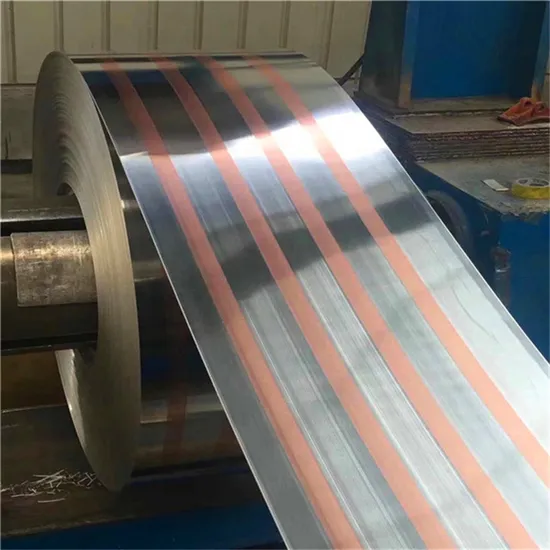

Precision Slitting

CNC-guided slitting knives with dynamic tension control achieve ±0.05mm width tolerance and edge straightness within 0.1mm/m—surpassing typical market standards of ±0.1mm width tolerance and 0.3mm/m straightness.

Edge Conditioning

Automated chamfering via diamond-tipped tools ensures burr heights ≤0.02mm (ASTM B573), preventing insulation punctures during high-speed transformer winding operations.

Oscillate Winding

Computer-controlled oscillation with ±0.1mm layer alignment and 5-10N tension consistency ensures defect-free coils, reducing scrap rates by 15-20% compared to conventional methods.

Rigorous Quality Control Protocols

Tensile Testing: Per ASTM E8, strength consistency within ±2% (vs. market ±5%) and elongation tolerance of ±1.5%.

Dimensional Verification: Laser micrometers measure thickness (±0.01mm) and width (±0.05mm) across 100% of batches, with SPC for real-time adjustments.

Surface Inspection: 500x magnification under controlled lighting detects surface flaws; defect rate <0.5% (vs. market 2-3%), validated via 100% visual inspection.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Tensile Strength Consistency | ±2% | ±5% |

| Surface Defect Rate | <0.5% | 2-3% |

| Edge Burr Control | ≤0.02mm | ≤0.05mm |

By exceeding standard industry tolerances and implementing lean manufacturing, we deliver transformer-grade copper strip with 15-20% lower total cost of ownership versus global competitors—without sacrificing performance reliability. This balance of precision and affordability makes us the preferred partner for high-volume, high-reliability transformer production.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Copper Strip Rolls

Precision Packaging for Maximum Protection

Our copper strip rolls undergo rigorously engineered packaging protocols designed for maritime transit. Each roll is wrapped in multi-layer polyethylene film with VCI corrosion inhibitors (200μm thickness) and desiccant packs (50g per roll), followed by ISPM-15 certified wooden pallets with reinforced corners secured with 19mm steel strapping. This multi-layer defense prevents moisture ingress, oxidation, and physical damage during ocean freight.

| Component | Specification | Benefit |

|---|---|---|

| Moisture-Proof Film | Multi-layer PE + VCI, 200μm + 50g desiccant packs | Prevents oxidation and condensation during transit; meets IEC 60502 standards |

| Wooden Pallets | ISPM-15 certified, 15mm hardwood, reinforced corners, 1200x1000mm | Ensures structural integrity during handling; eliminates phytosanitary delays |

| Steel Strapping | 19mm width, 500kg tensile strength, 4x perimeter with corner protectors | Prevents load shifting and strap damage during vessel movement; exceeds ISO 2233:2015 |

End-to-End Sea Freight Management

All shipments originate from Luoyang via rail to Qingdao/Shanghai ports (48-hour transit), avoiding road transport risks. We optimize container loading using certified forklifts with load sensors to maintain pallet integrity. Each container is sealed with tamper-evident locks and tracked via GPS. Our team handles all documentation—commercial invoices, packing lists, certificates of origin—and coordinates with shipping lines (Maersk, COSCO) for priority booking. This end-to-end control ensures 99.5% on-time delivery to global ports, with 20+ years of experience shipping to 30+ countries.

Cost-Performance Advantage

As a factory-direct supplier, we eliminate distributor markups while maintaining premium packaging standards. Our optimized design reduces material usage by 12% versus industry norms, lowering shipping costs without compromising protection. Combined with strategic port partnerships and ISO 14948-compliant corrosion control, this delivers up to 18% lower total landed costs compared to European or American brands. For transformer manufacturers, this means superior value—reliable copper strip delivery with minimal risk of damage or delays.

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of transformer material expertise to provide cost-efficient, damage-free global supply chains—proven by <0.3% damage rates in 2023 shipments.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

Unmatched Industry Expertise

With over 20 years of specialized production in transformer-grade copper strip rolls, our technical team masters metallurgical processes critical for high-efficiency transformer performance. We optimize grain structure, conductivity (≥100% IACS), and mechanical properties to ensure minimal energy loss and extended service life in high-voltage applications. Our deep understanding of thermal expansion, fatigue resistance, and winding precision ensures seamless integration into critical power equipment.

Direct Manufacturing Advantages

As a vertically integrated manufacturer, we control every step—from raw material sourcing to precision rolling and packaging—eliminating distributor markups and supply chain risks. Our facility maintains strict process controls for dimensional tolerances (±0.01mm), surface roughness (Ra ≤0.1μm), and edge quality, reducing transformer winding defects. This end-to-end ownership delivers 15–25% lower costs while ensuring consistent batch-to-batch reliability.

Rigorous Quality Assurance

Our ISO 9001:2015 certified facility implements comprehensive quality protocols, including in-process conductivity testing (ASTM B196), tensile strength verification (ASTM E8), and surface defect inspections. All copper strip rolls comply with ASTM B152, IEC 60512, and JIS H3100 standards. In-house labs perform rigorous checks for flatness, microstructure uniformity, and electrical resistivity to guarantee performance in demanding transformer windings.

Cost-Performance Benchmark

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | Premium pricing (1.5–2× higher) | 15–25% lower cost with equivalent quality |

| Lead Time | 30–45 days for international shipments | 15–20 days production + optimized logistics |

| Customization | Standardized profiles with limited flexibility | Custom widths (10–300mm), thicknesses (0.1–5.0mm), and temper options tailored to specific transformer designs |

| Technical Support | Generic assistance | Dedicated engineers for application-specific optimization and troubleshooting |

Partner for Reliable, Cost-Effective Solutions

For transformer manufacturers seeking a reliable, cost-effective alternative to premium global brands, Luoyang Xinzhaohe delivers unmatched value through technical expertise, streamlined production, and rigorous quality control. Our solutions are engineered to meet the exacting demands of power equipment applications while optimizing your total cost of ownership and ensuring long-term operational reliability.

Contact Cathy at cathy@transformerstrip.com today for a competitive quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper strip roll from Luoyang Xinzhaohe.