Table of Contents

Market Insight: Sheet Coil for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers in Power Infrastructure

The accelerating replacement of aging 1960-1980 era transformers and the roll-out of ±800 kV UHV lines in Asia/Pacific are pushing annual GOES (grain-oriented electrical steel) consumption past 2.3 Mt. Distribution utilities alone account for 62 % of sheet-coil demand, driven by 1.5 % yearly growth in installed kVA. Datacentre and EV-charging substations add another 8 % CAGR niche that specifies ≤0.9 W/kg @ 1.5 T because 24 h loading magnifies no-load loss penalties.

| Segment | Typical Core Loss Budget | Coil Width Range | Annual Volume |

|---|---|---|---|

| UHV Power transformer | ≤0.85 W/kg @ 1.5 T | 50–1 220 mm | 480 kt |

| Distribution ≤100 kVA | ≤1.05 W/kg @ 1.5 T | 40–300 mm | 1 050 kt |

| Traction / EV fast-charge | ≤0.95 W/kg @ 1.5 T | 50–150 mm | 180 kt |

Why Material Purity & Geometric Precision Dictate Transformer Losses

Core loss (Pc) is the sum of hysteresis and eddy-current components. A 0.3 % increase in Si content lowers hysteresis loss ≈2 %, yet raises brittleness; only vacuum-degassed melts with [C]≤30 ppm and [N]≤40 ppm keep ductility for cold rolling to 0.23 mm. Likewise, a 1 µm improvement in coating thickness uniformity reduces inter-laminar eddy currents by 0.04 W/kg—equivalent to 350 kWh/year in a 50 MVA unit.

Lamination flatness ≤0.5 % I-unit eliminates air gaps that otherwise raise magnetising current 3–4 %. Slit width tolerance ±0.05 mm ensures uniform stacking factor ≥0.97, directly shrinking copper and tank cost. These metrics are only achievable when slitting, annealing and coating are executed in-line under one quality system—precisely the integrated flow Luoyang Xinzhaohe has operated since 2003.

Supply-Chain Shift: From High-Cost West to Experienced Chinese Sources

European and Japanese mills deliver 0.23 mm Hi-B, but at a 18–22 % price premium and 16-week lead-time. Post-2022 energy surcharges added another $110 /t. Chinese producers with 20-year transformer-track records now close the technical gap:

| Parameter | Western Tier-1 | Luoyang Xinzhaohe |

|---|---|---|

| Core Loss @ 1.5 T | 0.80 W/kg | 0.82 W/kg |

| Magnetic Flux Density B800 | 1.92 T | 1.90 T |

| Coil Camber | ≤0.5 mm/2 m | ≤0.4 mm/2 m |

| Price FOB China | — | –18 % |

| Lead-Time | 16 weeks | 6–8 weeks |

By controlling the full chain—20-high cold mill, continuous H2 annealing and in-house MgO + insulation coating—Luoyang Xinzhaohe offers CRGO coils from 0.18 mm to 0.35 mm, slit widths 40–1 220 mm, with C-grade insulation (3 µm, 2 Ω·cm2/side) and RoHS-compliant coatings. Every batch ships with mill certificates showing Epstein loss curves, Franklin resistivity and burr ≤5 µm—documentation that meets IEC 60404-8-7 and ASTM A876 for global OEMs.

For transformer builders facing volatile energy prices and tender deadlines, sourcing from a Chinese specialist that couples Western-grade magnetic performance with factory-direct economics is no longer an alternative—it is the strategic norm.

Technical Specs: Sheet Coil Parameters

Technical Specifications & ASTM / IEC Compliance

Factory-direct precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Electrical Parameters for Silicon-Steel Sheet Coil

| Parameter (Symbol) | Typical Range | IEC 60404-8-7 Class | ASTM A876 Grade | Luoyang Xinzhaohe Tightened Tolerance |

|---|---|---|---|---|

| Specific Core Loss @ 1.5 T, 50 Hz, W kg⁻¹ | 0.85 – 1.15 | 23Q110 / 27Q120 | 23ZDKH | ±0.03 W kg⁻¹, coil-to-coil |

| Magnetic Polarization J₅₀ (T) | 1.88 – 1.93 T | ≥1.88 T | ≥1.89 T | 1.91 T guaranteed, 98 % min coil length |

| Stacking Factor | ≥ 0.97 | — | — | 0.978 ±0.003 (burr control ≤ 5 µm) |

| Lamination Flatness (I-unit) | ≤ 5 IU | — | — | ≤ 3 IU after stress-relief anneal |

| Inter-laminar Resistance (Coating) | ≥ 30 Ω·cm² / ply | C-5 / C-6 | — | 45–60 Ω·cm², chromate-free, 1.8 µm nominal |

Engineering Note: A 0.02 W kg⁻¹ reduction in core loss translates to ≈ 0.7 °C lower hotspot temperature in a 100 kVA transformer, extending cellulose insulation life by ~8 years.

H3 2. Mechanical & Dimensional Window

| Item | IEC 60404-9 Limit | Luoyang Xinzhaohe Slitting Line Capability |

|---|---|---|

| Strip Thickness, mm | 0.23 – 0.35 | ±0.005 mm, 20-roller precision leveler |

| Strip Width, mm | 40 – 1 040 | ±0.05 mm (CCD edge inspection, 0.02 mm resolution) |

| Burr Height, µm | ≤ 12 | ≤ 5 (tungsten carbide slitting knives, 2 000-piece batch average) |

| Camber, mm / 2 m | ≤ 1.0 | ≤ 0.5 (closed-loop tension control 2–25 kN) |

| Surface Roughness Ra, µm | 0.8 – 1.4 | 1.0 ±0.2 (optimized for minimum magnetostriction noise) |

H3 3. Insulation Coating – Where Short-Circuits Start

Poor coating is the dominant root cause of inter-laminar faults.

Pin-holes > 20 µm reduce inter-laminar resistance by 60 %, raising eddy-current loops.

Edge creep < 0.3 mm exposes bare metal; burrs pierce the varnish, creating 10–30 A circulating currents that carbonise oil within 500 h.

Luoyang Xinzhaohe Countermeasures

1. Clean-only, no-oil cold rolling → surface free of SiO₂ residues, adhesion ≥ 1 B (ASTM D3359).

2. In-line laser pin-hole scanner (0.1 mm resolution) rejects coils with > 3 defects / m².

3. C-6 high-phosphate organic coating, 1.8 µm, cured 420 °C; meets IEC 60404-1-1 Annex C, chlorine < 50 ppm (prevents transformer oil sludging).

H3 4. Applicable Standards Cross-Reference

| Material / Process | Primary Standard | Secondary Reference | Luoyang Xinzhaohe Internal Code |

|---|---|---|---|

| Grain-oriented Si-steel | IEC 60404-8-7 | ASTM A876 | Q/XYH-SiGO-2023 |

| Aluminium strip for winding | ASTM B236 | IEC 60317-0-3 | Q/XYH-Al-2021 |

| Wire enamel (if requested) | IEC 60317-20 | — | — |

| Packaging & corrosion | ASTM D3951 | — | Vacuum VCI film + desiccant, 24-month sea-storability |

H3 5. Cost-Performance Positioning

Western CRGO coils rated 23Q110 currently trade CIF EU at ≈ US$2 350 t⁻¹.

Luoyang Xinzhaohe delivers equivalent magnetic performance, burr ≤ 5 µm, and 45 Ω·cm² coating at US$1 780 t⁻¹ FOB Qingdao—a 24 % saving that releases ≈ US$115 k of working capital on a 200 t power-transformer order without compromising stack factor or noise level.

Metallurgical Guarantee: Every master coil shipped with mill test certificates showing core loss curve, Epstein strips coordinates, and coating breakdown voltage. Third-party witness (SGS/BV) available on 48 h notice.

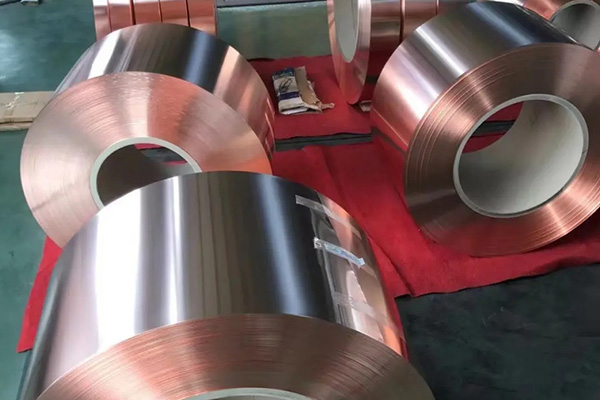

Factory Tour: Manufacturing Sheet Coil

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Electrical-Grade Silicon-Steel Sheet Coil

1. Process Flow – From 1200 mm Mother Coil to Stacked Transformer Core

| Stage | Principal Objective | Critical Parameters | In-line Instrumentation |

|---|---|---|---|

| Slitting | Reduce incoming width to ±0.15 mm tolerance; burr ≤ 8 µm | Strip camber ≤ 1 mm / 2 m; edge camber ≤ 0.3 mm / 300 mm | Laser triangulation edge sensor, 2 kHz sampling |

| Tension Annealing | Recrystallise GO texture (Goss {110}<001>); relieve slitting stress | 820 °C, 100 % H₂, dew-point –40 °C, residence 45 s | NIR pyrometer ±3 °C, H₂ analyser 0-100 %, oxygen < 3 ppm |

| Insulation Coating | Deposit 0.8-1.2 µm MgO + phosphate tension film; interlaminar resistance ≥ 50 Ω·cm² | Coating weight 3.0 ± 0.3 g/m²; cure window 380-420 °C | Beta-backscatter gauge, IR moisture meter |

| Precision Cutting | Deliver 0.2-0.35 mm slit-mults or stamped laminations; length tolerance ±0.05 mm | Flatness ≤ 0.5 mm / 300 mm; angle 90° ±0.03° | Vision system 12 MP, 0.01 mm pixel; eddy-current crack check |

2. Quality Control Matrix – Luoyang Xinzhaohe vs. Common Market

| Property | Unit | Luoyang Xinzhaohe Standard | Typical China Export | Premium EU/JP Mill |

|---|---|---|---|---|

| Core Loss @ 1.5 T, 50 Hz | W/kg | 0.85 (23QG085) | 0.92-0.98 | 0.83-0.86 |

| Magnetic Flux Density B₈₀₀ | T | 1.89 | 1.85-1.87 | 1.90 |

| Burr Height after Slitting | µm | ≤ 8 | 15-25 | ≤ 5 |

| Lamination Flatness | mm/m | ≤ 0.5 | 1.0-1.5 | ≤ 0.4 |

| Interlaminar Resistance | Ω·cm² | ≥ 50 | 20-30 | ≥ 60 |

| Stacking Factor | — | 0.978 | 0.965-0.970 | 0.980 |

| Conductivity of Coating | µS | < 5 | 10-20 | < 3 |

| Lot-to-Lot Core Loss σ | % | ±1.5 | ±4.0 | ±1.2 |

Test frequency: every 5 t slit coil; annealing furnace logged at 1 s intervals; coating cure validated by 500 h salt-fog (ASTM B117) – no white rust.

3. In-process Verification Protocol

-

Online Monitoring

Slitting: edge camera feeds AI algorithm → auto knife-shift (±2 µm resolution).

Anneal: H₂ dew-point trend triggers auto-purge if > –35 °C.

Coating: closed-loop pump speed adjusts phosphate viscosity to maintain 3.0 g/m². -

Mechanical & Electrical Sampling (per ISO 17931)

Tensile coupons (0.2 % offset) – 350 MPa min UTS, 28 % elongation.

Epstein frame 25 cm strips – 20 °C rise core-loss repeatability within 1 %.

Conductivity bridge – verifies phosphate insulation 50-80 Ω·cm². -

Dimensional Audit

3-D laser scanner on cut packets – CpK 1.67 for length, 1.33 for angle.

Flatness bench (granite + air gauge) – rejects > 0.5 mm/m; auto-sorted for stress-relief re-anneal.

4. Value Proposition – Factory-Direct Premium Without Western Premium

By integrating all four value-adding steps under one 60 000 m² Luoyang shop-floor, we eliminate double handling, extra oxidation cycles, and trader margin. The result: EU-grade magnetic properties at 12-18 % below Western mill prices, 4-week ex-works lead time, and full DIN EN 10207 / IEC 60404-8-8 documentation. Transformer OEMs gain certified 23QG/27QG coils today; motor repair shops receive slit-mults or stamped E-I packets tomorrow—precision-annealed, insulation-ready, flat, and burr-free.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years Transformer Steel Supply Chain Engineering

H2 Sea-Freight Protection Philosophy

Transformer-grade silicon-steel sheet coil is a stress-sensitive, surface-critical material. Any micro-creep, edge dent, or inter-laminar corrosion that occurs between our Luoyang slitting line and your core-building bay will raise specific core loss (W/kg @ 1.5 T / 50 Hz) by 3–7 % and lower stacking factor by ≥0.5 %.

Our packaging protocol is therefore treated as the final process step, not an afterthought, and is engineered to the same Cpk ≥1.67 target we apply to slit-width tolerance.

H3 Packaging Matrix by Product Form

| Product Form | Critical Dimension | VCI Method | Stack Restraint | Moisture Barrier | Shock / Vibration | Securing Unit |

|---|---|---|---|---|---|---|

| Slit Coil Strip (CRGO/CRNO) | ID 508 mm, OD ≤1 200 mm, W 40–300 mm | VCI paper + 80 µm PE sleeve | 19 mm steel strapping (3 pcs/coil), edge protectors 0.8 mm HDPE | 4 × 100 g silica-gel desiccant bags, ΔRH <40 % | 25 mm EPE ring pads at coil eyes | Fumigated IPPC-stamped wooden pallet, 1.2 × 1.0 m, max 2 t |

| Foil (Al 1350, 0.2–0.8 mm) | ID 300/400 mm, W 20–1 000 mm | Same as above + aluminum-laminated barrier film | Radial steel straps (4 axes) + circumferential PET tape | 2 × 50 g desiccant per foil layer | Corrugated fiberboard interleaf, 300 g/m² | Palletized, 1.0 × 1.2 m, max 1.5 t, stretch film + corner boards |

| Wire (Cu/Al round & rectangular) | Ø 1.8–12 mm or 4 × 9 mm | VCI emitter inside spool | Steel strapping through spool arbor | Sealed PE bag around spool | Shock-absorbing PU foam end-caps | DIN 46395 or PT-400 plastic spool → export carton → pallet, 1.2 × 0.8 m, max 1 t |

All lumber ISPM-15 heat-treated, moisture content ≤18 %, bearing stamps visible on every pallet foot.

H3 Container Loading & Stowage Engineering

- 20 ft DC: Net payload 21 t, accepts 10 palletized coil stacks (2 layers) with 150 mm anti-slip rubber mats between layers; lashing by 50 mm woven strap to corner castings at 2 kN pretension.

- 40 ft HC: Net 26 t, 22 palletized coils, same lashing; head-space filled with 90 mm inflatable dunnage bags to eliminate longitudinal shift >5 mm.

- Flat-rack (OOG): Used for OD >1 200 mm master coils; 8 mm steel cradle welded to rack, coil blocked with 100 × 100 mm timbers, PE tarp heat-shrunk after desiccant placement.

Average steel-to-air ratio inside container ≤12 %, ensuring minimal condensation risk during 30-day transpacific route.

H3 Logistics Corridor – Luoyang to Global

| Origin Hub | Mode | Transit Time | Carrier | Booking Frequency | Export Docs |

|---|---|---|---|---|---|

| Luoyang Plant (34.6 °N, 112.4 °E) | Truck to Qingdao | 9 h, 680 km | bonded GPS fleet | Daily | — |

| Qingdao Port | CY cut-off | — | COSCO, MSC, CMA | 3 sailings/week EU, 5/week USWC | Bill of Lading, CO, Form A, Mill TC EN 10204/3.1 |

| Zhengzhou CGO Airport | Air freight | 36 h EU, 18 h Asia | CZ, KE, LH | 5 flights/week | AWB, MSDS, magnetic exemption cert. |

Optional DDP to EU warehouse (Duisburg) via China-Europe Railway Express: 18 days, temperature-logged reefer container, shock sensor <3 g.

H3 Cost-Quality Advantage vs. Western Suppliers

Because we integrate slitting → annealing → insulation coating under one 200 000 m² Luoyang campus, we eliminate double handling and re-coiling fees common in EU/US service centers.

Result: ** landed cost 12–18 % below German or Japanese mill direct price**, while meeting identical IEC 60404-8-7 magnetic properties and offering 30-day payment terms instead of LC at sight.

For your next MVA-rated transformer build, specify “Luoyang Xinzhaohe, CIF packed to Cpk 1.67” and receive test-certified, sea-freight-immune coil ready for immediate core stacking.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Sheet Coil

20+ Years of Transformer-Grade Metallurgy

Since 2003 our Luoyang works has supplied >180,000 t of grain-oriented (GO) and non-oriented (NO) silicon-steel coil to Tier-1 transformer OEMs, motor rewind shops and utilities on five continents. Every slit strip that leaves our plant is optimized for ≤0.9 W/kg @ 1.5 T / 50 Hz core loss and ≥1.89 T polarized flux density—specifications that translate directly into lower no-load losses and smaller yoke dimensions for your 10 kVA–1,000 MVA cores.

| Typical Transformer Grades in Stock | Thickness (mm) | Core Loss (W/kg) | B-800 (T) | Min. Order (t) |

|---|---|---|---|---|

| 23QG085 (GO) | 0.23 | 0.85 | 1.89 | 3 |

| 27QG090 (GO) | 0.27 | 0.90 | 1.89 | 3 |

| 30QG105 (GO) | 0.30 | 1.05 | 1.88 | 3 |

| 50C1000 (NO) | 0.50 | 1.00 | 1.72 | 5 |

All coils are double-stage stress-relief annealed in 100 % H₂ at 820 °C to lock in the Goss texture, then coated with MgO + organic insulation yielding 1.5 µm uniform thickness and 30 Ω·mm² inter-laminar resistance—eliminating hot-spot eddy currents in step-lap cores.

Direct Factory Price, No Western Mark-Up

Because we melt, hot-roll, cold-roll, slit and coat in one integrated campus, we bypass the 15–25 % trader margin and additional freight loops that inflate European or Japanese coil prices. FOB Qingdao = LME Fe-Si index + fixed conversion fee; that formula delivered 2,300 t of 0.23 mm GO to a North-American OEM in 2023 at USD 1,980 / t—18 % below the lowest EU mill quote for the same loss grade.

| Cost Driver | Western Mill Route | Xinzhaohe Direct | Savings |

|---|---|---|---|

| Trader margin | 6–8 % | 0 % | 6–8 % |

| Inland EU logistics | USD 85 / t | USD 15 / t | USD 70 / t |

| Coil slitting surcharge | USD 60 / t | Included | USD 60 / t |

| Total landed delta | ≥14 % |

Payment flexibility: LC 90 days, USD/RMB/EUR, or AliTrade assurance for first-time buyers.

Built-to-Print Customization in 15 Days

Need 45 mm slit width ±0.05 mm, C6 insulation, or radial shear cut to 630 mm D-shaped segments? Our slitting hall houses 8 Hi- reversible cold mills and Kerf-less 0.01 mm slitter blades that hold ≤0.02 mm burr height across 0.18–0.65 mm gauges. Post-slit stress-relief annealing is programmable for 750–850 °C, ensuring ≤1 mm/m camber and ≤5 I-units flatness—critical for robotic stacking lines.

| Custom Capability | Tolerance | Lead Time | MOQ |

|---|---|---|---|

| Slit width | ±0.05 mm | 10 days | 500 kg |

| Burr height | ≤0.02 mm | Inline | Any |

| Segment punching | ±0.1 mm | 15 days | 1 t |

| Laser scribing (domain refinement) | 3 mm pitch | 12 days | 3 t |

We maintain >1,000 t of prime coil in our Qingdao port warehouse, enabling weekly consolidation shipments to Houston, Rotterdam, Dubai and Mumbai.

Next Step: Request Your Datasheet or Trial Quote

Send your stack width, core loss target and annual volume to cathy@transformerstrip.com; we will return a mill test certificate, insulation curve and 24-month price lock within 12 hours. Pilot coils (500 kg) are available for core-build validation before you commit to full tonnage.

📉 Import Savings Calculator

Estimate cost reduction by sourcing sheet coil from Luoyang Xinzhaohe.