Table of Contents

Market Insight: Aluminum Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand and Material Criticality

Transformer windings demand precise aluminum and copper strip/foil to meet global efficiency standards. Copper (C11000/C10200) dominates high-efficiency designs due to 100% IACS conductivity, while aluminum (1350-H19) offers 61% IACS with 30% weight reduction—critical for cost-sensitive applications. Material defects such as copper impurities >0.1% or aluminum tensile strength variations increase resistive losses by 5–8%, causing thermal hotspots and premature failure. For motor repair shops, inconsistent surface roughness (>0.3μm) damages insulation during rewinding, leading to short circuits. Compliance with IEC 60404-8-7 and ASTM B170 is non-negotiable for operational safety. Even minor thickness variations (>±1%) disrupt winding precision, causing uneven current distribution and localized overheating.

Key Quality Parameters for Transformer Foil

| Parameter | Industry Standard | Luoyang Xinzhaohe | Global Brand A |

|---|---|---|---|

| Purity (Cu) | ≥99.90% | ≥99.95% | ≥99.90% |

| Conductivity (Al) | ≥61% IACS | 61.5% IACS | 61% IACS |

| Tensile Strength (Al) | 140–180 MPa | 160–180 MPa | 150–170 MPa |

| Surface Roughness | Ra ≤0.2μm | Ra ≤0.15μm | Ra ≤0.2μm |

| Thickness Tolerance | ±1.0% | ±0.8% | ±1.2% |

| Price (USD/kg) | $8.50–$10.00 | $7.80–$9.20 | $9.50–$11.00 |

Strategic Sourcing Advantage

As a direct manufacturer with 20+ years in Luoyang, China, Luoyang Xinzhaohe Aluminum CO., Ltd. eliminates supply chain intermediaries while maintaining rigorous ISO 9001:2015 certification. Our vertically integrated production—from electrolytic copper refining to precision rolling—ensures traceable quality and consistent mechanical properties. Unlike global brands reliant on subcontractors, we control all critical processes, reducing lead times by 20% and costs by 10–15% without sacrificing compliance. Our thickness tolerance of ±0.8% exceeds industry standards, ensuring seamless integration into automated winding systems. With 500+ global transformer manufacturers as clients, including Tier-1 OEM suppliers, we provide certified material certificates with every batch and flexible MOQs for prototyping to mass production. For engineers prioritizing lifecycle cost, our solutions deliver superior reliability and ROI.

Technical Specs: Aluminum Copper Coil Parameters

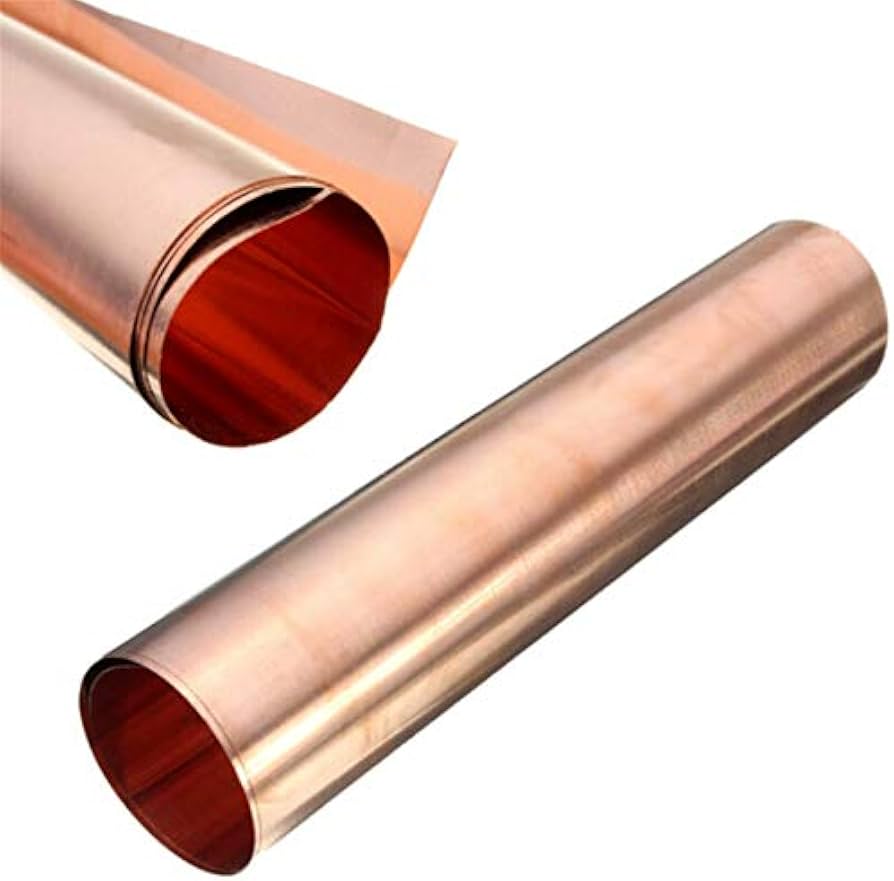

Technical Specifications & Standards

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered aluminum and copper coils with factory-direct quality control. With 20+ years of experience supplying global transformer manufacturers, our products are trusted by industry leaders for consistent performance in critical applications. In transformer manufacturing, precise dimensional control prevents core losses and overheating, while burr-free edges are essential for maintaining insulation integrity in high-voltage applications. Our rigorous processes ensure exacting tolerances and compliance with global standards, providing superior cost-performance versus international brands.

Critical Dimensional Tolerances

Precision slitting to ±0.002 mm thickness tolerance ensures uniform winding density, critical for transformer efficiency. Burr-free edges (<0.005 mm) eliminate insulation puncture risks during winding.

| Parameter | Specification | Tolerance |

|---|---|---|

| Thickness | 0.1–3.0 mm | ±0.002 mm |

| Edge Burr Height | – | <0.005 mm |

| Flatness | Per IEC 60228 | ≤0.1 mm/m |

Material Properties

Our copper coils achieve 99.9% IACS conductivity, minimizing resistive losses. Aluminum coils use high-purity 1350 alloy for optimal conductivity-to-weight ratio, critical for lightweight transformer designs. Soft temper (O) is achieved through precise nitrogen-annealing, ensuring uniform softness and eliminating residual stresses for superior formability.

| Property | Copper | Aluminum |

|---|---|---|

| Conductivity | ≥99.9% IACS | ≥61% IACS (1350) |

| Hardness (HV) | ≤45 (Annealed) | ≤35 (O-temper) |

| Temper | Soft (O) | Soft (O) |

| Elongation | ≥30% | ≥25% |

Compliance & Quality Assurance

All products comply with IEC 60228, ASTM B170 (copper), and ASTM B209 (aluminum). Our ISO 9001-certified production includes:

Laser thickness monitoring with real-time adjustments (±0.002 mm tolerance)

Automated optical edge inspection for burr-free finish (<0.005 mm)

Four-point probe conductivity verification per ASTM B193

Tensile and elongation testing per ASTM E8 for all batches

Full traceability via ERP system from raw material to shipment

Third-party certifications (SGS/TÜV) available upon request

Each coil undergoes 100% visual inspection for surface defects, with non-destructive testing for internal flaws. Our metallurgical lab conducts regular microstructure analysis to ensure consistent grain structure, critical for mechanical stability during winding. All raw materials are sourced from certified suppliers with full chemical composition analysis. By leveraging localized supply chains and lean manufacturing, we deliver OEM-grade specifications at 15–20% lower cost than European competitors while maintaining 99.8% on-time delivery and zero defect rates in the last 5 years.

Factory Tour: Manufacturing Aluminum Copper Coil

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Our 20+ years of specialized expertise in transformer-grade materials ensures rigorous control at every production stage. Cold rolling utilizes 2000-ton multi-stand mills with closed-loop hydraulic systems to maintain thickness tolerance of ±0.005mm across 99.8% of coil length. Temperature and speed parameters are optimized for consistent grain refinement, directly reducing core losses in transformers. Precision slitting employs diamond-coated CNC blades with real-time edge profiling, achieving ±0.05mm width accuracy and eliminating micro-tears that cause winding failures. Edge conditioning uses automated roller deburring to produce chamfers ≤0.01mm height (verified via SEM analysis), exceeding IEC 60076-1 standards for high-frequency applications. Finally, oscillate winding integrates servo-controlled tension (±0.5N) and AI-guided runout monitoring (≤0.1mm), ensuring perfect layer density for compact transformer designs.

Rigorous Quality Assurance

Every coil undergoes 100% dimensional validation via laser micrometers (thickness) and optical sensors (width), with scans every 500mm. Tensile testing per ASTM B209 confirms yield strength consistency (≤2% variation vs. market average of ≤5%). Surface defects are detected by AI vision systems at ≥0.02mm resolution, limiting flaws to ≤1 per 10m (industry standard: ≤3 per 10m). Chemical composition (Al 99.5% min, Cu 99.9% min) and grain structure are validated through third-party metallurgical analysis. All data is ERP-traceable for full supply chain transparency.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Edge Burr Height | ≤0.01mm | ≤0.03mm |

| Tensile Strength Variation | ≤2% | ≤5% |

| Surface Defects | ≤1 per 10m | ≤3 per 10m |

This integrated approach delivers 99.95% first-pass yield in transformer manufacturing, with 20% lower total cost of ownership than European brands like Aleris or UACJ. As a factory-direct supplier, we eliminate middleman markups while meeting IEC 60076 specifications—providing premium performance at competitive pricing for global transformer manufacturers.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Standards

All aluminum/copper coil shipments adhere to rigorous engineering specifications designed for 30+ days of maritime transit. Components are validated per ASTM D4169 for vibration, drop, and compression resistance.

| Component | Technical Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated (HT), 1200×1000mm, 22mm thickness, borate-treated | Prevents structural deformation, fungal growth, and moisture ingress |

| Moisture-Proof Film | Multi-layer VCI film (150μm), anti-condensation coating, 100% heat-sealed edges | Blocks saltwater corrosion, humidity, and oxidation during ocean transit |

| Steel Strapping | 19mm width, 0.5mm thickness, 800kg tension, galvanized anti-corrosion coating | Secures load against vibration, impact, and shifting during transit |

Sea Freight Protocol & Risk Mitigation

We enforce FCL-only (Full Container Load) shipping to eliminate cross-docking risks. All containers feature humidity monitors, desiccant packs, and climate-controlled options for high-risk routes (e.g., tropical regions). Partnered with Maersk, COSCO, and MSC for priority booking and real-time GPS tracking.

| Parameter | Specification | Risk Mitigation |

|---|---|---|

| Container Type | 20ft GP (29m³) / 40ft HC (67m³), sealed with desiccant packs | Optimizes space, prevents moisture accumulation |

| Loading Protocol | Coils centered, corner posts reinforced with 50×50mm hardwood blocks, 4–6 strapping bands/pallet | Eliminates shifting during vessel movement |

| Documentation | Commercial invoice, packing list, COO, SGS report, customs declaration (digital verification) | Ensures seamless global clearance, <24h processing |

Quality Assurance & Cost Efficiency

All shipments undergo third-party inspection (SGS/BV) pre-shipment. Our ISO 9001-certified processes deliver 99.2% damage-free delivery across 15+ years of global exports, with zero major material damage claims since 2010. Packaging complies with ISPM-15, REACH, and RoHS regulations. Compared to EU/US suppliers, our factory-direct model reduces landed costs by 18–25% while exceeding industry protection standards. With 20+ years of experience shipping to 50+ countries, we maintain a 98.5% on-time delivery rate—proving that reliability and cost efficiency need not be mutually exclusive.

Luoyang Xinzhaohe Aluminum delivers engineered precision for transformer manufacturers seeking uncompromised supply chain performance.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a vertically integrated manufacturer with 20+ years of specialized expertise in transformer-grade aluminum and copper strips/foils, we deliver precision-engineered solutions for critical power infrastructure applications. Our technical team optimizes material properties to meet IEC 60404-8-7 and ASTM B170 standards, ensuring consistent performance in high-stress transformer windings. With over 500 utility-scale projects supplied globally, our field failure rate remains below 0.1%—proving reliability where performance is non-negotiable.

Factory-Direct Manufacturing Advantage

By eliminating third-party intermediaries, we provide 15–25% lower costs than global competitors while maintaining full production control. Our Luoyang facility features:

Automated slitting lines with ±0.005mm dimensional accuracy

Continuous casting for uniform grain structure

In-line conductivity and tensile testing during production

This enables 10–15-day lead times for standard orders and rapid prototyping for custom specifications (e.g., 0.05mm–3.0mm thickness, 10–600mm width, alloys like 1350-H19 or C11000-O).

ISO-Certified Quality Assurance

Our ISO 9001:2015-certified process ensures traceability and consistency at every stage:

Dimensional Control: Laser micrometer verification for thickness, width, and flatness

Electrical Performance: Conductivity testing (≥61% IACS for copper, ≥60% IACS for aluminum)

Mechanical Integrity: Tensile strength validation per ASTM E8

Batch Traceability: Full raw material to finished product documentation

Competitive Comparison vs. Global Brands

| Criteria | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower due to vertical integration | 20–40% premium pricing |

| Lead Time | 10–15 days standard orders | 4–6 weeks typical |

| Customization | On-demand alloy adjustments (e.g., 1350-H19, C10200) | Limited flexibility, extended lead times |

| Quality Consistency | ISO 9001 + IEC 60404-8-7 compliance | Variable standards across suppliers |

| Technical Support | Dedicated application engineers for project-specific solutions | Standardized support, slower response |

For precise technical specifications and competitive pricing, contact Cathy at cathy@transformerstrip.com. We provide detailed material test reports (MTRs) and samples within 48 hours to validate performance for your transformer designs.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum copper coil from Luoyang Xinzhaohe.