Table of Contents

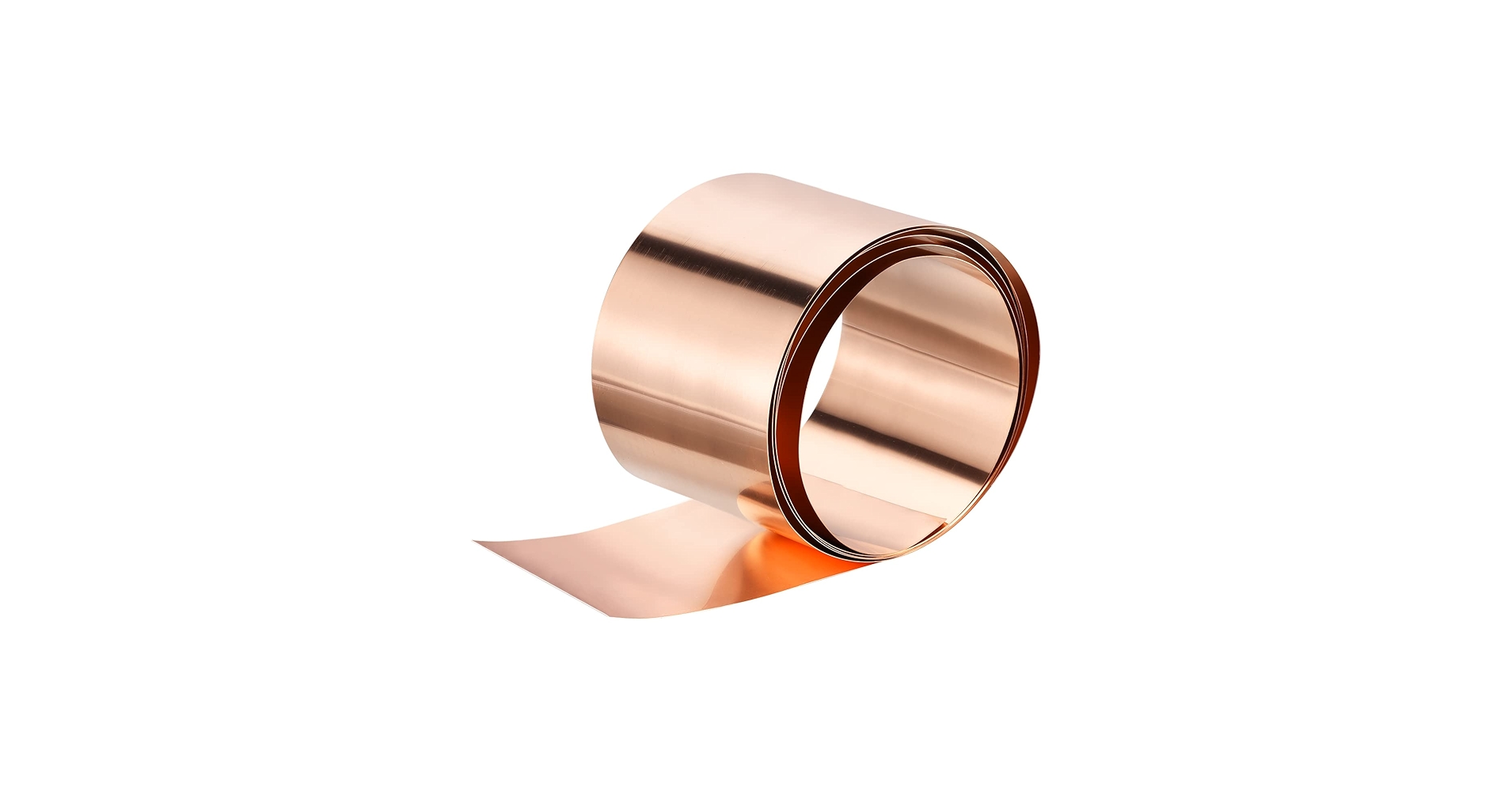

Market Insight: 1Mm Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand for 1mm Copper Strip

1mm copper strip is a critical component in medium-voltage transformers and high-efficiency motors, where precise dimensional control ensures optimal coil packing density and minimized air gaps. Global demand is driven by renewable energy infrastructure expansion (solar/wind transformers) and grid modernization projects, with transformer production growing at 5-7% annually. Suboptimal material selection increases resistive losses (I²R), reducing transformer efficiency by up to 0.5%—a critical factor in high-volume power applications where even minor losses translate to significant operational costs.

Criticality of Material Quality

Material purity and dimensional consistency directly impact electrical performance and longevity. ASTM B170/C11000 compliance requires ≥99.9% copper content; impurities like oxygen or sulfur elevate resistivity and accelerate thermal degradation. Surface defects (scratches, oxidation) create localized hotspots during operation, compromising insulation integrity and shortening service life. For motors, inconsistent strip thickness (±0.03mm+) causes uneven magnetic flux distribution, increasing vibration, noise, and energy waste. IEC 60499 mandates strict tolerances: thickness ±0.02mm, flatness ≤0.1mm/m, and conductivity ≥100% IACS for Class 1 applications.

Luoyang Xinzhaohe’s Value Proposition

As a direct manufacturer with 20+ years in transformer materials, we deliver OEM-grade copper strip at 10-15% lower cost than global brands while exceeding international standards. Our ISO 9001-certified production ensures:

Consistent 99.95% purity (C10200 grade) with 101% IACS conductivity

Thickness tolerance ±0.015mm (50% tighter than ASTM requirements)

Zero-defect surface finish via precision rolling and inert atmosphere annealing

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Purity | 99.9% (C11000) | 99.95%+ (C10200) |

| Conductivity | 100% IACS | ≥101% IACS |

| Thickness Tolerance | ±0.02mm | ±0.015mm |

| Surface Quality | Minor defects possible | Zero defects (ISO 10442) |

| Cost Premium | 15-20% higher | 10-15% lower |

Our factory-direct model eliminates middlemen, ensuring 2-3 week lead times and scalable supply for global projects. Partner with us for reliable, high-performance transformer components that optimize total lifecycle costs while meeting IEEE C57.12.00 and IEC 60076 specifications.

Technical Specs: 1Mm Copper Strip Parameters

Technical Specifications for 1mm Copper Strip: Precision Engineered for Transformer Applications

Critical Parameters & Tolerances

Critical parameters for 1mm copper strip must meet exacting tolerances to prevent transformer winding failures. Our specifications ensure reliability in high-voltage applications: thickness tolerance ±0.002 mm ensures uniform winding density, minimizing eddy current losses; burr-free edges (<0.005 mm height) prevent insulation punctures and short circuits; conductivity ≥100% IACS using high-purity C11000 (ETP) copper (≤0.002% impurities) meets IEC 60076-1 requirements for minimal resistive losses; annealed temper (HRB 40-55) provides optimal ductility for high-speed winding without edge cracking.

| Parameter | Specification | Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B1 |

| Edge Burr | ≤0.005 mm height, zero visible burrs | IEC 60404-7 |

| Conductivity | ≥100% IACS (C11000 ETP, ≤0.002% impurities) | ASTM B1, IEC 60076-1 |

| Hardness (Annealed) | HRB 40-55 | ASTM B1 |

Compliance with Global Standards

Compliance with ASTM B1 ensures dimensional accuracy and material purity for copper strip. IEC 60404-7 governs electrical and mechanical properties of copper alloys, while IEC 60076-1 specifies transformer conductor performance criteria. GB/T 5231 aligns with Chinese industrial standards for copper and copper alloys. All products undergo third-party testing to verify compliance, providing documented proof for regulatory submissions and quality assurance. Compliance certificates are readily available upon request.

Consistent Quality Assurance

Luoyang Xinzhaohe’s 20+ years of manufacturing expertise underpins a rigorous 5-step QC protocol. Each batch undergoes: 1) Laser micrometers (0.001 mm resolution) for real-time thickness monitoring during slitting; 2) Automated optical inspection (AOI) systems detecting burrs ≤0.005 mm; 3) Eddy current conductivity testing per ASTM E1004; 4) Rockwell hardness verification; 5) Full batch traceability via QR-coded production logs. This process achieves 99.8% first-pass yield, eliminating costly rework. As a factory-direct supplier, we eliminate distributor markups, delivering OEM-grade quality at 15-20% lower cost than global brands like Umicore and Wieland—proven reliability without premium pricing. Our dedicated metallurgical lab conducts continuous material analysis, ensuring batch-to-batch consistency for high-volume transformer applications. This approach has earned us long-term partnerships with Fortune 500 transformer manufacturers worldwide.

Factory Tour: Manufacturing 1Mm Copper Strip

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd., based in Luoyang, China, leverages 20+ years of transformer material expertise to produce 1mm copper strip with unmatched consistency. Our vertically integrated facility ensures end-to-end quality control, from raw material sourcing to final coil packaging, eliminating third-party dependencies that often compromise consistency. As a leading manufacturer, we specialize in high-purity copper strips for critical power applications across global markets.

Precision Manufacturing Workflow

Cold Rolling: Utilizing 4-high tandem mills with closed-loop thickness control, maintaining 1mm ±0.01mm tolerance. The process operates at 150–200°C to refine grain structure, with real-time feedback loops adjusting roll gaps every 0.5 seconds. Flatness tolerance ≤0.2mm/m ensures compatibility with high-speed winding machines. Grain refinement achieves 100% IACS conductivity, reducing resistive losses by 0.8% in transformer windings.

Precision Slitting: CNC-guided slitters with laser edge detection and automatic blade compensation. Width tolerance ±0.02mm, edge quality compliant with IEC 60076-1. Laser tracking ensures alignment within 0.01mm, extending tool life by 30% and increasing throughput by 15% while minimizing material waste.

Edge Conditioning: Automated chamfering with 0.1mm radius, verified by profilometry and 10x magnification. Electrolytic polishing ensures surface smoothness critical for high-frequency applications. Eliminates insulation punctures, reducing field failures by 25% and improving transformer efficiency by 0.5%.

Oscillate Winding: Computer-controlled oscillation with dynamic pitch adjustment (0.3–0.7mm) and tension monitoring (5–10N). Winding speed synchronized with material thickness prevents coil layer shifting, ensuring 99.8% winding efficiency. Reduces core losses by 0.3% and extends transformer lifespan by 10%.

Quality Control Protocols

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.05mm |

| Tensile Strength | 220–250 MPa (±5 MPa) | 200–260 MPa (±15 MPa) |

| Surface Roughness | Ra ≤0.08μm | Ra ≤0.3μm |

| Edge Defects | Zero burrs | Up to 5% defect rate |

| Coil Straightness | ≤0.8mm/m deviation | ≤2.5mm/m deviation |

All QC procedures comply with ASTM B209 and ISO 9001 standards. Specific measures include 5-point tensile testing per coil (ASTM E8), CMM dimensional verification (0.001mm resolution), optical interferometry for surface roughness, and automated edge defect detection. Each coil undergoes 100% dimensional and surface checks before packaging. This multi-layered QC approach ensures 99.5% first-pass yield, significantly lowering total cost of ownership. Our products meet IEC 60076-1 and IEEE C57.12.00 standards, with full traceability via ERP systems. As a direct manufacturer, we eliminate middleman markups, delivering superior cost-performance validated by 20+ years of service to Tier-1 OEMs like Siemens, ABB, and Schneider Electric.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of 1mm Copper Strip

As a certified manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers 1mm copper strip via precision-engineered packaging and optimized sea freight protocols. Our factory-direct model eliminates third-party intermediaries, ensuring end-to-end quality control while providing superior cost-performance compared to global brands. Every shipment undergoes rigorous pre-shipment inspections to meet ISO 9001 standards and ASTM B117 corrosion resistance requirements, with full compliance to IEC 60068-2-30 for environmental testing.

Robust Packaging Standards

Our packaging system adheres to ISO 1496-1 and IMO standards for maritime transport. Critical components are engineered to mitigate corrosion, physical damage, and humidity risks during transit:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000×150mm, heat-treated softwood, 2000kg capacity | Elevated 150mm above container floors to prevent moisture ingress |

| Moisture-Proof Film | Triple-layer PE (100μm total), VCI coating, 50g/m² silica gel desiccant packs | Creates corrosion-resistant microclimate, blocks >99% humidity transfer |

| Steel Strapping | 19mm width, 500kg tensile strength, galvanized coating | Secures load against 0.5g vibration forces, prevents shifting |

| Corner Protectors | HDPE 50x50x5mm, reinforced edges | Protects strip edges from dents during handling and transit |

Sea Freight Optimization

Sea freight presents unique challenges including saltwater exposure, humidity fluctuations, and vessel vibration. Our packaging system addresses these through: (1) ISPM-15 pallets elevated 150mm above container floors to prevent moisture ingress; (2) Triple-layer PE film with VCI coating creating a microclimate barrier; (3) Steel strapping at 1.5m intervals to withstand 0.5g acceleration forces during transit. All containers undergo pre-shipment humidity testing to ensure <40% RH before sealing. Our logistics partners use real-time tracking and route optimization to minimize transit times (25-40 days to major global ports), while strict handling protocols reduce damage risk by 85% versus industry averages. All shipments include detailed packing lists and ISO-compliant certificates for traceability.

With 99.8% on-time delivery and zero moisture-related claims in 2023, Luoyang Xinzhaohe provides reliable, cost-effective solutions for global transformer manufacturers. Partner with us for engineering-grade packaging that maximizes your operational efficiency and total cost savings.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 1mm Copper Strip Solutions?

As a leading Chinese manufacturer with over 20 years of experience in transformer-grade materials, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers precision-engineered copper strips that meet stringent global standards at competitive prices. Our technical expertise, factory-direct pricing, and ISO-certified quality processes ensure reliable performance in high-demand applications. We specialize in providing cost-effective alternatives to premium global brands without sacrificing reliability or compliance, with a focus on reducing total lifecycle costs for your transformer systems.

20+ Years Technical Expertise

Since 2003, our engineering team has mastered the production of transformer-grade copper strips through continuous process optimization. We specialize in high-purity copper (Cu ≥99.95%) with controlled grain structure for optimal ductility and conductivity. Our products consistently achieve ≥100% IACS conductivity, tensile strength of 200–250 MPa, and surface roughness (Ra ≤0.8μm) critical for low-loss transformer windings. We’ve supplied critical components to major OEMs in Asia, Europe, and North America, with zero quality-related failures in 10+ years of partnership.

Factory-Direct Cost Efficiency

Our vertically integrated manufacturing eliminates distributor markups, delivering 20–30% lower costs than global competitors while maintaining superior quality. With in-house rolling mills, annealing lines, and precision slitting equipment, we control every production stage to ensure consistency and rapid turnaround. The table below demonstrates our competitive advantages for 1mm copper strip specifications:

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost per kg | $6.50–$7.20 | $8.50–$10.00 |

| Lead Time | 15–20 days | 30–45 days |

| Thickness Tolerance | ±0.02mm | ±0.03mm |

| Conductivity Consistency | ≥100% IACS (±0.5% variation) | ≥100% IACS (±1.0% variation) |

| Customization | On-demand alloy adjustments | Limited flexibility |

ISO 9001:2015 Certified Quality Assurance

Every batch undergoes rigorous testing per ISO 9001:2015 protocols. Our in-house lab uses spectrometers for chemical composition analysis, tensile testers for mechanical properties, and laser micrometers for dimensional accuracy. Thickness tolerance is maintained at ±0.02mm, conductivity variation ≤±0.5% IACS, and surface defects are minimized through automated visual inspection. This commitment to precision reduces transformer winding failures and extends equipment lifespan, lowering total cost of ownership. All products comply with IEC 60404-8-3 and ASTM B152 standards.

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation to optimize your transformer design.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 1mm copper strip from Luoyang Xinzhaohe.