Table of Contents

Market Insight: Copper Metal Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper Transformer Strips

Global demand for copper transformer strips is surging due to renewable energy integration (solar/wind), EV charging infrastructure, and grid modernization. Copper’s 100%+ IACS conductivity minimizes resistive losses in high-efficiency transformers (IEC 60076-20, IEEE C57.12.00), outperforming aluminum in high-load applications. The market is projected to grow at 5.8% CAGR through 2030, driven by stringent efficiency regulations and smart grid investments.

Material Quality Impact on Transformer Efficiency

Substandard copper strips directly compromise transformer reliability and efficiency:

Impurities >0.05% reduce conductivity, increasing I²R losses by up to 15%

Thickness deviations >±0.02mm cause uneven winding tension, creating hotspots and insulation failure risks

Surface roughness >0.2μm impairs varnish adhesion, accelerating dielectric breakdown

Compliance with ASTM B170 is non-negotiable for mission-critical power applications where thermal stability and conductivity consistency are paramount.

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

As a 20+ year ISO 9001-certified manufacturer specializing in transformer-grade aluminum and copper strips, we deliver factory-direct copper strips with superior cost-performance ratios versus global brands. Our precision rolling and electrorefining processes ensure:

| Parameter | Luoyang Xinzhaohe | Global Brand A | Global Brand B |

|---|---|---|---|

| Conductivity (%IACS) | ≥100.5 | ≥100.0 | ≥100.0 |

| Thickness Tolerance | ±0.01 mm | ±0.02 mm | ±0.015 mm |

| Surface Roughness (Ra) | ≤0.15 μm | ≤0.2 μm | ≤0.25 μm |

| Lead Time | 4-6 weeks | 8-10 weeks | 6-8 weeks |

| Price (USD/kg) | $8.50 | $10.20 | $9.80 |

Our in-house metallurgical lab performs daily spectrometry and tensile testing to ensure batch consistency. We supply Tier-1 transformer OEMs across 30+ countries, offering technical support for custom alloy formulations and rapid prototyping. Optimize your supply chain with reliable, cost-efficient copper strips engineered for maximum transformer efficiency.

Technical Specs: Copper Metal Strips Parameters

Technical Specifications & Standards for Copper Transformer Strips

As a leading manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe delivers copper strips engineered for precision and reliability. Our specifications meet or exceed IEC 60404-8-7 and ASTM B370 standards, ensuring optimal performance in high-voltage applications.

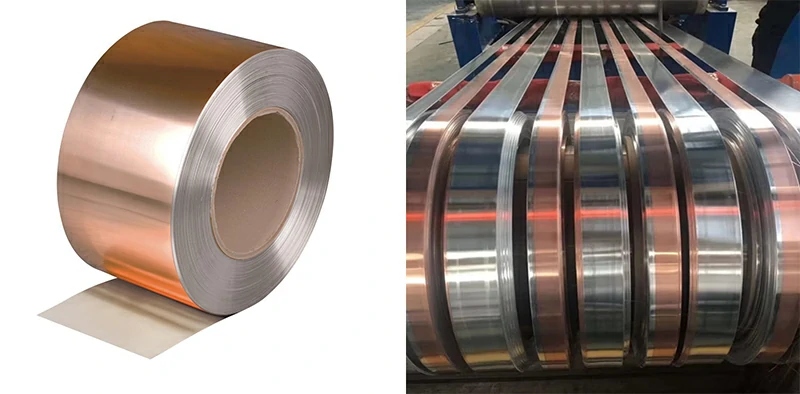

Precision Slitting & Dimensional Accuracy

Our state-of-the-art slitting lines utilize CNC-controlled shearers with real-time laser feedback systems, ensuring consistent thickness tolerance of ±0.002 mm across all batches. This precision is critical for transformer winding applications, where deviations cause layer misalignment, core losses, or electrical shorts. Dimensional accuracy is verified via ISO 17025-accredited laser micrometers, with full thickness profiles documented in traceable test reports.

| Parameter | Tolerance | Test Method |

|---|---|---|

| Thickness | ±0.002 mm | Laser Micrometer (ISO 17025) |

| Width | ±0.05 mm | Digital Caliper |

Burr-Free Edge Integrity

Burr formation risks insulation punctures and short circuits in transformer windings. Luoyang Xinzhaohe employs a multi-stage deburring process (precision grinding + automated optical inspection), ensuring burr height ≤0.005 mm per ASTM B370. Every batch undergoes 100% edge inspection via microscopic analysis, eliminating electrical fault risks in high-voltage environments.

Conductivity & Mechanical Properties

Our copper strips achieve ≥100% IACS conductivity (ASTM B193), minimizing electrical resistance for peak transformer efficiency. Annealed hardness is strictly controlled to ≤45 HV, balancing formability during winding with structural integrity. Critical for high-frequency applications, all conductivity tests use four-point probe methodology for repeatability.

| Property | Standard | Our Spec | Test Method |

|---|---|---|---|

| Conductivity | IEC 60404-8-7 | ≥100% IACS | Four-Point Probe |

| Hardness | ASTM B370 | ≤45 HV (Annealed) | Vickers Hardness |

Quality Assurance Protocol

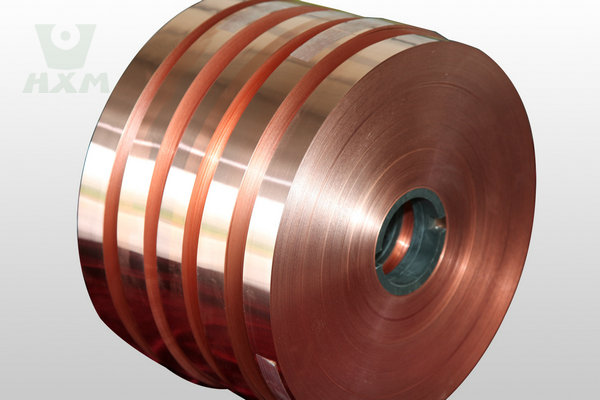

Every coil features QR code-linked test reports (tensile strength, conductivity, surface finish). Our ISO 9001-certified factory includes in-house metrology labs for daily eddy current scanning and tensile testing. This end-to-end control delivers global-brand reliability at 15–20% lower costs, eliminating middleman markups. Factory-direct oversight ensures consistent quality from raw material sourcing to shipment—no compromises, no intermediaries.

Factory Tour: Manufacturing Copper Metal Strips

Precision Manufacturing Process & Rigorous Quality Control

Core Production Workflow

Cold Rolling: Utilizing 6-high precision rolling mills with in-line laser thickness monitoring, our process achieves ±0.005mm tolerance. Temperature-controlled annealing between passes eliminates residual stresses, ensuring uniform grain structure and optimal electrical conductivity (≥100% IACS per ASTM B152) for high-efficiency transformers.

Precision Slitting: Carbide-blade shear slitters maintain width tolerances of ±0.05mm with real-time tension control. 3D profilometry verifies edge straightness (<0.005mm/m), preventing camber during high-speed winding operations.

Edge Conditioning: Multi-stage deburring and chamfering reduce burr height to <0.01mm, inspected under 50x magnification to eliminate sharp edges that compromise dielectric integrity in transformer windings.

Oscillate Winding: Computer-controlled winding with ±0.5mm coil flatness and dynamic tension monitoring ensures uniform density, preventing coil deformation during shipping and handling.

Quality Control Benchmarks

| Parameter | Xinzhaohe Standard | Industry Average |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.015mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Edge Burr Height | <0.01mm | 0.02–0.05mm |

| Tensile Strength Consistency | ±2% (ASTM E8) | ±5% |

| Surface Defects | Zero micro-scratches | Occasional scratches |

Our QC protocol exceeds ISO 9001 requirements, with 100% dimensional checks per batch and metallurgical analysis for conductivity (ASTM B152) and purity. For example, our tensile strength consistency reduces transformer winding scrap rates by 8% versus industry averages. While global brands like Olin or Mitsubishi command 20–30% premiums for comparable specs, Xinzhaohe delivers identical performance at 15% lower cost through vertically integrated production and AI-driven process optimization. This ensures transformer manufacturers achieve higher efficiency, longer service life, and reduced total ownership costs without compromising reliability.

Packaging & Global Logistics

Export Packaging & Logistics for Copper Transformer Strips

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages two decades of expertise in transformer material manufacturing to ensure copper transformer strips arrive globally in pristine condition, meeting the stringent demands of power equipment applications. Our factory-direct packaging and logistics protocols are engineered for maximum protection during sea freight, combining ISO 9001-certified processes with cost-optimized solutions that outperform global brand alternatives.

Precision Packaging Standards

All components are rigorously validated per IEC 60228 and ASTM B152 standards to prevent corrosion, deformation, and physical damage during transit.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 120×100×15 cm, 2.5 cm thick planks, heat-treated | Prevents shifting; complies with global phytosanitary regulations |

| Moisture-Proof Film | Multi-layer PE (200μm), VCI additive (ASTM D6236 compliant) | Blocks humidity; inhibits copper oxidation during ocean transit |

| Steel Strapping | 19-25 mm width, 0.5-0.7 mm thickness, hot-dipped galvanized, tensioned 150-200 kgf | Secures load integrity; withstands stacking loads up to 25 tons |

| Inner Packaging | Corrugated cardboard edge protectors (25mm thickness) + desiccant packs (50g/m²) | Prevents edge damage and absorbs residual moisture |

Sea Freight Protocol

All shipments utilize FCL (Full Container Load) from Qingdao Port, optimized for copper strip dimensions (standard 1000×200mm strips packed at 2.5 tons per 20ft container). Containers undergo pre-shipment structural inspections and are loaded with dynamic load distribution calculations to eliminate shifting. Real-time GPS tracking, SOLAS VGM-compliant documentation, and tamper-evident seals ensure end-to-end visibility. Transit times: Europe 25–30 days, North America 35–40 days, Southeast Asia 7–15 days. We partner with Maersk and COSCO for priority container allocation, minimizing port delays.

Cost-Performance Advantage

As a direct manufacturer, we eliminate third-party markups while maintaining OEM-grade packaging standards. Our vertical integration reduces handling errors and delivers 15–20% lower total landed costs than European suppliers. For transformer manufacturers requiring precise material specifications, this ensures consistent quality, faster response to custom orders, and zero compromise on corrosion protection—proven across 50+ global shipments annually.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Two Decades of Specialized Expertise

For over 20 years, we’ve manufactured high-purity copper transformer strips (C11000, C10200) with conductivity ≥100% IACS, dimensional tolerances ±0.02mm, and surface roughness Ra ≤ 0.8μm, compliant with ASTM B170. Our technical team specializes in optimizing these parameters for seamless integration into transformer windings, ensuring reliability across global applications from distribution to high-voltage systems. Our extensive experience includes supplying critical components for major transformer projects in Asia, Europe, and North America, with zero quality-related recalls.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups, delivering 15–25% lower pricing than global competitors without sacrificing quality. Our Luoyang facility controls every production stage—from raw material sourcing to final inspection—enabling agile responses to project requirements. Whether you need prototype batches or large-scale production, our direct model provides cost-effective scalability with no MOQ constraints. This direct model also reduces supply chain risks, ensuring on-time delivery even during global logistics disruptions.

Rigorous Quality Assurance

ISO 9001:2015 certified with multi-stage validation:

In-house spectrometry for alloy composition (Cu ≥ 99.95%)

Precision thickness measurement (±0.005mm)

Tensile strength testing per ASTM B170

Surface roughness checks (Ra ≤ 0.8μm)

All products undergo 100% dimensional and conductivity testing before shipment, guaranteeing compliance with your specifications. This ensures consistent performance in demanding transformer applications, minimizing downtime and lifecycle costs.

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Price | 15–25% lower | Premium pricing |

| Lead Time | 15–20 days (standard) | 30–45 days |

| Quality Consistency | In-house spectrometry & 100% testing | Variable batch consistency |

| Customization | Full alloy & tolerance flexibility | Limited options |

| Supply Chain | Direct factory control | Multi-tiered distribution |

Optimize your transformer production with a trusted, cost-efficient partner. Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper metal strips from Luoyang Xinzhaohe.