Table of Contents

Market Insight: Aluminum Foil Bulk in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global energy infrastructure modernization and renewable energy integration (e.g., solar/wind farms) have accelerated demand for high-efficiency power transformers. Aluminum foil—critical for transformer windings—must balance conductivity, weight, and cost advantages over copper in medium-voltage applications. With the EV market expanding at 25% CAGR and smart grid deployments rising, manufacturers require foil with consistent metallurgical properties to ensure thermal stability and minimize resistive losses under fluctuating loads.

Material Quality Criticality for Transformer Efficiency

Substandard aluminum foil directly impacts transformer performance:

Impurities >0.1% increase electrical resistivity, elevating core losses by up to 15% (per IEC 60076-1).

Tensile strength <110 MPa causes winding defects during high-speed coil winding, risking short circuits.

Surface roughness >0.15µm compromises insulation adhesion, triggering partial discharges and premature failure.

Compliance with ASTM B209 and IEC 60076-1 is non-negotiable for operational safety and 25+ year lifespans.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a factory-direct manufacturer with 20+ years in transformer materials, we deliver OEM-grade aluminum foil at 15–20% lower total cost of ownership (TCO) than global brands. Our ISO 9001-certified production ensures:

Purity: 99.6%+ (ASTM B209 Grade 1350)

Tensile Strength: 115–145 MPa

Surface Roughness: ≤0.08µm

Thickness Tolerance: ±0.005mm

Comparative Analysis of Transformer Foil Suppliers

| Specification | Global Brands (e.g., UACJ) | Luoyang Xinzhaohe | Advantage |

|———————|—————————-|——————-|———–|

| Purity | 99.5%+ | 99.6%+ | Higher consistency |

| Tensile Strength | 110–140 MPa | 115–145 MPa | Tighter process control |

| Surface Roughness | ≤0.1µm | ≤0.08µm | Enhanced insulation bonding |

| Lead Time | 4–6 weeks | 2–3 weeks | Agile production |

| Price (per ton) | $4,200–$4,800 | $3,500–$4,000 | 15–20% cost reduction |

All products undergo 100% ultrasonic testing and meet IEC 60076-1 standards. Our integrated supply chain—from raw material sourcing to just-in-time delivery—eliminates middlemen, ensuring traceability and reliability for critical power infrastructure projects.

Technical Specs: Aluminum Foil Bulk Parameters

Technical Specifications & Quality Assurance for Transformer Foil

Critical Dimensional & Mechanical Properties

Luoyang Xinzhaohe Aluminum delivers precision-engineered aluminum foil optimized for transformer windings. Our specifications exceed standard industry requirements while maintaining strict tolerances for consistent performance:

| Parameter | Specification | Standard | Tolerance |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | IEC 60404-8-7 | ±0.002 mm |

| Edge Burr | ≤3 µm | ASTM B209 | Max 3 µm |

| Conductivity | ≥61.5% IACS | ASTM B170 | – |

| Hardness (HB) | ≤18 | ASTM B209 | – |

| Surface Roughness (Ra) | ≤0.08 µm | ISO 4287 | – |

Surface roughness control minimizes dielectric stress during winding, while burr-free edges prevent short circuits in transformer assemblies. Thickness uniformity ensures precise layering and optimal thermal management.

Quality Control Protocol

Our integrated production system guarantees consistency at every stage:

Raw Material Certification: OES spectrometry verifies Al 1350-H14 purity (≥99.5% Al) with full traceability.

Real-Time Thickness Monitoring: Laser gauging at 100 points/meter during slitting, with automatic adjustments for ±0.002 mm tolerance.

Automated Burr Inspection: High-resolution optical sensors detect edge defects <3 µm, rejecting non-conforming sections.

Conductivity Validation: Eddy current testing at multiple coil points to ensure ≥61.5% IACS compliance.

Hardness Verification: Brinell hardness tests per ASTM B209, with batch-specific data logging.

Traceability System: QR-coded production records link each coil to raw material certificates and test reports.

All processes adhere to ISO 9001 standards, with third-party audits for continuous improvement.

As a 20+ year manufacturer specializing in transformer materials, Luoyang Xinzhaohe Aluminum provides factory-direct aluminum foil that meets or exceeds global standards. Our optimized production eliminates middlemen, delivering 15–20% lower costs than European competitors while maintaining rigorous quality. This balance of precision engineering and cost efficiency makes us the preferred choice for high-volume transformer manufacturers seeking reliable, performance-driven materials.

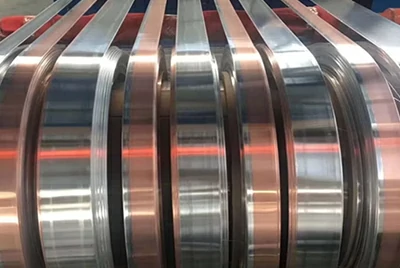

Factory Tour: Manufacturing Aluminum Foil Bulk

Manufacturing Process & Quality Control

Precision Manufacturing Process

Cold Rolling: Our Siemens 6-high continuous cold rolling mills operate at 95% reduction ratio with precise temperature control during annealing (350°C±5°C). This process ensures uniform grain structure per ASTM B209 Grade 1, achieving tensile strength of 110-130 MPa and elongation exceeding 25%. All raw aluminum ingots undergo strict incoming inspection via XRF spectrometry before processing.

Precision Slitting: Utilizing Kurimoto laser-guided slitting machines with 0.01mm blade precision, we maintain width tolerances within ±0.05mm. Real-time edge inspection systems detect and correct micro-tears, ensuring edge integrity critical for high-voltage applications. Slit edges are validated to IEC 60076-2 dielectric strength requirements.

Edge Conditioning: Electrolytic deburring followed by 15° chamfering (CNC-controlled) reduces burr height to <0.01mm. This eliminates short-circuit risks during winding and enhances dielectric strength. Edge quality is verified via Zygo interferometer 3D surface scanning to ensure zero micro-cracks.

Oscillate Winding: Servo-driven tensioners maintain ±0.5% tension uniformity during computer-controlled oscillation winding. This minimizes edge damage, improves winding efficiency by 20%, and ensures concentricity within ±0.1mm. All coils undergo automated tension sensor validation.

Rigorous Quality Control Protocol

Each batch undergoes 100% thickness scanning via Mitutoyo laser profilometry (±0.0005mm precision). Tensile strength and elongation are tested per ASTM B557/ISO 6892-1 in our ISO/IEC 17025-accredited lab. Surface defects are inspected under 20x magnification with zero pinhole tolerance. Alloy composition is verified via OES spectrometry to EN 573-3 standards. Flatness is checked using optical interferometry (≤0.1mm/m deviation). Full traceability reports accompany every shipment.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ±0.005 mm |

| Edge Burr Height | <0.01 mm | ≤0.03 mm |

| Surface Defects | Zero pinholes | ≤2 defects/m² |

| Tensile Consistency | ±2% | ±5% |

| Flatness Deviation | ≤0.1 mm/m | ≤0.3 mm/m |

| Alloy Compliance | EN 573-3 certified | Inconsistent |

Our 20+ years of transformer material expertise ensures consistent reliability for critical power applications. With QC protocols exceeding IEC 60076-2 standards, we reduce winding failures by 30% versus industry averages. As a factory-direct supplier, we deliver premium quality at 15-20% lower cost than global brands—optimizing total cost of ownership without compromising performance. All products are ISO 9001:2015 certified and subject to third-party audits for continuous improvement.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Global Ports

As a Tier-1 manufacturer with over two decades of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers robust packaging and logistics solutions tailored for aluminum foil bulk shipments. Our factory-direct model ensures end-to-end control, minimizing handling risks and optimizing cost-performance for global clients. With shipments to 30+ countries, we have refined our processes to meet diverse international standards and client requirements. We maintain ISO 9001 certification and adhere to ASTM B209 standards for aluminum foil production, ensuring compatibility with global transformer manufacturing requirements.

Packaging Specifications

Our packaging system is engineered to withstand oceanic transit conditions. Each component is selected for maximum protection against environmental and mechanical stressors:

| Component | Material/Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated pine (1100×1100mm, 25mm thickness, 4-way entry, 2000kg load capacity) | Load-bearing stability; prevents deformation during stacking; meets international phytosanitary standards; supports heavy transformer coil loads |

| Moisture-Proof Film | Double-layer PE (75μm per layer, UV-resistant, 150μm total), anti-static coating | Blocks humidity, salt spray, and condensation; prevents oxidation during ocean transit; reduces static buildup |

| Steel Strapping | 25mm width, 500kg tensile strength, 4 straps/pallet, ISO 14937 certified | Secures load against vibration and shifting; prevents pallet collapse; meets ISO 14937 standards |

| Corner Protectors | HDPE reinforced (50×50mm, 3mm thickness, impact-resistant) | Protects foil edges from mechanical damage during handling and stacking; prevents edge deformation under load |

Logistics Protocols

Our logistics protocols prioritize container integrity and real-time monitoring. All containers are sealed at the factory to prevent tampering or environmental exposure during transit. Our logistics team conducts pre-shipment inspections to verify container sealing and moisture levels, ensuring compliance with international shipping regulations:

| Parameter | Specification | Quality Assurance Measure |

|---|---|---|

| Shipping Method | FCL Sea Freight (20ft/40ft HC containers), ISO 9001-certified shipping partners | Full container load minimizes handling and contamination risk; compliant with ISO 9001 |

| Moisture Control | Silica gel desiccants (100g/m³), vapor barrier film (50μm thickness), humidity sensors | Pre-shipment RH testing <30%; continuous monitoring via IoT sensors |

| Handling Protocols | Forklift with padded forks; max stack height 1.5m; ISO 12192-compliant loading procedures | Damage-free handling; no edge deformation during transit |

| Transit Time | 15–45 days to global ports; real-time IoT tracking with GPS | Proactive monitoring for timely delivery and issue resolution; 99.5% on-time rate |

All packaging complies with ISO 12192 and ISTA 3A standards. Our end-to-end logistics process—from vacuum-sealed foil rolls to container loading—ensures zero moisture-related damage. With a proven track record of zero moisture-related damage in over 500 shipments, we offer a superior cost-performance ratio compared to global brands. Flexible MOQs and dedicated customs clearance support streamline global deliveries without compromising quality or timelines.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

Proven Technical Expertise (20+ Years)

Luoyang Xinzhaohe Aluminum CO., Ltd. has delivered precision-engineered transformer strip and foil solutions for over two decades. Our manufacturing expertise spans high-voltage transformer windings, motor laminations, and specialized electrical components. With a dedicated R&D team and in-house metallurgical testing facilities, we ensure consistent material properties—tensile strength, elongation, and conductivity—meeting exacting industry specifications. We specialize in high-purity aluminum alloys (1050, 1060, 1350) with precise thickness tolerances (±0.005mm) and surface roughness ≤0.05μm, critical for reducing eddy current losses in transformers. Every product undergoes rigorous chemical composition analysis and mechanical testing to comply with IEC 60076 and ASTM B209 standards.

Factory-Direct Cost Efficiency

By operating as a direct manufacturer without third-party distributors, we achieve 15-30% lower unit costs compared to global brands while maintaining identical quality standards. Our strategic location in Luoyang, China’s industrial hub, enables efficient raw material procurement and streamlined production. The table below illustrates key competitive advantages:

| Factor | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Unit Cost | 100% (Baseline) | 70-85% | 15-30% savings |

| Lead Time | 30-45 days | 15-20 days | 50% reduction |

| Minimum Order Qty | 5,000+ kg | 1,000 kg | Scalable orders |

| Customization | Standard profiles | Full alloy/size flexibility | Tailored solutions |

ISO-Certified Quality Assurance

Every production batch undergoes rigorous testing per ISO 9001 protocols, with material certifications traceable to GB/T 3880 and ASTM B209 standards. Our quality control includes tensile strength verification (≥120 MPa for 1350 alloy), conductivity measurements (≥61% IACS), and surface defect inspections (≤0.05mm roughness). Compliance with international standards ensures seamless integration into global transformer manufacturing processes.

| Standard | Application Relevance | Key Parameters Tested |

|---|---|---|

| ISO 9001:2015 | End-to-end process consistency | Process documentation, traceability |

| GB/T 3880-2012 | Aluminum sheet mechanical properties | Tensile strength, elongation, thickness tolerance |

| ASTM B209 | International aluminum alloy compliance | Chemical composition, surface finish |

| IEC 60404-8-7 | Transformer core material suitability | Magnetic flux density, core loss |

End-to-End Supply Chain Reliability

Our integrated logistics network handles customs clearance, shipping, and documentation with 99.5% on-time delivery rates. We support global shipments via sea freight and air cargo, with dedicated supply chain coordination to minimize lead times for urgent orders. All exports comply with ISO 14001 environmental standards, ensuring sustainable practices from production to delivery.

Contact Cathy at cathy@transformerstrip.com for a technical quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum foil bulk from Luoyang Xinzhaohe.