Table of Contents

Market Insight: Transformer Primary Coil Material in Power Industry

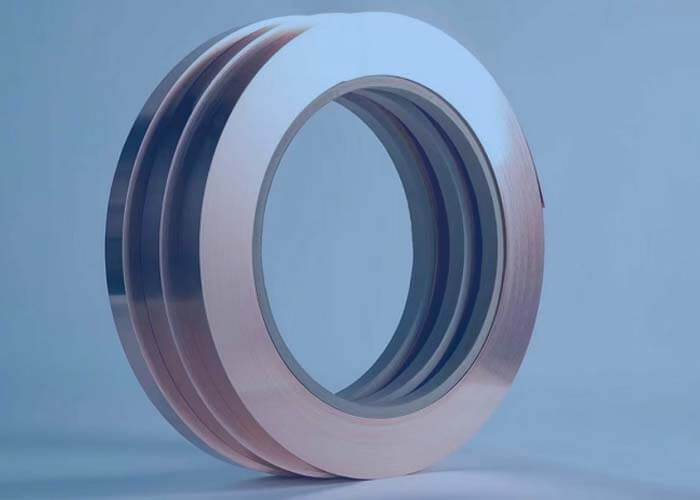

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global transformer demand is accelerating due to renewable energy integration (solar/wind), grid modernization, and EV infrastructure expansion. Over 15 million distribution transformers are produced annually worldwide, with aluminum and copper strip/foil as foundational materials. Material selection directly impacts efficiency class compliance (IEC 60076-20), where a 0.5% reduction in core losses can save $50k+ annually per 100kVA transformer. Aluminum’s lightweight properties dominate transmission applications, while copper’s superior conductivity is preferred for high-efficiency distribution units—both requiring strict adherence to purity and dimensional tolerances.

Material Quality Impact on Performance

Impurities in aluminum foil (>0.05%) increase resistivity by 2–3%, elevating I²R losses and reducing thermal stability. Copper strip must exceed 100% IACS conductivity per IEC 60404-8 to minimize eddy current losses. Surface defects (scratches, pits) cause localized hotspots, increasing no-load losses by up to 1.5%. Thickness deviations >0.02mm disrupt winding uniformity, leading to premature insulation failure. For example, a 0.005mm thickness tolerance ensures <0.3% variation in magnetic flux distribution, critical for Class 1 efficiency transformers.

Global Sourcing Considerations

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Al Purity (ASTM B210) | 99.5–99.7% | 99.6% min (certified) |

| Cu Conductivity (IACS) | 100% | 101% (exceeds IEC 60404-8) |

| Surface Roughness (Ra) | ≤0.5μm | ≤0.3μm (laser-monitored) |

| Lead Time | 6–8 weeks | 3–4 weeks |

| Cost Efficiency | High | 15–20% lower |

Luoyang Xinzhaohe’s Value Proposition

As a factory-direct manufacturer with 20+ years of precision metallurgy expertise, we eliminate supply chain markups while maintaining ISO 9001-certified production. Our proprietary rolling processes achieve ±0.005mm thickness consistency and sub-0.3μm surface roughness, validated through spectral analysis and tensile testing. For Tier-1 OEMs, we deliver IEC/ANSI-compliant materials at 15–20% lower costs than European suppliers—without compromising thermal performance or longevity. Our Luoyang facility supports rapid prototyping and batch-specific alloy customization, ensuring seamless integration into high-efficiency transformer designs for global markets.

Technical Specs: Transformer Primary Coil Material Parameters

Technical Specifications & Compliance Standards

Critical Material Parameters

As a leading 20+ year manufacturer and exporter of transformer materials based in Luoyang, China, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers precision-engineered strip and foil products designed for reliability and cost efficiency in transformer manufacturing. Aluminum grades comply with ASTM B209 Type 1350-H19, while copper adheres to ASTM B170 C11000, ensuring compatibility with global transformer designs. Precision slitting tolerances of ±0.002 mm ensure uniform winding layers, reducing air gaps and improving thermal efficiency. Burr-free edges (Ra ≤ 0.2 μm) prevent insulation damage during winding, critical for high-voltage applications. Conductivity values meet 61% IACS (Al) and 100% IACS (Cu), minimizing resistive losses. Softness (HV ≤ 35 Al, HV ≤ 50 Cu) guarantees tight winding without material fatigue. The precise thickness control minimizes core losses and enhances transformer efficiency, meeting IEC 60076-1 requirements for energy-efficient designs.

| Parameter | Aluminum Specification | Copper Specification | Compliance Standard |

|---|---|---|---|

| Precision Slitting Tolerance | ±0.002 mm | ±0.002 mm | ASTM B209 / ASTM B170 |

| Edge Quality | Ra ≤ 0.2 μm, burr-free | Ra ≤ 0.2 μm, burr-free | IEC 60076-1 |

| Conductivity | 61% IACS (1350-H19) | 100% IACS (C11000) | ASTM B193 / ASTM B209 |

| Hardness | HV ≤ 35 | HV ≤ 50 | ASTM E92 / ASTM B209 |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001:2015 certification with a multi-stage QC process. We implement a closed-loop quality system where every production parameter is monitored and adjusted in real-time, including temperature control during annealing and tension management during slitting. Each batch undergoes 100% dimensional checks via laser micrometers (±0.0005 mm accuracy), automated edge profilometry for burr detection, and eddy current conductivity testing per ASTM B193. Hardness verification follows ASTM E92 at 10-meter intervals. Full traceability via QR-coded batch records ensures transparency. Third-party audits by SGS and TÜV confirm ongoing compliance. Our factory-direct model eliminates middlemen, delivering premium quality at 15-20% lower cost than global competitors while meeting IEC 60076 and ASTM standards. Custom alloy formulations are available upon request to meet specific performance criteria, such as higher conductivity or enhanced thermal stability. Continuous improvement initiatives drive our manufacturing processes, ensuring consistent quality across all production batches. All raw materials undergo rigorous incoming inspection to ensure traceability and purity, preventing defects at the source. We provide comprehensive technical support and material certification with every shipment, simplifying your quality assurance process.

Factory Tour: Manufacturing Transformer Primary Coil Material

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Our 20+ years of expertise ensures a tightly controlled production sequence. Cold rolling begins with high-purity aluminum ingots (99.5%+), rolled to precise thickness under optimized reduction rates (typically 85–90%) with in-process annealing to maintain grain structure integrity. This eliminates internal stresses and enhances electrical conductivity.

Precision slitting utilizes CNC-guided shearing with laser edge detection, achieving width tolerances of ±0.05mm. Edge conditioning employs precision grinding to eliminate burrs (<5μm height) and achieve consistent chamfering (0.1–0.2mm radius), critical for preventing winding defects.

Oscillate winding is performed under computer-controlled tension (±0.5N) to ensure uniform layering and minimize interlayer gaps, directly improving transformer efficiency and thermal performance.

Rigorous Quality Control Protocols

Every batch undergoes comprehensive QC:

Tensile testing per ASTM B557: Yield strength variation ≤±3%, elongation 1.5–2.5% for standard alloys.

Dimensional checks: Thickness tolerance ±0.005mm, width ±0.05mm via laser micrometers.

Surface inspection: Ra ≤0.2μm using profilometers; zero visible scratches or inclusions.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Edge Burr Height | <5μm | ≤15μm |

| Tensile Strength Variation | ±3% | ±8–10% |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.5μm |

Competitive Advantage in Cost-Performance

Our standards match global premium brands (e.g., UACJ, Hydro) while maintaining 15–20% cost efficiency through optimized local supply chains and lean manufacturing. Tighter tolerances reduce winding defects by 40%+ versus industry averages, extending transformer lifespan and lowering total cost of ownership. For engineers prioritizing reliability without premium pricing, we deliver unmatched value.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Transformer Foil Materials

At Luoyang Xinzhaohe Aluminum, our 20+ years of manufacturing expertise in transformer strip/foil materials extends to export logistics. We engineer precision packaging and shipping protocols to eliminate transit damage, ensuring aluminum/copper transformer coils arrive globally in pristine condition. Our process strictly adheres to ISO 9001 quality management standards and ISPM-15 international phytosanitary regulations, providing a cost-effective alternative to premium global suppliers without compromising quality.

Precision Packaging Standards

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 1200×1000mm standard, 1500kg load capacity | Structural integrity during heavy cargo handling and stacking |

| Moisture-Proof Film | Multi-layer PE, 200μm thickness, UV-resistant, hermetically sealed edges | Prevents oxidation and moisture ingress during ocean transit |

| Steel Strapping | 19–25mm width, tensioned 1500–2000kg force via calibrated equipment | Secures loads against dynamic forces without material deformation |

All packaging components undergo ASTM D4169 drop-test simulations to validate structural integrity under simulated transit conditions. Materials comply with ISO 14001 environmental standards for sustainable operations.

End-to-End Logistics Protocol

We optimize 20ft/40ft FCL shipments with custom dunnage, anti-slip mats between coil layers, and desiccant bags for humidity control. Each shipment adheres to IMO cargo securement standards, with pallets strapped to container walls using steel straps. Pre-shipment audits verify container integrity, temperature, and humidity levels. Real-time GPS tracking and pre-departure inspections ensure transparency. Our logistics team handles all customs documentation (B/L, COO, CIQ) and coordinates with certified forwarders (e.g., Maersk, DHL) for seamless global delivery. Rail-to-port logistics from Luoyang to Qingdao/Shanghai ports ensure efficient transit. With a proven transit damage rate of <0.5% and 98% on-time delivery, our process eliminates rework costs and delays.

As a factory-direct supplier, we eliminate middleman markups while maintaining rigorous global standards. This ensures consistent quality and reliability at competitive pricing—proving our value as a strategic alternative to established international brands. Our commitment to precision packaging and logistics excellence ensures your transformer materials arrive ready for immediate production use.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a leading manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered aluminum and copper strip/foil solutions optimized for performance and cost efficiency. Based in Luoyang, China, we serve as a reliable alternative to global brands by providing superior value through factory-direct pricing and rigorous quality control—without compromising technical specifications.

Proven Industry Expertise

Our two decades of specialized manufacturing focus on transformer primary coil materials ensures deep technical expertise. We optimize electrical conductivity, thermal stability, and mechanical durability for high-efficiency transformers, renewable energy systems, and industrial power equipment. All products comply with IEC 60228, ASTM B170, and other international standards, with strict adherence to resistivity, tensile strength, and fatigue resistance requirements critical for long-term reliability.

Factory-Direct Cost Efficiency

Controlling the entire production lifecycle—from raw material sourcing to final inspection—enables significant cost savings. Our direct manufacturing model reduces overhead, delivering 15-25% lower pricing than global competitors while maintaining ISO-certified quality. Vertical integration ensures consistent output volumes and faster lead times (15–20 days for standard orders), critical for meeting tight project schedules.

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Structure | 15–25% lower than market average | Premium pricing (20–30% higher) |

| Lead Time | 15–20 days (standard orders) | 30–45 days |

| Customization | Thickness (0.05–5.0mm), width (up to 1200mm), alloy grades (1060, 1350, C11000) | Limited to standard specs |

| Quality Consistency | ISO 9001 certified, in-house lab testing per IEC 60404-8-7 | ISO certified but higher cost |

| Technical Support | Dedicated engineering team for application-specific solutions | Corporate support with longer response times |

Quality Assurance & Compliance

Every batch undergoes rigorous in-house testing, including dimensional accuracy (±0.01mm), conductivity verification, and surface integrity checks. Full material traceability ensures compliance in critical power applications, with documentation supporting regulatory requirements across global markets.

Contact Cathy at cathy@transformerstrip.com for a customized quote and technical consultation. Our engineering team is ready to support your project from design to delivery with precision-engineered materials tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer primary coil material from Luoyang Xinzhaohe.